7

Operating Instructions

2. Using a good grade of light oil,

lubricate the stud, the needle thrust

bearings (2), roller clutch bearing (1)

and needle bearing (1).

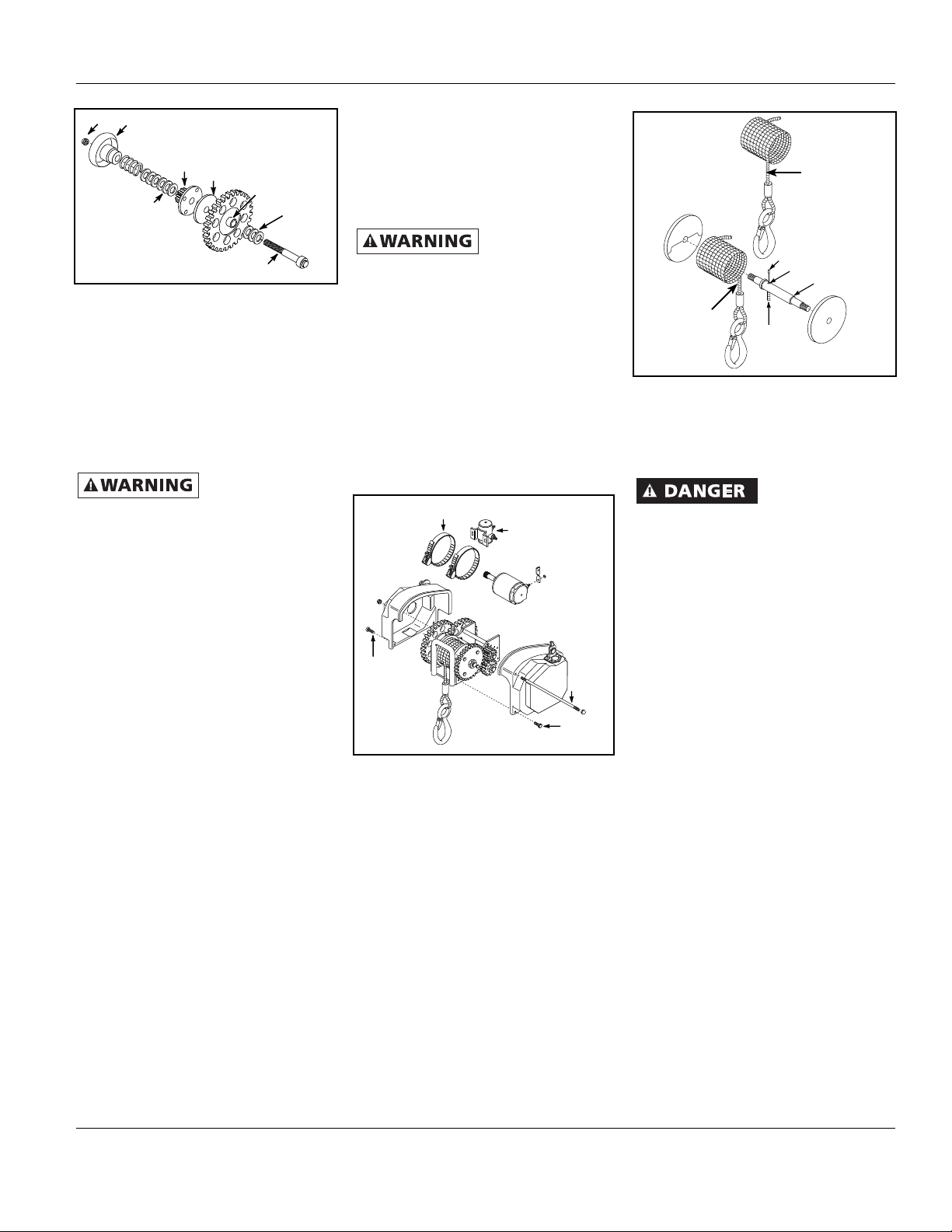

MOTOR REPLACEMENT

