PowerTech MI-5180 User manual

Pure Sine Wave DC to AC

Power Inverter

User Manual

MI-5180

Distributed By:

Electus Distribution Pty Ltd

320 Victoria Road

Rydalmere, NSW 2116 Australia

Tel : 1300 738 555

Fax: 1300 738 500

www.electusdistribution.com.au

-2-

Table of Contents

A.Introduction 3

B.Application 3

C.Features 3

D. Safety Instructions 3

E.FrontView&MainFunctions 4

F.RearView&MainFunctions 4

G. Pre-Installation Information 5

H.ElectricalRequirements 5

I. Installation Requirements 6

J. Connection and Testing 7

K.Operation 8

L.GreenPowerAdjustment 9

M.TroubleShooting 9

N.Maintenance 11

O. Specifications 12

-3-

A. Introduction

We are experts in DC to AC Power Inverter design and manufacture. Our engineers use advanced technological

design that results in an inverter that is excellent, smarter and easier to use than any other inverter with similar power

ratings. Our inverters have been engineered to provide you with years of trouble free operation. The inverters provide

a Pure Sine Wave output with very high quality power, usually with less spikes and surges than grid-supplied power.

Please read the entire User Manual carefully before commencing installation.

B. Application

The MI-5180 Pure Sine Wave Power Inverter will provide 1200 watts of Pure Sine Wave AC power from a 12VDC

source.

C. Features

Capable of driving inductive loads i.e. electric

tools and appliances Microprocessor-based design with accurate and

stable frequency

Minimal effect on equipment like TV, radio…etc Standard adjustable output 240Vac, 50Hz

Standard specially-designed AC and DC line

filters Standard input 12V

Specific chassis for harsh environments Very low harmonic distortion, THD<3%

No problem with microwave ovens (power

dependent) Very efficient stand-by circuit

Standard low battery sensing and cut-off Quick response, stand-by functions

Overload sensing Can be used anywhere

State-of-Art auto load sense Simplified system design

Pure sine wave at 50Hz Remote control unit

Lowest installation cost Green Power function

Extremely efficient Reliable

Easily mounted

No noise

D. Safety Instructions

1. General Safety Instructions

•Do not expose the Inverter to high levels of moisture, rain, snow, spray, bilge, dust, sources of heat or sunlight.

•To reduce risk of hazard, do not cover or obstruct the ventilation openings. The Inverter uses exhaust fans for

forced ventilation which will operate when the inverter reaches a certain temperature.

•Do not install the Inverter in a zero-clearance compartment. Overheating may result.

•To avoid a risk of fire and electronic shock, make sure the installed wiring and terminations are in good electrical

condition and that all cables are not undersized.

•Do not operate the Inverter with damaged or substandard wiring.

•Keep the Inverter in a secure and safe place, out of the reach of children.

•Check the ‘ON/OFF’ switch is in the ‘OFF’ position before installation.

•To prevent electric shock, do not remove the cover. Dangerous voltages exist inside the unit even after it has been

switched ‘OFF’. If a fuse blows, or protective device fails, parts of the Inverter still remain functional. There are no

user serviceable parts inside. Only qualified personnel should carry out maintenance or service the device.

WARNING!

Before installing and using your inverter, please read the General Safety

Instructions!

-4-

2. Explosive Gas Precautions

This equipment contains components that can produce electrical arcs or sparks. To prevent fire or explosion do not

install in compartments containing batteries or flammable materials, or in locations that require ignition-protected

equipment. This includes any space containing gasoline-powered machinery, fuel tanks, or joints, fittings, or other

connections between components of the fuel system.

3. Precautions When Working With Lead-Acid Batteries

If battery acid contacts skin or clothing, wash immediately with soap and water. If acid gets into eyes, immediately

flood eyes with running cold water for at least 20 minutes and get medical attention immediately.

•NEVER smoke or allow a spark or flame in vicinity of batteries or an engine. Do not drop a metal tool on the

battery. The resulting spark or short-circuit of the battery may cause an explosion.

•Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a

lead-acid battery. A lead-acid battery can produce short-circuit currents high enough to weld a ring or

similar metal, causing a severe burn.

4. Installation and Operation

To get the most out of the Power Inverter, it must be installed and used properly.

