FB8X Service Manual Rev. C, 9/28/10 Page 1

SUMMARY

1

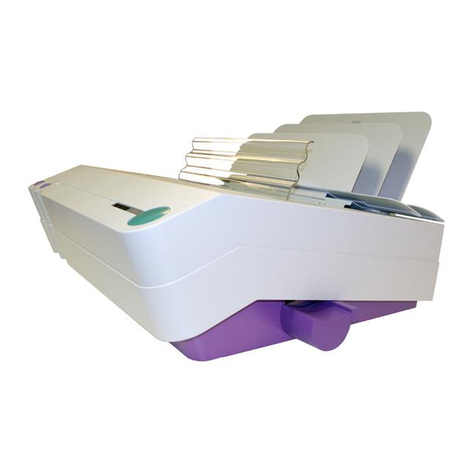

The newly redesigned Fastback Model 8x makes service and repair

easier than ever. While in outward appearance it looks very similar

to its predecessor, the Model 8 binder, you will find that beneath the

covers the binder has been dramatically simplified and improved. This

manual will guide you through the various routines needed to service

this machine. It will provide you with diagrams of the User Menu,

Service Menu, and Electrical Connectivity, as well as a complete list

of Service Parts and pictures of the machine partially exploded. This

manual will introduce you to the Service Menu and various functions

to test Heaters, Sensors, and Mechanisms. It will guide you through

the process of upgrading the Firmware using your computer. The

manual will provide you with a troubleshooting chart to quickly and

accurately diagnose and solve common problems, and it will tell you

how to perform routine service procedures, and how to disassemble

and reassemble the machine correctly and efficiently. In all, this

manual will tell you everything you need to know to keep the machine

binding and the customer happy.

The process by which the Model 8x binds documents has not

changed. The Model 8x has three heaters located in the binding

recess that heat the adhesive coating on the Lx-Strip or the spine on

the Halfback Cover, and adhere it to the spine, front, and back of the

document. These three heaters are called the Bender Heater, the

Spine Heater, and the Back Heater. They have been upgraded from

the previous versions with additional temperature sensing elements

that will allow the heaters to better regulate temperature.

The Model 8x binder has two sensors, the Book Sensor and the

Strip Sensor, designed to detect the presence of the document and

the strip when they are inserted in the binding recess. While the

Book Sensor determines only the presence of the book, the Strip

Sensor will sense the presence of a strip and determine whether you

are using the correct width strip for the document you are binding.

The binder is also equipped with encoders and switches that

determine the thickness of the document you are binding and the

pressure the Carriage Assembly must clamp the document to achieve

the best possible bind without overexerting the motors or any of the

other mechanical parts.

After giving the new Model 8x a few test binds you will find that the

improvements made to the binder will provide the customer and the

service technician with a machine that is both easy to use and easy to

service.