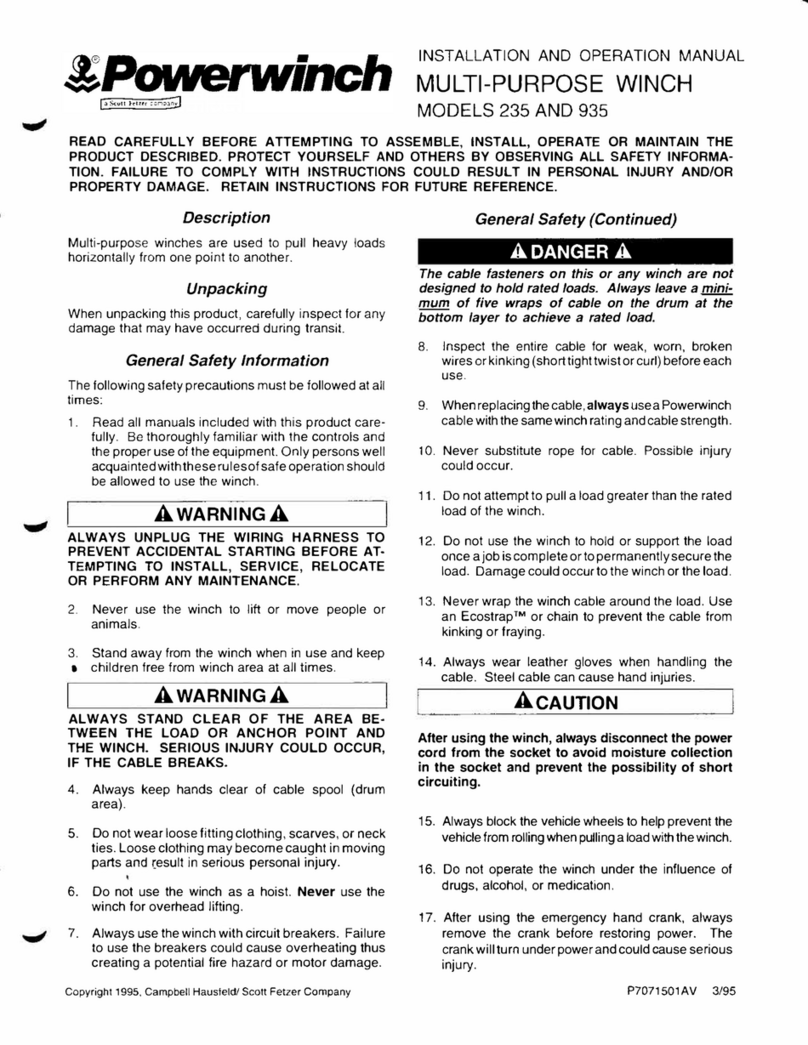

To replace the motor, refer to Figure 12

and follow the outlined procedures.

Always unplug the

wiring harness

to prevent accidental starting before

attempting to install, service, relocate or

perform any maintenance.

