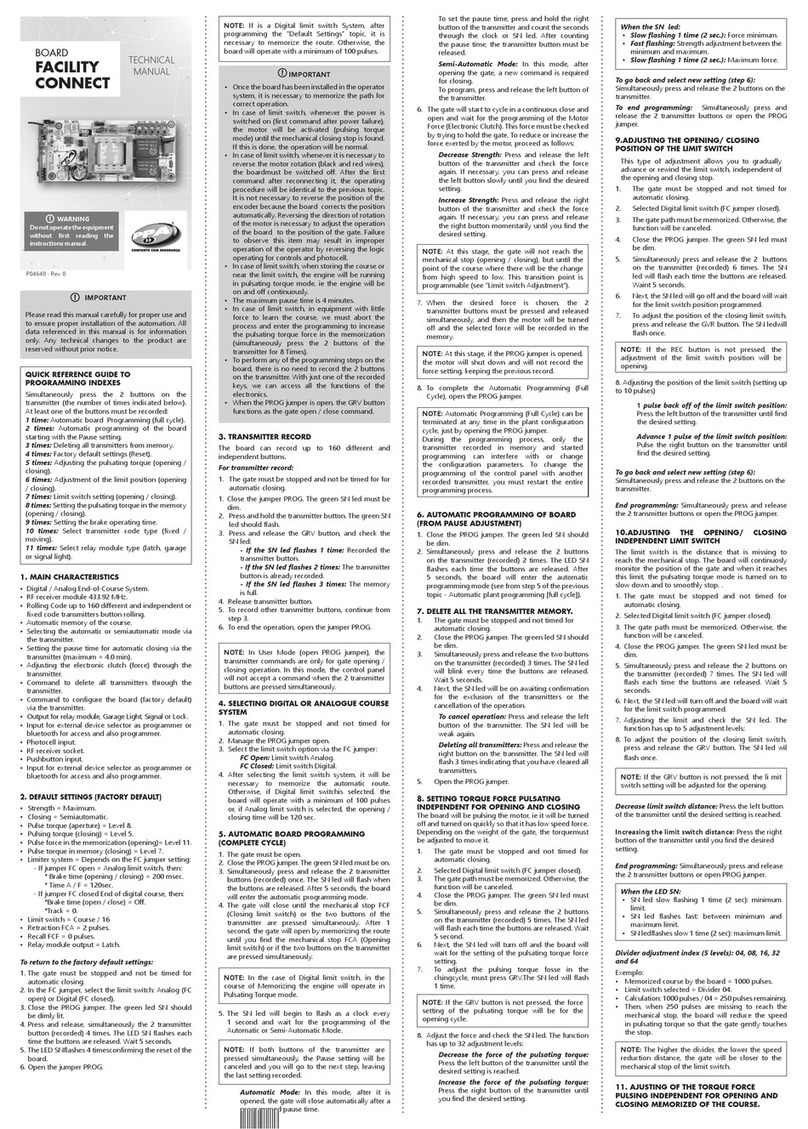

TECHNICAL CHARACTERISTICS

• 433.92MHz Receiver Module;

• 164 xed code controls;

• 82 PPA standard rolling code controls;

• Output for garage lock and light modules;

• Analog limit switch;

• Photocell input;

• Electronic clutch adjustment;

• Entry to pushbutton;

• Automatic A/F route memorization;

• Brake adjustment;

• Adjustment of the ramp;

• Ramp torque adjustment;

• Delay time for opening with a signal;

• Allows conguration via PROG;

• Enables activation of the board via Wi-Fi Connect;

• Pre-setup conguration via jumpers according to gate

type, weight and speed;

• Source: 12v, 450mA

DELETE THE RECORDED COURSE

With the gate stopped, press the GRV button for

approximately three seconds until LED1 is lit, conrming

the action. When you release it, the route will be delete.

FACTORY STANDARD

Restore settings to factory default, with ramp disabled.

With the gate stopped, press the GRV button for

approximately ve seconds until LED1 ashes quickly,

conrming the action.

MODEL SELECTION

Set a pattern according to the model of the gate and

operator.

With the gate stopped, close the PROG jumper, make

the model selection according to the gate type jumpers

(sliding or overhead), gate weight (light or heavy) and

operator speed (fast or slow).

To conrm, press the GRV(+) and CMD(-) button until

led1 ashes quickly.

RECORD TRANSMITTERS

PPA standard transmitters.

1. With the gate stopped, close jumper TX, LED1 starts

ashing 2x until any button is pressed.

2. Press transmitter button, LED2 will start ashing

whenever it receives a valid code;

3. Press and release GRV button;

4. Release TX button;

5. Transmitter successfully saved LED1 ash 1x;

6. Button already registered ashes LED1 2x;

7. Memory full LED1 ashes 3x;

8. To record new transmitter button go back to step of

pressing transmitter button;

9. Remove jumper to nish;

DELETE TRANSMITTERS

Clears memory to record new transmitters.

1. With the gate stopped, close jumper TX, LED1 starts

ashing 2x until any button is pressed.

2. Press CMD button for three seconds until LED2 ashes

quickly, conrming the action.

3. Remove jumper to nish

AUTOMATIC / SEMI – AUTOMATIC TIME

After the end of the opening cycle, the gate waits for the

pause time set by the user to close the gate automatically.

