General Usage

1.Suitable for de-soldering and soldering BGA,SOIC,CHIP,QFP,PLCC package SMD IC,

Particularly suitable for de-soldering BGA module ,computer motherboard north and south

bridge, all kind of mobile phone motherboard SMT IC and LED lights.

2.Shrinking,Paint drying, adhesive removal, thawing, warming, Plastic welding etc.

Feature

1.Using microcomputer processor PID programmable temperature control technology, the

program cycle every 20 milliseconds to detect the actual temperature of the heating element

and a quick correction, rapid return temperature, temperature stability LED display, precise

preheating station, air gun and soldering iron temperature.

2.Preheating station is to use a glaze layer having a high thermal effect, good thermal shock

resistance of the ceramic as the substrate, high-quality nickel branded alloy wire once

sintering. It has a high thermal effect, overall good ,good thermal stability, uniform heating,

high dielectric strength, clean, easy to install and so on features.

3.Air Gun heater use ceramic heater, heating elements firmly wrapped around the model

ceramic, rapid and uniform heating. Use the upgraded version fan, the airflow larger than the

ordinary fan, spiral out of the wind, long life.

4.Soldering iron part using Hakko heater, heating up rapidly, temperature stability,long servic

life; antistatic design to prevent electrostatic damage to delicate SMD components.

5.The machine has a self-test function full intelligent over-temperature, short-circuit,overload

and fault display and protection functions.

6.853A preheating station practical and easy to operate,the card plate sliding bracket bearing

technology,to move around treely durable, convenient card board,coupled with a fixed sliding

bracket screws at the same time, the card board is solid and reliable.

7.853AA/853AAA preheating station using the user-friendly design, the cover affixed with a

high-temp,insulated protection pads to prevent scalding operation.The stent uses magnetic

induction technology, card board bracket to prevent protective pads suck hood above, can

rotate 360 degrees, flexible card board, it is suitable for the circuit boards of different shapes

and sizes.

8.853AA/853AAA temperature correction function to adapt to the environmental impact: or

replace the heating elements, soldering iron tips etc. spare parts caused by temperature

deviation, can use this function calibration temperature.The correction temperature range is

-50℃ +50℃.

9.853AA/853AAA has Celsius/Fahrenheit temperature display function:meet different market

needs to design the temperature display mod, you can choose under customary interest.

