Operation

SCR system

cleaning

INHIBIT

Should only be activated when the

environment is unsafe to allow high exhaust

temperatures (i.e., in a bldg.). To activate function, press and hold the icon for

three seconds. The fuel gauge display is replaced with

red text HOLD 3 SECONDS.

SCR system

cleaning

FORCED

Allows a manual (parked) exhaust system

cleaning. It is used infrequently for unusual

duty cycles. If required, it will illuminate

amber. Should NOT be performed indoors.

HEST lamp Do NOT park vehicle indoors when lamp

is on. Appears when the engine enters a SCR system clean-

ing. This will not hinder normal vehicle operation.

Overriding

engine

shutdown

This should only be done in an emergency

situation (e.g., clearing a railroad) as engine

damage may occur.

Press the PRESS HERE TO OVERRIDE message that

alternate with SHUTDOWN IN message. The countdown

timer for shutdown will reset to 30 seconds.

Tools menu

Accessible through the fuel icon and gauge. Press and hold the fuel icon and gauge display for

two seconds. Tools and brightness symbols come up.

Pressing the brightness symbol will display the backlighting control function. Adjust if necessary.

NOTE: Display will revert back to fuel icon and gauge if backlighting control function is not pressed for

five seconds or if the DEF icon and gauge are pressed.

Pressing the tools symbol brings up the languages menu and software version.

Tips and Shortcuts

Enter

Programming

Mode

Ignition ON.

Press and hold PROGRAM and SELECT at

the same time, until the CDM display enters

Programming mode.

Exit

Programming

Mode Press PROGRAM.

Change

Language to

English

Ignition OFF.

Press and hold HEADER INDEX and

PROGRAM and SELECT.

Clear

Sub-Acres

Cab-Forward position.

Ignition ON.

Press SELECT until SUB-ACRES is viewed

on the bottom line of the display.

Press and hold PROGRAM until

SUB-ACRES changes to "0.0".

NOTE: See M155E4 Operator’s Manual for complete

instructions and detailed information

Header Model Application / System Suggested Overload Warning

Setting psi (kPa) Windrower Pressure

Relief Setting psi (kPa)

R-Series Disc pressure 4000 (27,579) 4200 (28,958)

Reel / draper pressure 3000 (20,684) 3200 (22,063)

Knife / conditioner pressure 4000 (27,579) 4200 (28,958)

A-Series

D-Series

Enhanced reel/conveyor speed controls may be desirable in

variable crop and terrain conditions.

Allows the reel and conveyor to be driven by reference to

ground speed, so that header systems will speed up and

slow down as ground speed changes.

Operation of Header Index for REEL SPEED:

(A-Series and D-Series)

1. With all bystanders clear, start windrower, and engage

the header.

2. While stationary, with the GSL in PARK, use the REEL

SPEED control switch to set a ‘Minimum Reel Speed’.

3. When operating at ground speed faster than the Mini-

mum Reel Speed + Header Index value, REEL SPEED

display will change to REEL INDEX. Using the GSL

REEL SPEED switch, Header Index can be adjusted.

4. Reel speed will be equal to the greater of: ‘Ground

Speed + Index Value’ OR ‘Minimum Reel Speed’.

Operation of Header Index for DRAPER SPEED:

(D-Series Only)

Follow instructions above, using the CDM AUGER/DRAPER

speed control, rather than the GSL REEL SPEED switch.

Header Index Mode

M155E4 Windrower Quick Card - Form 147797 Rev. A

Supplement to M155E4 Windrower Operator’s Manual M155E4 Windrower Quick Card - Form 147797 Rev. A

Supplement to M155E4 Windrower Operator’s Manual

Programming the CDM Fuel and Diesel Exhaust Fluid (DEF) Display Module

Alarm Tone Reason Duration

When DEF or fuel level amber light first starts to blink (1/16th tank) 5 seconds

When the SCR system cleaning INHIBIT is active and system calls for a

passive SCR system cleaning 5 seconds, repeat

every 30 mins

Single moderate tone At the end of the delay for entering the brightness/tools menu

