SHORT & SWEET PLEASE READ

Please take a few minutes to! Maybe even read them.

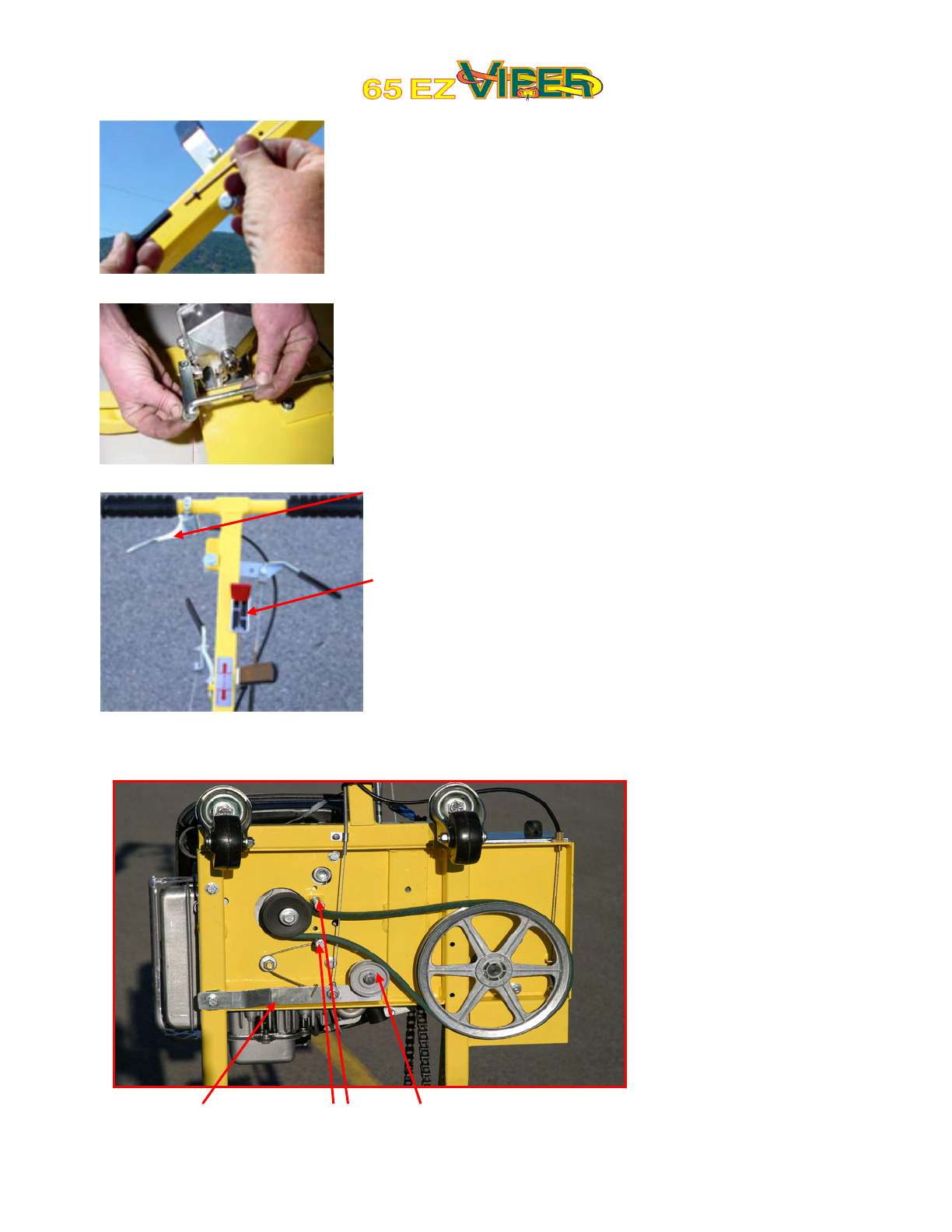

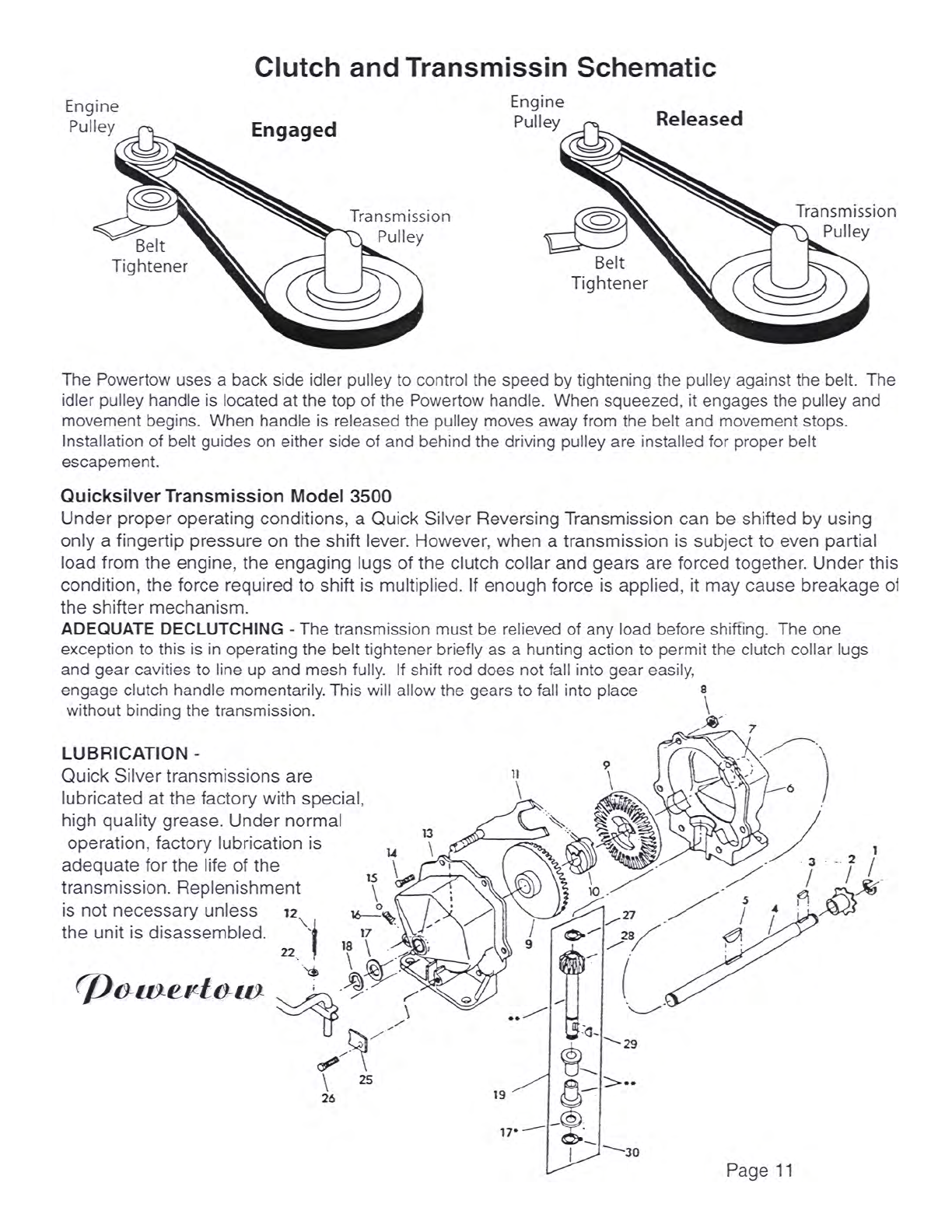

Transmission

The transmission has three positions, Forward – Neutral – Reverse. Neutral is the center

detent. Roll the machine up to the plane hook up to aircraft. Always start the unit neutral.

Time to take the 65EZ Viper out for a solo, without your aircraft! It’s very important to make

sure the controls are all working correctly before you hook your beautiful bird up to it.

Engine – Don’t forget the oil for the engine, it will take approximately ¾ of quart. A

splash of 100LL, and we’re ready to start up the unit. First, place the throttle control in

the choke position (full forward) and push starter button on battery box and return to run

after starting. Move control to run position at about medium speed. Greatest torque is

developed at two-thirds throttle setting.

HANGARING AIRCRAFT

Move the shift rod in the direction you want to go. If shift rod does not fall into gear –

engage clutch handle momentarily.

Clutch Handle To move the airplane, squeeze the clutch handle slowly. A slight down

pressure on the Powertow handle and away you go. Release clutch to stop drive.

When you release the clutch handle, the drive belt should disengage completely, there

should be no creeping (If there is, refer back to set-up instructions). Run the unit out in

the open for a few minutes to break in a new belt. You can also stop by lifting the

Powertow handle up.

Steering – Steering is accomplished by lifting and shifting the Powertow handle left or

right, just like a hand towbar. In the case of a heavy plane, especially with cold tires, a

rocking technique, with power applied, and using down handle pressure at the right time

get the plane rolling.