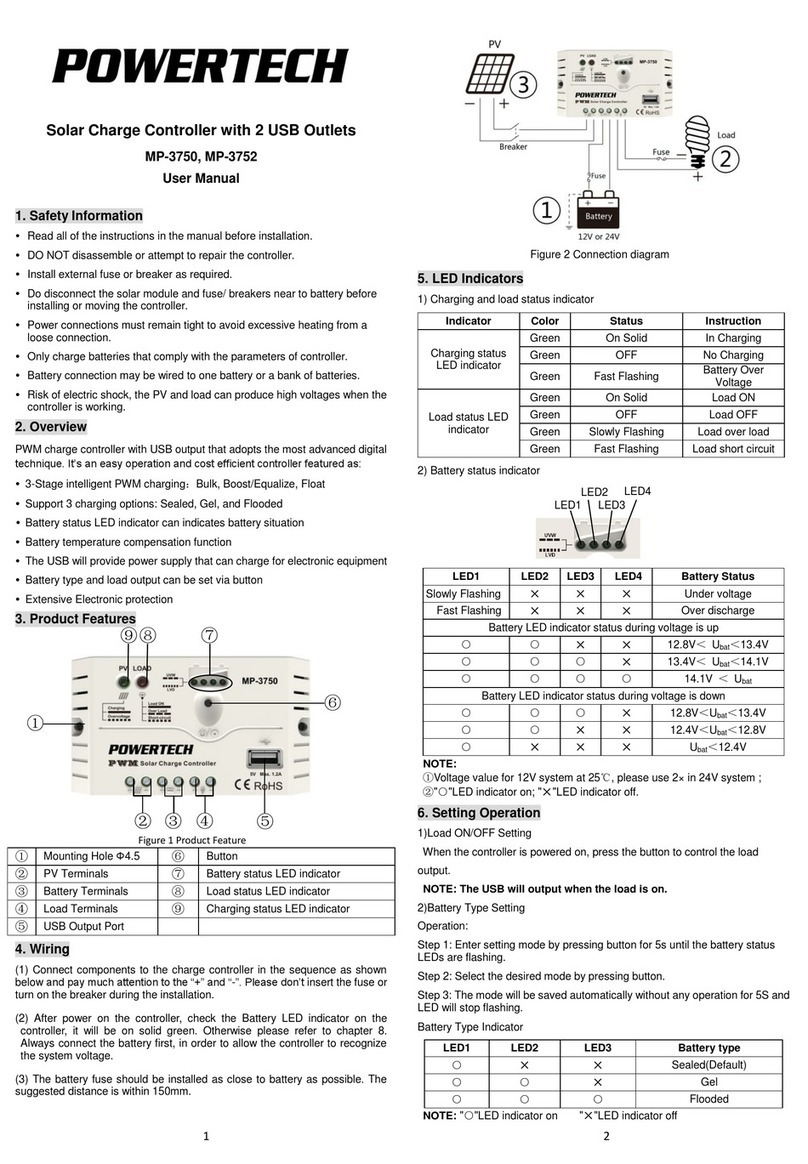

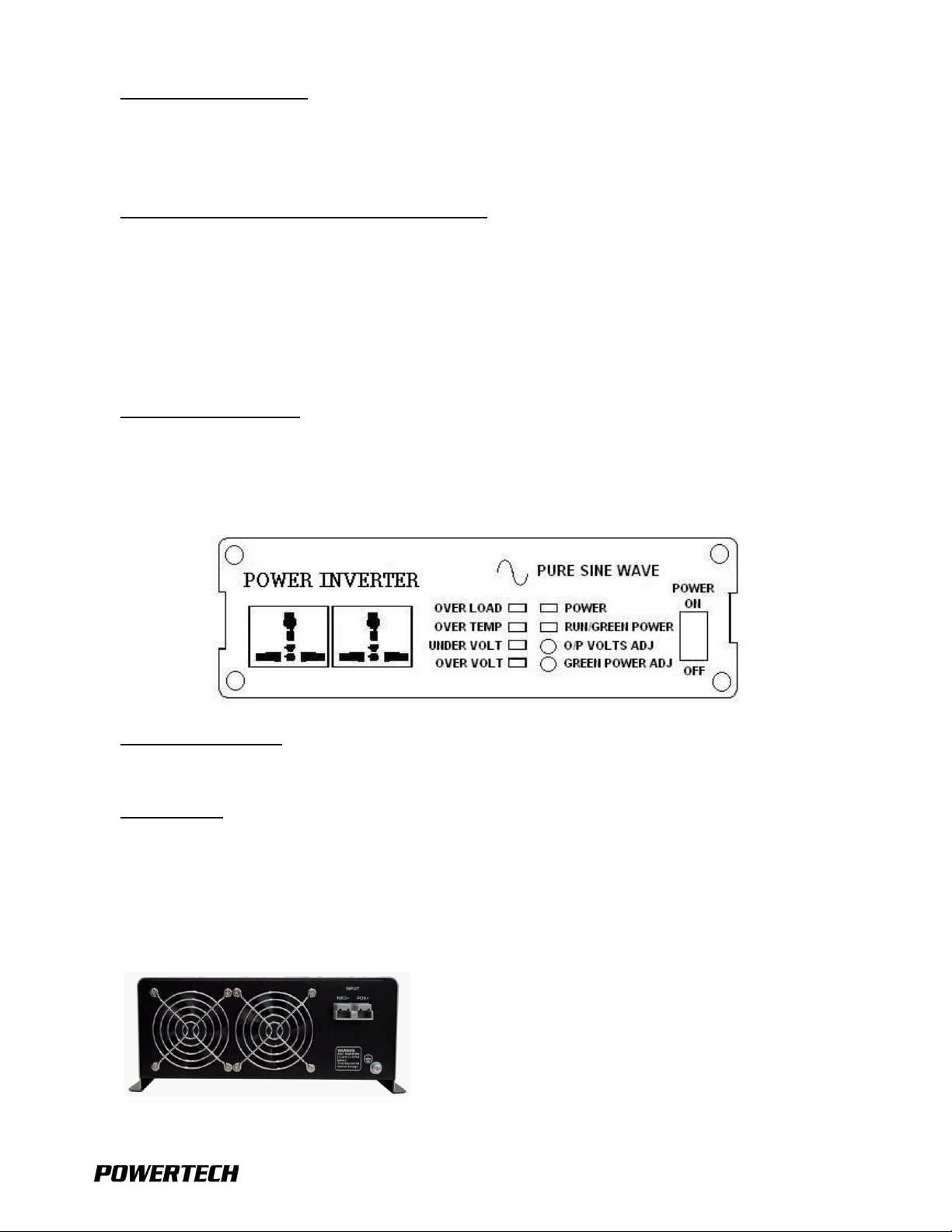

E. Front View & Main Functions

1. Power ‘ON/OFF’ Switch

Make sure the Power Switch is in the ‘OFF’ position during installation.

2. LED Indicators

Over Volt: Over Voltage Protection. Over Temp: Over Temperature Protection.

Under Volt: Under Voltage Protection. Over Load: Over Load Protection.

Power: Power ON. Run/Green Power: Indicates current operating condition of the inverter.