At the end of the delay when switch (icon) is activated

Ongoing intermittent

moderate tone until

the condition

is corrected

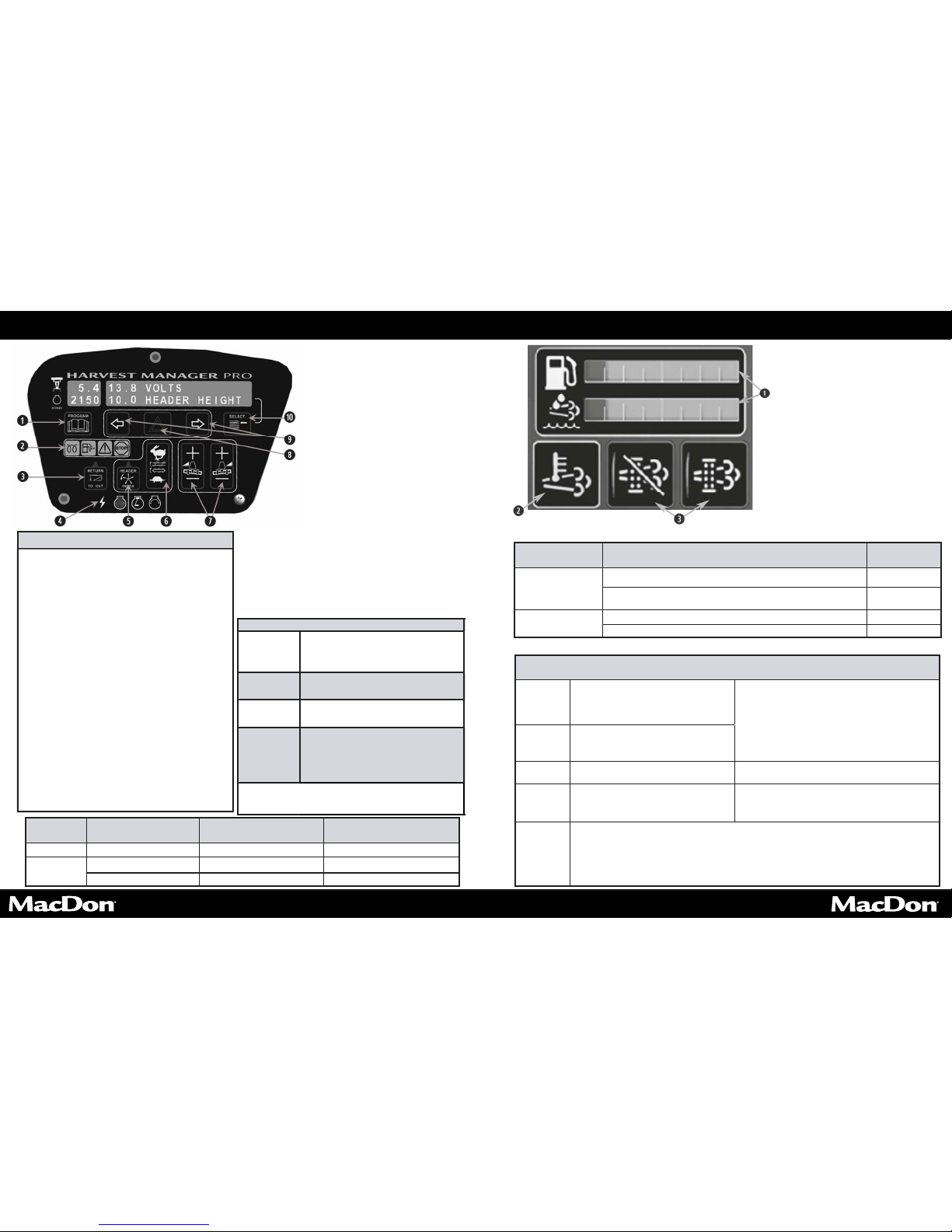

1 FUEL and DEF LEVEL - Amber light

blinks when tank level reached 1/16.

2 HIGH EXHAUST SYSTEM

TEMPERATURE (HEST) - When

warning is active, icon is black and

background amber. When inactive, icon

is not visible.

3 SCR SYSTEM CLEANING INHIBIT and

SCR SYSTEM CLEANING FORCED -

Icons are gray when functions are

inactive and turn black with amber

background when active.