To disable and set the time to zero, the board will wait for

a new command to close.

1. With the gate stopped, close the JPROG jumper where

LED1 starts to ash 2x until any button is pressed.

2. Press CMD button 1x, LED1 will stop ashing and stay

lit.

3. Press the GRV button to enter the function, where LED

will start to signal the setting level.

4. Press GRV button to increase auto timeout and CMD to

decrease time.

5. Resetting the automatic time leaves the board in mode

semi-automatic, LED1 ashes quickly.

6. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

7. Remove jumper.

Levels:

• N1 ashing = Semi-automatic.

• N1 lit = 5 sec.

• N2 lit = 10 sec.

• N3 lit = 30 sec.

• N4 lit = 60 sec.

• N5 lit = 90 sec.

• N6 lit = 120 sec.

• N7 lit = 180 sec.

• N8 lit = 240 sec.

ADJUSTMENT OF THE OPENING AND CLOSING

RAMP

The ramp is the distance to reach the mechanical stop.

The board will be continuously monitoring the gate

position and when it reaches this limit the operating

torque reduces, reaching the mechanical stop smoothly.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. For close ramp: press CMD button 2x LED1 will stop

ashing and LED2 should remain lit. Press the GRV

button to enter the function, where LED will start to

signal the setting level.

3. For opening ramp: pressing the CMD button 4x LED1

will stop ashing and LED4 should remain lit. Press the

GRV button to enter the function, where LED will start

to signal the setting level.

4. Press GRV to move the limit to the mechanical stop,

increasing the distance;

5. Press CMD to decrease the distance to the limit switch;

6. At the minimum value the ramp is disabled, it does not

reduce the torque, with the possibility of adjusting 8

levels;

Levels:

• N1 ashing = ramp disabled;

• N1 lit = 5% of route

• N2 lit = 10% of route.

• N3 lit = 15% of route.

• N4 lit = 20% of route.

• N5 lit = 25% of route.

• N6 lit = 30% of route.

• N7 lit = 35% of route.

• N8 lit = 40% of route.

TORQUE ON RAMP

The board will decrease the operating torque as soon as

it reaches the programmed ramp. Torque is set separately

for opening and closing.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. For closing torque: press CMD button 3x LED1 will stop

ashing and LED3 should remain lit. Press the GRV

button to enter the function, where LED will start to

signal the setting level.

3. For opening torque: press CMD button 5x LED1 will

stop ashing and LED5 should remain lit. Press the GRV

button to enter the function, where LED will start to

signal the setting level.

4. Press GRV to increase the ramp torque;

5. Press CMD to decrease the ramp torque;

6. At the minimum value the ramp is disabled, it does not

reduce the torque, with the possibility of adjusting 8

levels;

7. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

8. Remove Jumper.

Levels:

• N1 ashing = disabled;

• N1 lit = Minimum;

...

• N8 lit = Maximum;

BRAKE

When there is a command to turn o the engine, the

brake will be activated with the possibility of sensitivity

adjustment.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. Pressing the CMD button 6x LED1 will stop ashing and

LED 6 should remain lit.

3. Press the GRV button to enter the function, where LED

will start to signal the setting level.

4. Press GRV to increase the time the brake will be applied;

5. Press CMD to decrease the brake;

6. At the minimum value the brake is disabled;

7. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

8. Remove Jumper.

Levels:

• N1 ashing = disabled;

• N1 lit = Minimum;

...

• N8 lit = Maximum;

POWER (ELECTRONIC CLUTCH)

Adjust the engine operating force. For the use of this

safety sensor device to be eective, proceed as follows:

• After proper installation of the gate operator, adjust

the electronic clutch so that the force is the minimum

necessary to move the gate leaf along its entire path, in

opening and closing;

• At the end of the adjustment, test the function by

blocking the movement of the gate by placing a rigid

object in the limit switch of the gate.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. Pressing the CMD button 7x LED1 will stop ashing and

the LED7 should remain lit.

3. Press GRV button to enter setup, LED will start to signal

setup level.

4. Press GRV button to increase strength and CMD to

decrease;

5. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

6. Remove jumper.

GARAGE LIGHT TIME

Setting the time to turn o the garage light relay

module when the gate reaches the closing limit switch.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. Pressing the CMD button 8x LED1 will stop ashing and

LED 8 should remain lit.

3. Press GRV button to enter setup, LED will start to signal

setup level.

4. Press GRV button to increase the standby time to turn

o the light and CMD to decrease it;

5. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

6. Remove jumper.

Levels:

•N1 ashing = trac light, turns o as soon as it closes.

• N1 lit = 30 sec.

• N2 lit = 60 sec.

• N3 lit = 90 sec.

• N4 lit = 120 sec.

• N5 lit = 150 sec.

• N6 lit = 180 sec.

• N7 lit = 210 sec.

• N8 lit = 240 sec.

EXTRA SETTINGS MADE ONLY USING THE

PROG

Using the PROG programmer module it is also possible

to congure:

• Rollback: enabled or disabled;

• TX Type: the board accepts TX reception in xed mode

and in rolling mode, changing these parameters delete

all previously registered TX’s.

• Delay in opening: Time between reception of

the opening command and the board sending

the command to the gate, activating a trac light

connected to the garage light for signaling. It can be

congured as disabled or with time congured every

3s, ten of the maximum value of 24s.

