I

I

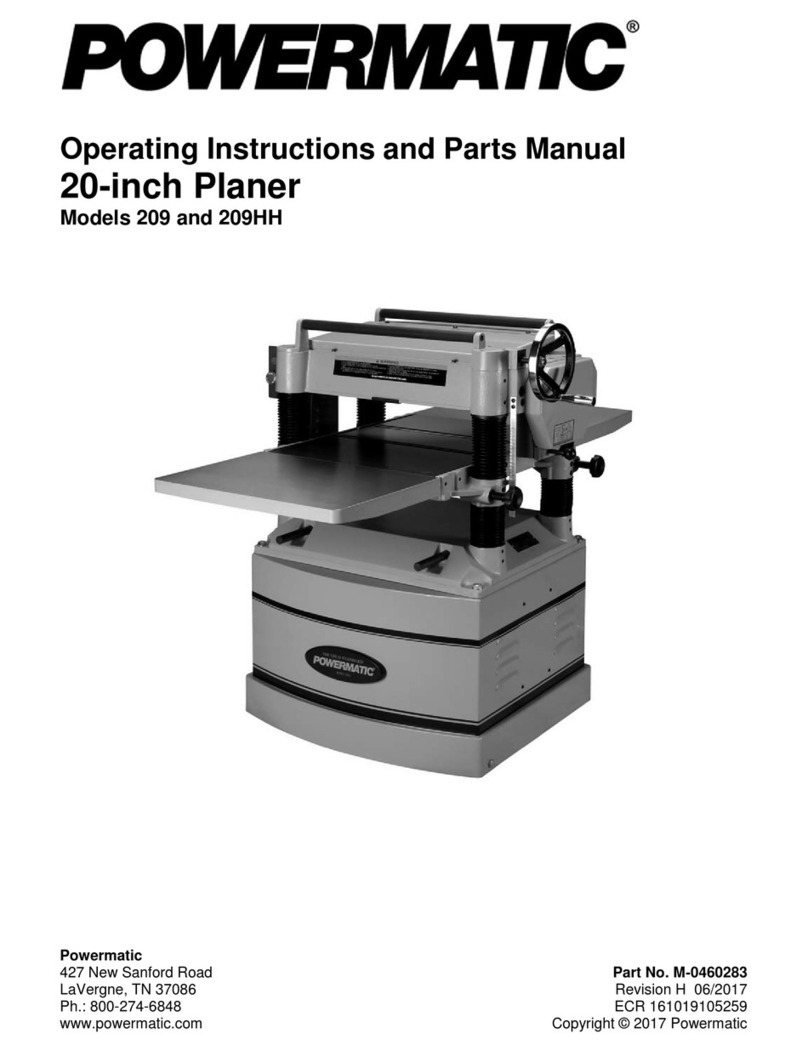

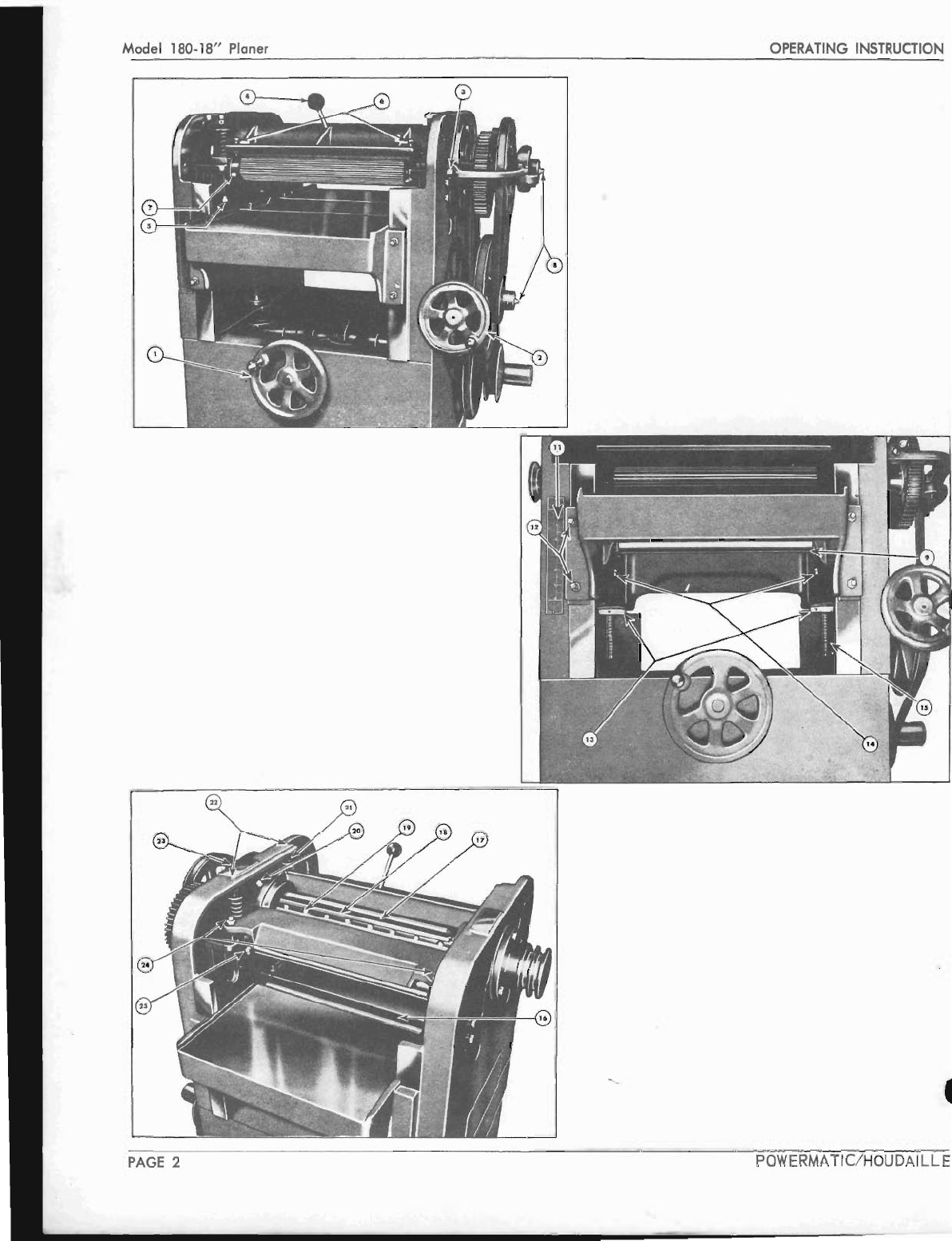

Model 180-18" Planer

I.

GENERAL

SET-UP

AND

ALIGNMENT

1.

RECEIYING

Uncrate

and

check

for

shipping

damage.

Clean

all

coated

and greased surfaces. Read instructions thoroughly.

Lo-

cate

all

lubrication points; adjustment; methods

of

drive

.

2.

MOUNTING

Mount

machine securely

to

solid foundation. Concrete

base mounting preferred. Locate

in

clean,

dry

and

well

vent.ilated building if p()ssible.

Motor

and

electrical con-

nections should be protected when not

in

operation

or

if

exposed to weather elements.

3.

EXHAUST

SYSTEM

Recommended

as

a must

if

efficient

production

operation

is

required.

Not

a necessity where limited amount

of

operation being performed

and

machine can be kept

clean

of

shavings.

4.

INSPECTION

The

above machine requires the minimum amount

of

attention

in

service. Periodic

or

regular

inspections

are

recommended to insure machine

is

in

proper

adjustment,

positive electrical connections; worn

or

loose

"Y"

belts

and

bearings heating

or

loose.

5.

BEFORE

OPERATING

Check motor nameplate

date

or

wiring

diagram

of

motor

and switch

for

proper

voltage

connection before

wiring

into line.

Run

motor without

load

to

check the connections

and direction

of

rotation. Always refer

to

motor name-

plate

for

rotation connections.

II.

LUBRICATION

1.

The

cutterhead

and

variable

speed

pulley

are mounted in

sealed bearings

and

do

not require

any

lubrication.

2.

GREASE

LUBRICATION

The

clutch,

table

and feed rollers are

equipped

with pres-

sure gun fittings and must be lubricated

regularly

every

twenty-five hours

of

operation with a

good

grade

High

Speed Boll Bearing grease. Also, the feed

drive

gears

should be surfaced greased with the same grease.