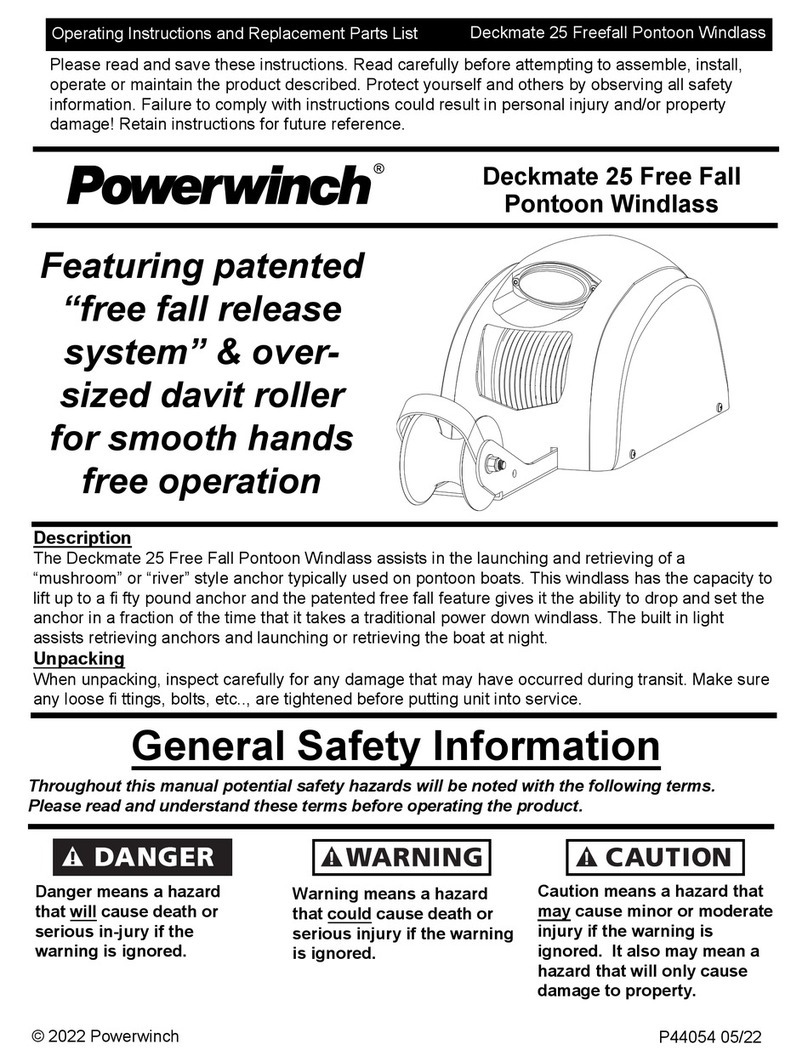

1. Unplug the wiring harness, remove

the two cover rods and the four cover

screws.

2. Gently hand turn the gears of the old

motor back and forth to notice the

backlash (.005). The gears of the new

motor should have the same degree

of play.

3. Loosen the screws on the motor

bands and remove the bands.

4. Disconnect the motor leads, pay

attention to the connections and

remove the motor.

5. Put the new motor in place, taking

care to see that the gears mesh

properly.

6. Fasten the motor band and

connect the new motor leads to the

appropriate lead connections.

7. Check the motor for correct backlash.

The gears should not be too tight

or too loose. Adjust the backlash

by increasing or decreasing the

thickness of the shims between the

motor and motor support rods.

8. Install the cover, two cover rods and

the four cover screws and connect the

wiring harness.