SETTINGS BY THE PROGRAMMER “PROG”

PROG: Allows you to make the settings with more

precision.

While the PROG is in the board, the commands through

the pushbutton, the CMD button and the separate

receiver will be disabled for engine activation commands

in the limit switch.

Only PROG can send commands for opening and

closing the gate, with the button (+) and the registered

transmitter, if it is on the main sensor status screen.

Keeping any key pressed in the PROG, after 3 seconds, it

will enter the auto-repeat mode of the key pressed, which

will speed up the progress of the screens or adjustments.

HOME SCREEN

Monitoring of sensors and board

peripherals: (Gate status, FCF, FCA,

Photocell and Transmitter).

TYPE FACTORY

DEFAULT SETUP

Restores settings to factory

default.

RECORD

TRANSMITTERS

Records new transmitters

(controls) in the electronics board.

DELETE

TRANSMITTERS

Deletes (erases) all transmitters

(control) recorded on the

electronics board.

BREAK TIME

Time for automatic closing

• Semi-automatic (disabled)

• 1 (5 sec.)

• 2 (10 sec.)

• 8 (240 sec.)

CLOSING RAMP

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

CLOSING TORQUE

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

OPENING RAMP

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

OPENING TORQUE

9 Niveis

• 0 (Desabilitado)

• 1(Minimo)

• 8(Maximo)

BRAKE

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

STRENGTH

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

GARAGE LIGHT

TIME

Garage light time

• 0 (Disabled)

• 1 (30 sec.)

• 2 (60 sec.)

• 8 (240 sec.)

REVERSAL

Pushbutton or transmitter command

permission to work during the

closing limit switch of the gate to

reversal.

CODE TYPE

Select the type of transmitter

protocol (TX):

• Rolling Code (PPA);

• Fixed Code

OPENING DELAY

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

CLOSING LOCK

Collect the lock pin when the gate

is closing and release the lock

when closing is complete

ROUTE Delete recorded route

LANGUAGE Select the PROGRAM language

ST: FCF: FCA:

FOT: RF:

ST – STATUS: Signals the opening or closing state.

FCF: Identies the position between reed and drive nut

magnet

FCA: Identies the position between reed and drive nut

magnet

FOT: Identies the photocell pulse

RF: Identies radio frequency signal

FACTORY PATTERN

FACTORY PATTERN: In this screen press (-) until you

reach factory pattern done, press the keys (-) and (+) for 5

seconds until it appears written done on the screen.

Also on this screen dene the type and weight of the gate

using the (+) and (-) keys to navigate through the options:

• Light and slow BV

• Light and fast BV

• Heavy and slow BV

• Heavy and fast BV

• Light and slow DZ

• Heavy and slow DZ

RECORD TRANSMITTERS – [000]

In this function the display shows no signal, when sending

a signal the display will show (+) transmitter, to conrm

press and release the (+) key and the transmitter will be

saved.

DELETE TRANSMITTERS

To delete all recorded transmitters, just press and release

the (+) key, doing so will display a 10-sec counter. descend

to 0 sec, to conrm the action press and release the (+)

key.

BREAK TIME

To increase the automatic time press the (+) key and to

decrease it press the (-) key.

CLOSING RAMP

To increase the closing ramp, just press the (+) key and to

decrease it, just press the (-) key.

CLOSING TORQUE

To increase the closing torque, just press the (+) key to the

desired torque level and to decrease it, just press the (-)

key.

OPENING RAMP

To increase the opening ramp just press the (+) key and to

decrease it just press (-) key.

OPENING TORQUE

To increase the opening torque, just press the (+) key to

the desired torque level and to decrease it, just press the

(-) key.

CENTRAL AGILITY

POP CONNECT

TECHNICAL MANUAL

ATTENTION

Do not use the equipment

without fir reading the

inruction manual.

P09852 - 12/2021

Rev. 0

BRAKE

To increase the brake level, just press the (+) key and to

decrease it, just press the (-) key.

STRENGTH

The force leaves the factory at the maximum level, to

decrease it just press the (-) key to the desired level, to

increase it just press the (+) key.

GARAGE LIGHT TIME

To increase the garage light time, just press the (+) key

and to decrease it, just press the (-) key.

REVERSAL

To disable the rollback just press the (-) key to enable press

the (+) key.

CODE TYPE TX

To set xed code, press (-) key and to set rolling code press

(+) key.

OPENING DELAY

To increase the opening delay time press and release the

(+) key and to decrease it press the (-) key.

CLOSING LOCK

To enable and increase the latch retraction time during

the closing limit switch press the (+) key and to decrease

press the (-) key.

ROUTE

To delete the recorded route, just press the (+) key.

SETTINGS COMMAND TABLE

Parameters Select function Enter the function Increment Decrement

Automatic Time Press 1 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Closing Ramp Press 2 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Closing Torque Press 3 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Opening Ramp Press 4 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Opening Torque Press 5 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Brake Press 6 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Strength Press 7 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Garage Light Time Press 8 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

NOTE: To change the parameter without having to open JUMPER PROG, it is necessary to press both CMD (-) and GRV (+)

buttons at the same time. LED1 starts ashing 2x until the CMD (-) button is pressed again for the next parameter.

