Contents

General........................................................................3

ElectricalSystem-VNL,VNM(06.96to02.98)........3

Specifications.............................................................5

ReplacementWireSizes............................................5

Tools............................................................................7

SpecialEquipment.....................................................7

DesignandFunction..................................................9

GeneralCircuitInformation........................................9

CircuitTypes............................................................11

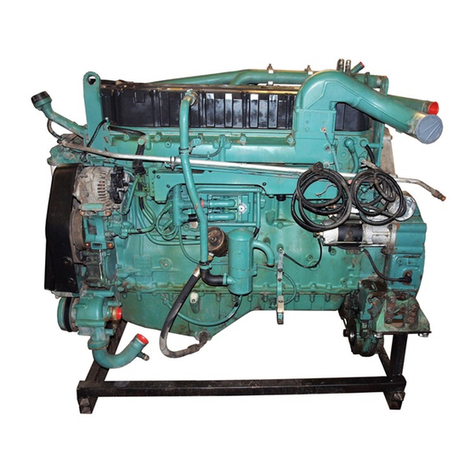

StartingandChargingSystem.................................18

ElectricalPass-ThroughforCabWiring,Powerand

Ground.....................................................................22

SwitchesandControls.............................................23

FuseandRelayLocations.......................................29

LightingSystem........................................................35

Instrumentation.........................................................41

ServiceProcedures..................................................43

GeneralWorkPracticesandCautions....................43

Soldering/WireSplicing............................................46

BatteryCableFusibleLinkReplacement(Battery

toStarter).................................................................47

BatteryCableFusibleLinkReplacement(Ground

Cable).......................................................................48

IgnitionSwitchReplacement....................................50

IgnitionSwitchandHousingReplacement..............52

HornContactsReplacement....................................54

TurnSignal/CCSwitchReplacement......................56

WindshieldWiperSwitchReplacement...................58

Headlight/ParkingLampSwitchReplacement.........60

RoadLamp(FogLamp)SwitchReplacement........62

DimmerControl(dashillumination)Rheostat

SwitchReplacement................................................64

RearSuspensionCabUnloaderControlValve

Replacement............................................................66

LiftAxleControlValveReplacement.......................66

FifthWheelSliderValveReplacement....................66

DifferentialLockoutValveReplacement..................66

AxleLockControlValveReplacement....................66

DashAirSwitchReplacement.................................66

CigarLighterReplacement......................................68

HazardLampSwitchReplacement.........................69

AuxiliaryLightSwitchReplacement.........................69

Dash(LeftSide)SwitchReplacement.....................69

MarkerInterruptSwitchReplacement.....................70

IdleControlSwitchReplacement.............................70

HeatedMirrorSwitchReplacement.........................70

TractionControl(TCS)SwitchReplacement...........70

Dash(RightSide)SwitchReplacement..................71

RadioReplacement(DashMounted)......................72

IgnitionPowerRelayReplacement..........................74

AccessoryPowerRelayReplacement.....................76

DaytimeRunningLampControlModuleReplace-

ment.........................................................................79

CombiRelayReplacement......................................80

PowerWindowSwitchReplacement(RightorLeft)82

PowerMirrorSwitchReplacement..........................83

DigitalClock(Sleeper)Replacement.......................84

SleeperReadingLampSwitchReplacement..........86

SleeperHeaterControlSwitchReplacement..........86

SleeperControlPanelSwitchReplacement............86

WindshieldWiperMotorReplacement....................87

WindshieldWiperLinkageAssemblyReplacement88

OperationNumbers

1