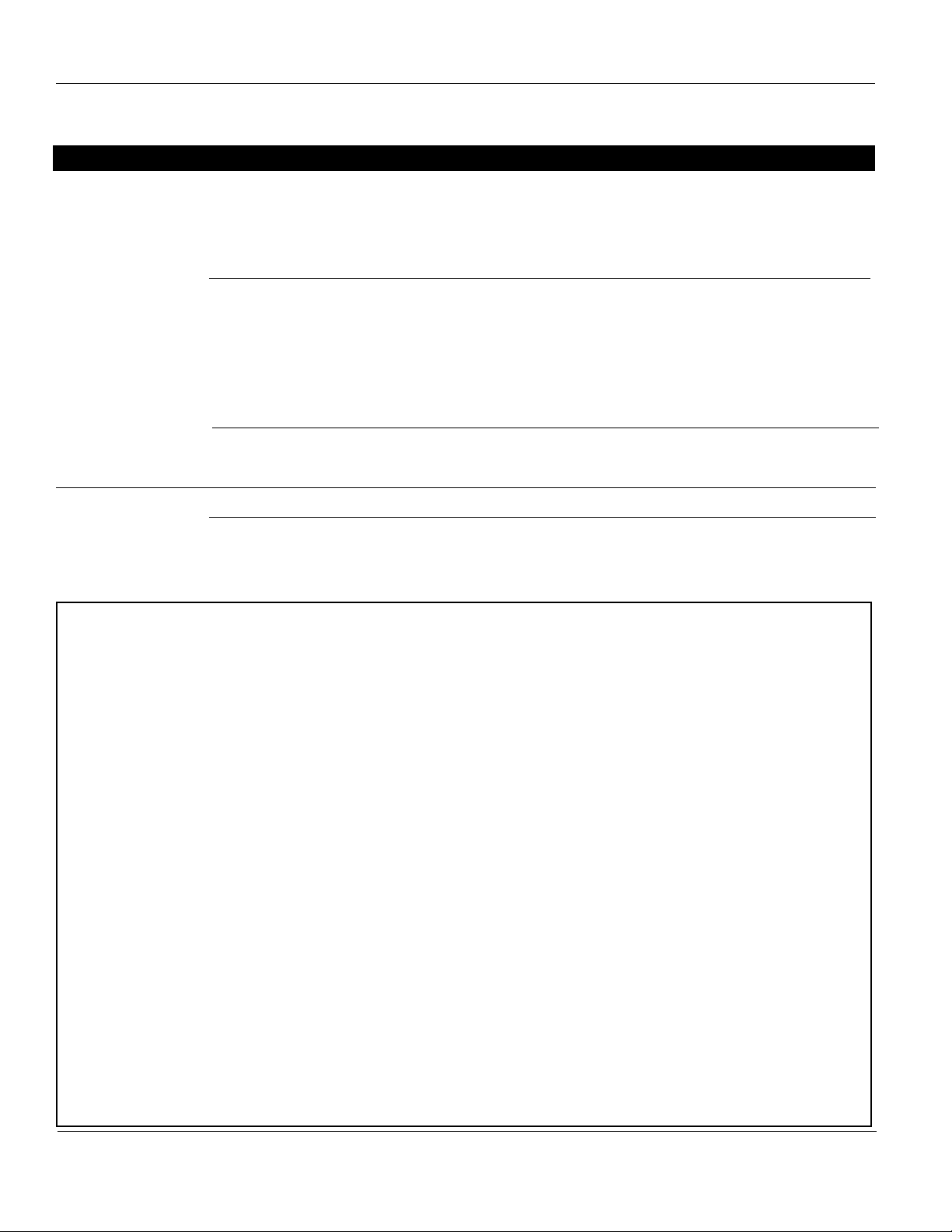

CABLE REPLACEMENT

To replace the cable, follow the outlined

procedures. Use an exact replacement

cable Powerwinch. The winch rating and

cable strength are carefully matched.

Never replace the cable with rope.

Always unplug the

wiring harness

to prevent accidental starting before

attempting to install, service, relocate or

perform any maintenance.