3.

OIL

LUBRICATION

The

surface fittings, bed ways, handwheel drive shaft

gears and thrust screws should be lubricated

regularly

every ten hours

of

operation with oil equivalent

to

SAE

10.

A light film

of

oil

on

the

table

when

not

in

use

will

prevent

rusting.

III.

OPERATING

ADJUSTMENTS

PLANER

BED:

The

planer bed mounts in the main frame panels

and

is

raised and lowered on acme screws mounted

in

thrust

bearings.

The

screws are operated through gears

by

a

large hondwheel (l ) on the front

of

the Planer.

The

planer bed

is

held

rigid

between frames

by

shims on

each side

of

the bed

and

is

adjusted with

two

jack screws

(

12

) that can be tightened against the shims. These shims

should be adjusted

tight

enough to prevent rocking

or

moving when material

is

fed through the Planer but not

tight enough to prevent raising

or

lowering

of

the

table

.

If planer bed rocks when the machine

is

in operation, dips

will

appear

in the material being

planed

. The

planer

bed

POWERMATIC/HOUDAILLE

OPERATING

INSTRUCTIONS

must be level with the cutterhead. Check this

by

lowering

the bed

to

permit

placing

a small jack-screw

type

gauge

(

or

small square block) between the bed and the cutter-

head

at

the extreme

right

side

of

the bed.

Raise

bed with

handwheel (1) until the screw

gauge

or

block just touches

the cutterhead. Move the block

to

the

left

side

of

the

table

and

check under the cutterhead. If the bed

is

not .

level with the cutterhead, the bed can be raised or

lowered

by

loosening the set screw· in bed nut (13) and

turning

to

the

right

or

left

to

raise

or

lower the bed to the

proper

height-lock

the bed nut with the set screw.

PLANER

BED

IDLER

ROLLERS:

