INTRODUCTION

Machine Description

1

1-2 doc052521 INTRODUCTION

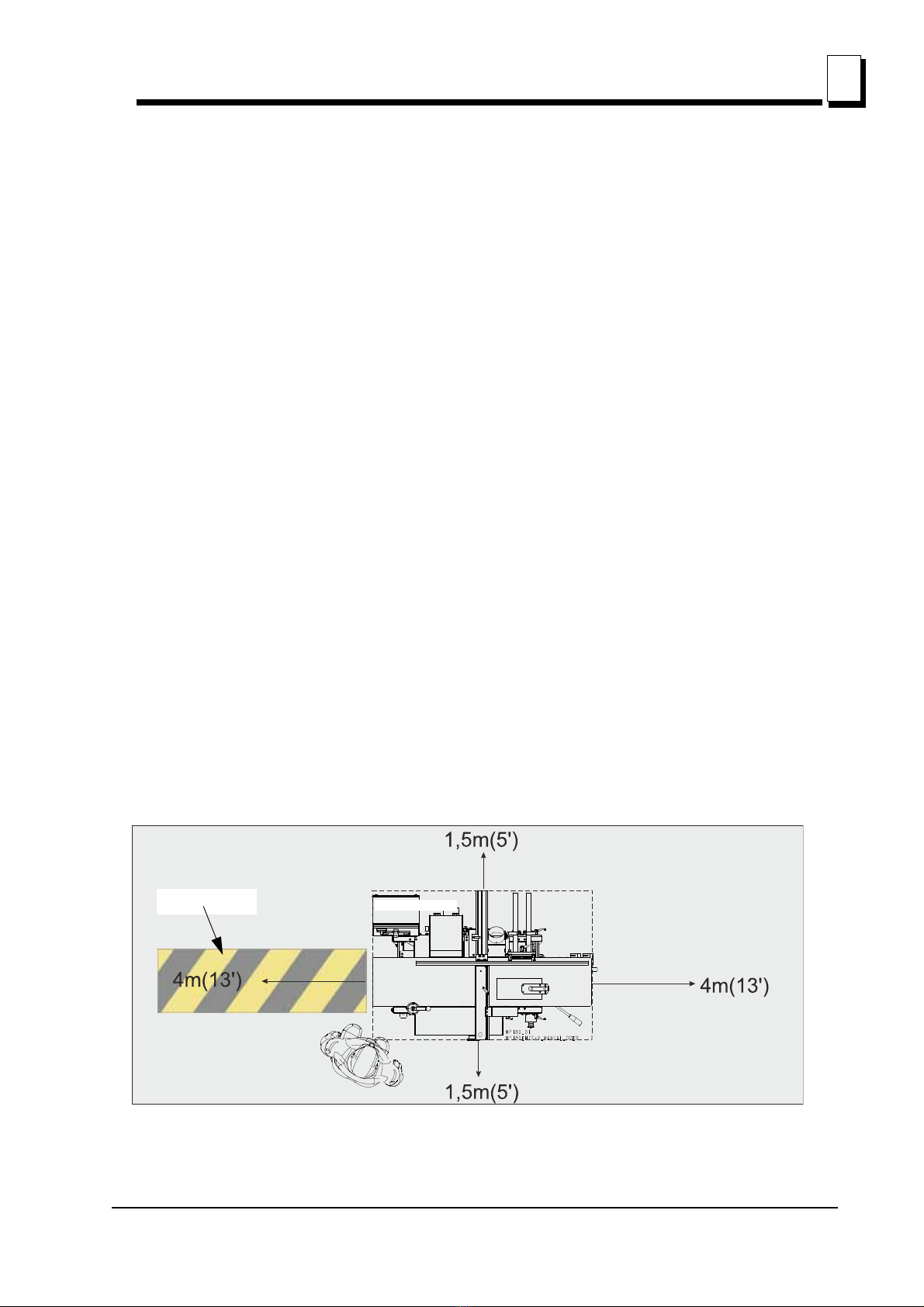

TIPS: An extended infeed table is practical to use, and prevents anyone from coming into the risk

area.

STORAGE

The machine must be placed in a dry area, as it is not fully protected against corrosion. If the machine

is placed in a cold area for an extended period of time, its unprotected components, such as tables or

cutters, must be lubricated with a large amount of e.g. paraffin. It is also a good idea to cover the device

for additional protection against corrosion. If the machine is supposed to be placed outdoors, its

unprotected components must be covered and lubricated with anti-corrosive agents.

1.1 Machine Description

The Wood-Mizer Multi-Planer is designed for straight and profiled planing of wooden elements used

for production of wooden houses and other construction elements used in the building industry and

garden programs. Other applications of the planer are forbidden.

The MP180 is a planer/moulder/thicknesser that can process two sides of a workpiece in a single pass.

The machine is contained in a stable and strong chassis. The Multi-Planer table is made of planed cast

iron.

The workpiece is fed, lying on the planer table, through the planer by feed rollers as well as an outfeed

roller. The rollers are driven by a chain transmission with separate motor. The workpiece is controlled

laterally with adjustable fences and pressure rollers.

The work is done using a top cutter and side cutter which are fixed to the planer table. All the cutters are

driven by separate motors, via a belt transmission.

The cutters and feed rollers are covered with a protective cover plate. The cover plate is supplied with a

safety switch. A 100 mm (4”) dia. hose is connected to the cutter.

TABLE SURFACE

The table is made of the highest quality cast. The table surface is specially processed for the highest

precision and the best anti-friction qualities.

When the Multi-Planer is new, it requires a breaking-in period until the table gets a slightly shinier surface

to optimize the anti-friction qualities. It is recommended that lubricant or wax be applied to the table

during this period.

Using the machine correctly, you will obtain a perfectly smooth surface and a high degree of accuracy.

The Multi-Planer should be operated only by an adult who has read and understood the entire operator’s

manual.

The Multi-Planer is built to be durable and easy to operate and maintain.