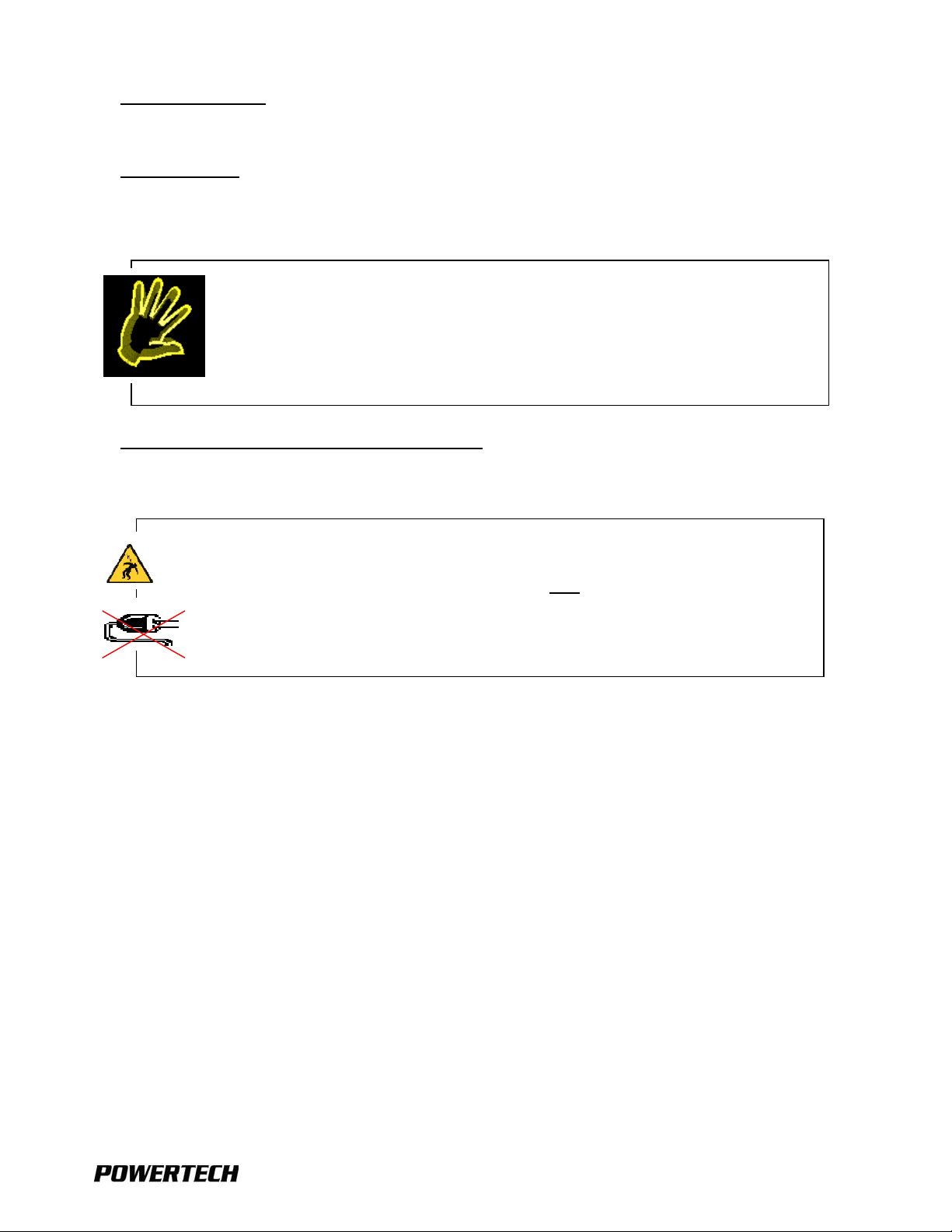

F. Rear View & Main Functions

1200L

-5-

1. Ventilation Openings

Do not obstruct the ventilation openings; allow at least 25mm for airflow around all openings.

2. Battery terminals

Only connect the Inverter to a 12VDC battery, battery bank or other 12VDC power source. (POS+)is Positive, (NEG-)

is Negative.

3. Remote Control (Located on the side of the inverter)

Connect remote control unit (supplied) as necessary.

G. Pre-Installation Information

Before installing your Inverter, please makesure that youhave appropriately-sized batteries with sufficient ampere-hour

capacity. A battery that is too small will not allow the Inverter to perform to its full specification.

H. Electrical Requirements

•The DC input voltage of the Inverter must be the same as the battery bank voltage.

•The DC cabling must be connected to the correct polarity terminals of the battery bank. Red (POS+) Positive,

Black (NEG-) Negative).

•DO NOT extend the DC cable length to the Inverter unless you are prepared to increase the diameter of the cable.

If this is necessary consult your supplier/ installer for advice.

•DO NOT connect AC power to the AC output of the Inverter: THIS WILL DAMAGE THE INVERTER.

•Between the Inverter and any generator / mains supply, it is essential you install a double-pole

“break-before-make” changeover switch that switches both line and neutral AC power.

•DO NOT place the AC power cable and the 12VDC cable in the same cable duct.

•To prevent electrical shock, DO NOT operate the Inverter without connecting it to ground.

•Always disconnect the inverter when not in use.

WARNING! Shock Hazard!

Before proceeding, ensure the Inverter is NOT connected to any Batteries or DC

Power Source.

Do not connect the AC output Terminals of the Inverter to an incoming AC

Power Sources such as the mains.

WARNING!

Do not reverse the polarity of the input connections.

Reverse polarity connection will blow internal fuses and may damage Inverter

permanently.

-6-

I. Installation Requirements

1. Where to install

The Power Inverter should be installed in a location that meets the following requirements:

•Dry – Do not expose the Inverter to high levels of moisture, rain, snow, spray or bilge fluids. Make sure the

Inverter is not exposed to salt water vapour.

•Temperature – Ambient air temperature should be between 0°Cand 40°C. Do not expose the Inverter to heat

sources or direct sunlight.

•Safety – Do not install in a battery compartment or other areas where flammable fumes may exist, such as fuel

storage or engine compartments.

•Ventilation – Allow at least 25mm of clearance around the inverter for airflow. Ensure the ventilation openings on

the sides and bottomof the unit are not obstructed. The installation site should not be susceptible to temperatures

in excess of 50°C.