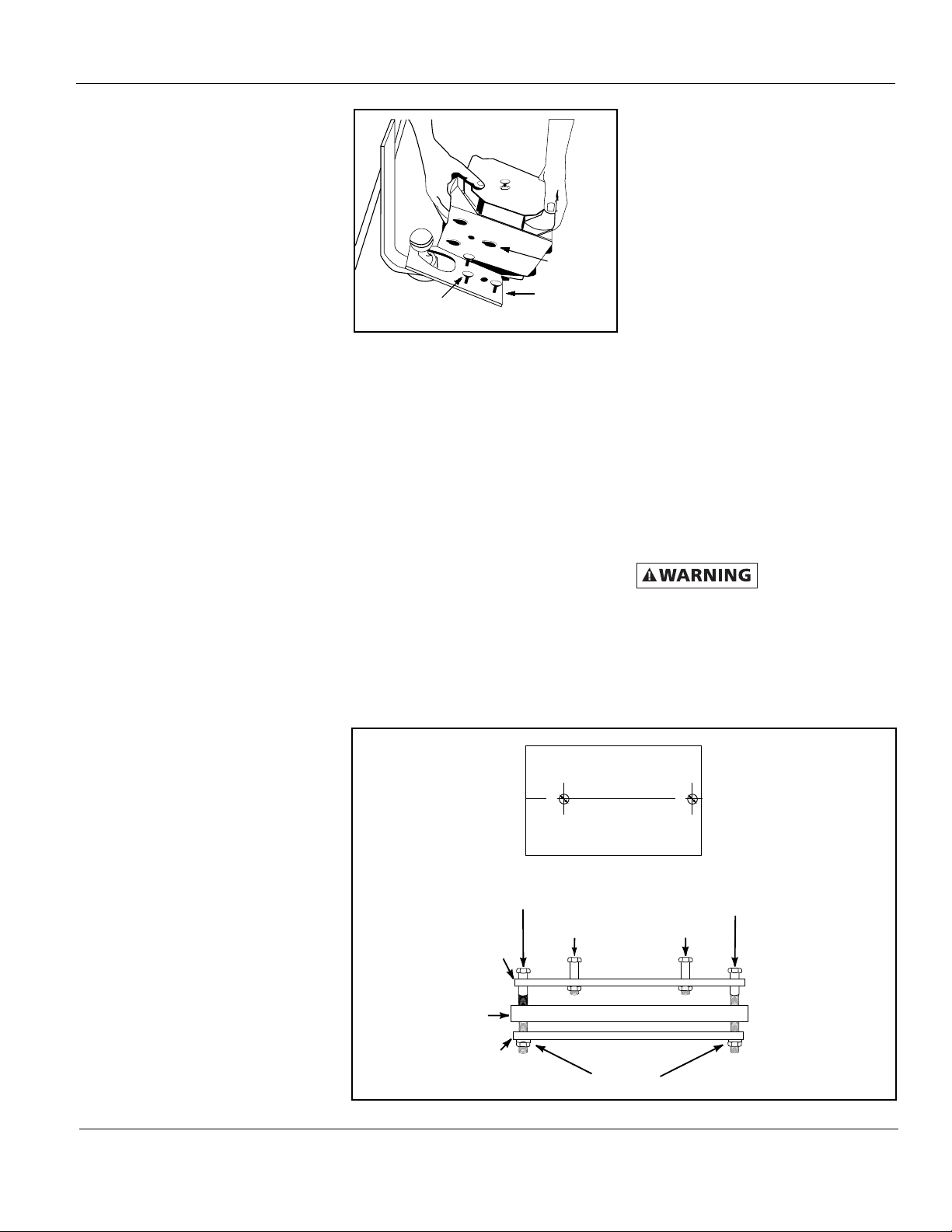

1. Power-out the cable using the remote

control device and unplug the wiring

harness.

2. Remove the two cover rods and the

four cover screws (See Figure 12).

