I N S T A L L A T I O N M A N U A L H 5 0 0 1 H Y B R I D I N V E R T E R

R e v . 2 © 2 0 1 8 D a r f o n E l e c t r o n i c s C o r p . 2 | P a g e

TABLE OF CONTENTS

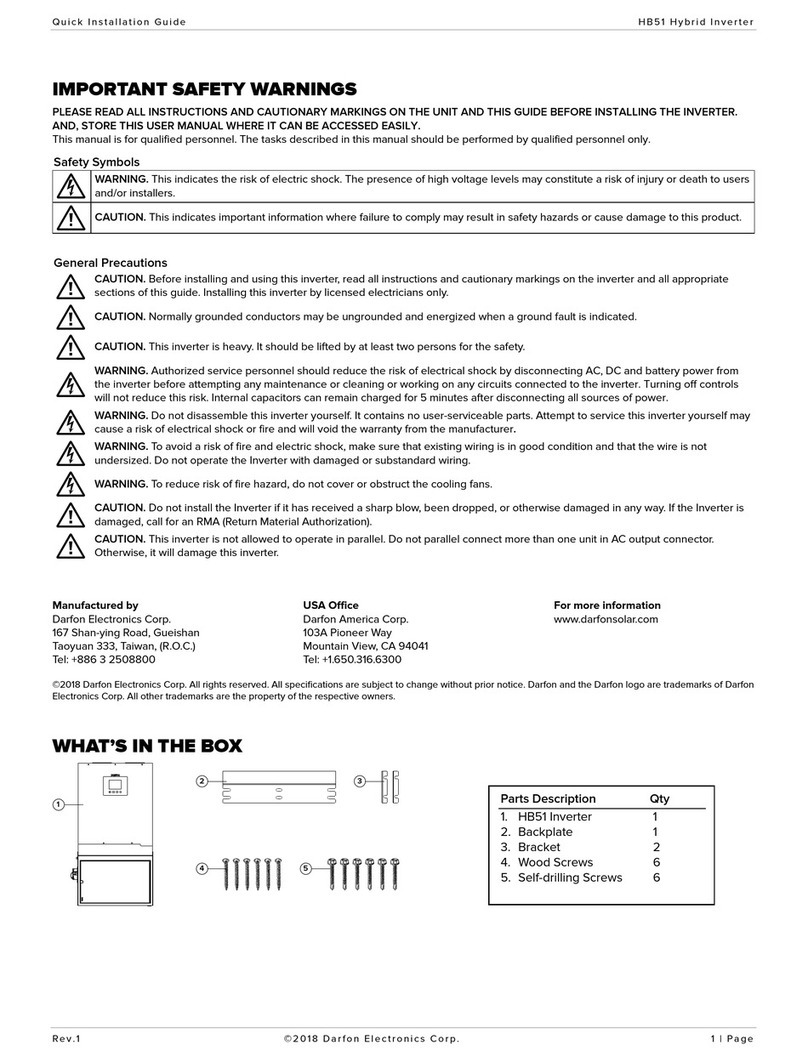

IMPORTANT SAFETY