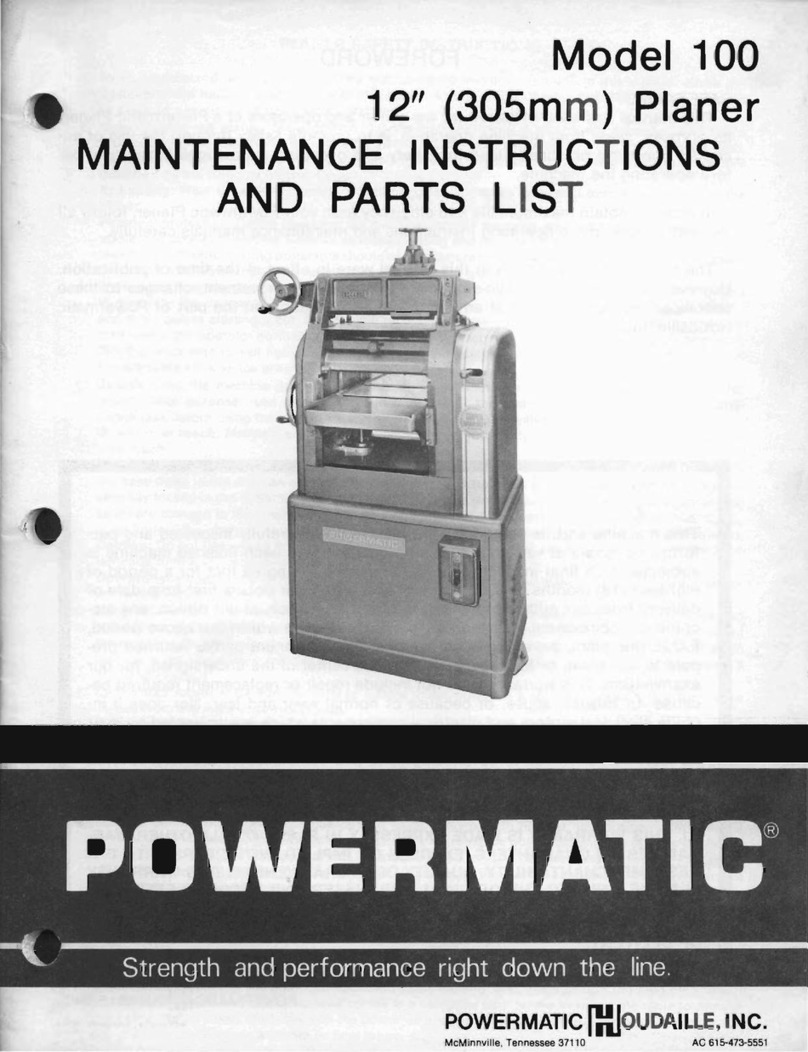

Model 100-12"

Planer

HOLDDOWN

BAR:

FEED

DRIVE

BELTS:

MATERIAL

THICKNESS

GAUGE:

CUTTERHEAD:

KNIFE

CARE:

Page

6

OPERATING INSTRUCTIONS

The holddown

bar

is

adjusted

with

adjusting

nuts

(14) and

should be

adjusted

.003" below

arc

of

cutter

head knife. To ad-

just

holddown

bar,

loosen lock

nut

and

turn

adjusting

screw

(14) to

the

right

to

raise

and

to the

left

to lower.

To

adjust

feed belts, loosen

nuts

(20)

on the inside of

planer

frame

and

slide

studs

in slots until belts have

proper

tension.

If

machine does not feed properly remove

guard

and check for

belt slippage.

The infeed

and

outfeed rollers have

grea

se fittings (8) and

(9).

Feed drive sheaves

are

lubricated

at

(16) and

(17).

These

fittings

require

greasing

every ten (10) hours of operation with

No.1

grease,

or

a light weight type.

Planer

bed ways, bed

raising

screws, bed idle roller bearings

should be greased every ten

(10)

hours

of operation

with

SAE

No. 10 oil

or

equivalent.

To set

the

indicator on the

material

thickness scale (6) to indi-

cate

properly

after

changing knives, loosen

the

screw in the

planer

bed which holds

the

brass

pointer

and set to

the

thickness

the

material

measures when planed or fed

through

the

machine.

The hole which mounts the

brass

pointer

is slotted

and

will per-

mit

proper

adjustment.

The

cutter

head is equipped

with

three

knives held in position

with

the

lock shims

and

set screws

(10).

Knives

must

be ad-

justed

to

set

evenly and level in the

cutterhead.

Before remov-

ing knives from cutterhead,

the

knife

gauge

should be adjusted

to

the

height

of

the

knives. so

the

height

of

the

knives will not

be changed relative to the

other

parts

of

the

head when the

knives

are

replaced. The feed rollers,

chipbreaker

and pressure

bar

are

adjusted

to the

arc

of

the

knife

cut.

If

the height of

the

knives

are

raised

or

lowered, the feed rollers, chipbreaker

and

pressure

bar

should be

adjusted

accordingly. Knives should

not

protrude

more

than

.030" beyond

radius

of cutterhead.

When replacing knives

after

sharpening,

place

the

"jack

screw"

studs

in place

making

sure

the

"step"

will

act

as a seat

for

the

knife. Drop knife

and

shim into

cutterhead

slot so

that

the

beveled edge of knife is

just

below

the

surface

of the head.

Tighten

the two outside knife shim screws

just

enough to hold

the

knives snugly in the head., With knife

settin~

gauge in

place over one

extreme

end of

the

head,

turn

the

allen screw in

"jack

screw"

plugs,

raising

knife until knife touches stop on

knife

setting

gauge. Repeat operation on

other

end of

the

cut-

terhead.

Next,

tighten

the

center

knife

locking shim bolt. Set

the

other

knives in

the

cutterhead

before

tightening

remainder

of

the shim bolts.

After

th~

knives have been set, final locking

of knives should be done by

rotating

cutter

head and locking all

shims uniformly.

CAUTION-If

one knife is locked tightly

before

the

others,

it

may

spring

the

cutterhead

and cause vi-

bration

or

uneven knife height.

IMPORTANT:

Knives should be kept

sharp.

The knives

do

all

of

the

work

and

they

will

not

do

satisfactory

work

if

they

are

DULL. The sets of knives

are

matched and balanced

at

the

factory. When

the

knives

are

sharpened, care should be taken

that

they

are

kept

in balance.

POWERMATIC,

McMinnville,

Tenn.