Issue 1 Page 2 of 34 Initial Issue 19 December 2017 Engineering Manager

Contents

1Introduction..........................................................................................................4

2Description and Intended Use .............................................................................6

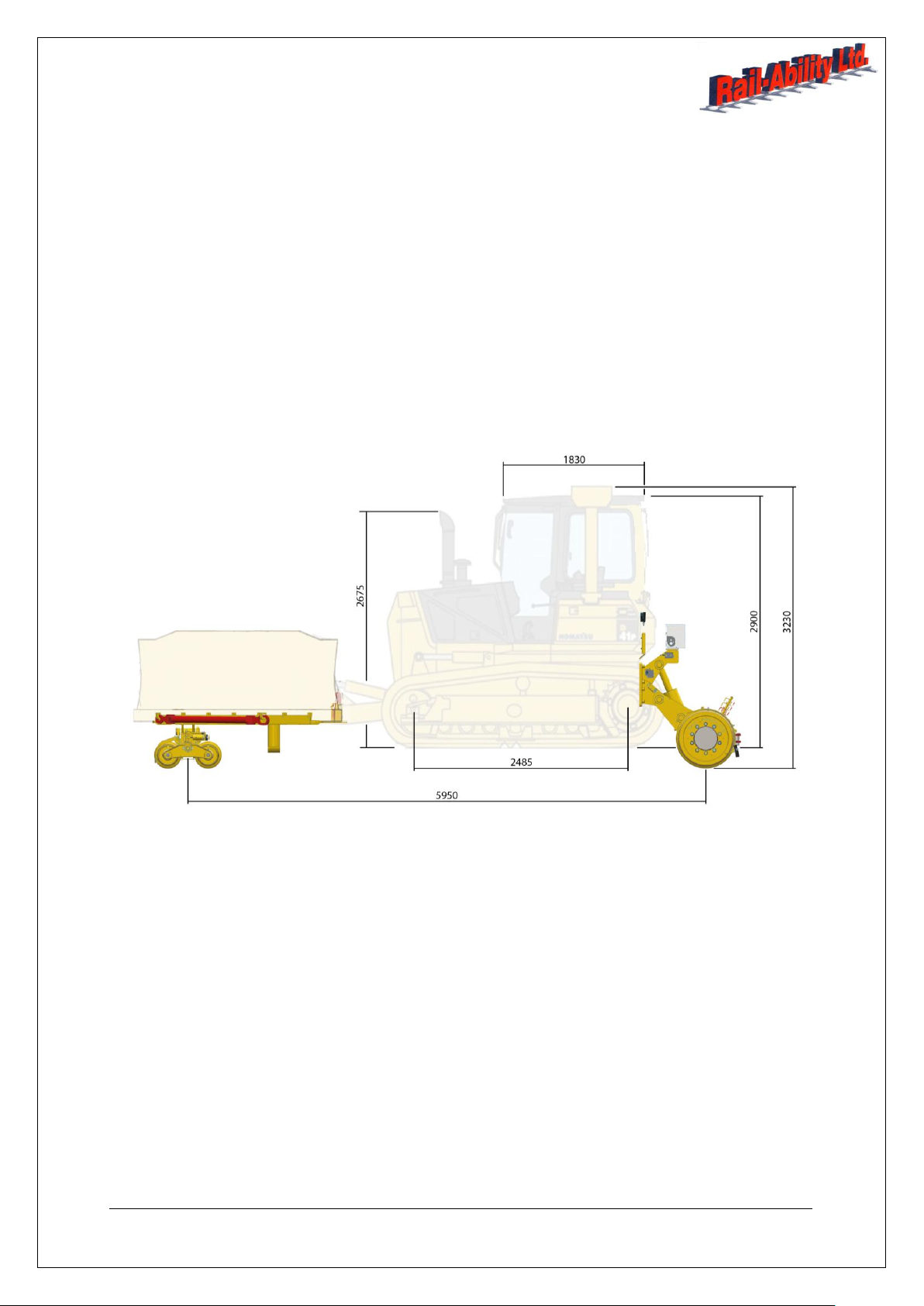

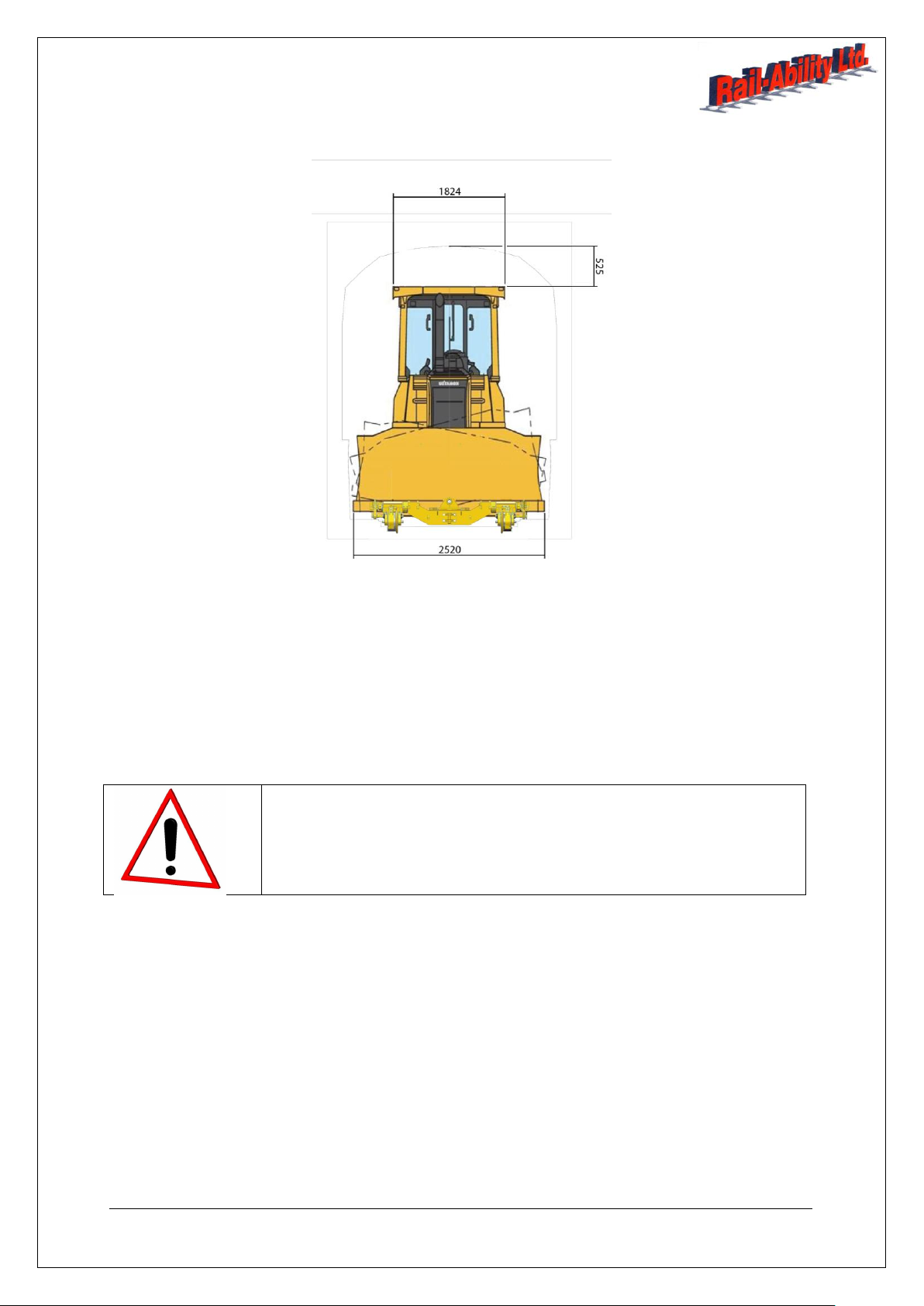

3General Dimensions............................................................................................6

4Rail Specifications ...............................................................................................6

5Gauge Dimensions..............................................................................................7

6Limitations ...........................................................................................................7

7Operational Safety Precautions...........................................................................7

8Safety Rules ........................................................................................................9

8.1 General...................................................................................................................9

8.2 Electrocution Hazards.............................................................................................9

8.3 Travel Hazards .....................................................................................................10

8.4 Tip-over Hazards ..................................................................................................10

8.5 Fall Hazards..........................................................................................................11

8.6 Collision Hazards..................................................................................................11

8.7 Crushing Hazards.................................................................................................11

8.8 Explosion and Fire Hazards..................................................................................11

8.9 Burn Hazards........................................................................................................12

8.10 Bodily Injury Hazards.........................................................................................12

8.11 Lifting Hazard....................................................................................................12

8.12 Damaged or Malfunctioning Machine Hazards ..................................................12

8.13 Component Damage Hazards...........................................................................12

9Rail Safety .........................................................................................................13

9.1 General.................................................................................................................13

9.2 On/Off Track.........................................................................................................13

10 Control Layout ...................................................................................................14

11 Operating Control Principles..............................................................................15

11.1 Rail Systems .....................................................................................................15

11.2 Blade UP-DOWN/Ripper Control Lever.............................................................15

11.3 Rail Axle Deploy/Rail Drive Change-Over..........................................................15

11.4 Rail Axle Deploy................................................................................................15

11.5 Bogie Axle Deploy.............................................................................................15

11.6 Blade Rams Lock..............................................................................................15

11.7 Crawler Tracks Interlock....................................................................................16

11.8 Rail Drive Acknowledge Interlock ......................................................................17

11.9 Rail Travel.........................................................................................................17

11.10 Low Speed Selector ..........................................................................................17

12 On / Off Tracking ...............................................................................................18

13 Suggested On / Off Tracking Area Requirements..............................................19