WARNINGS...................................................................................3

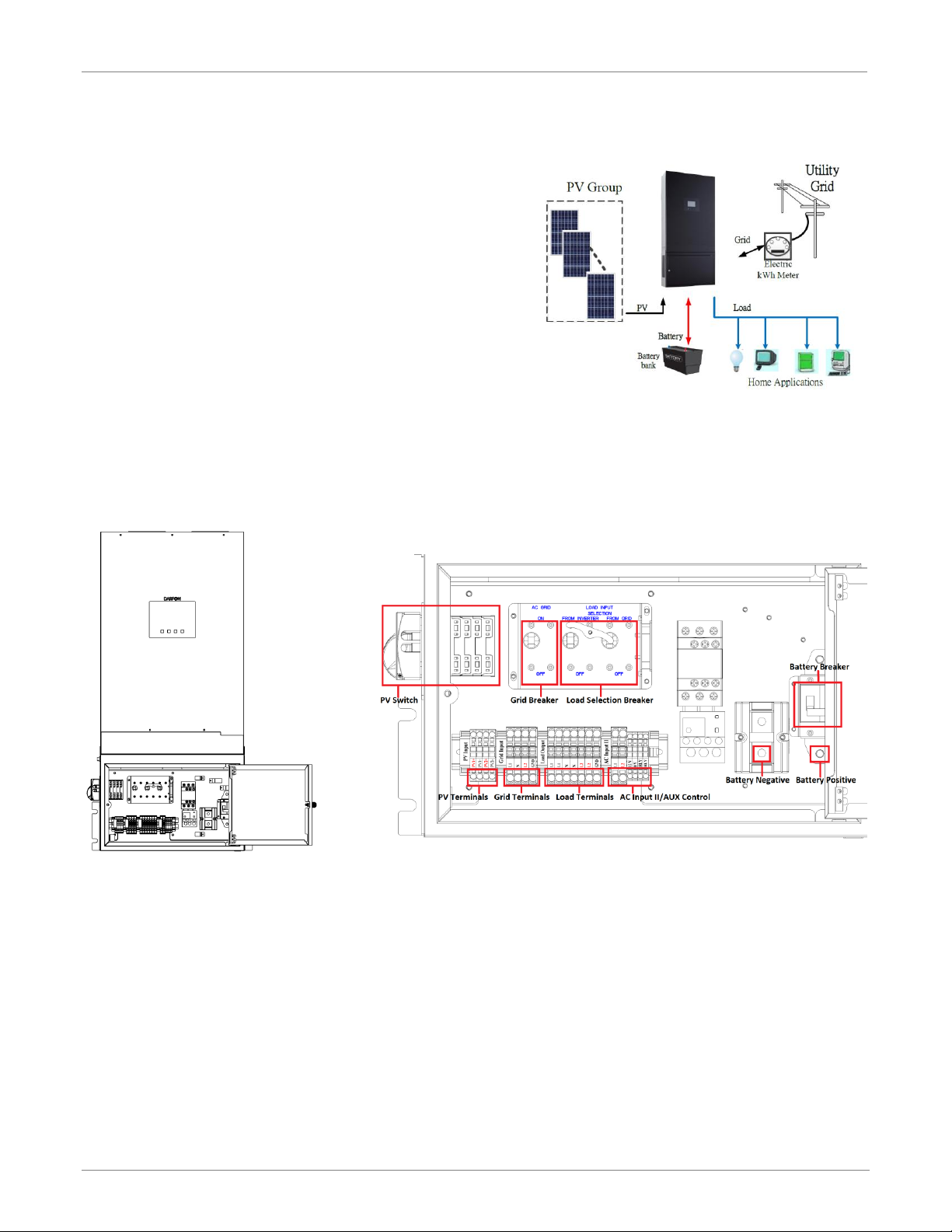

PRODUCT OVERVIEW.......................................................................................................4

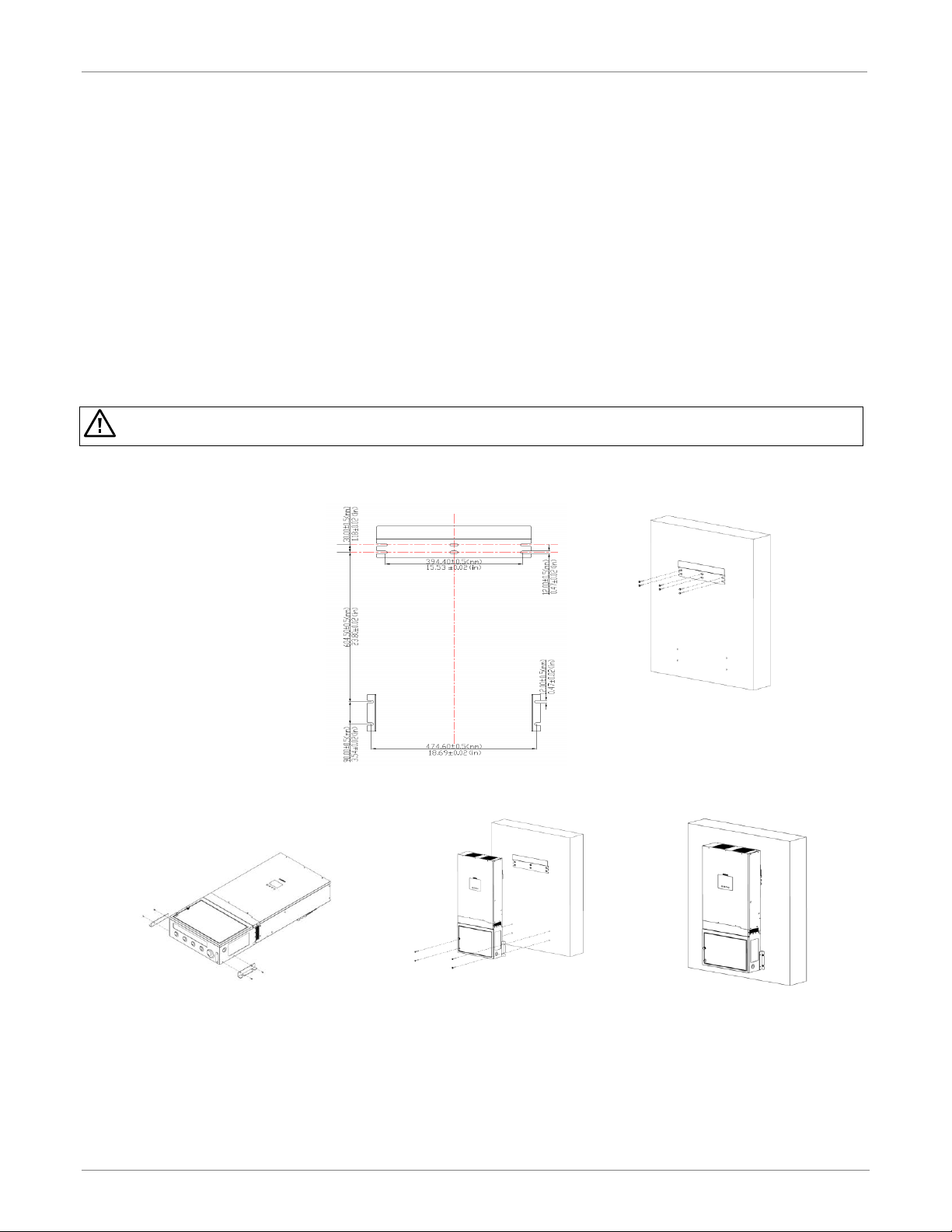

MOUNTING THE INVERTER..............................................................................................5

Installing the Inverter onto the Wall ....................................................................................... 5