•Dust-free – Do not install the inverter in an environment where there is dust, wood particles or other

filings/shavings present. These can pull into the unit blocking the cooling fans.

•Close to battery/batteries – Avoid excessive cable lengths (Mount the inverter between one and two meters

from the batteries) but do not install the inverter over or in the same compartment as batteries. Use the

recommended wire lengths and sizes. Do not mount the inverter where it will be exposed to the gases produced

by the battery or battery bank. These gases are very corrosive and prolonged exposure will damage the inverter.

•Wall-mount –Inspection and operation of the Inverter is easier if the unit is mounted at a convenient height and

the DC cables hang naturally out of the way.

2. Safety Grounding

To prevent electrical shock, DO NOT operate the Inverter without connecting it to an appropriate ground.

3. 230V Models

There is no connection made inside the Inverter from either of the lineconductors (line orneutral) to theearth ground.

Please read these instructions carefully before commencing installation.

Installation should be performed by competent qualified installer as dangerous voltages can be present. Complete

the following steps in the order shown:

4. Mounting

•Unpack the Inverter from the shipping container and inspect the unit for any obvious transit damage. Report any

concerns immediately to your supplier.

•Mount the Inverter to a suitable surface, paying close attention to the mounting requirements previously

mentioned in this manual.

5. AC Wiring

Important: to satisfy warranty requirements and conditions, a qualified electrician must perform all AC wiring.

WARNING!

Operation of the inverter without a proper ground connection may result in an

electrical safety hazard.

-7-

6. DC Wiring

IT IS ESSENTIAL that the battery bank voltage match the DC input voltage rating of the Inverter. Damage to the

Inverter could result from improper voltage connections.

A Battery Fuse must be installed between the batteries and the Inverter; appropriately sized Motor-Starting fuses or

similar are recommended.

Before making any connections ensure that the Inverter Power Switch is in the ‘OFF’ position.

The DC cables should be as short as possible (ideally, less than 3 metres) and large enough to handle the required DC

current in accordance with electrical codes or regulations applicable to your installation.

Cables that are not an adequate gauge ( ie too small in diameter) or are too long will cause decreased inverter

performance such as:

•poor surge capability

•frequent low input voltage warnings

•shutdowns.

J. Connection and Testing

For a quick connection and performance check, please follow these guidelines:

Note: The connection to the Negative (NEG-) terminal of the Inverter should be the last connection made. A spark

when making this final connection is normal.

Step 1: Unpack and inspect the Power Inverter for any damage.

Step 2: Make sure the power switch in the ‘OFF’ position.

Step 3: Connect the DC Positive cable to the Positive (POS+) terminal on the battery. Next, connect the DC Positive

cable to the Positive terminal on the Inverter (via the Battery Fuse). Make sure the connections are secure.

Before proceeding further, recheck the cable you have just connected to the Positive terminal of Inverter, and to the

Positive terminal of the battery or DC power source.

WARNING!

Do not operate the power inverter without connecting it to ground. Electrical

shock hazard may result.

WARNING!

Make sure all the DC connections/ terminations are tight (torque to 9-10

ft-lbs,11.7-13Nm). Loose connections will overheat and could result in a fire

hazard.

-8-

Step 4: Connect the DC Negative cable to the Negative terminal of the Inverter. Next, connect the DC Negative cable

to the Negative (NEG-) terminal on the battery or power source. Make sure the connections are secure.

Step 5: Set the Inverter power switch to the ‘ON’ position. Check the POWER and RUN/GREEN POWER LED

indicators on the front panel of the Inverter are illuminated. If the LED is not illuminated, check your power

source and the connections to Inverter. The other indicators should be off.

Step 6: Set the Inverter power switch to the ‘OFF’ position. The indicator lights may blink and the internal alarm may

sound momentarily. This is normal.

Step 7: Plug the AC test load into the AC receptacle on the front panel of the Inverter. Leave the AC test load switch

in the ‘OFF’ position.

Step 8: Set Inverter power switch to the ‘ON’position and turn the test load ‘ON’. The Inverter should supply power to

the test load. If you plan to measure the AC output voltage of the Inverter, a Digital Multi Meter with true RMS

voltage capabilities must be used.

K. Operation

To operate the Inverter, turn it ‘ON’ using the Power ‘ON/OFF’ switch on the front panel. The Inverter is now ready to

deliver AC power to your appliances/ loads. If you are operating several appliances/ loads from the Inverter, turn them

‘ON’ separately after the Inverter has been switched ‘ON’. This will ensure that the Inverter does not have to deliver the

starting currents for all loads at once and hence, minimizes the risk of a shutdown.