Subject to change without notice

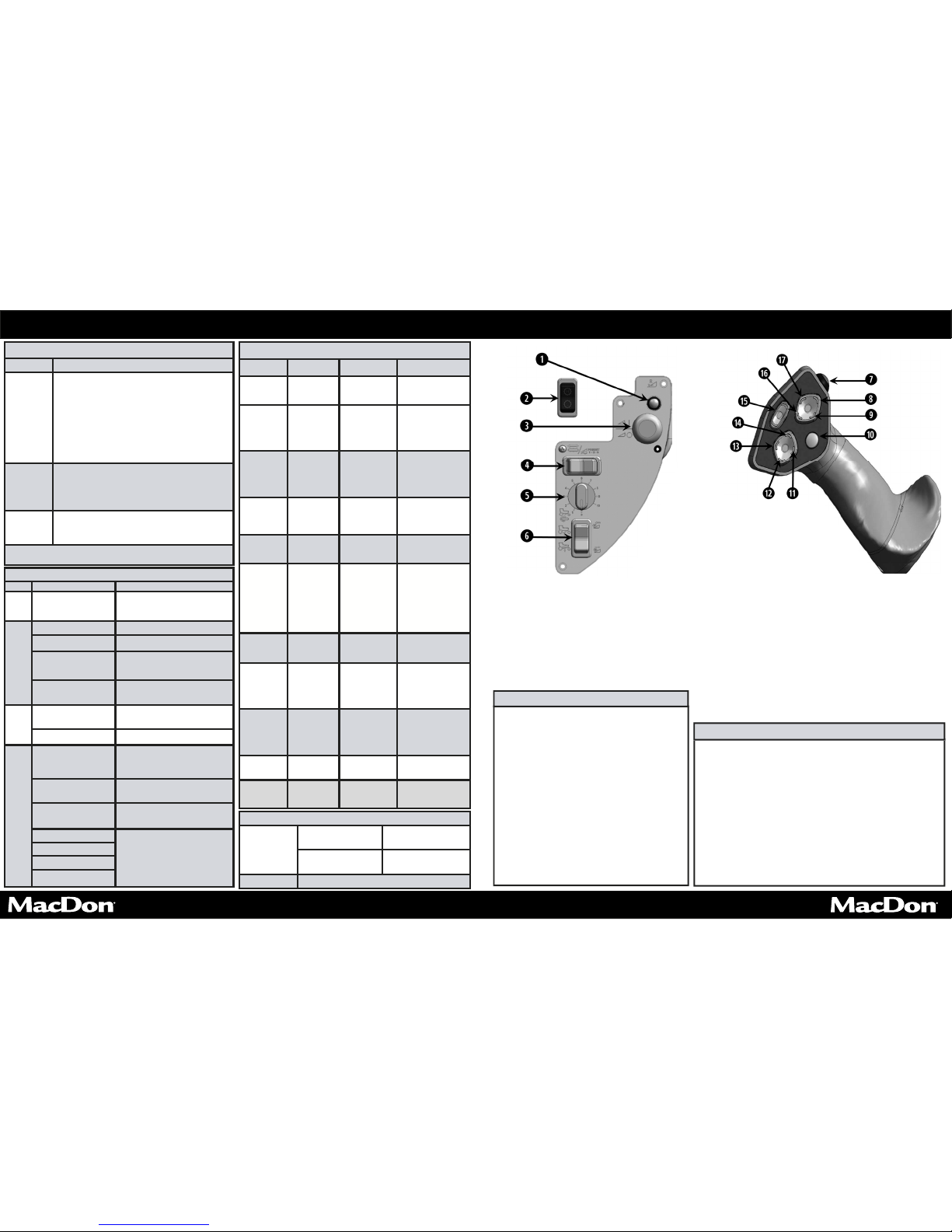

1 PROGRAM - Press to enter and exit set-up

modes and for key shortcuts.

2 ENGINE WARNING - Engine Pre-Heat,

Water In Fuel, Engine Malfunction,

Stop Engine.

3 RETURN TO CUT - When the green light is

“ON”, activates the RETURN TO

CUT function.

4 IGNITION - Accessory, Stop, Run, Start.

5 HEADER INDEX - When the green light is

“ON”, activates the reel/conveyor

speed features.

6 AUGER / DRAPER SPEED - Adjusts draper

or auger speed, depending on the header

that is attached.

7 FLOAT - Provides in-cab adjustments for

header floating system. Left and right

cylinders adjust independently.

8 HAZARD WARNING LIGHT - Flashing

amber lights operates in both cab-forward

and engine-forward positions.

9 TURN SIGNAL - Activates the turn indicators

and scrolls through the CDM set-up screens.

10 SELECT - Changes bottom line of the

display and works as the “enter” button in

Program mode.