Figure 12 - Motor Replacement

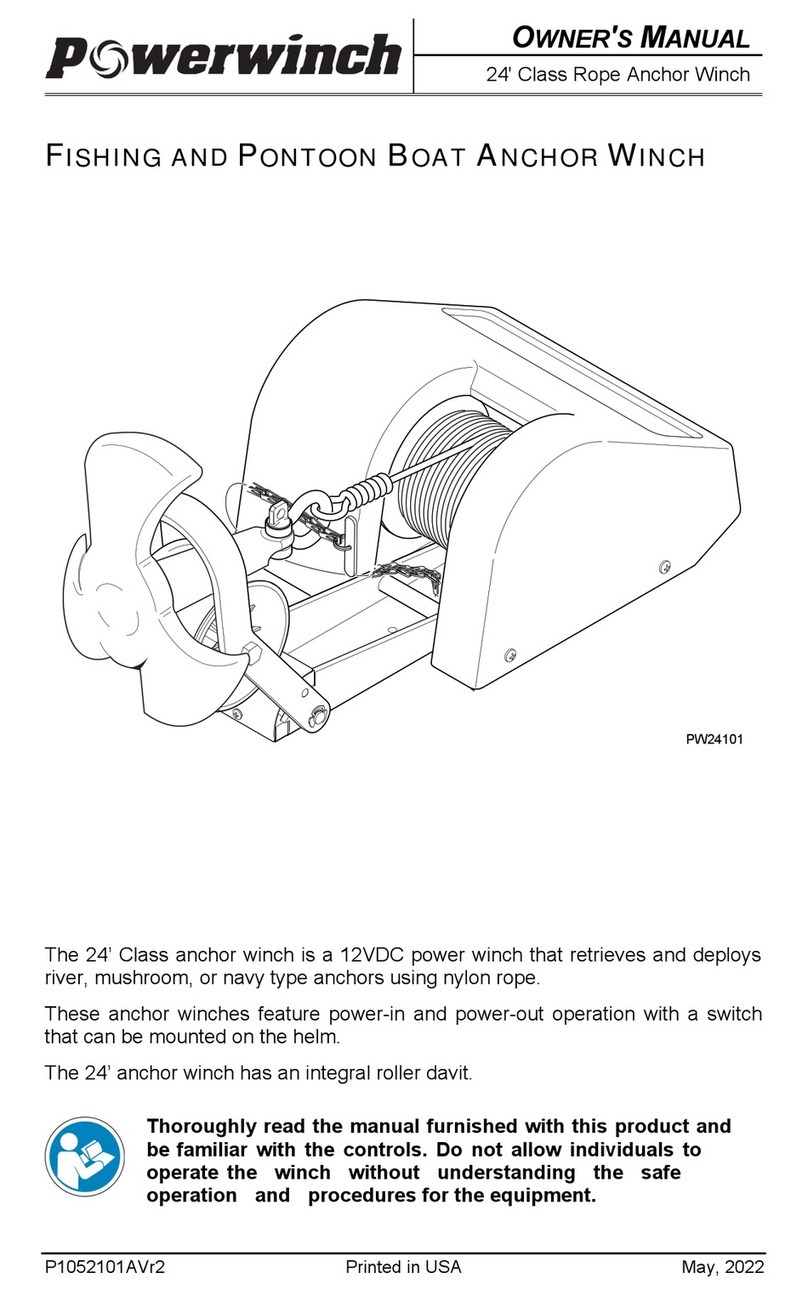

3. Cut the old cable approximately 2”

from the drum and push the remaining

cable and fastener through the drum

to remove (See Figure 13).

4. Insert the new cable into the drum

shaft hole at the end opposite

the counterbored end. Draw the

cable through the hole and out the

counterbored side of the shaft.

5. Push the cable through the fastener

until the cable is flush with the end of

the fastener.

6. Crimp the fastener onto the cable and

pull the cable through the drum shaft

until the fastener seats inside the

counterbore.

Figure 13 - Cable Replacement

7. Install the cover, two cover rods and

the four cover screws and connect the

wiring harness.

8. Power-in the cable with a light load to

help wind the cable straight into the

drum.

The cable fasteners

on this or any winch

are not designed to hold rated loads.

Always leave a minimum of five wraps of

cable on the drum at the bottom layer to

achieve a rated load.

LEVELWIND PLATE

When powering-in the cable, the motor

will continue to run for a few seconds after

releasing the button on the remote control

device, especially without a load. Be sure

to allow for this. Do not let the cable hook

go into the winch and bend the level wind

plate. When winding the cable onto the

drum with no load, keep the cable taut

(tight) going into the drum.

STORAGE

The winch cable must be lubricated

before storing. Lubricate the cable with

Whitmore’s Wire Rope Spray, WD40 or a

similar product. Spray the drum and the

cable as the cable is being wound.

Technical Service

For information regarding the operation,

repair or replacement parts for this

product, please call 1-800-243-3097 for

assistance. Please provide the following

information:

• Model number

• Serial number

• Part number and description

NEEDLE

THRUST

BEARING

CLUTCH

LINING

NEEDLE

BEARING

INSIDE

NEEDLE

THRUST

BEARING

STUD

ROLLER

CLUTCH

BEARING

NUT TRI-MATIC

CONTROL

KNOB

Figure 11 - Tri-Matic Lubrication

MOTOR

BAND

SOLENOID

COVER

ROD

COVER

SCREW

COVER

SCREW

CABLE

FASTENER

COUNTERBORE

CABLE DRUM

INSERT

NEW

CABLE

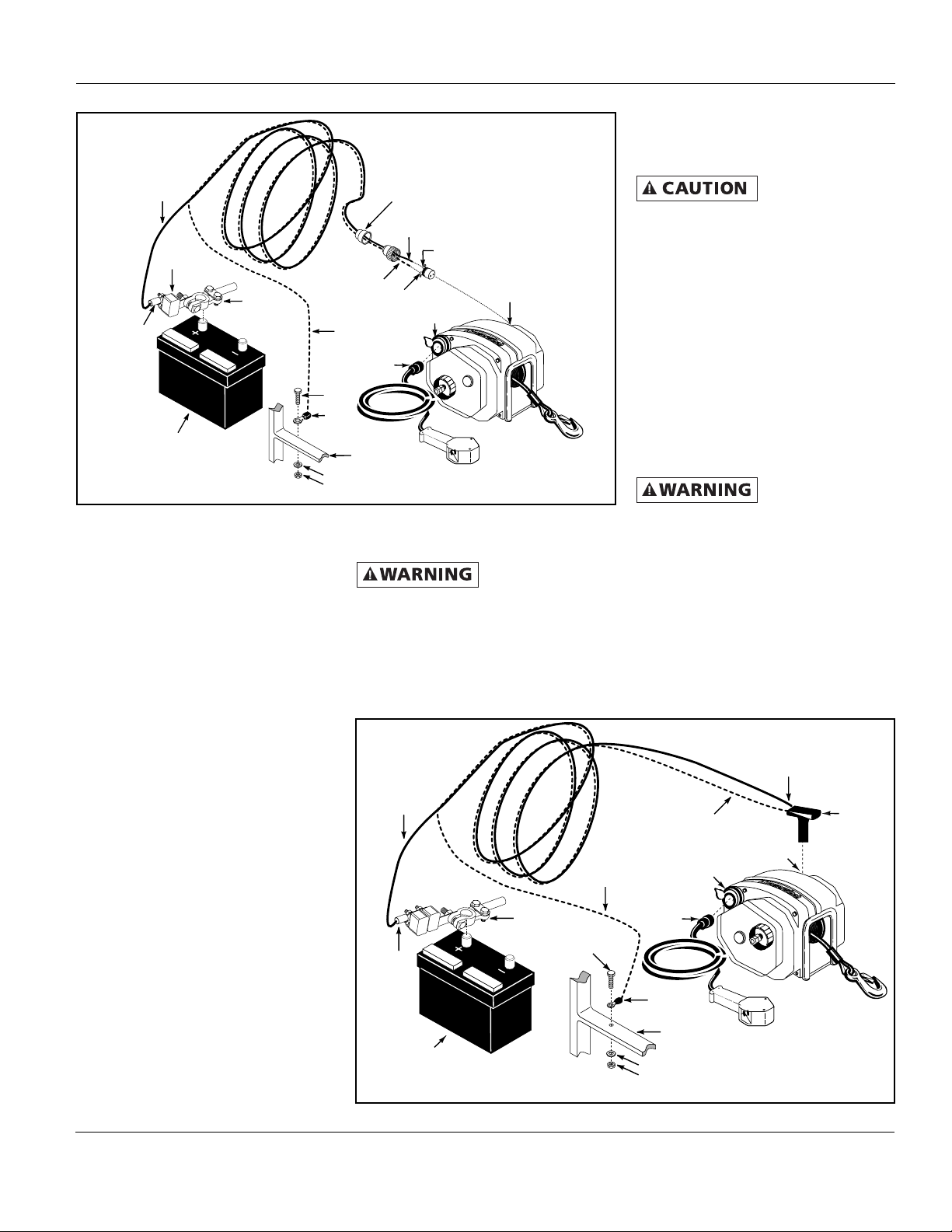

Models

AP1500

QC1500

QC2500

QC4500

Cable Winds

Over The TOP

Of The Drum

Models

AP3500

QC3500

Cable

Winds

UNDER

The Drum