JUMPERS SETTINGS

PARAMETERS STATE

OPEN CLOSE

JUMPERS

RAP / SLOW FAST SLOW

LIGHT/WEIGHT LIGHT GATE HEAVY GATE

DZ/BV SLIDING OVERHEAD

PROG WORKING PROGRAMING

TX WITHOUT RECORDING RECORDING

FACTORY DEFAULT SETTINGS TABLE

Parameters

Automatic Time Semi automatic

Closing Ramp Level 0

Closing Torque Level 1

Opening Ramp Level 0

Opening Torque Level 1

Brake Level 1

Strenth Level 8

Garage Light Time 0 sec.

Reversal Able

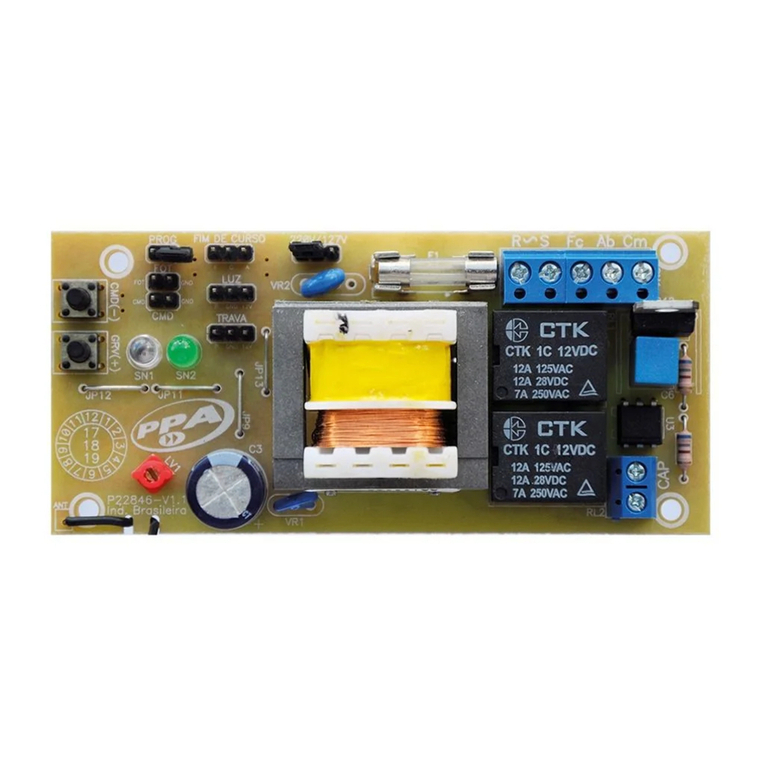

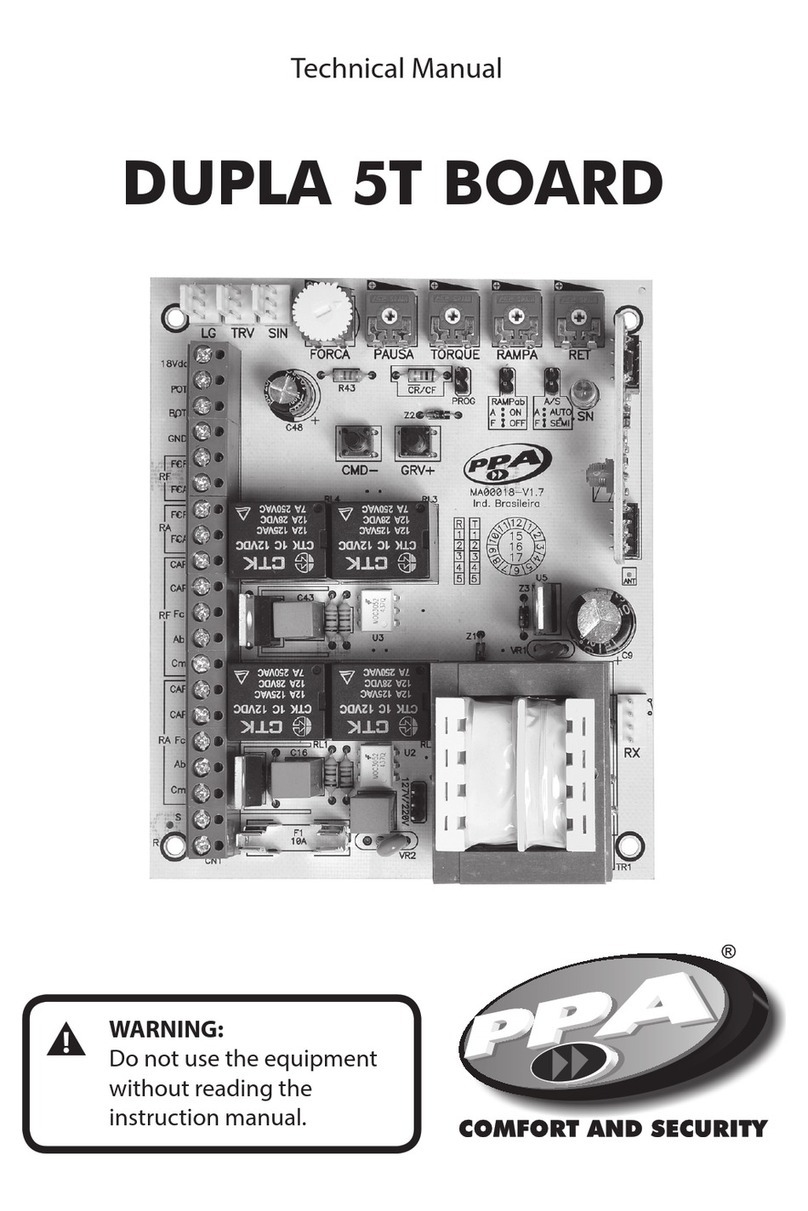

ELECTRICAL POWER

100 - 240 VAC

50 - 60 Hz

ELECTRICAL POWER

127 -220 V

ENGINE

START

CAPACITOR

LIMIT SWITCH

REEDS

C A C F

M

TACT

6

8

9

12

13

4

1

2

5

3

10

11

7

SUBTITLE

1 - RECORD button (+);

2 - COMMAND button (-);

3 - JUMPER Programming;

4 - JUMPER Application model;

5 - JUMPER Select gate weight;

6 - JUMPER Select technology;

7 - JUMPER Records transmitter (TX);

8 - LOCK connector;

9 - GARAGE LIGHT connector;

10 - PROG PPA connector;

11 - LED Signaling;

12 - Photocell Connector;

13 - RX / BOT Connector

GENERAL TERMS AND CONDITIONS OF WARRANTY

MOTOPPAR, Indury and Commerce of Automatic Gate Operators Ltd., regiered with the CNPJ (National Regiry of Legal Entities) under Number 52.605.821/0001-55, located at 3526 Dr.

Labieno da Coa Machado Avenue, Indurial Dirict, Garça – SP – Brazil, Zip Code 17400-000, manufacturer of PPA Products, hereby guarantees this product again design, manufacturing or

assembly defects and/or supportively as a result of material quality aws that could make its intended use improper or inadequate, within a legal period of ninety days from time of acquisition,

provided that the inallation inructions described in the inruction manual are observed.

Due to the credibility and tru placed on PPA products, we will add 275 more days to the period mentioned above, reaching a warranty period of one year, likewise counted from the time of

acquisition proven by consumer through proof of purchase (Cuomer Receipt).

In case of defect, within the warranty period, PPA responsibilities are rericted to the repair or subitution of the product manufactured by the company, under the following conditions:

1. Repair and readjument of equipment may only be carried out by PPA Technical Assiance, which is qualied to open, remove, and subitute parts or components, as well as repair defects

covered by this warranty; thus, failure on observing this guideline and the veried use of any non-original parts will cause the resignation of this warranty on the part of the user;

2. The warranty will not extend to accessories such as cables, screw kit, xing brackets, power supplies etc.;

3. Expenses for packaging, transportation and product reinallation will be sole responsibility of the consumer;

4. The equipment mu be sent directly to the Company responsible for the sale (manufacturer's representative), through the address contained in the purchase invoice, properly packed, thus

avoiding loss of the warranty;

5. Within the additional period of 275 days, visits and transportation in places where authorized technical assiance is not available will be charged. The co of transportation of the product and/

or technician will be sole responsibility of the consumer and

6. The subitution or repair of the product does not prolong the warranty time.

This warranty will be terminated if the product:

1. Is damaged by natural agents, such as atmospheric discharges, oods, wildres, landslides etc.;

2. Is inalled in an improper electric power supply or if it is not according to any of the inallation inructions displayed on the manual;

3. Shows defects caused by droppings, collisions or any other physical accident;

4. Shows signs of product violation or attempted repair by unauthorized personnel;

5. Is not used for its intended purpose;

6. Is not used under normal conditions;

7. Is damaged by accessories or equipment connected to it.

Recommendation:

We recommend that both the inallation and the maintenance of the operator to be performed by an authorized PPA technical service. If the product fails or has an improper operation, seek

an Authorized Technical Service to x it.

TECHNICAL CHARACTERISTICS

• 433.92MHz Receiver Module;

• 164 xed code controls;

• 82 PPA standard rolling code controls;

• Output for garage lock and light modules;

• Analog limit switch;

• Photocell input;

• Electronic clutch adjustment;

• Entry to pushbutton;

• Automatic A/F route memorization;

• Brake adjustment;

• Adjustment of the ramp;

• Ramp torque adjustment;

• Delay time for opening with a signal;

• Allows conguration via PROG;

• Enables activation of the board via Wi-Fi Connect;

• Pre-setup conguration via jumpers according to gate

type, weight and speed;

• Source: 12v, 450mA

DELETE THE RECORDED COURSE

With the gate stopped, press the GRV button for

approximately three seconds until LED1 is lit, conrming

the action. When you release it, the route will be delete.

FACTORY STANDARD

Restore settings to factory default, with ramp disabled.

With the gate stopped, press the GRV button for

approximately ve seconds until LED1 ashes quickly,

conrming the action.

MODEL SELECTION

Set a pattern according to the model of the gate and

operator.

With the gate stopped, close the PROG jumper, make

the model selection according to the gate type jumpers

(sliding or overhead), gate weight (light or heavy) and

operator speed (fast or slow).

To conrm, press the GRV(+) and CMD(-) button until

led1 ashes quickly.

