- 2 -

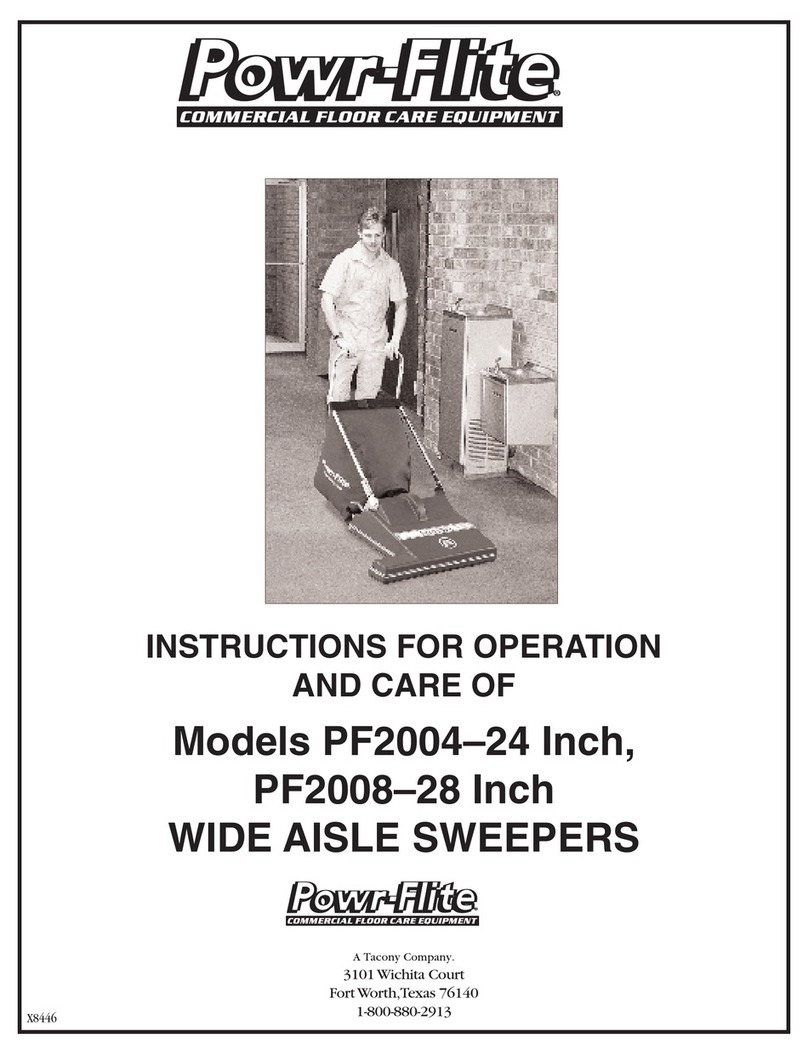

Unpacking and Assembly

1. Your sweeper is shipped on a pallet. To remove the sweeper, cut the front

side of the box open and fold it under to form a ramp. Roll the sweeper over

the ramp so that the running wheels are still standing on

the pallet.

2. While the machine is in this position, install the side brushes. The side

brushes are located in the dirt container under the side brush plate in the

front exterior portion of the machine. Simply apply light pressure, twisting

the brushes upwards until you feel them lock into place.

NOTE: Do not tip over the machine in this process. There is a danger of

battery acid running out, creating a hazardous condition.

3. Roll the machine from the box and off of the pallet.

4. Put the handle in the upright position by pulling it downwards into the two

tappets completely. Tighten with the two thumbscrews.

5. Install and connect the battery cables. Set the

safety switch on the handle to the "0" position.

6. The tool to unlatch the main cover is found inside the dirt collector bin.

Remove the dirt collector and using the tool, unlatch the main cover.

Connect the positive pole of the battery and tighten with a wrench.

Connect the negative pole of the battery and tighten with a wrench.

The machine is now assembled and ready for operation.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

Read all instructions before using this machine.

IMPORTANT SAFETY INSTRUCTIONS

This manual is to ensure that the PS900 is operated correctly. All oper-

ators must read, understand practice the following safety instructions.

Before use, check that the unit and operating equipment are in perfect

condition and are safe to operate. Do not use the machine if it is not in

perfect condition. This vacuum sweeper is intended exclusively for

operation on solid, level and dry surfaces with an inclination not

exceeding 2%.

CAUTION: Use only as described in this manual.

CAUTION: This sweeper must not be used for removing

hazardous materials.

CAUTION: Use only on surfaces indicated in the

operating instructions.

CAUTION: Never leave sweeper unattended while running.