~

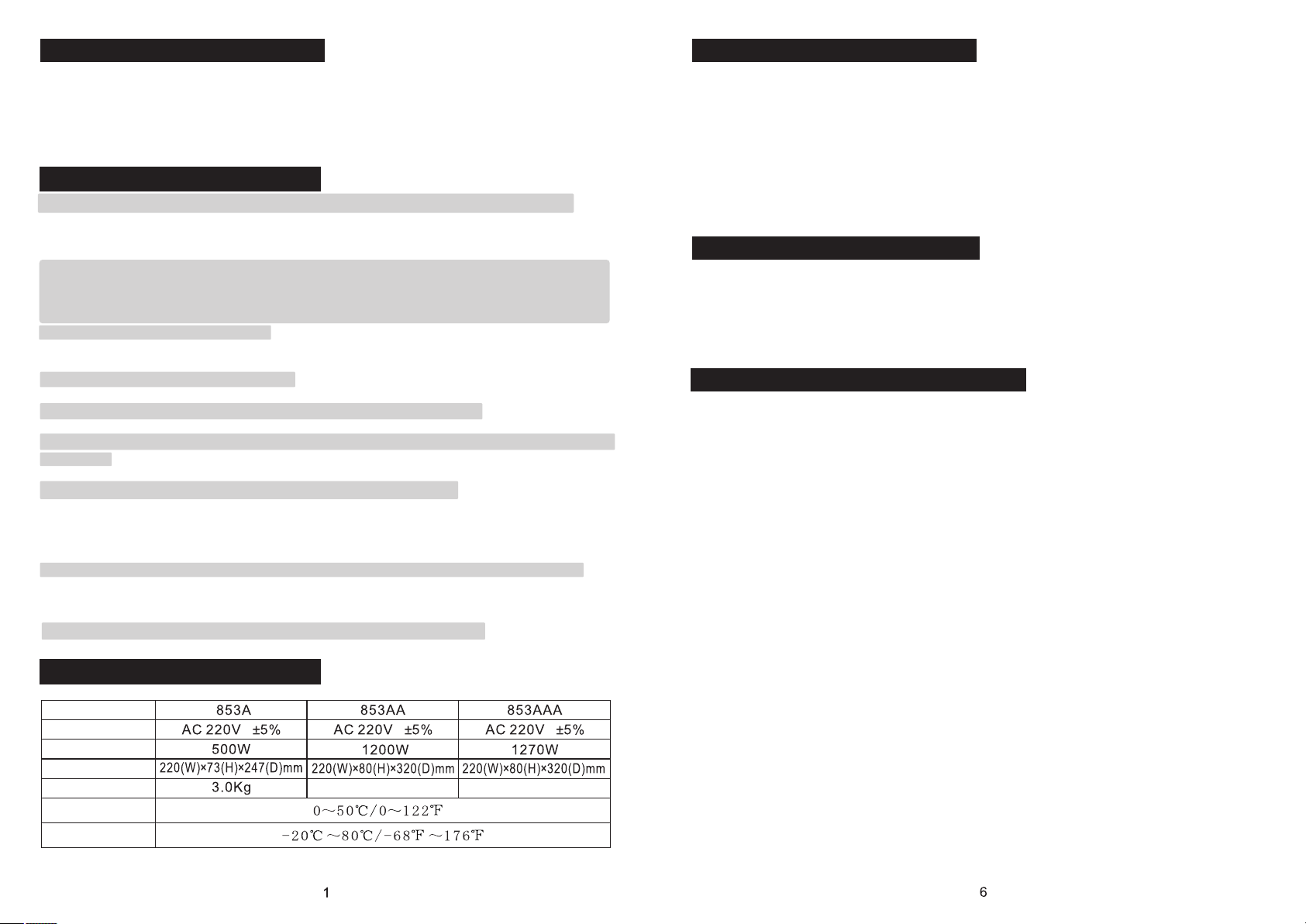

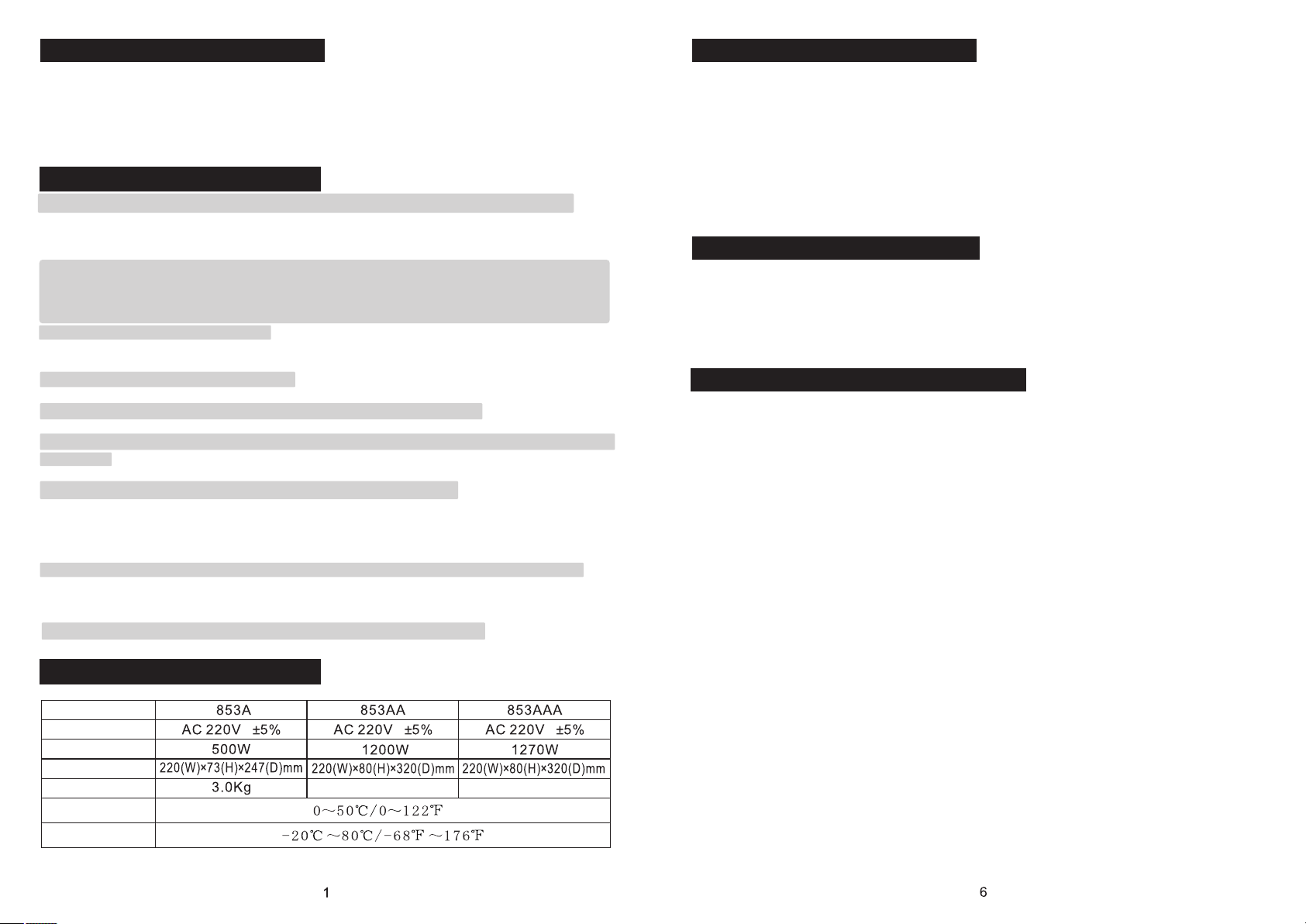

Specification

Model

Voltage

Max power consumption

Measurement

Weight

Working environment

Storage environment

The do’s and don’t s

1.DO NOT install/De-install Nozzles with excessive force.DO NOT use pliers to pull the nozzle

edge out,DO NOT tight the nozzle’s bolt exessively.

2.Only install nozzles when the unit is cool(room temperature)

3.DO NOT use unit near flammable gas or liquid or any combustible material WHATSOEVER

especially when using the unit in high-temperature operation.DO NOT face the hot air outlet

or touch the soldering Iron to the human body WHATSOEVER because it is very hot and can

instantly burn the skin/body.When the first use the unit might starte initially with white smoke.

but this soon will go away.

4.Replacement heater,be carful not to damage the grounding line!

5.Replacement the cable should pay attention to the order and color, can not.

Display Notes

A. When the LED digital displays”---”, it means the outlet temperature is below 100℃;the hot

air rework station is standby mode,and the handle is placed on the handle’s rack.

B. When the LED digital displays”S-E”,it means the Soldering iron and Hot air

rework’s sensor is having a problem or handle is un-plugged,if this the case it

needs to replace the heating element(heating core’s element and sensor components)

Interchangeable Component Desiption

A.Replacement of Hot Air rework heating element(Figure 4)