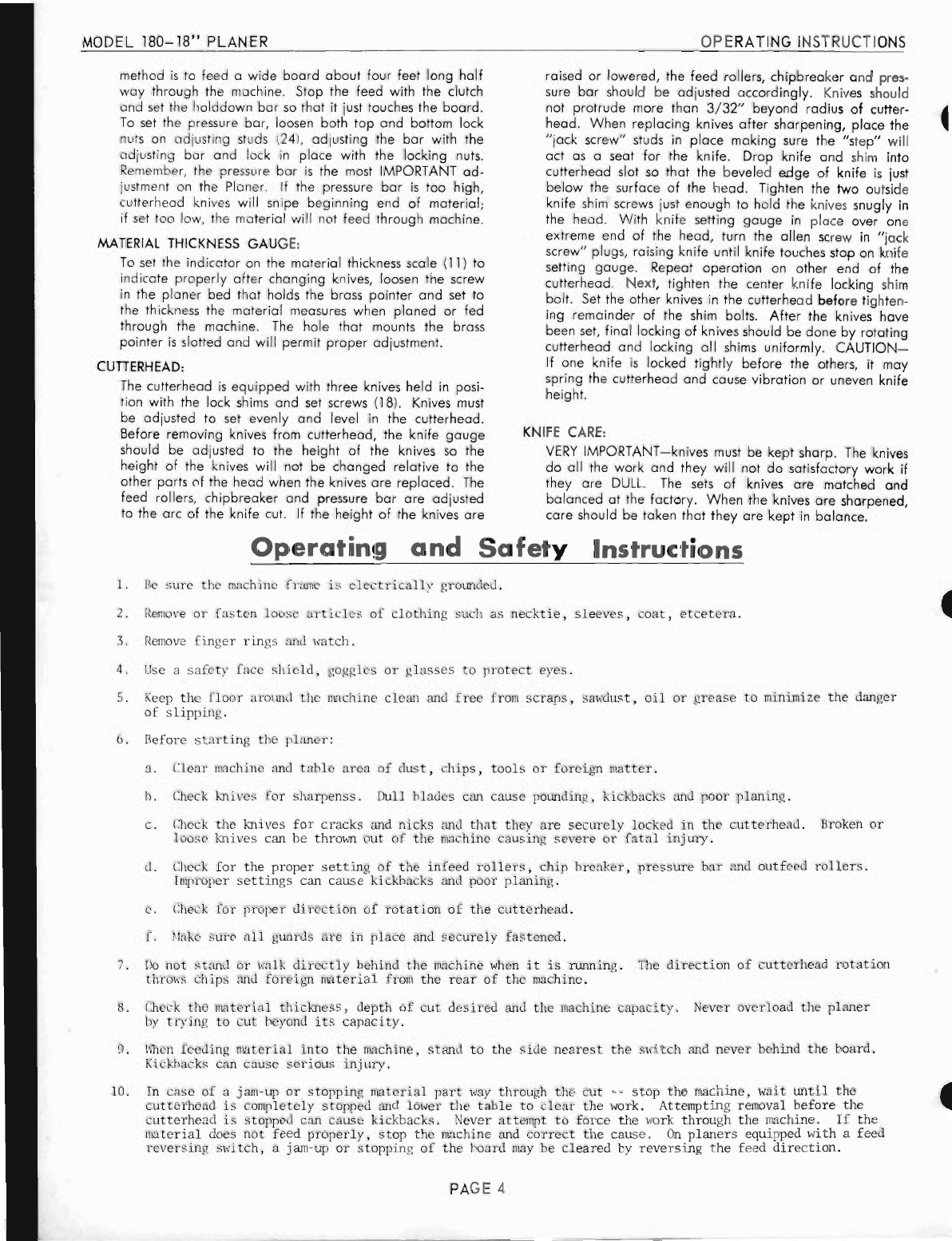

Adjusting screws (14)

for

planer

bed idler rollers are lo-

cated

directly

under the bearings. Adjust from .000 to

.

010"

above bed level

for

planing

smooth

or

dry

material,

.010"

to

.015"

for

medium rough

and

.

025"

to

.035"

for

rough sawed

or

green material. Keep rollers adjusted to

same height

at

each end.

When

rollers are set too high,

a snipe

or

bite

will

appear

at

the ends

of

planed

material.

If set too

low

feeding

will

be restricted due to friction

on

planer

bed.

(WITH

QUIK-SET

ADJUSTMENTS)

Planer bed rollers are adjusted

to

the

proper

height with

a quik-set

handle

mounted on the

right

side

of

the

planer

bed.

The

height

of

the rollers in relation to the bed sur-

face

is

indicated

by

a

graduated

dial

and

pointer on the

qUik-set handle. If

table

rollers

do

not correspond with

the height

indicator

scale, adjustments can be made' by

loosening the set screw (26) fig. 4 in the

roller

adjusting

arms. Set indicator pointer

at

zero on the

gauge

and

turn adjusting screws (27) until the bed rollers are level

with the

planer

bed.

To

plane rough lumber, set quik-set

indicator on

.030",

for

medium rough

.010"

to

.

015"

and

for

finished lumber

.000"

to

.010".

Set the rollers high

enough

so

that

the lumber

will

feed through the machine

without hesitation.