RECORD TRANSMITTERS

PPA standard transmitters.

1. With the gate stopped, close jumper TX, LED1 starts

ashing 2x until any button is pressed.

2. Press transmitter button, LED2 will start ashing

whenever it receives a valid code;

3. Press and release GRV button;

4. Release TX button;

5. Transmitter successfully saved LED1 ash 1x;

6. Button already registered ashes LED1 2x;

7. Memory full LED1 ashes 3x;

8. To record new transmitter button go back to step of

pressing transmitter button;

9. Remove jumper to nish;

DELETE TRANSMITTERS

Clears memory to record new transmitters.

1. With the gate stopped, close jumper TX, LED1 starts

ashing 2x until any button is pressed.

2. Press CMD button for three seconds until LED2 ashes

quickly, conrming the action.

3. Remove jumper to nish

AUTOMATIC / SEMI – AUTOMATIC TIME

After the end of the opening cycle, the gate waits for the

pause time set by the user to close the gate automatically.

To disable and set the time to zero, the board will wait for

a new command to close.

1. With the gate stopped, close the JPROG jumper where

LED1 starts to ash 2x until any button is pressed.

2. Press CMD button 1x, LED1 will stop ashing and stay

lit.

3. Press the GRV button to enter the function, where LED

will start to signal the setting level.

4. Press GRV button to increase auto timeout and CMD to

decrease time.

5. Resetting the automatic time leaves the board in mode

semi-automatic, LED1 ashes quickly.

6. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

7. Remove jumper.

Levels:

• N1 ashing = Semi-automatic.

• N1 lit = 5 sec.

• N2 lit = 10 sec.

• N3 lit = 30 sec.

• N4 lit = 60 sec.

• N5 lit = 90 sec.

• N6 lit = 120 sec.

• N7 lit = 180 sec.

• N8 lit = 240 sec.

ADJUSTMENT OF THE OPENING AND CLOSING

RAMP

The ramp is the distance to reach the mechanical stop.

The board will be continuously monitoring the gate

position and when it reaches this limit the operating

torque reduces, reaching the mechanical stop smoothly.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. For close ramp: press CMD button 2x LED1 will stop

ashing and LED2 should remain lit. Press the GRV

button to enter the function, where LED will start to

signal the setting level.

3. For opening ramp: pressing the CMD button 4x LED1

will stop ashing and LED4 should remain lit. Press the

GRV button to enter the function, where LED will start

to signal the setting level.

4. Press GRV to move the limit to the mechanical stop,

increasing the distance;

5. Press CMD to decrease the distance to the limit switch;

6. At the minimum value the ramp is disabled, it does not

reduce the torque, with the possibility of adjusting 8

levels;

Levels:

• N1 ashing = ramp disabled;

• N1 lit = 5% of route

• N2 lit = 10% of route.

• N3 lit = 15% of route.

• N4 lit = 20% of route.

• N5 lit = 25% of route.

• N6 lit = 30% of route.

• N7 lit = 35% of route.

• N8 lit = 40% of route.

TORQUE ON RAMP

The board will decrease the operating torque as soon as

it reaches the programmed ramp. Torque is set separately

for opening and closing.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. For closing torque: press CMD button 3x LED1 will stop

ashing and LED3 should remain lit. Press the GRV

button to enter the function, where LED will start to

signal the setting level.

3. For opening torque: press CMD button 5x LED1 will

stop ashing and LED5 should remain lit. Press the GRV

button to enter the function, where LED will start to

signal the setting level.

4. Press GRV to increase the ramp torque;

5. Press CMD to decrease the ramp torque;

6. At the minimum value the ramp is disabled, it does not

reduce the torque, with the possibility of adjusting 8

levels;

7. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

8. Remove Jumper.

Levels:

• N1 ashing = disabled;

• N1 lit = Minimum;

...

• N8 lit = Maximum;

BRAKE

When there is a command to turn o the engine, the

brake will be activated with the possibility of sensitivity

adjustment.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. Pressing the CMD button 6x LED1 will stop ashing and

LED 6 should remain lit.

3. Press the GRV button to enter the function, where LED

will start to signal the setting level.

4. Press GRV to increase the time the brake will be applied;

5. Press CMD to decrease the brake;

6. At the minimum value the brake is disabled;

7. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

8. Remove Jumper.

Levels:

• N1 ashing = disabled;

• N1 lit = Minimum;

...

• N8 lit = Maximum;

POWER (ELECTRONIC CLUTCH)

Adjust the engine operating force. For the use of this

safety sensor device to be eective, proceed as follows:

• After proper installation of the gate operator, adjust

the electronic clutch so that the force is the minimum

necessary to move the gate leaf along its entire path, in

opening and closing;

• At the end of the adjustment, test the function by

blocking the movement of the gate by placing a rigid

object in the limit switch of the gate.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. Pressing the CMD button 7x LED1 will stop ashing and

the LED7 should remain lit.

3. Press GRV button to enter setup, LED will start to signal

setup level.

4. Press GRV button to increase strength and CMD to

decrease;

5. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

6. Remove jumper.

GARAGE LIGHT TIME

Setting the time to turn o the garage light relay

module when the gate reaches the closing limit switch.

1. With gate stopped, close JPROG jumper, LED1 starts

ashing 2x until any button is pressed.