1. Controls and Indicators

The power ‘ON/OFF’ switch turns the control circuit in the Inverter ‘ON’ and ‘OFF’. It does not disconnect DC power

from the Inverter.

The Inverter operates from an input voltage ranging from 10VDC to 16VDC for 12V models.

2. Over Voltage Indicator

The over voltage indicator indicates that the Inverter has shut down because the protection circuits have sensed the DC

input voltage is higher than that recommended for safe operation.

WARNING!

You may observe a spark when you make this connection. Do not make this

connection in the presence of flammable fumes. Explosion or fire may result.

CAUTION!

Reversed polarity connections will blow a fuse and may permanently damage

the Inverter. Damage caused by a reverse polarity connection is Not covered by

warranty.

¡

Ï

¡Ð

-9-

3. Under Voltage Indicator

The under voltage indicator indicates that the Inverter has shut down because the protection circuits have sensed the

DC input voltage is lower than that recommended for safe operation.

4. Over Temp Indicator

The over temp indicator indicates that the Inverter has shut down because the thermal protection circuits have sensed

the Inverter has become overheated. The Inverter may overheat because it has been operated at power levels above

its rating, or because it has been installed in a location which does not allow it to dissipate heat properly.

The power inverter will restart automatically once it has cooled down. If the Inverter continues to shut down, reduce the

load, and check the ambient temperature.

5. Overload Indicator

The overload indicator indicates that the Inverter has shut down because its output circuit has been short circuited, or

drastically overloaded. Switch the ‘ON/OFF’ switch to ‘OFF’, correct the fault condition, and then switch the ‘ON/OFF’

switch back to ‘ON’.

L. Green Power Adjustment

The Inverter features automatic load-sensing, which means it will wait in Standby Mode until an AC load is switched

‘ON’. When an AC load appears, the Inverter will immediately start. This feature conserves valuable battery energy as

the Inverter uses only about 10% of normal power when in Standby Mode (Standby Mode is indicated by flashing

GREEN indicator). The amount of AC power required to start the Inverter can be adjusted on the front panel. Follow the

procedure below. Ensure the battery voltage is at the nominal 12V level.

1. Adjusting Load Sensitivity for Green Power Mode

•Turn ‘OFF’ allAC loads, keeping theAC wiring connected to the Inverter AC output. Some loads such as TVs

must be turned ‘OFF’ at the power point as they can still represent a small load to the Inverter.

•Using a small screwdriver, adjust the black plastic trim pot located to the right of the over voltage indicator and to

the left of the power switch. Turning this control fully clockwise will override the Standby circuit and keep the

Inverter ‘ON’ all the time. This could be used if you have a very small load that must stay ‘ON’ at all times.

•Adjust the trim pot until the indicator is a steady GREEN; then turn the trim pot back a little until the indicator

flashes GREEN. Allow 10 seconds between adjustments for stabilisation: clockwise decreases the sensitivity or

threshold; counter-clockwise is increases the sensitivity or threshold.

•Note: the trim pot is extremely sensitive.

•When the indicator flashes GREEN, the Inverter is in Standby Mode.

•Turn ‘ON’ the smallest AC load connected to the Inverter. The Inverter should now deliver 240VAC, and AC status

indicator should be a steady GREEN. However, if the indicator is ORANGE the sensitivity must be increased by

turning the control trim pot a little counter-clockwise.

•Now turn ‘OFF’ the AC load. The indicator should return to flashing GREEN, indicating that the Inverter is in

Standby Mode. If this does not occur, reduce sensitivity by turning the control trim pot a little clockwise and check

again.

M. Trouble Shooting:

1. AC Output Does Not Remain ‘ON’

If Green Power Mode is being used, some AC loads may not be large enough to hold the Inverter ‘ON’. This condition

is indicated by the Inverter turning ‘OFF’ after every eight to ten seconds, then back ‘ON’ again. The AC Status

indicator will also be flashing ORANGE.

There are two possible solutions:

•Increase the sensitivity of the inverter by turning the Standby control slightly counter-clockwise until the indicator

is a steady GREEN; or

•Increase the amount of AC load on the Inverter.

-10-

2. Over Temperature Shut Down

Your inverter will safely provide the output power defined in the technical data section under the conditions specified.

If the Inverter shuts down and indicates over temperature, it may be that you have exceeded one of the parameters.

Check the following:

•Ensure the Inverter has adequate ventilation. Insufficient ventilation can severely restrict the power output of your

Inverter as it does not allow proper heat dissipation.

•Ensure that the true power rating of your appliance (including power factor) is less than the output rating of your

Inverter.

3. Shut Down When Trying to Start a Load

A sudden surge in load, such as a motor starting, may cause the inverter to shut down. If this occurs:

•Ensure the battery voltage is within specifications when the device is trying to start. If the input voltage drops too

low, you may need to increase the capacity of your batteries. Also check DC cables and terminations.

•If the battery voltage is ok when measured at the Inverter, then the Inverter AC output power rating may be too.

4. Overload Shut Down

The overload indicator indicates that the Inverter has shut down. If this occurs:

•Ensure the output circuit is not short circuited, or drastically overloaded. Switch the ‘ON/OFF’ switch to ‘OFF’,

correct the fault condition, and then switch the ‘ON/OFF’ switch back to ‘ON’.

5. Under Voltage Shut Down

The under voltage indicator indicates that the Inverter has shut down because the protection circuits have sensed the

DC input voltage is lower than that recommended for safe operation. If this occurs:

•Charge the battery.

•Check the battery voltage at the terminals of the Inverter is within specification. If the input voltage drops too low,

you may need to increase the capacity of your batteries. Also check DC cables and terminations.

6. Over Voltage Shut Down

The over voltage indicator indicates that the Inverter has shut down because the protection circuits have sensed the DC

input voltage is higher than that recommended for safe operation. If this occurs:

•Check the DC power source or battery voltage at the terminals of the Inverter is within specification.

7. Television Interference

Operation of the Inverter can interfere with television reception on some channels. If this occurs, the following steps

may help alleviate the problem:

•Make sure that the chassis ground lug on the back of the Inverter is solidly connected to the ground system of

your vehicle, boat or home. Make sure there is no oxidation or corrosion on any groumd terminations.

•Try not to operate high power loads with the Inverter while watching television.

•Make sure that the antenna feeding your television provides an adequate (“Snow free”) signal and that you are

using high quality shielded cable between the antenna and the television.

•Move the television as far away from the Inverter as possible.

•Keep the cables between the battery and the Inverter as short as possible. Twist them together with about 6 to 9

twists per metre as this helps minimising radiated interference from the cables.

-11-

N. Maintenance

Very little maintenance is required to keep the Inverter operating properly. With the Inverter switched ‘OFF’, clean the

exterior of the unit periodically with a slightly damp cloth to prevent accumulation of dust and dirt. At the same time,

check and tighten all cable terminations on the DC input terminals.

WARNING!

There are no user serviceable parts inside. Only qualified personnel should

carry out maintenance or service the device. Do not open or disassemble the

Inverter. Attempting to service the unit yourself may result in a risk of

electrical shock or fire.

-12-

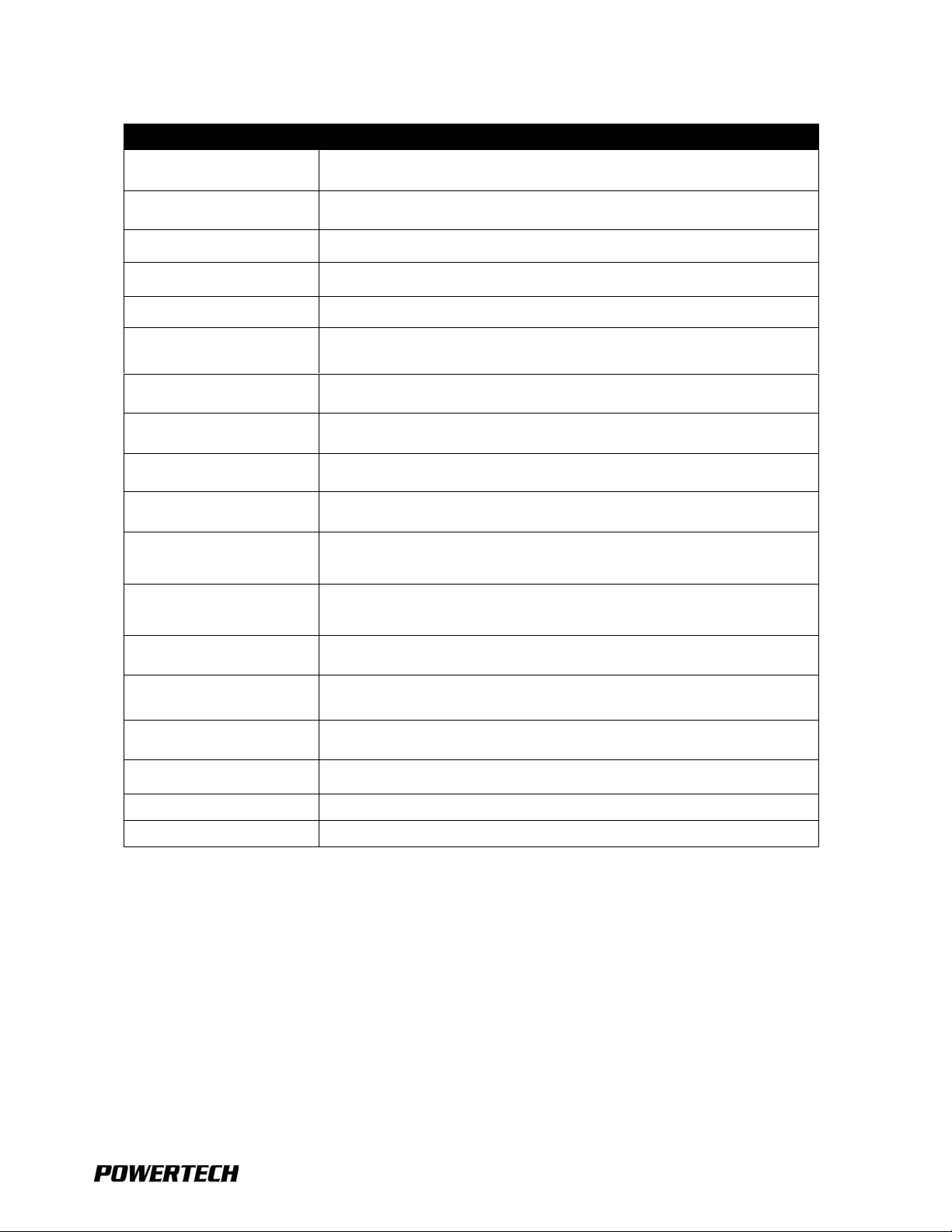

O. Specifications

Model No. 1200W (L)

Continuous Output

Power 1200W

Output Power

Surge 3600W

AC Output Voltage 200VAC ~ 240VAC ±1~2% Adjustable

Output Voltage Regulation ~ -1.5% to +1.0%

Output Frequency 50Hz ± 0.5%

Output Wave

Form Pure Sine Wave <2% THD

Efficiency

(Full Load) >70%

No Load Power

Consumption <4W (In Green Power Standby Mode)

Input Voltage

Range ~10VDC to 16VDC

Green Power

Recovery Time 1 Second

LED Status

Indication Power ON/ OFF, RUN/GREEN POWER Standby, Under/Over Voltage

Shutdown, Over Temperature Shutdown, and Over Load Shutdown

Protection Input Under/Over Voltage, Over Temp, Reverse Input Polarity (Fuse),

Over Load, Short Circuit Shutdown, Restarts, Soft Start

Remote Control ON/OFF Switching with 3M cable

Operation Temperature

Range 0°C ~ 40°C (32°F ~ 104°F)

Storage Temperature

Range -30°C ~ 70°C (-22°F ~ 158°F)

Dimensions

(L x W x H) 465 x 280 x 120mm

Nett Weight 11.5kg

Gross Weight 14.0kg

Table of contents

Other PowerTech Inverter manuals

Popular Inverter manuals by other brands

New Holland

New Holland Windrow Inverter Specifications

Darfon

Darfon H5001 installation manual

Ingeteam

Ingeteam Ingecon Sun Lite 2.5TL Maintenance Guide

Rowan Elettronica

Rowan Elettronica 400 Series Installation and instruction manual

Tesla Kala

Tesla Kala SY8600 Series user manual

Fosera

Fosera PSHS 3000 user manual

Shindaiwa

Shindaiwa DGA37CM Owner's and operator's manual

Thermal Arc

Thermal Arc ARCMASTER 400TS Service manual

Profi-pumpe

Profi-pumpe INVERTER PUMP CONTROL 5 operating instructions

iWeld

iWeld MIG 251 DIGITAL user manual

Mitsubishi Electric

Mitsubishi Electric FR-HEL-0.4K instruction manual

Vector

Vector VEC411 User's manual & warranty information