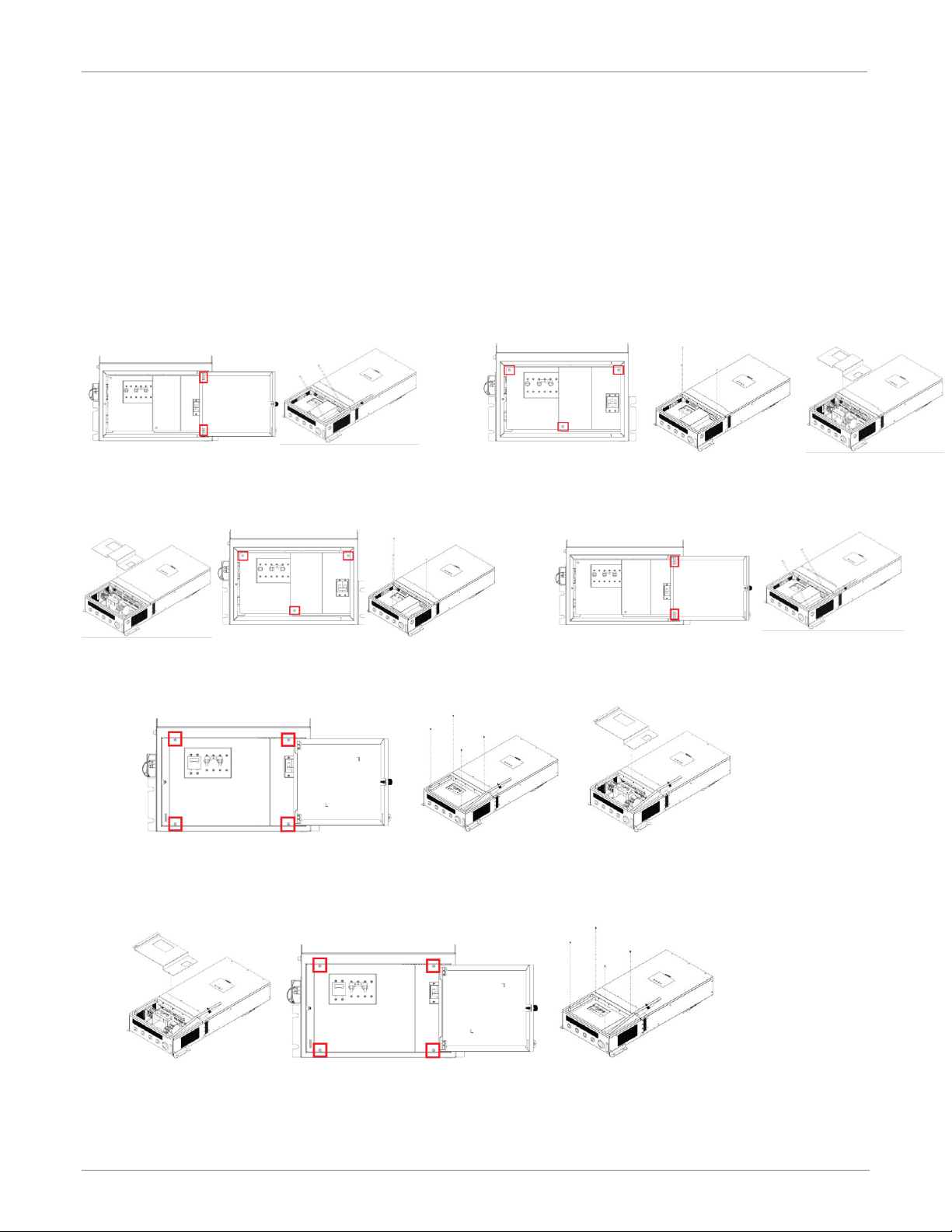

REMOVING AND INSTALLING THE DEAD-FRONT COVER...........................................6

PV MODULE (DC) CONNECTION .....................................................................................7

Connecting the PV Arrays......................................................................................................... 7

GRID (UTILITY) CONNECTION .........................................................................................8

Connecting to the Grid/Utility ..................................................................................................8

Circuit Protection......................................................................................................................8

BATTERY CONNECTION AND CHARGING REQUIREMENTS.......................................9

Connecting the Batteries .........................................................................................................9

BATTERY CHARGING REQUIREMENTS.......................................................................10

Charging Characteristics..........................................................................................................10

LOAD (AC OUTPUT) CONNECTION...............................................................................11

Connecting to the Load........................................................................................................... 11

OPERATION AND DISPLAY PANEL...............................................................................12

Display Panel Overview ...........................................................................................................12

Starting the System .................................................................................................................12

Stopping the System ...............................................................................................................12

LCD Screen –Icons and Pages ................................................................................................13

System Settings .......................................................................................................................15

Error and Warning Definition..................................................................................................17

GENERATOR [GENERATOR KIT SOLD SEPARATELY]..............................................19

Generator Sizing ......................................................................................................................19

Automatic Start Generator .....................................................................................................19

CONFIGURING THE HARDWARE ..................................................................................20

Connecting to the Hardware ................................................................................................. 20

Using the Application Software..............................................................................................21

Modifying the Parameters (Installer Login Only) ................................................................. 23

AP Parameters ........................................................................................................................ 25

MAINTENANCE & CLEANING.........................................................................................26

Wiring Diagram ....................................................................................................................... 26

SPECIFICATIONS.............................................................................................................27

GRID SUPPORT PARAMERTERS (UL1741SA).............................................................28