14 15

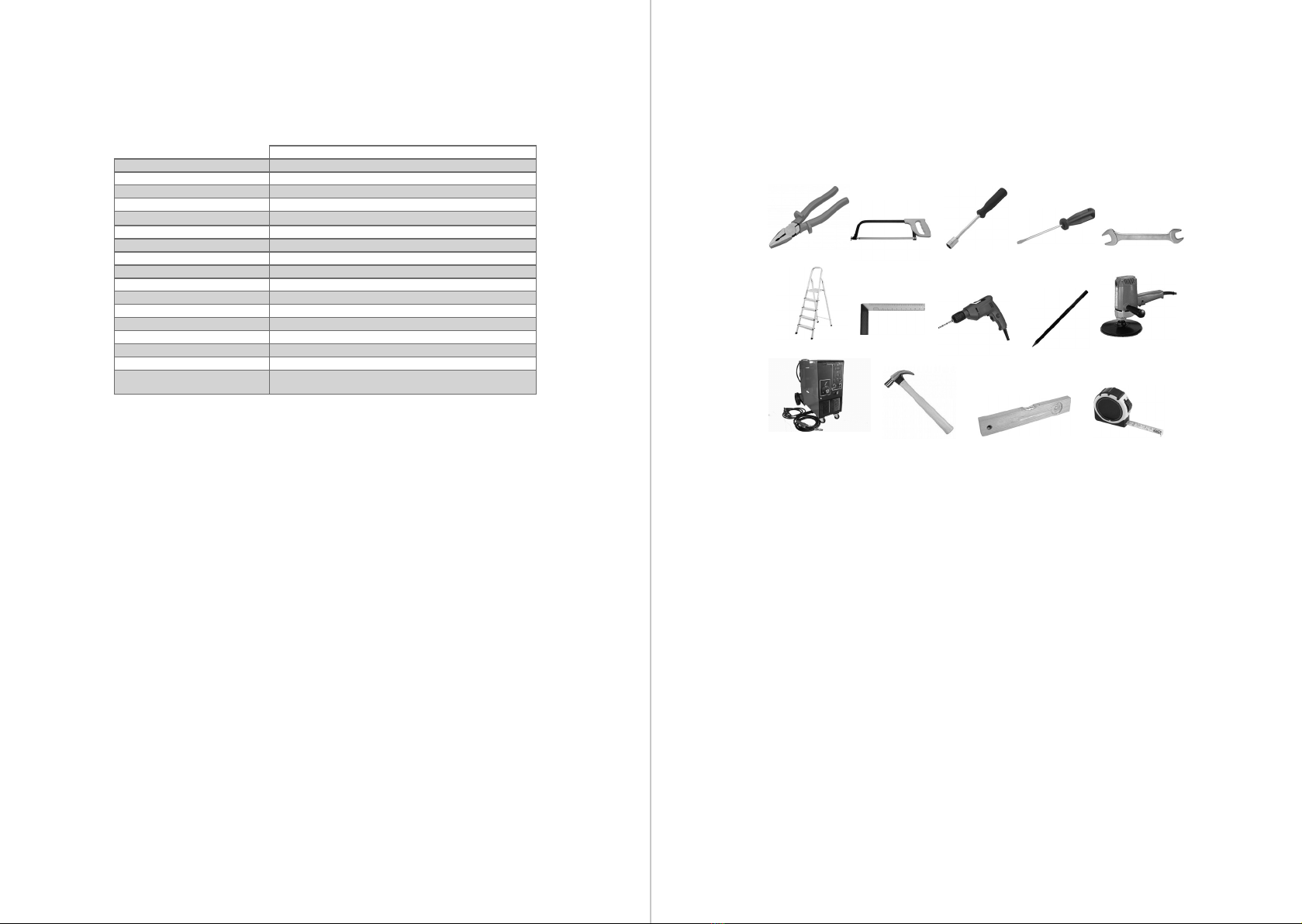

COMMAND BOARD:

Check the label attached to the product

(according to the model on the side)

which is the automation center. After

that, consult the control unit manual

that is available for download at

www.ppa.com.br and make all the

connections and congurations.