2. Pressing the CMD button 8x LED1 will stop ashing and

LED 8 should remain lit.

3. Press GRV button to enter setup, LED will start to signal

setup level.

4. Press GRV button to increase the standby time to turn

o the light and CMD to decrease it;

5. To congure another parameter, press the CMD(-)

and GRV(+) buttons together, returning to the initial

programming state;

6. Remove jumper.

Levels:

•N1 ashing = trac light, turns o as soon as it closes.

• N1 lit = 30 sec.

• N2 lit = 60 sec.

• N3 lit = 90 sec.

• N4 lit = 120 sec.

• N5 lit = 150 sec.

• N6 lit = 180 sec.

• N7 lit = 210 sec.

• N8 lit = 240 sec.

EXTRA SETTINGS MADE ONLY USING THE

PROG

Using the PROG programmer module it is also possible

to congure:

• Rollback: enabled or disabled;

• TX Type: the board accepts TX reception in xed mode

and in rolling mode, changing these parameters delete

all previously registered TX’s.

• Delay in opening: Time between reception of

the opening command and the board sending

the command to the gate, activating a trac light

connected to the garage light for signaling. It can be

congured as disabled or with time congured every

3s, ten of the maximum value of 24s.

SETTINGS BY THE PROGRAMMER “PROG”

PROG: Allows you to make the settings with more

precision.

While the PROG is in the board, the commands through

the pushbutton, the CMD button and the separate

receiver will be disabled for engine activation commands

in the limit switch.

Only PROG can send commands for opening and

closing the gate, with the button (+) and the registered

transmitter, if it is on the main sensor status screen.

Keeping any key pressed in the PROG, after 3 seconds, it

will enter the auto-repeat mode of the key pressed, which

will speed up the progress of the screens or adjustments.

HOME SCREEN

Monitoring of sensors and board

peripherals: (Gate status, FCF, FCA,

Photocell and Transmitter).

TYPE FACTORY

DEFAULT SETUP

Restores settings to factory

default.

RECORD

TRANSMITTERS

Records new transmitters

(controls) in the electronics board.

DELETE

TRANSMITTERS

Deletes (erases) all transmitters

(control) recorded on the

electronics board.

BREAK TIME

Time for automatic closing

• Semi-automatic (disabled)

• 1 (5 sec.)

• 2 (10 sec.)

• 8 (240 sec.)

CLOSING RAMP

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

CLOSING TORQUE

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

OPENING RAMP

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

OPENING TORQUE

9 Niveis

• 0 (Desabilitado)

• 1(Minimo)

• 8(Maximo)

BRAKE

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

STRENGTH

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

GARAGE LIGHT

TIME

Garage light time

• 0 (Disabled)

• 1 (30 sec.)

• 2 (60 sec.)

• 8 (240 sec.)

REVERSAL

Pushbutton or transmitter command

permission to work during the

closing limit switch of the gate to

reversal.

CODE TYPE

Select the type of transmitter

protocol (TX):

• Rolling Code (PPA);

• Fixed Code

OPENING DELAY

9 levels

• 0 (Disabled)

• 1 minimum

• 8 Maximum

CLOSING LOCK

Collect the lock pin when the gate

is closing and release the lock

when closing is complete

ROUTE Delete recorded route

LANGUAGE Select the PROGRAM language

ST: FCF: FCA:

FOT: RF:

ST – STATUS: Signals the opening or closing state.

FCF: Identies the position between reed and drive nut

magnet

FCA: Identies the position between reed and drive nut

magnet

FOT: Identies the photocell pulse

RF: Identies radio frequency signal

FACTORY PATTERN

FACTORY PATTERN: In this screen press (-) until you

reach factory pattern done, press the keys (-) and (+) for 5

seconds until it appears written done on the screen.

Also on this screen dene the type and weight of the gate

using the (+) and (-) keys to navigate through the options:

• Light and slow BV

• Light and fast BV

• Heavy and slow BV

• Heavy and fast BV

• Light and slow DZ

• Heavy and slow DZ

RECORD TRANSMITTERS – [000]

In this function the display shows no signal, when sending

a signal the display will show (+) transmitter, to conrm

press and release the (+) key and the transmitter will be

saved.

DELETE TRANSMITTERS

To delete all recorded transmitters, just press and release

the (+) key, doing so will display a 10-sec counter. descend

to 0 sec, to conrm the action press and release the (+)

key.

BREAK TIME

To increase the automatic time press the (+) key and to

decrease it press the (-) key.

CLOSING RAMP

To increase the closing ramp, just press the (+) key and to

decrease it, just press the (-) key.

CLOSING TORQUE

To increase the closing torque, just press the (+) key to the

desired torque level and to decrease it, just press the (-)

key.

OPENING RAMP

To increase the opening ramp just press the (+) key and to

decrease it just press (-) key.

OPENING TORQUE

To increase the opening torque, just press the (+) key to

the desired torque level and to decrease it, just press the

(-) key.

CENTRAL AGILITY

POP CONNECT

TECHNICAL MANUAL

ATTENTION

Do not use the equipment

without fir reading the

inruction manual.

P09852 - 12/2021

Rev. 0

BRAKE

To increase the brake level, just press the (+) key and to

decrease it, just press the (-) key.