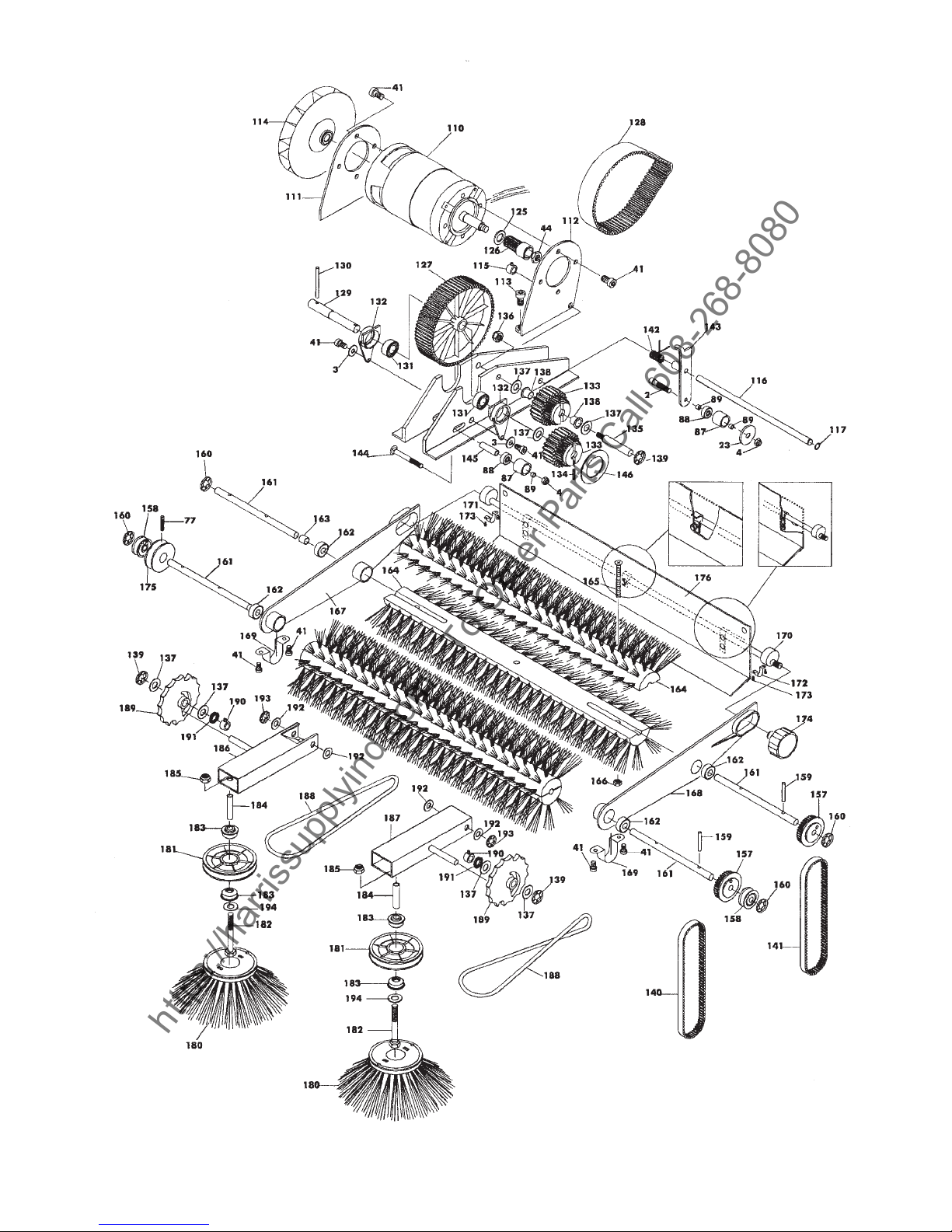

CAUTION: Replace damaged or worn parts with genuine original

equipment parts in order to maintain safety and to

protect your warranty.

CAUTION: Never sweep over surfaces that are wet.

CAUTION: Do not store outdoors.

CAUTION: Keep hair, loose clothing, fingers, and all parts of body

away from openings and moving parts.

CAUTION: Do not reach into or under the machine under any

circumstances when the motor is running.

CAUTION: The hood latch should remain secured in the closed

position except when performing maintenance work.

CAUTION: Switch off the motor and secure the unit before

transporting.

CAUTION: Use only accessories and spare parts that have been

approved by the manufacturer.

CAUTION: Do not spray clean the unit.

CAUTION: Repairs may only be carried out by authorized customer

service centers.

Battery Operated Units

CAUTION: Remove the battery lug or disconnect the battery before

working on the electrical system of battery-operated

units.

CAUTION: Always keep the batteries clean and dry in order to avoid

leakage current. Protect batteries from contaminants.

CAUTION: Do not place any tools, etc., on the battery to avoid risk

of short-circuiting and explosion.

CAUTION: Do not smoke, generate sparks or use open flame near

a battery or in a charging area.

CAUTION: Use caution when handling battery acid. Comply with

corresponding safety regulations.

CAUTION: Avoid picking up strings, cords, wires or

similar materials.

https://harrissupplyind.com-ToOrderPartsCall608-268-8080