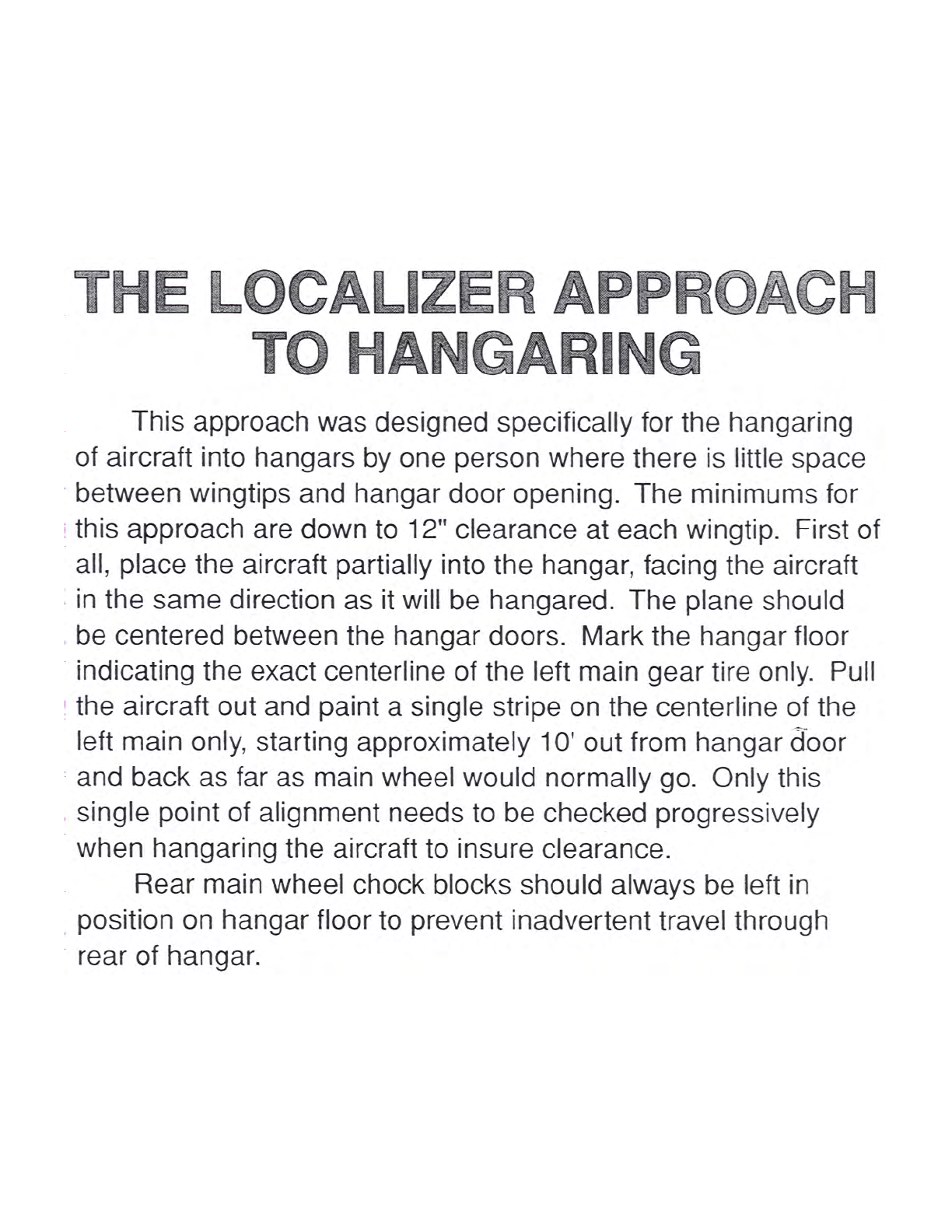

Tips: Door Tracks -To get a heavy plane over door rails or ledges, a moderate amount of

speed is necessary so that the momentum of aircraft mass will help carry it over, but smoothly.

Icy surfaces are naturally a traction problem, as well as smooth painted concrete floors. A bit of

sand spread around will help. Wing walk for the Powertow drive tire is great for traction on the

hangar floor.

Now here’s a good tip. Get up kind of early on Saturday morning, and get out to

the airport before the rest of the hangar bums get there. Pull your plane out of the hangar by

hand for the last time, and get it out on the apron well away from all hard objects. Go through

the above procedures until you really have it down. By the time those guys show up, you will

have become super proficient and will be able to put on a good show. Always have chock

blocks of some kind anchored at the rear of your main wheel position in the hangar to prevent

inadvertent travel through the rear of your hangar.

Last Tip: If you really want to get smart, re-read this stuff after you have actually used

the machine a few times – it will be more meaningful. 3-2006