STRENGTH

The force leaves the factory at the maximum level, to

decrease it just press the (-) key to the desired level, to

increase it just press the (+) key.

GARAGE LIGHT TIME

To increase the garage light time, just press the (+) key

and to decrease it, just press the (-) key.

REVERSAL

To disable the rollback just press the (-) key to enable press

the (+) key.

CODE TYPE TX

To set xed code, press (-) key and to set rolling code press

(+) key.

OPENING DELAY

To increase the opening delay time press and release the

(+) key and to decrease it press the (-) key.

CLOSING LOCK

To enable and increase the latch retraction time during

the closing limit switch press the (+) key and to decrease

press the (-) key.

ROUTE

To delete the recorded route, just press the (+) key.

SETTINGS COMMAND TABLE

Parameters Select function Enter the function Increment Decrement

Automatic Time Press 1 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Closing Ramp Press 2 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Closing Torque Press 3 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Opening Ramp Press 4 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Opening Torque Press 5 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Brake Press 6 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Strength Press 7 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

Garage Light Time Press 8 x CMD (-) 1 x GRV (+) GRV (+) CMD (-)

NOTE: To change the parameter without having to open JUMPER PROG, it is necessary to press both CMD (-) and GRV (+)

buttons at the same time. LED1 starts ashing 2x until the CMD (-) button is pressed again for the next parameter.

JUMPERS SETTINGS

PARAMETERS STATE

OPEN CLOSE

JUMPERS

RAP / SLOW FAST SLOW

LIGHT/WEIGHT LIGHT GATE HEAVY GATE

DZ/BV SLIDING OVERHEAD

PROG WORKING PROGRAMING

TX WITHOUT RECORDING RECORDING

FACTORY DEFAULT SETTINGS TABLE

Parameters

Automatic Time Semi automatic

Closing Ramp Level 0

Closing Torque Level 1

Opening Ramp Level 0

Opening Torque Level 1

Brake Level 1

Strenth Level 8

Garage Light Time 0 sec.

Reversal Able

ELECTRICAL POWER

100 - 240 VAC

50 - 60 Hz

ELECTRICAL POWER

127 -220 V

ENGINE

START

CAPACITOR

LIMIT SWITCH

REEDS

C A C F

M

TACT

6

8

9

12

13

4

1

2

5

3

10

11

7

SUBTITLE

1 - RECORD button (+);

2 - COMMAND button (-);

3 - JUMPER Programming;

4 - JUMPER Application model;

5 - JUMPER Select gate weight;

6 - JUMPER Select technology;

7 - JUMPER Records transmitter (TX);

8 - LOCK connector;

9 - GARAGE LIGHT connector;

10 - PROG PPA connector;

11 - LED Signaling;

12 - Photocell Connector;

13 - RX / BOT Connector

GENERAL TERMS AND CONDITIONS OF WARRANTY

MOTOPPAR, Indury and Commerce of Automatic Gate Operators Ltd., regiered with the CNPJ (National Regiry of Legal Entities) under Number 52.605.821/0001-55, located at 3526 Dr.

Labieno da Coa Machado Avenue, Indurial Dirict, Garça – SP – Brazil, Zip Code 17400-000, manufacturer of PPA Products, hereby guarantees this product again design, manufacturing or

assembly defects and/or supportively as a result of material quality aws that could make its intended use improper or inadequate, within a legal period of ninety days from time of acquisition,

provided that the inallation inructions described in the inruction manual are observed.

Due to the credibility and tru placed on PPA products, we will add 275 more days to the period mentioned above, reaching a warranty period of one year, likewise counted from the time of

acquisition proven by consumer through proof of purchase (Cuomer Receipt).

In case of defect, within the warranty period, PPA responsibilities are rericted to the repair or subitution of the product manufactured by the company, under the following conditions:

1. Repair and readjument of equipment may only be carried out by PPA Technical Assiance, which is qualied to open, remove, and subitute parts or components, as well as repair defects

covered by this warranty; thus, failure on observing this guideline and the veried use of any non-original parts will cause the resignation of this warranty on the part of the user;

2. The warranty will not extend to accessories such as cables, screw kit, xing brackets, power supplies etc.;

3. Expenses for packaging, transportation and product reinallation will be sole responsibility of the consumer;

4. The equipment mu be sent directly to the Company responsible for the sale (manufacturer's representative), through the address contained in the purchase invoice, properly packed, thus

avoiding loss of the warranty;

5. Within the additional period of 275 days, visits and transportation in places where authorized technical assiance is not available will be charged. The co of transportation of the product and/

or technician will be sole responsibility of the consumer and

6. The subitution or repair of the product does not prolong the warranty time.

This warranty will be terminated if the product:

1. Is damaged by natural agents, such as atmospheric discharges, oods, wildres, landslides etc.;

2. Is inalled in an improper electric power supply or if it is not according to any of the inallation inructions displayed on the manual;

3. Shows defects caused by droppings, collisions or any other physical accident;

4. Shows signs of product violation or attempted repair by unauthorized personnel;

5. Is not used for its intended purpose;

6. Is not used under normal conditions;

7. Is damaged by accessories or equipment connected to it.

Recommendation:

We recommend that both the inallation and the maintenance of the operator to be performed by an authorized PPA technical service. If the product fails or has an improper operation, seek

an Authorized Technical Service to x it.