Batch:

Code:

Model:

Reduction:

Technology:

Voltage:

Board:

Size:

Mounting:

Housing:

Gear:

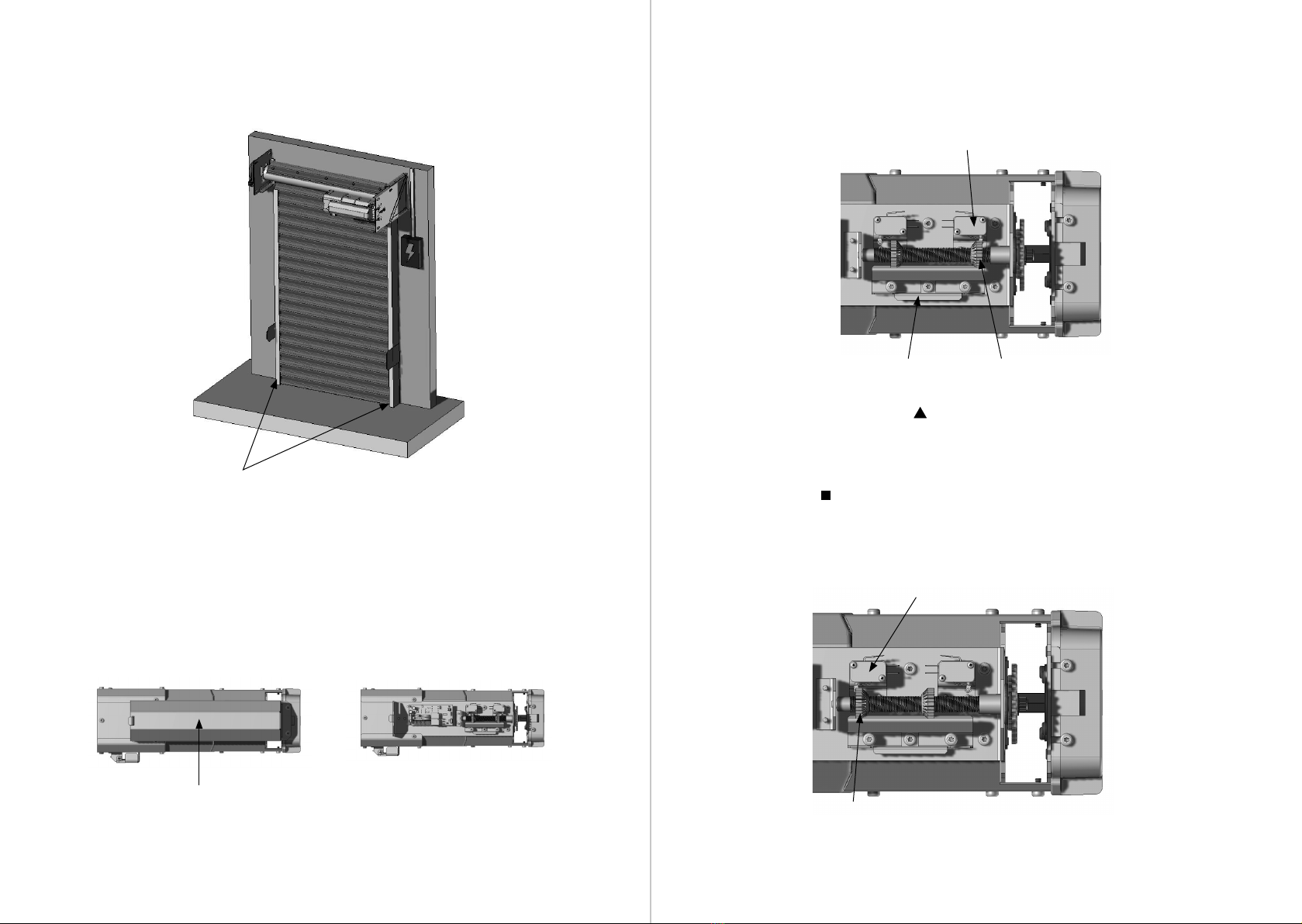

MAINTENANCE

In the table below, some PROBLEMS will be mentioned — DEFECTS, PROBABLE

CAUSES AND CORRECTIONS — that may occur in your Operator. Before any

maintenance, it is necessary to completely disconnect the electrical network.

DEFECTS PROBABLE CAUSES CORRECTIONS

Motor does not

start / does not

move

A) Power o

B) Fuse open / blown

C) Locked gate

D) Limit switch with defective

A) Make sure the mains is

connected correctly

B) Replace the fuse with the same

specication

C) Make sure there is no object

blocking the

gate operation

D) Replace the limit switch system

(analog and/or digital)

Motor blocked A) Inverted motor connection

B) Locked gate or operator

A) Check the motor wires

B) Put in manual mode and check

separately

Electronic board

does not accept

command

A) Fuse blown

B) Mains disconnected (power

supply)

C) Defect in the discharged remote

control

D) Transmitter range (remote

control)

A) Replace the fuse

B) Turn on the mains (power supply)

C) Check and change battery

D) Check the position of the

receiver antenna and, if necessary,

reposition it to ensure range

Motor only turns

to one side

A) Inverted motor wires

B) Inverted limit switch system

C) Defect in the command board

A) Check the motor connection

B) Invert the limit switch connector

(analog and/or digital)

