TI-e700 Page 2

OPERATION

Maximum Temperature Setting/Handle Rotation

Stop

The handle rotation setting must be adjusted to limit

the distance the user can rotate the handle towards

the full hot water position.

CAUTION: Any repair or modification of the valve may

affect the high temperature setting. The maximum

temperature setting must be checked by the installer

before use.

1. Remove the valve handle and sleeve.

2. Adjust the valve to the desired maximum outlet

temperature [110°F (43°C) max]. Screw on the

high temp. limit stop until it touches the stem

shoulder.

3. Turn the stem clockwise until the water stops.

Open valve to full hot position and verify maxi

mum outlet temperature setting.

4. Place sleeve "O" Ring on the bonnet shoulder.

Slide sleeve over the "O" Ring until it stops.

5. Replace handle.

Reversed Inlets

Valve is factory-set for standard inlets If reversed inlets

are required due to back-to-back installation (Cold water

supply on the left and Hot water supply on the right), follow

instructions athrough dbelow:

a. Connect cold inlet to hot port (“H”) and hot inlet to

cold port (“C”). Note: Do not turn valve upside down. If

valve is upside down, water will not flow properly

through tub spout or showerhead.

b. Turn water off with checkstops, remove bonnet and

cartridge.

c. Reinstall cartridge. “H” on the cold side of the valve

body and “C” should be on the hot side of the valve

body.

d. Reinstall bonnet with high temperature limit stop on it.

Note: Be certain that valve opens in full cold!

e. Hot and Cold inlets should be re-identified for reversed

inlets to avoid confusion during future maintenance.

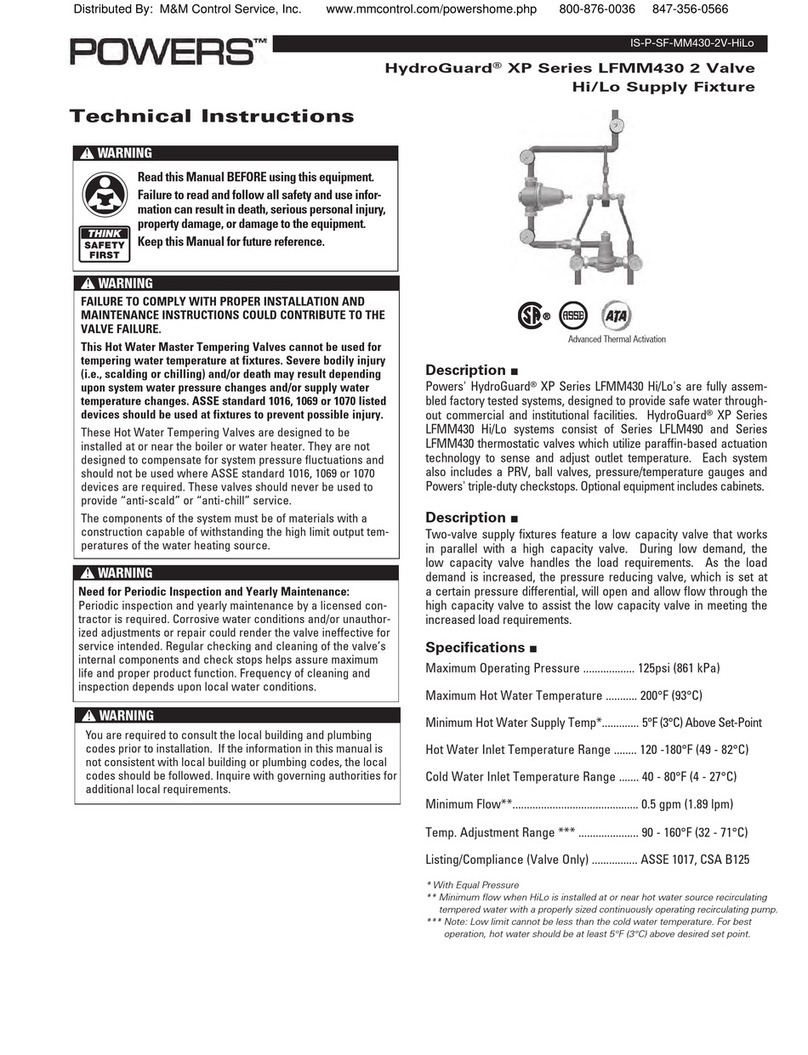

Hot and cold water enter respective ports in the valve

and mix in a chamber containing an advanced thermal

actuator (refer to cutaway view). This actuator controls

the position of the plunger and temperature.

Rotating the adjustment handle repositions the plunger

in the cartridge assembly to produce the desired tem-

perature. The mixed water passes over the shut-off disc

to the outlet. If the hot or cold supply water temperature

or pressure changes, the thermal actuator will contract

or expand. This movement repositions the plunger to

maintain the desired temperature. With the adjustment

handle in full clockwise (OFF) position, the shut-off disc

closes the mixing chamber from the outlet.

A high temperature limit stop restricts the movement of

the control handle. All HydroGuard T/P e700 valves are

factory set to deliver tempered water up to 110°F [43°C]

with equal supply pressures, with hot water tempera-

ture 140°F [60°C], cold water temperature 60°F [15.6°C].

Note: The handle rotation stop must be adjusted

by the installer.

PREVENTIVE MAINTENANCE

EVERY 12 MONTHS:

Open up the checkstops and check for free movement

of the poppet. To access the checkstops, remove the

handle assembly and trim plate.

Before servicing the valve, turn off the water supply

upstream OR close the checkstops. To close the

checkstops, turn the adjustment screw fully clockwise

on each checkstop.

Remove the valve bonnet and rinse all grit and impuri-

ties from the cartridges.

Winterize valves that are used outdoors. Remove and

store the internal components and drain all water from

the valve.

NOTE: Before servicing checkstops or piping, always

turn off the upstream water supply.