Table of Contents

1. Safety Guidelines ·························································································1

2. Specifications ······························································································5

2-1. Data ······································································································5

2-2. Ambient Condition·····················································································6

3. Use·············································································································6

4. Parts···········································································································6

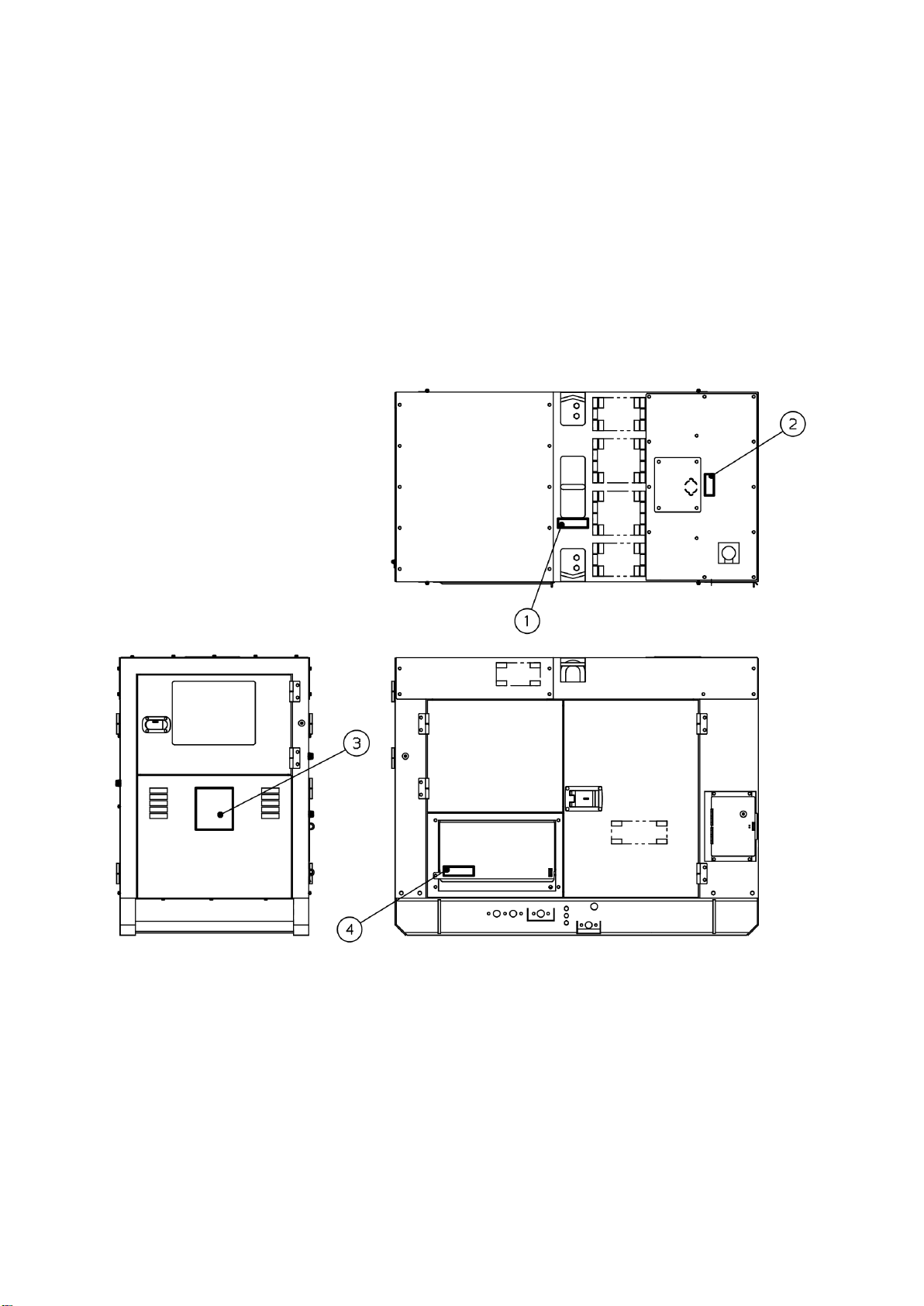

4-1. Outer and Main Components·······································································6

4-2. Operation Panel ·······················································································7

4-3. Output Panel ···························································································8

5. Equipment···································································································9

5-1. Controller································································································9

5-2. Switches································································································11

5-3. Voltage Regulator and Throttle Lever ·························································· 13

5-4. Fuel Line Changeover Valve (3-Way Valve) ·················································· 14

6. Transportation & Installation ········································································ 15

6-1. How to transport····················································································· 15

6-2. Installation ···························································································· 16

7. Connecting load························································································· 17

7-1. Select Load Cable ·················································································· 17

7-2. Connecting Load Cable············································································ 18

7-3. RCCB and Grounding·············································································· 19

8. Initialization and Pre-check·········································································· 22

8-1. Engine Oil····························································································· 22

8-2. Coolant / Water······················································································ 23

8-3. Fan Belt································································································ 25

8-4. Fuel····································································································· 25

8-5. Fuel, Engine Oil and Coolant Leakage························································· 26

8-6. Battery ································································································· 26

9. Operation ·································································································· 28

9-1. Initialization and Preparation ····································································· 28

9-2. Procedures during Operation····································································· 30

9-3. Stopping······························································································· 31

9-4. Protection Functions················································································ 32

9-5. Connecting with External Fuel Tank ···························································· 33

10. Check and Maintenance············································································· 34

11. Long Term Storage···················································································· 43

12. Troubleshooting ······················································································· 44

13. Generator Circuit Diagram·········································································· 47

14. Engine Circuit Diagram·············································································· 48