SECTION II

HOW TO USE YOUR WINCH

NOW USE YOUR WINCH

TrI-Matlc Control Knob and Cable

The Tri-Matic Control Knob on the side of the winch

controls the braking of the winch. Turn the knob all

the way counterclockwise .._3. This releases the

clutch and brake so the cable can be pulled out.

To Pull The Cable Out By Hand

t. Turn the Td-Matic Control Knob counterclock-

wise,LF) as far as it will go.

2. Pull the cable out by the hook to the length you

wanL

Always Leave The Last Three [3) Turns Of

Cable On The Drum. This Prevents The

Cable Fastener From Pulling Out Under

Heavy Load.

Winch A Load Under Power

1. Turn the Tri-Matic Control Knob clockwise r'_

until fingertip tight only! DO NOT overtighten or

the clutch will be damaged•

2. Press the button on the remote control to winch

in the load.

Never Winch ALoad With Your Vehicle's

Automatic Transmission in "Park." This

Could Damage Your Transmission. Put

Your Vehicle In "Neutral" With Your Emer-

gency Brake On, And Block The Wheels.

Winch Objects To Your Vehicle

1. Do not jerk any object free using vehicle power.

This will cause severe shock damage to the

winch.

2. Keep the vehicle standing still with the engine

running and the transmission in Fig. 8. Use your

emergency brake and block the wheels.

"_..J=cl

FIG. 8

Keep Vehicle Engine Running Full Power

Your winch will run" at its best if it gets full power

from your battery and alternator. To be sure of this

keep the vehicle engine running.

When To Use Your Emergency Hand Crank

The Emergency Hand Crank should ONLY be used

when there is NO electric power--for example: a

dead batlery. It should NEVER be used to help out a

|

running motor. This could damage the winch and/or

hurt the user.

"HandCrank is optionalon Model 316.