1.Ensure the Hot Rework is fully cooled down before replacing the element.

2.Figure, loosen the two screws on the handle.

3.Turns the handle antic-clockwise until it comes off and then remove the handle’s cover.

4.Gently takes out the fan,loosen the three screws to remove the fixed wiring board.

5.The wiring board vice versa, apart from the heater wiring board connection cable, pay

attention to the connection location.

6.Remove from the heat pipe heat body with mica paper,careful not broken ground wire of

the steel.

7.Wraps well with the new heater mica,inserted into the tube, the attention heater to install

in place.

8.According to the original location of the connection to connect heater.

9.When the revers process by open bottles and handle back.

B.Replacement of the soldering iron’s tip and soldering iron heating core’s element(Figure5)

1.Unscrews the nut NO.1,and then removes the steel tube NO.2,followed by removing the

tip which is going to be replaced.

2.For the replacemnet of heating core’s element can be performed by unscrewing the plastic

cap NO.4,pulls out gently the heating core’s element NO.6 along with the circuit board NO.7,

please carefully remember the connection of spring NO.5.

3.The iron core from the circuit board welding, the replacement of the heating core, can be

fitted well.Note that the order of the iron corewire connection.

C.Replacement of the preheating plate(Figure6)

1.Remove the topo cover1.

2.Unscrew the screws2.

3.Remove the warm-up bracket.

4.Pull out the clamp.

5.Remove the preheated plate.