Sentinel Installation Manual m-Senzor

2

© 2015 PowerShield Ltd.

Contents

Table of Contents

1Introduction 4

2Definitions for this Manual 5

3Installation QuickGuide 6

4The SENTINEL Battery Monitoring System 9

................................................................................................................................... 10

Installation - Preliminaries

.......................................................................................................................................................... 10Sentinel Monitor

.......................................................................................................................................................... 10Pow er Supply

.......................................................................................................................................................... 10Faceplate

.......................................................................................................................................................... 11System Capacity

.......................................................................................................................................................... 11Sentinel Communications

.......................................................................................................................................................... 12m-Senzor

.......................................................................................................................................................... 13BBus ................................................................................................................................... 13

Installation

.......................................................................................................................................................... 13Step 1 - Monoblocks/Jars

.......................................................................................................................................................... 14Step 2 - Sentinel

......................................................................................................................................................... 14Set the Sentinel ID

......................................................................................................................................................... 14Mount and Pow er Up the Sentinel

.......................................................................................................................................................... 15Step 3 – Mounting Rail for m-Senzors

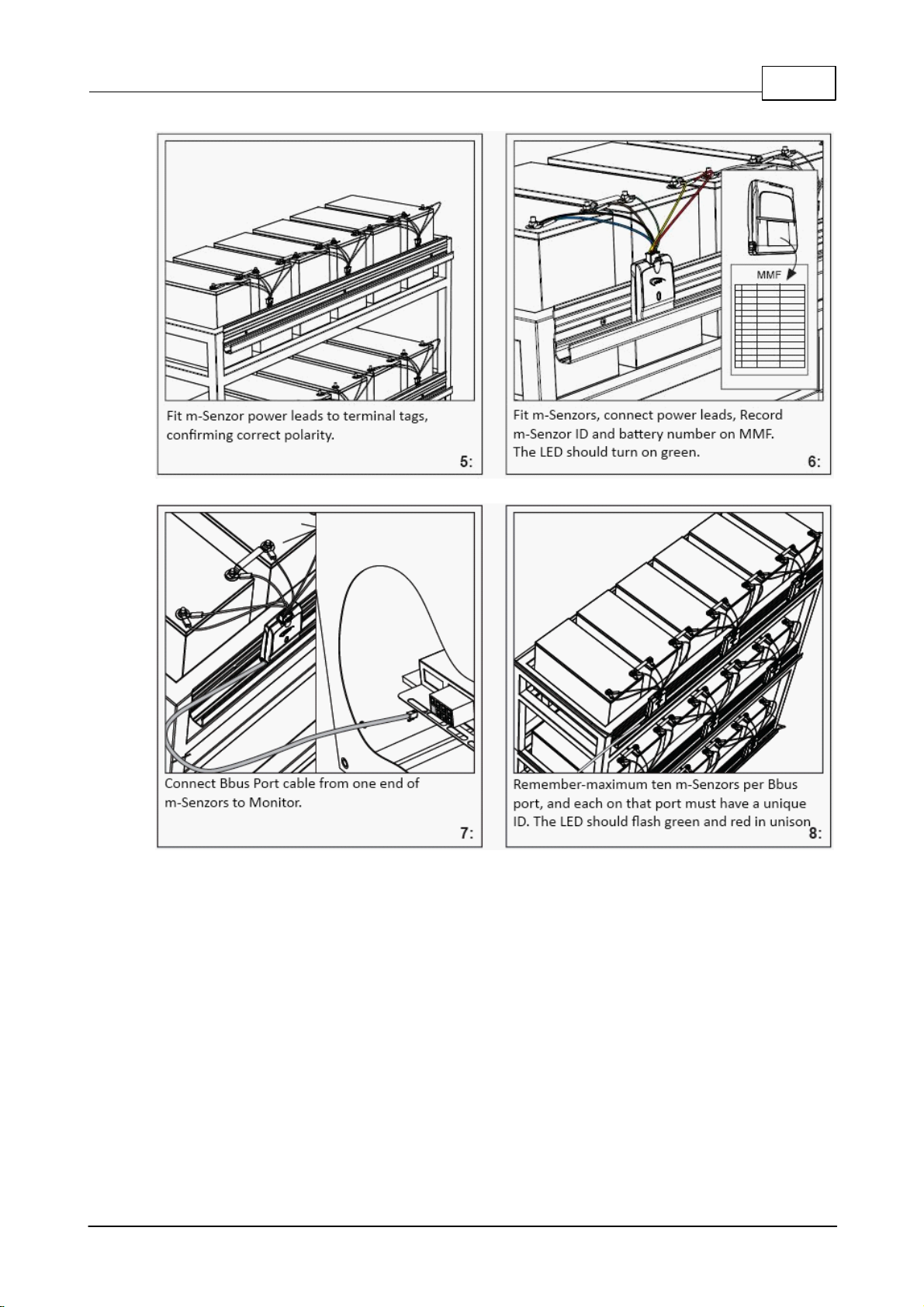

.......................................................................................................................................................... 15Step 4 – m-Senzor Pow er Leads

.......................................................................................................................................................... 16Step 5 – Connect m-Senzors

.......................................................................................................................................................... 17Step 6 – Connect the BBus

.......................................................................................................................................................... 18Step 7 – Connecting the Current Transducer

.......................................................................................................................................................... 19Step 8 – Connecting the Temperature Probe

.......................................................................................................................................................... 19Step 9 – Communications

.......................................................................................................................................................... 20Step 10 – Confirmation

5Appendix 1 - LED Behaviour 21

................................................................................................................................... 21

Sentinel................................................................................................................................... 22

m-Senzor

6Appendix 2 – Sentinel Rear Panel 23

7Appendix 3 - Communications 24

................................................................................................................................... 24

Service Port

................................................................................................................................... 24

Port 1 ................................................................................................................................... 25

Port 2 ................................................................................................................................... 26

Port 3

8Appendix 4 - Relay Outputs and Auxillary Inputs 27

................................................................................................................................... 27

Alarm Output Relays

................................................................................................................................... 27

Auxillary Inputs

9Appendix 5 - m-Senzor Connections 28

................................................................................................................................... 28

Dual m-Senzor Power Lead Connection Detail

................................................................................................................................... 28

Single m-Senzor Power Lead Connection Detail

10 Appendix 6 - Installation Forms 29

................................................................................................................................... 29

Site Identification Form (SIF)