II-129-025

Page 2

SERIES 440

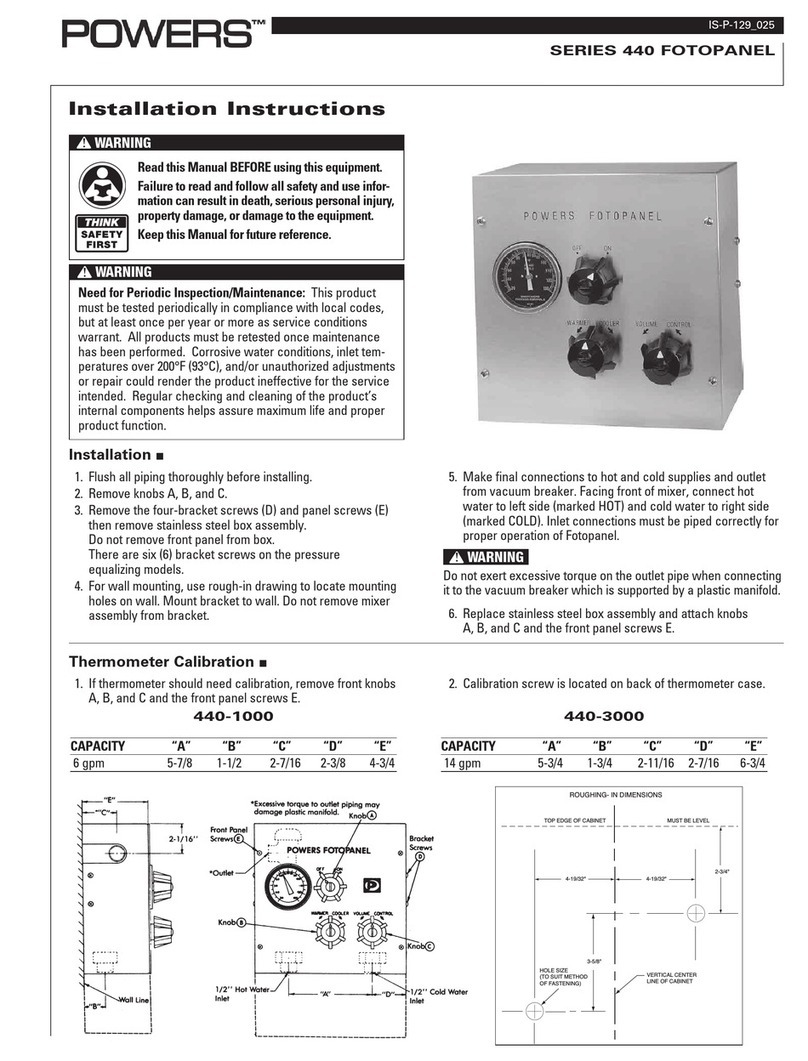

FOTOPANEL

440-1000

TROUBLESHOOTING AND REPAIR FOR SERIES 440 MIXING VALVES

What to look for if:

The maximum temperature cannot be obtained...

a. Lime deposits may have accumulated in the hot water

pipes, restricting the hot water supply.

b. The hot water supply temperature may be too low.

c. The knob rotation setting may be too low. Remove

knobs and stainless box assembly, then readjust the

high temperature limit stop. (Refer to maximum tem-

perature setting section).

Flow of water is less than desired…

a. The upstream supply valves may not be fully open.

b. The inlet supply pressure(s) may be low.

c. Lime deposits may have accumulated in cartridge,

restricting water flow. Replace cartridge kit.

d. The fixture head may be clogged. Remove and clean.

e. The checkstops may be clogged. Clean checkstops.

The valve opens with hot water flow rather than cold

water flow...

a. The inlet water supplies are connected to the wrong

ports. Remove the valve and reinstall.

The tempered water is too cold, although motor has been

replaced, 0R the hot water temperature is below 115°F...

a. Raise the temperature of the hot water supply.

Flow of water is completely shut off...

a. The upstream supply valves may be completely closed.

b. The hot or cold water supply pressure may have failed.

The Hydroguard 420 valve is designed to close down

upon cold water failure.

c. The checkstops may be closed. Access the checkstops

and open by turning the adjustment screw fully counter-

clockwise.

REPLACEMENT PARTS KIT

PART DESCRIPTION REPAIR KIT

BONNET AND STEM ASSEMBLY 420-454

WAX ELEMENT 420-453

CARTRIDGE ASSEMBLY 420-452C

TEMPERATURE SETTING FOR SERIES 440 MIXING VALVES

Test the System

1. Verify that the valve is in the OFF position (fully clock-

wise position).

2. Turn on water supply and then rotate the valve knob

(warmer, cooler) counter-clockwise. Water should come

through the fixture head.

Maximum Temperature Setting/Knob Rotation Stop

The knob rotation setting must be adjusted to limit the

distance the user can rotate the handle towards the full

hot water position.

CAUTION: Any repair or modification of the valve may

affect the high temperature setting. The maximum

temperature setting must be checked by the installer

before use.

3. Remove the knobs, stainless steel box assembly and

both splined stops.

4. Re-insert the knob back on the (warmer, cooler) valve

stem and adjust the valve to the desired maximum out-

let temperature. Install the splined limit stop with its tab

against the bottom of the bonnet stop.

6. Re-assemble the stainless steel box assembly and the

knobs.