How To Use Your Emergency Hand Crank

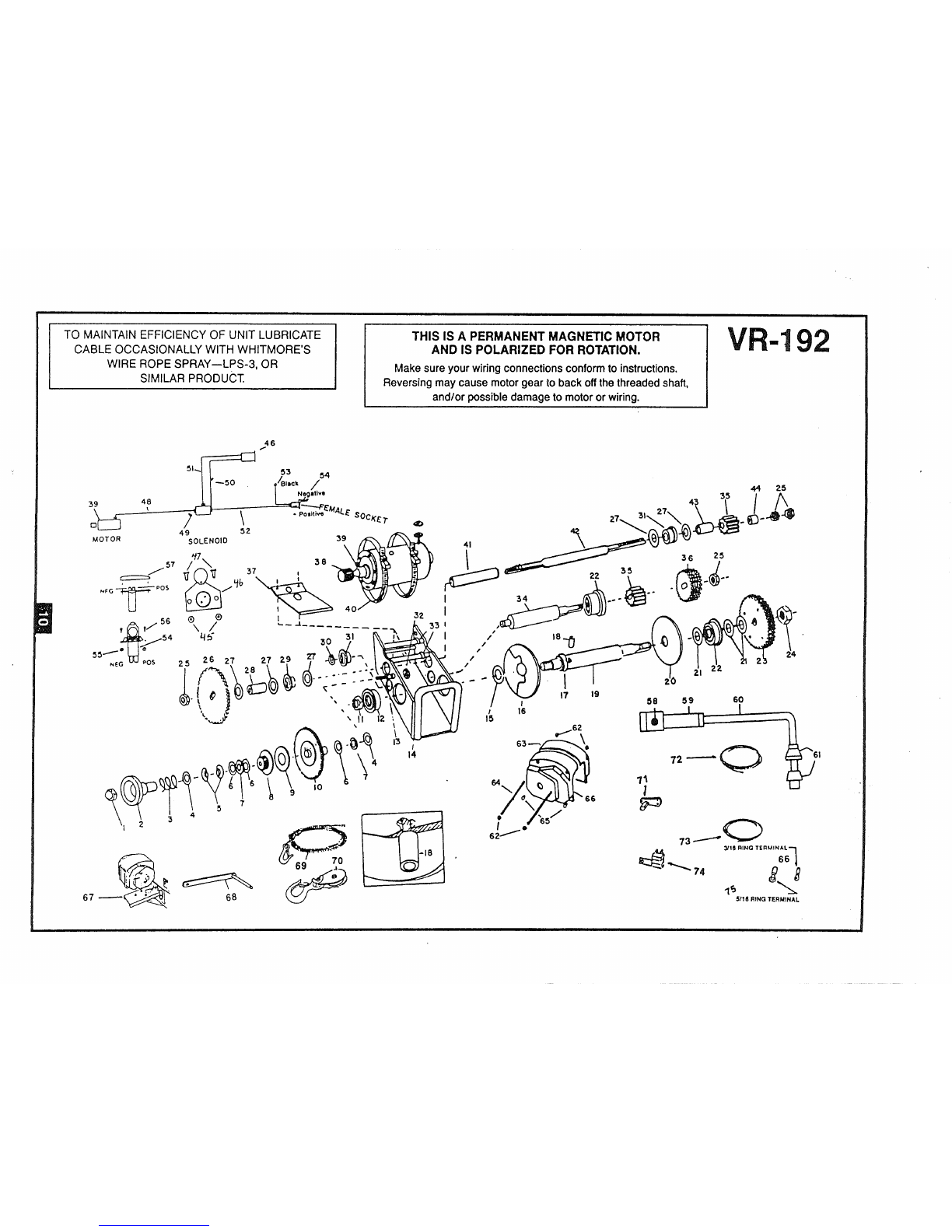

(See Fig. 10)

1. Tighten the Td-Matic Control Knob all the way

clockwise("_or there isno braking action.

2. Remove the outernut.

3. Put the Emergency Hand Crank on the shaft.

4. Replace the outernut.

When you have finished using the Emergency Hand

Crank:

1. Remove the outernut.

2. Remove theEmergency Hand Crank.

3. Replace the outernutfor locking.

VR-192 Shown. On Model 316 attach hand crank

on tri-knob shaft.

RG. 10

A Caution: Be Careful Wlth The Cable Hook

DO NOT let the cable hock go into the drum area of

the winch. (The drum area is where the cable

winds.) The hook will bend the levelwind plate or the

levelwind spring if it goes too far into the winch.

Your motor will Idle for •second or two after

the winch Is released and about 1foot of cable

will unwind. Be sure to allow for thisl

Remove The Plug When Winch Is Not fn Use

Inspect the cable often and spray with a light oil or

LPS-3. We recommend spraying the cable once a

week if in regular use.

Gears - Every 6 Months

To grease the gears:

1. Remove the Td-Mafic Control Knob

(Part =79402}.

2. The right and left Side Covers.

3. Use any marine type grease.

SECTION. III

MAINTENANCE/SERVICE

A. CABLE--Lu_icate the cable occasionallywith

Whitmore's Wire Rope Spray, WD40 or a similar

product.Spray the drumand the cable as it is

being wound.

B. IMPROPERLY WOUND CABLE--If for some

reason yourcable is notpropedy wound

(either wound loosely or wound on one side)

unwind the cable and rewind under power,

keeping tensionon it.This should wind the

cable tightlyand evenly. Otherwise the wrap

of the cable may squeeze down to a lower

layer--causing stlckin_ loss of power, and risk

damage to the levelwlnd spdngs.

C. REPLACING THE CABLE--Cut end remove

the old cable from the drum.Insert the new

cable Intothe drum shafthole at theend

opposite thecounterborod end. Draw the cable

through the hole and outthe counterbored side

of the shaft. Push the cable through the fastener'

until It ISflush withthe shoulder end, and soit-

[,.'t:1;t,vj[_JI_[._ll I;i PiiYj!';_/ [oil ;[o1li J

MODEL VR-lg2 ONLY

A. The Tri-matic Roll-n-Gage Control isthe heart

of your Powerwtnch uniL it controls loading,

unloading and braking.

B. Since this isa highlyengineered assembly, care

should be taken on its maintenarice.

C. To lubricate, remove nut(79720} and unscrew

Tri-matic Control Knob =79402. Remove case

on control side, putcontrol knob back on so

thatparts of the Roll-n-Gage Control will notslip

off.

Using a good grade grease° lubricate the stud,

=71101, thrust beadngs =71609, roller clutch bear-

Ing Inside =71716 compound ddve gear and needle

beadng Inside =71755 compound pinion clutch gear

assembly and needle thrust beadng =71609.

i

solderthe end of the cable to the fastener.

Insert thecable fastener intothecounterbored

hole In thedrum shaft, tapping lightlyuntil the

topof thefastener is flushwiththe drumshaf'L

Bend the cable sharply around the firstgrooveof

the drumshaft.Rewind the cable ontothe drum

under power, keeping tensionon the cable.

WARNING: When replacing thecable, use anexact

replacement cable. The winch rating and cable

strength are carefully matched. Your warrantyis

void if any other cable is used.

D. CARE OF THE LEVELWIND SPRINGS ON

DRUM--Your motorwill continue torun for a

secondor twoafter the spdng loaded switch

Isreleased, especially withouta load. Be sure

to allow for this. Don'tlet thehook go intothe

winch and bend the levelwind springs. When

winding cable onto the drum wIthno load, keep

the cable tautgoing intothe drum.

NOTE: Extreme care should be taken to avoid

getting any grease on clutch lining,1t73602, as this

may cause slippage.

CAUTION: Do not tryto remove bearings from

insidecompound drive gear or compound pinion

gear.

\.,//,_ _# :;)s