PowerQuick Powered Ascender (5) PQ500-1 1-Sep-15

Reverse charging is not acceptable. PowerQuick Battery Charger is equipped with a circuit to prevent reverse

charging.

Charge before use.

Do not charge/discharge with more than the specified current.

Do not short circuit the cell/battery.

Do not incinerate or mutilate the cell/battery.

The life expectancy may be reduced if the cell/battery is subjected to adverse conditions, like extreme temperature,

deep cycling, and excessive overcharge/over-discharge.

Store the cell/battery in a cool dry place.

Keep away from children. If swallowed, contact a physician at once.

Avoid using this product during an electrical storm. There may be remote risk of electric shock from lightning.

Use with PowerQuick Ascender only. DO NOT use to power other devices

4.1.Use Instructions

Charging the Battery

Charge the battery using the battery pack provided by PowerQuick

Concepts, Inc with your PowerQuick Ascender. (Figure 1)

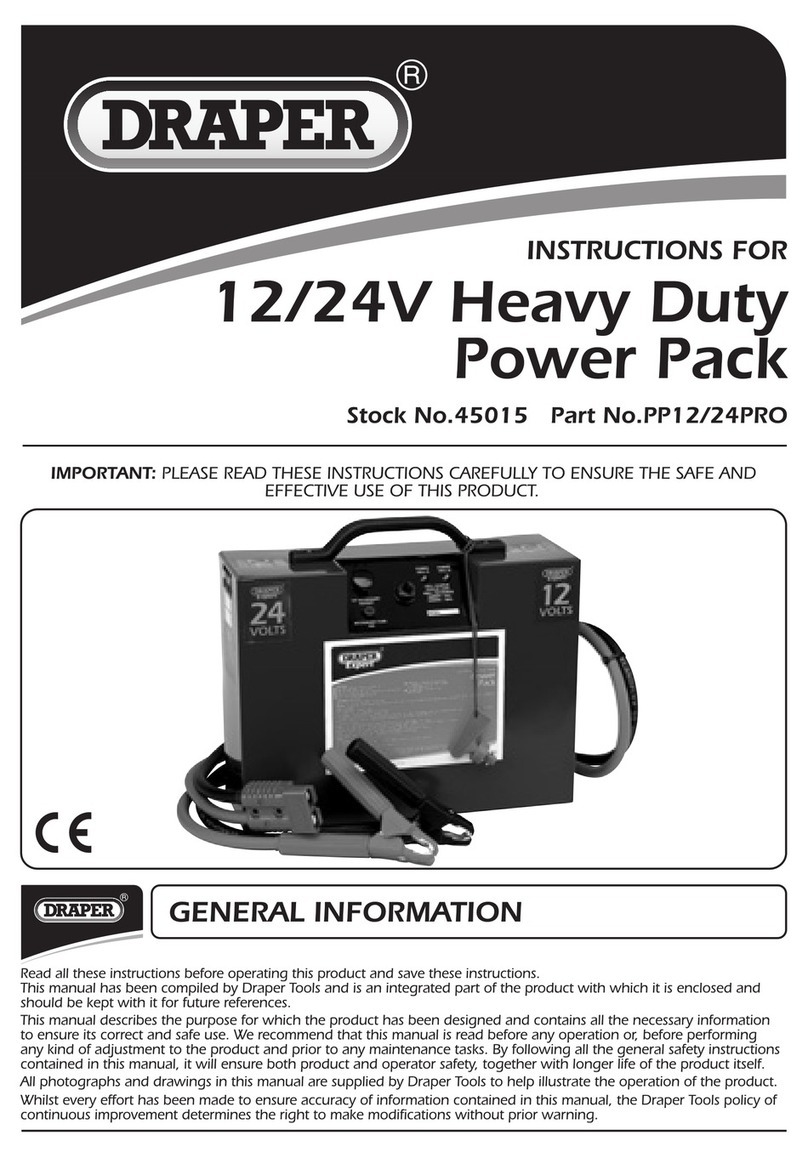

Insert the 3-pin plug on the battery charger into the matching receptacle

on the top of the battery. (Figure 2)

Plug the charger into the electrical outlet. The charger is compatible with

110 and 230VAC. Locate the switch on the end of the charger and, using

a ball point pin, move it to the correct setting.

An LED on the end of the charger indicated red for power on, yellow for

charging and green for full charge. When the indicator turns green,

disconnect the battery, and then remove the battery from the charger.

4.2.Battery Warranty

PowerQuick Concepts, Inc. Battery Packs are warranted against defects in workmanship, material and construction for a

period of one (1) year from date of shipment. The warranty period is void if the purchaser does not adhere to storage

instructions specifying both storage time and temperature (a charged battery may be stored up to 1 year at room temperature

68° F), are modified, subjected to abuse, physically damaged when allowed to discharge below 25 VDC, or charged with a

charging device not approved by PowerQuick Concepts, Inc.

If the battery pack is found to be defective it will be replaced at no charge. If, however, it is defective due to misuse as

outlined in this warranty the customer will be so advised and replacement will NOT be issued. The liability of PowerQuick

Concepts, Inc. under the warranty is limited to a replacement of the defective battery pack subject to the conditions as

outlined in this paragraph. The warranty is the exclusive remedy.

THERE ARE NO OTHER WARRANTIES EITHER EXPRESSED OR IMPLIED INCLUDING THOSE OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE AND SUCH WARRANTY IS LIMITED TO THE

EXPRESS WARRANTY PERIOD. LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES UNDER ANY AND ALL

WARRANTIES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. THE SOLE REMEDIES FOR

BREACH OF ANY AND ALL GUARANTEES OR WARRANTIES AND THE SOLE REMEDIES FOR POWERQUICK

CONCEPTS, INC.PRODUCT’S LIABILITY OF ANY KIND WITH RESPECT TO THE PRODUCTS FURNISHED UNDER

THIS AGREEMENT, OR PURSUANT TO THIS AGREEMEN T, SHALL BE LIMITED TO THE REMEDIES PROVIDED IN

THE PRECEDING APPLICABLE PARAGRAPHS HEREOF. IN NO EVENT SHALL POWERQUICK CONCEPTS,

INC.PRODUCT’S LIABILITY FOR DAMAGES WITH RESPECT TO ANY OF THE PRODUCTS FURNISHED EXCEED THE

CHARGES PREVIOUSLY PAID BY CUSTOMER FOR SUCH PRODUCTS.

CUSTOMER AGREES THAT POWERQUICK CONCEPTS, INC.PRODUCT’S SHALL NOT BE LIABLE FOR ANY SPECIAL,

INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES OR LOSS OF USE, REVENUE OR PROFIT, EVEN IF

POWERQUICK CONCEPTS, INC.PRODUCT’S SHALL HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH

POTENTIAL LOSS OR DAMAGE.

4.3.Battery Disposal

In accordance with the Environmental Protection Agency Rechargeable Battery Management Act, 42 U.S.C 14301-

14336 (“Battery Act”) rechargeable batteries must be disposed of by recycling. To locate a recycling facility in your