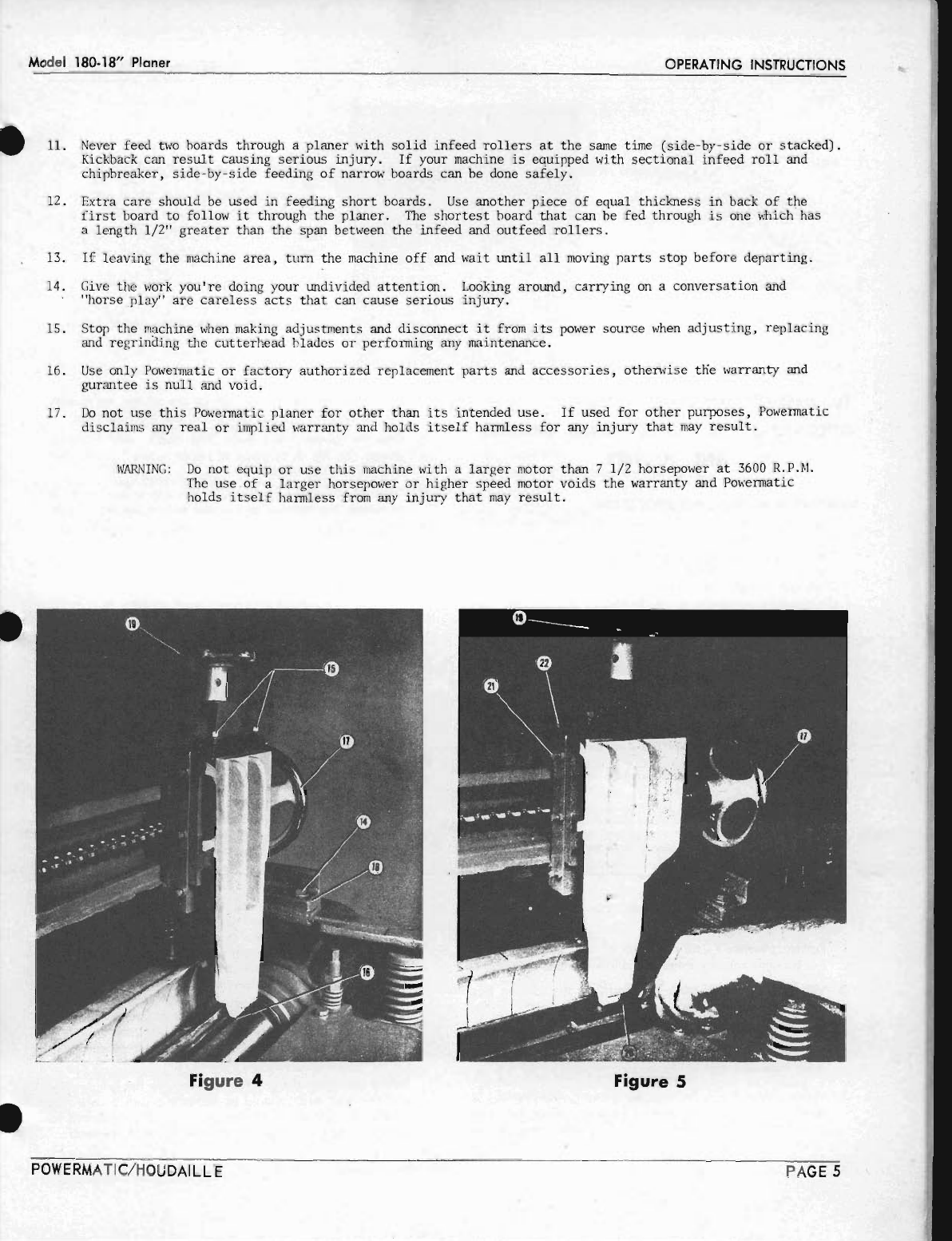

POWER

DRIYEN

FEED

ROLLS:

The

power

driven

corrugated

infeed

roller

(7)

and

smooth

outfeed

roller

(25) are

gear

driven through Y-belts

ar-

rangement from cutterhead shaft.

The

feed roller bearing

housings

are

floating

type

and

held against the feed roller

adjusting screws (14)

by

means

of

adjustable pressure

springs (22). The feed rollers should be adjusted

to

set

approximately

1/

16"

below

arc

of

the cutterhead knives.

A

gauge

or

block

may

be used to assure

proper

height.

To

set feed rolls, lower

planer

bed

about

3"

below

arc

of

cutterhead. Place

gauge

or

wooden

block directly under

cutterhead

and

turn head until one knife

is

down.

Raise

planer

bed until block

is

1/

16"

below

knife edge. Check

the

roller

to

see

that

each end

is

the same. Too much pres-

sure on infeed

corrugated

roller

will

leave markings on

material. Too little pressure

will

restrict feed.

CHIPBREAKER:

The

chipbreaker

is

a three piece

type

which mounts and

adjusts concentric with cutterhead.

The

chipbreaker

ad-

justing screws (6) should be adjusted

to

allow

chipbreaker

to

set

1/16"

below

level

of

infeed

corrugated

feed roller.

PRESSURE

BAR:

The pressure

bar

is

a three piece

type

which mounts

and

adjusts concentric with cutterhead. The pressure

bar

should be set equal

to

the arc

of

the cutterhead.

One

PAGE 3