C) Replace the command board

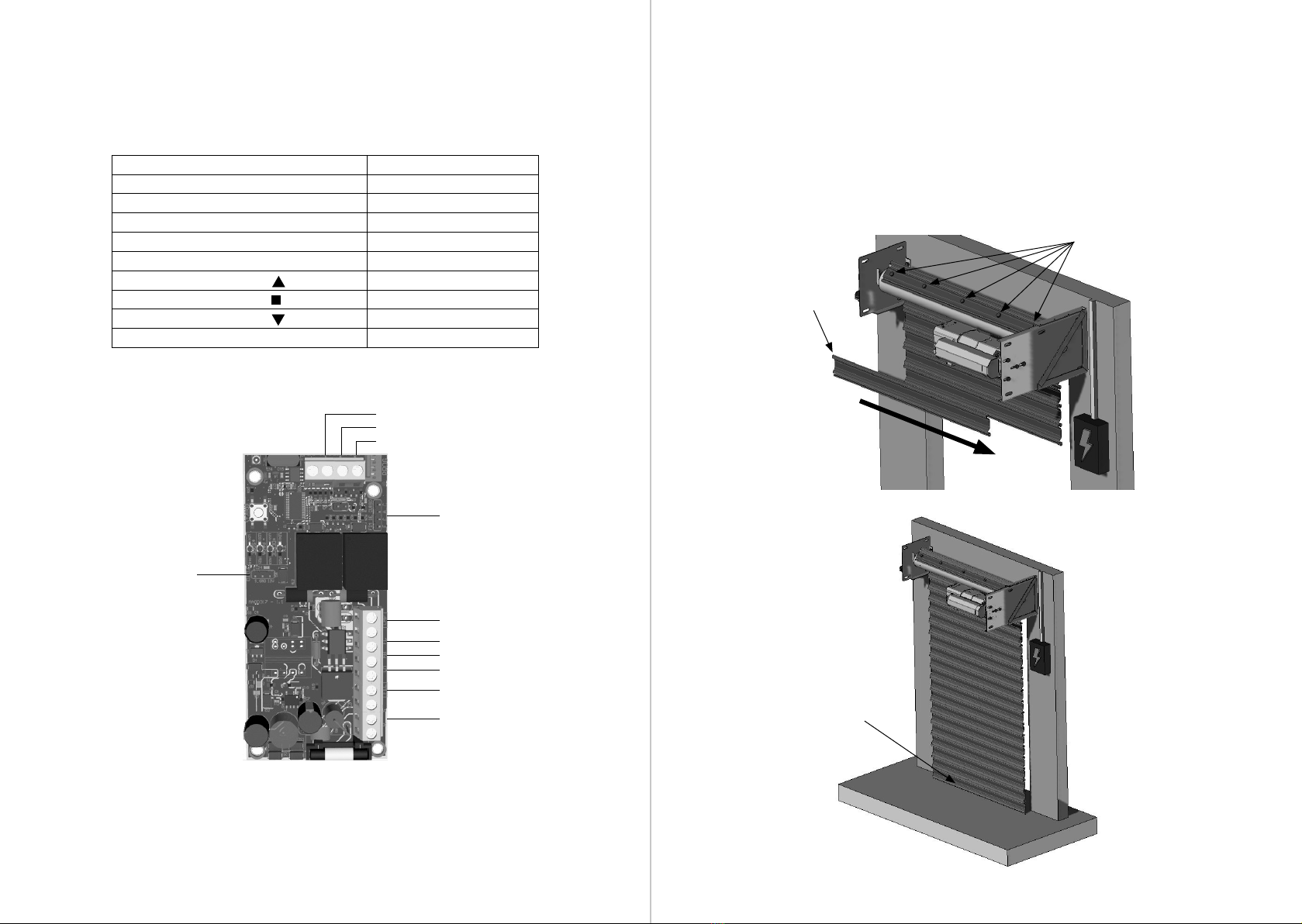

4th Step: With the two limit switches adjusted, do the opening and closing test.

Press the DOWN button ( ) to close the door, after it is completely closed, press

the UP button ( ) to open the door and wait for it to open completely. There is

also the STOP ( ), option, which works both to stop the door from opening and

to stop the door from closing.

SAFETY ITEMS

It is recommended to use a photocell (for doors up to 10 meters), as exemplied in

the image below:

It is also recommended to install the Anti-Fall Device, which prevents the door

leaf from falling in cases of poor structural installation or unnatural wear of door

components. This safety device must be installed on the opposite side of Operator

BR1. As shown in the image below: