PR POWER PR4000 User manual

PR4000 9mt 4x1000W METAL HALIDE

2

TL073-11-02-03

01-02-2011

INDEX

1. CE MARK ..............................................................................................................................................4

2. MAINTENANCE & OPERATION...........................................................................................................4

3. GENERAL INFORMATION...................................................................................................................5

3.1 EQUIPMENT DOCUMENTATION FOR THE LIGHTING TOWER......................................................5

4. SAFETY SIGNS.....................................................................................................................................6

5. SAFETY REGULATIONS TO OBSERVE.............................................................................................8

5.1 BEFORE OPERATING THE MACHINE...............................................................................................8

5.2 DURING MAINTENANCE....................................................................................................................8

5.3 DURING TRANSPORT........................................................................................................................8

6. GENERAL DANGER INFORMATION...................................................................................................9

6.1 DANGER OF BURNS ..........................................................................................................................9

6.2 DANGER OF ELECTROCUTION........................................................................................................9

6.3 DANGER OF INJURY..........................................................................................................................9

6.4 WARNING OF FIRE OR EXPLOSION DURING REFUELING............................................................9

6.5 NOISE..................................................................................................................................................9

6.6 EXHAUST FUMES...............................................................................................................................9

7. GENERAL DESCRIPTION OF THE LIGHTING TOWER...................................................................10

8. LIGHTING TOWER NOT IN USE........................................................................................................10

9. TECHNICAL SPECIFICATION............................................................................................................11

9.1 GENERATOR....................................................................................................................................11

9.2 ENGINE.............................................................................................................................................11

9.3 HYDRAULIC GEAR BOX...................................................................................................................12

9.3.1 ELECTRICAL MOTOR................................................................................................................12

9.3.2 GEAR PUMP...............................................................................................................................12

9.3.3 UNLOADING SOLENOID VALVE...............................................................................................12

9.3.4 HYDRAULIC FLUID....................................................................................................................12

9.4 LIGHTING TOWER ...........................................................................................................................13

9.5 RAISING AND LOWERING ROPE....................................................................................................13

9.6 FLOODLIGHT....................................................................................................................................14

9.7 LAMP.................................................................................................................................................15

10. LIGHTING FOOT PRINT DIAGRAM...................................................................................................16

11. IDENTIFICATION OF EXTERNAL COMPONENTS...........................................................................17

11.1 LIGHTING TOWER COMPOSITION.................................................................................................17

11.2 EMERGENCY STOP BUTTON AND EARTH CLAMP.......................................................................19

11.3 BATTERY SWITCH...........................................................................................................................20

11.4 RADIATOR CAP PROTECTION PLATE...........................................................................................21

12. IDENTIFICATION OF INNER COMPONENTS...................................................................................22

12.1 CONTROLS DESCRIPTION .............................................................................................................22

12.2 HYDRAULIC GEAR BOX...................................................................................................................24

12.2.1 LOWERING HANDLE BAR BRACKET IN CASE OF EMERGENCY.........................................25

12.3 BATTERY ..........................................................................................................................................26

12.4 FUEL TANK .......................................................................................................................................27

12.5 ENGINE OIL CAP ..............................................................................................................................28

12.6 CHANGE ENGINE OIL ......................................................................................................................29

13. OPERATING INSTRUCTIONS............................................................................................................30

PR4000 9mt 4x1000W METAL HALIDE

3

TL073-11-02-03

01-02-2011

13.1 LIGHTING TOWER POSITIONING...................................................................................................30

13.2 CONNECTING OF THE BATTERY...................................................................................................30

13.3 EARTHING ........................................................................................................................................30

13.4 PRELIMINARY CHECKS...................................................................................................................30

13.5 ENGINE STARTING..........................................................................................................................30

13.6 RUNNING IN......................................................................................................................................31

13.7 USE OF MACHINE ............................................................................................................................31

13.8GENERATOR ALARMS.....................................................................................................................31

13.9 REMARKS .........................................................................................................................................32

13.10 USE OF THE LIGHTING TOWER.....................................................................................................33

13.11 STOPPING THE ENGINE..................................................................................................................36

14. ENGINE MAINTENANCE....................................................................................................................37

14.1 REPLACEMENT OF FUEL PRE-FILTER..........................................................................................38

14.2 CLEANING THE FUEL FILTER POT.................................................................................................38

14.3 FUEL FILTER CARTRIDGE REPLACEMENT...................................................................................39

14.4 ENGINE OIL.......................................................................................................................................40

14.5 CHECKING LEVEL AND ADDING ENGINE OIL ...............................................................................40

14.6 CHANGING ENGINE OIL AND REPLACING THE OIL FILTER CARTRIDGE..................................41

14.7 RADIATOR ........................................................................................................................................42

14.8 CHECKING COOLANT LEVEL, ADDING COOLANT .......................................................................43

14.9 CHANGING COOLANT.....................................................................................................................44

14.10 AIR CLEANER ...................................................................................................................................45

15. LIGHTING TOWER MAINTENANCE..................................................................................................46

15.1 LUBRICATION OF THE ROLLERS...................................................................................................46

15.2 LUBRICATION OF MAST SECTIONS...............................................................................................46

15.3 LUBRICATION OF STABILIZERS.....................................................................................................46

15.4 CHECK OF HYDRAULIC CYLINDER................................................................................................46

15.5 CHECK OF STEEL CABLES .............................................................................................................46

15.6 CHECK OF HYDRAULIC CONNECTIONS .......................................................................................46

16. TROUBLESHOOTING GUIDE............................................................................................................47

16.1 MAIN TROUBLES..............................................................................................................................47

17. REPLACE THE LAMP AND FLOODLIGHT GLASS..........................................................................54

18. SPARE PARTS....................................................................................................................................55

18.1 COMMAND PANEL SPARE PARTS LIST.........................................................................................55

18.2 EMERGENCY STOP BUTTON SPARE PARTS LIST.......................................................................57

18.3 HYDRAULIC COMPONENTS SPARE PARTS LIST .........................................................................58

18.4 BASE SPARE PARTS LIST...............................................................................................................60

18.5 CARPENTRYSPARE PARTS LIST ..................................................................................................62

18.6 TELESCOPIC MAST SPARE PARTS LIST.......................................................................................64

18.7 FLOODLIGHTS GROUP SPARE PARTS LIST.................................................................................66

18.8 ALTERNATOR SPARE PARTS LIST ................................................................................................68

18.9 TRAILER FOR FAST TOWING SPARE PARTS LIST.......................................................................70

18.10 STICKERS FOR LIGHTING TOWER................................................................................................71

19. WIRING DIAGRAM FIRST PART .......................................................................................................73

20. WIRING DIAGRAM SECOND PART ..................................................................................................74

PR4000 9mt 4x1000W METAL HALIDE

4

TL073-11-02-03

01-02-2011

1. CE MARK

The CE mark (European Community) certifies that the product complies with essential safety

requirements provided by the applicable Community Directives.

2. MAINTENANCE & OPERATION

Dear Customer, many thanks for the purchase of our product. Contained in this manual is all the

necessary information for use and the general maintenance of the lighting tower.

The responsibility for the correct operation of the lighting tower depends on the operator.

Before installation and operation of the lighting tower, read the manual carefully. If this manual is

not clear or comprehensible, contact PR Power Australia wide on:

1300 399 499

All the specifications and pictures in this manual are subject to modifications without prior

notice.

PR4000 9mt 4x1000W METAL HALIDE

5

TL073-11-02-03

01-02-2011

3. GENERAL INFORMATION

The lighting tower is designed, produced and tested to meet the European Standards and to

reduce the electrical risks in compliance with the laws.

3.1 EQUIPMENT DOCUMENTATION FOR THE LIGHTING TOWER

The manufacturer declines responsibility from any unauthorised modification of the

product.

Together with this manual we are supplying the following documents:

•Engine use and maintenance manual.

•Instruction manual and use for the lighting tower (this manual).

•Alternator use and maintenance manual.

•Check list for the lighting tower.

•CE declaration of conformity. Warranty certificate.

•Pre-delivery check report.

PR4000 9mt 4x1000W METAL HALIDE

6

TL073-11-02-03

01-02-2011

4. SAFETY SIGNS

These signs inform the user of any danger which may cause injury.

Read the precautions and descriptions below:

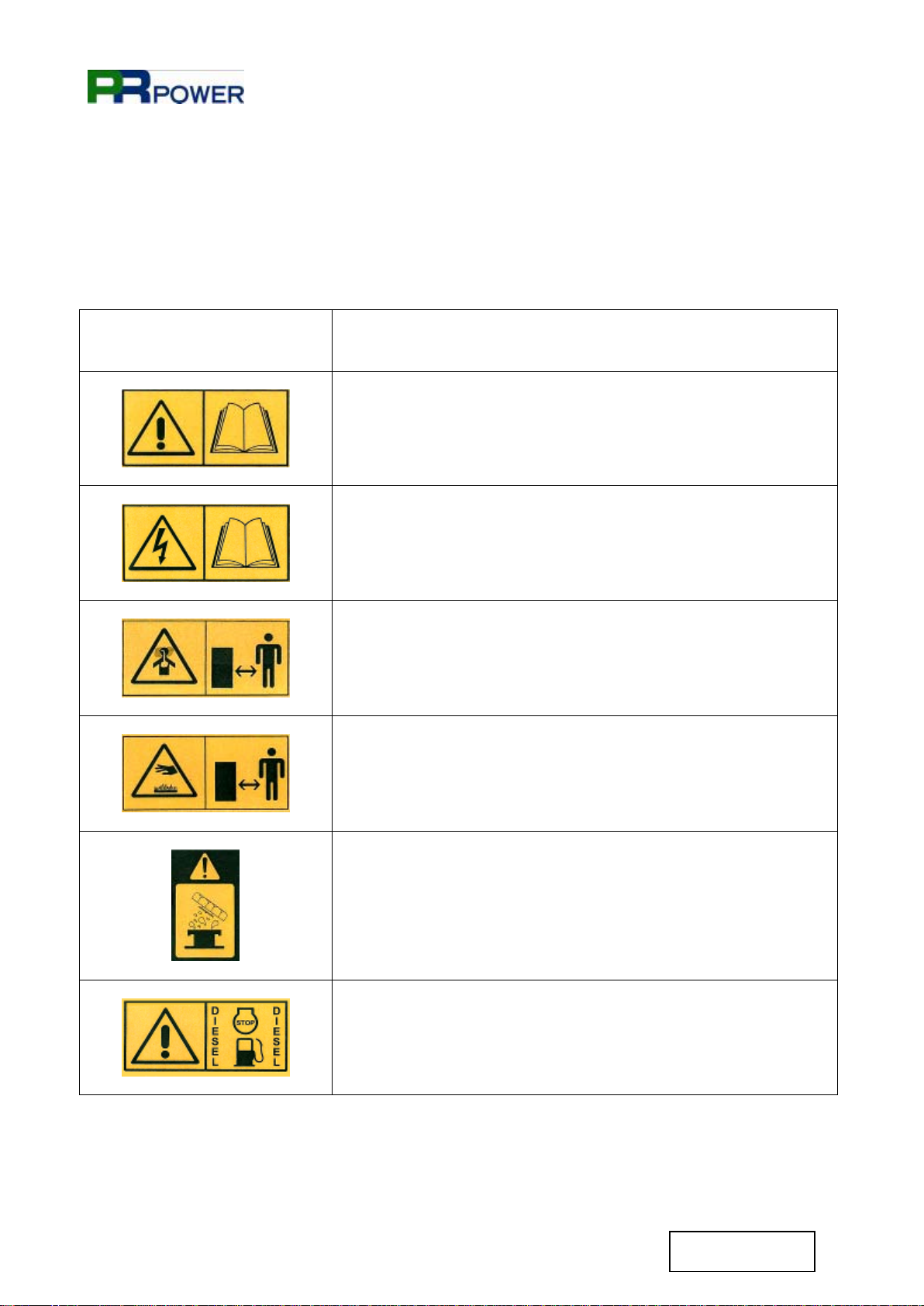

Danger signs

Description

•Read the instruction handbook before operating the lighting

tower.

•Danger of electric discharges.

•Consult the manual.

•Attention dangerous exhaust fumes.

•Maintain safe distance from the emission zone.

•Danger of burns.

•Don’t touch the exhaust and engine when the lighting tower

is in operation.

•Danger: don’t open when the engine is hot

•Stop the engine before refueling.

•Use diesel fuel only.

PR4000 9mt 4x1000W METAL HALIDE

7

TL073-11-02-03

01-02-2011

•Danger possible spillage of corrosive substances

•Danger possible crush point

Prohibition signs

Description

•It is prohibited to clean, lubricate or regulate moving parts.

•It is prohibited to extinguish fires with water, use fire

extinguishers only.

•It is prohibited to use open flames.

Information signs

Description

•This sign indicates the lifting point for the lighting tower.

PR4000 9mt 4x1000W METAL HALIDE

8

TL073-11-02-03

01-02-2011

5. SAFETY REGULATIONS TO OBSERVE

The manufacturer is not responsible of any damage to equipment or persons, as a result of

operators not adhering to the correct safety regulations.

5.1 BEFORE OPERATING THE MACHINE

•It is advised you wear protective clothes, gloves, safety shoes and ear plugs.

•It is recommended you understand the correct operation of the lighting tower.

•It is recommended that all authorised staff read and understand all warnings and dangers

described in this manual.

•Place barriers 2 meters from the lighting tower to prevent unauthorised staff approaching the

unit.

•Ensure yourself that the lighting tower is not operating and that there are no moving parts.

•Only authorised staff can operate the lighting tower.

•Read the operating instructions and safety warning stickers placed on the lighting tower.

•Connect the unit to the earth through the earth clamp.

•The unit must be connected to the earth using a copper cable with a minimum cross-section of

6 mm².

•Project Rentals is not responsible for any damage caused by failure to earth.

5.2 DURING MAINTENANCE

•Always turn off the lighting tower before any maintenance.

•Extraordinary maintenance must always be carried out by authorized staff.

•Before any maintenance operation on the floodlights, disconnect the power and wait for the

lamps to cool.

•The fluid of battery contains sulphuric acid which is extremely corrosive and harmful to the

skin. Always wear protective gloves and be extremely careful to avoid spillage when pouring

the acid.

•Contact with engine oil can damage your skin. Put on gloves when using engine oil. If you

come in contact with engine oil, wash it off immediately.

5.3 DURING TRANSPORT

•Warning!

Before towing the lighting tower, ensure the engine is switched off to avoid causing damage to

the equipment.

•Only use the correct lifting points as indicated on the tower.

•The lifting point, where present, must be used for the temporary raising and not for suspension

in the air of the equipment for long periods.

•The manufacturer is not responsible for any damage caused by negligence during transport.

PR4000 9mt 4x1000W METAL HALIDE

9

TL073-11-02-03

01-02-2011

6. GENERAL DANGER INFORMATION

6.1 DANGER OF BURNS

•Do not touch hot surfaces with hands e.g. silencers and engine when it is operating.

•Do not touch the floodlights when turned on.

•Always use gloves.

6.2 DANGER OF ELECTROCUTION

•Do not touch electrical parts, it may cause an electric shock.

•Do not touch the electric cables when the lighting tower is operating.

6.3 DANGER OF INJURY

•Do not remove the protective guards placed on the moving parts including, air intakes and fan

belts.

•Do not clean or attempt maintenance on moving parts.

•Use appropriate clothing and safety wear, whilst operating the lighting tower.

6.4 WARNING OF FIRE OR EXPLOSION DURING REFUELING

•Turn off the engine before refueling.

•Do not smoke during refueling.

•Refueling must be conducted in a way that does not cause fuel spillage.

•In the event of fluid spillage during refuelling, dry and clean parts as required.

•Check that there isn’t any spillage of fuel and hoses and hoses are not damaged.

6.5 NOISE

•Use ear plugs or ear muffs for noise protection.

6.6 EXHAUST FUMES

•The exhaust fumes are dangerous for your health. Maintain a safe distance from the emission

zone.

•In the event the lighting tower is used in a closed area, ensure that the exhaust fumes can be

easily dispersed in a safe manner.

PR4000 9mt 4x1000W METAL HALIDE

10

TL073-11-02-03

01-02-2011

7. GENERAL DESCRIPTION OF THE LIGHTING TOWER

The PR4000 has been designed to take into consideration 3 fundamental characteristics:

•Compact design

•Reliability

•Quality manufacturing and design

The construction materials used, guarantee not only extreme strength of the tower, but they are

also synonymous of longer life, in fact these materials are protected against oxidation like rust.

The ability to lower the tower is a key factor for manouverability and transportation. The lighting

tower can be installed and used by a single operator safely. The floodlights used on the lighting

tower, complete with lamps, are made from the world’s leading manufacturers.

8. LIGHTING TOWER NOT IN USE

If the lighting tower is not in operation for a long period (more than one year), we recommend you

keep the oil, fuel and the coolant in the engine to avoid oxidizing effects; we recommend you also

disconnect the battery cables.

When the lighting tower is in operation again, the fluids must be replaced, the battery charged; the

belts and hoses must be checked and a visual inspection of the electrical connections must be

performed.

PR4000 9mt 4x1000W METAL HALIDE

11

TL073-11-02-03

01-02-2011

9. TECHNICAL SPECIFICATION

9.1 GENERATOR

Model Synchronous

Single phase voltage 9 kVA - 240 V

Frequency 50 Hz

Cos ϕ0,8

Insulation class F

Mechanical protection IP 23

9.2 ENGINE

Make/Type Kubota D1105-E

Number of cylinders 3

Displacement 1123 cm3

Power 13,7 HP

Engine speed 1500 r.p.m.

Cooling Water

Fuel Diesel

Starting system Electric

Oil sump capacity 4,5 l

Radiator capacity 4 l

Specific fuel consumption 265 gr/kWh

Fuel tank capacity 116 l

Average operating hours 42 h ~

Noise level DBA at 7 metres 90 Lwa

Battery 12 V - 44 Ah

PR4000 9mt 4x1000W METAL HALIDE

12

TL073-11-02-03

01-02-2011

9.3 HYDRAULIC GEAR BOX

9.3.1 ELECTRICAL MOTOR

Feeding 240 V 50-60 Hz ± 10%

Power 0,55 kW

Poles 4

Duty factor S1

9.3.2 GEAR PUMP

Displacement 1,3 cm3

Maximum pressure 210 bar

Factory setting pressure 180 bar

Emergency action system Manual

9.3.3 UNLOADING SOLENOID VALVE

Coil thermal insulation Class F – VDE0585

Electric connection DIN 43650-A / ISO 4400

Protection degree IP 65

Coil duty cicle ED 100%

Coil voltage 230 V 50-60 Hz ± 10%

9.3.4 HYDRAULIC FLUID

Reservoir capacity 5 l

Fluid type ISO/DIN 6743/4 mineral oil

Fluid viscosity 15-100 mm2 sec – ISO 3448

Fluid temperature -15°C ÷ +80°C

Fluid maximum contamination level Class 10 in accordance with NAS

1638 with filter B 25 > 75

PR4000 9mt 4x1000W METAL HALIDE

13

TL073-11-02-03

01-02-2011

9.4 LIGHTING TOWER

Maximum height 9 mt

Raising Hydraulic

Section 7

Rotation Section 340°

Floodlights group tilt 41°

Electrical coiled cable 11G2,5 mmq

Electrical cable of floodlights H07RN-F

Maximum cable load 3300 kg

Maximum wind stability 110 km/h

Minimum dimension with trailer for

fast towing type B (L x W x H mm) 3417 x 1580 x 2330

Maximum dimension with trailer for

fast towing type B (L x W x H mm) 3417 x 1850 x 9000

Dry weight 1115 kg

9.5 RAISING AND LOWERING ROPE

Rope type AZN625APPCOM

Rope diameter 6 mm

Outer wires diameter 0,4 mm

Weight per meter 0,15 Kg

Costruction 6x(12+(6)+6+1)KF+PP

Type of lay Right hand ordinary lay

Tensile strenght 2160 N/mm²

Strands Compacted

Preformed Yes

Steel wires Carbon

Protection of wire rope Galvanized class B

Minimum breaking load 32,3 kN 3230 Dan 3294 Kg

PR4000 9mt 4x1000W METAL HALIDE

14

TL073-11-02-03

01-02-2011

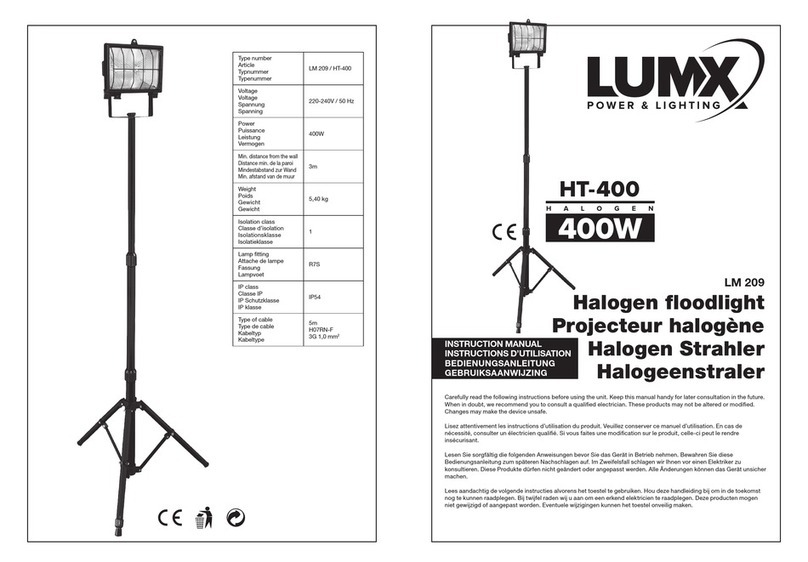

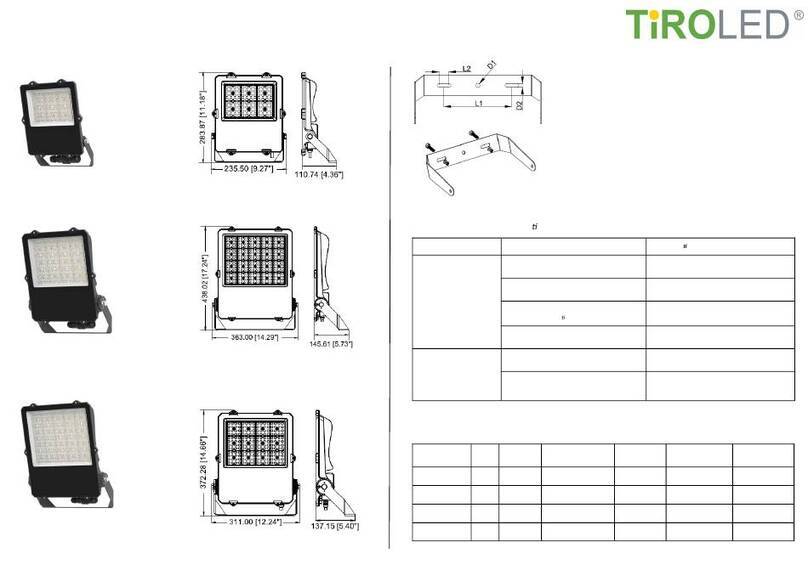

9.6 FLOODLIGHT

Lamp Metal halide

Power 4x1000 W

Degree of protection IP 66

Constructor material of the body Die-cast aluminium

Constructor material of lampholder Ceramic

Reflector Polished and anodized aluminium

99,85

Cable gland Stainless steel

Optical case opening system Stainless steel clips

Dimensions (L x H x D mm) 404 x 260 x 328

The floodlight is provided by tempered glass and silicone seals. Closing hooks and external nuts

and bolts in stainless steel. The casing’s protection against corrosion is ensured by Alodine 1200

chromate treatment and polyester powder coating for outdoors in graphite grey finishing. The

frame is equipped with special drains to prevent water from accumulating.

PR4000 9mt 4x1000W METAL HALIDE

15

TL073-11-02-03

01-02-2011

9.7 LAMP

The metal halide lamps used in the floodlights of the lighting tower allow to a greater lighting

system regarding the traditional halogen lamps and concur to an inferior energetic consumption

beyond to one duration much elevating of near 8000 hours.

The metal halide lamp is a high intensity discharge lamp based on the emission of electromagnetic

cancellation from part of a ionizated gas plasma. The ionization of the gas is obtained for means

of a discharge electrical worker (from which the name) through the gas.

The metal halide lamps derive from the high pressure sodium vapor lamps with the added of

thallium, Indian, dysprosium, holmium, cesium, thulium, which they improve the yield of the colors

of the sodium lamps, and give one temperature to their color much elevated (4000-5600) K. Their

chromatic yield renders them particularly adapted where there is the necessity of having a light

perfectly white. For being ignited they need of apposite igniters and injectors that produce

impulses of tension between 0,75 and 5 kV and for the attainment of the full light flux, in phase of

ignition, they are necessary few minutes.

In case of accidental putting out it is necessary to wait the cooling of the lamp (about 15

minutes) before a new ignition, because of the high tension that would be necessary for a

hot ignition.

PR4000 9mt 4x1000W METAL HALIDE

16

TL073-11-02-03

01-02-2011

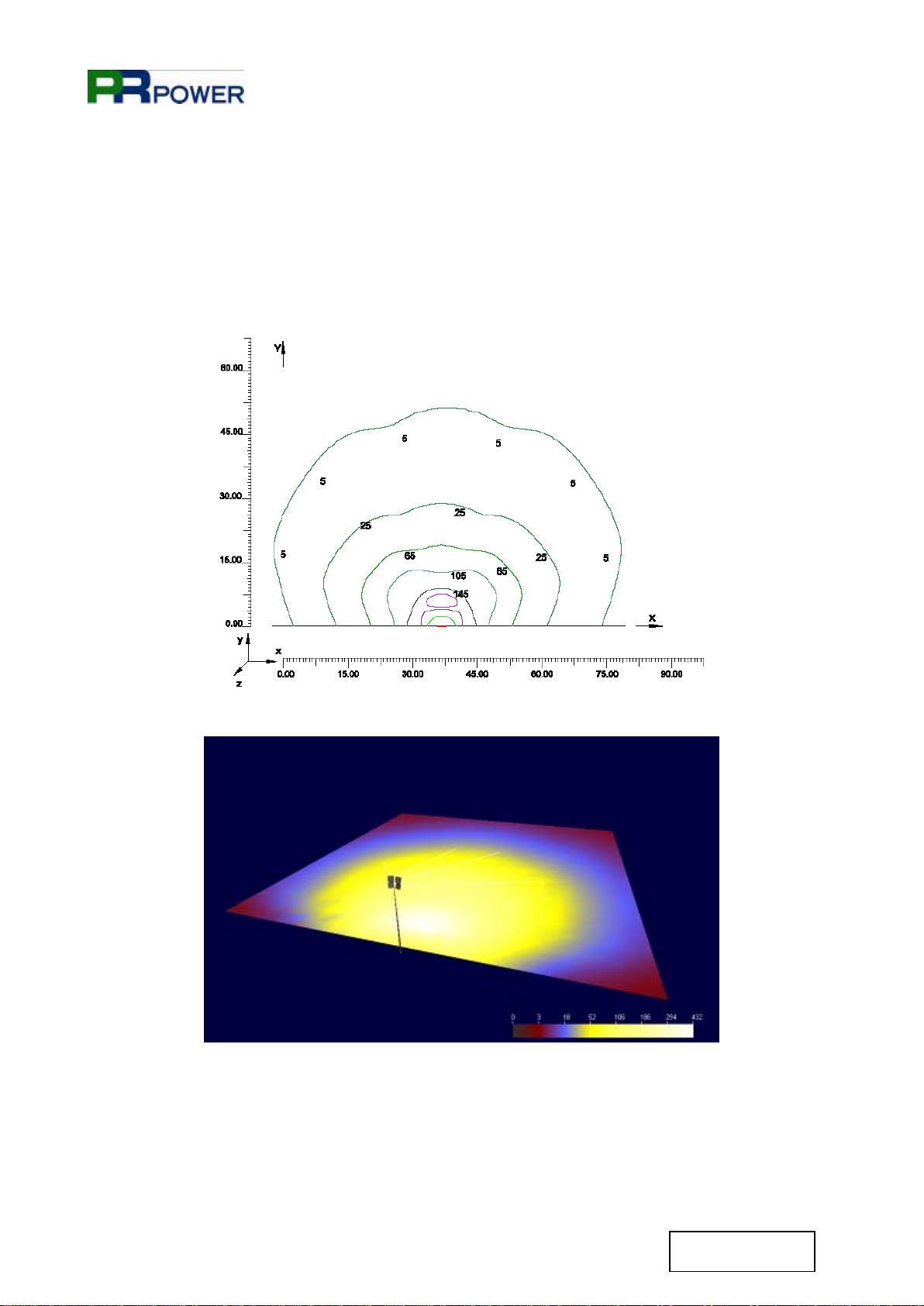

10. LIGHTING FOOT PRINT DIAGRAM

ILLUMINATED AREA

4200 m²

PR4000 9mt 4x1000W METAL HALIDE

17

TL073-11-02-03

01-02-2011

11. IDENTIFICATION OF EXTERNAL COMPONENTS

11.1 LIGHTING TOWER COMPOSITION

Items

Description

1

Floodlights rotation handles

2

Telescopic mast

3

Floodlights

4

Floodlights blocking rotation pin

5

Gas exhaust outlet

6

Radiator cap

7

Engine inspection door with command panel

8

Emergency stop button

9

Plate for transport through forklift

3

2

1

8

6

5

7

9

4

PR4000 9mt 4x1000W METAL HALIDE

18

TL073-11-02-03

01-02-2011

Items

Description

10

Fixed stabilizers

11

Air inlet grill

12

Lockable battery insulator switch

13

Air outlet grill

14

Lifting hook

15

Extractable stabilizers

16

Trailer for fast or slow towing (on the ground of model)

17

Door engine inspection

13

14

16

15

11

10

17

12

PR4000 9mt 4x1000W METAL HALIDE

19

TL073-11-02-03

01-02-2011

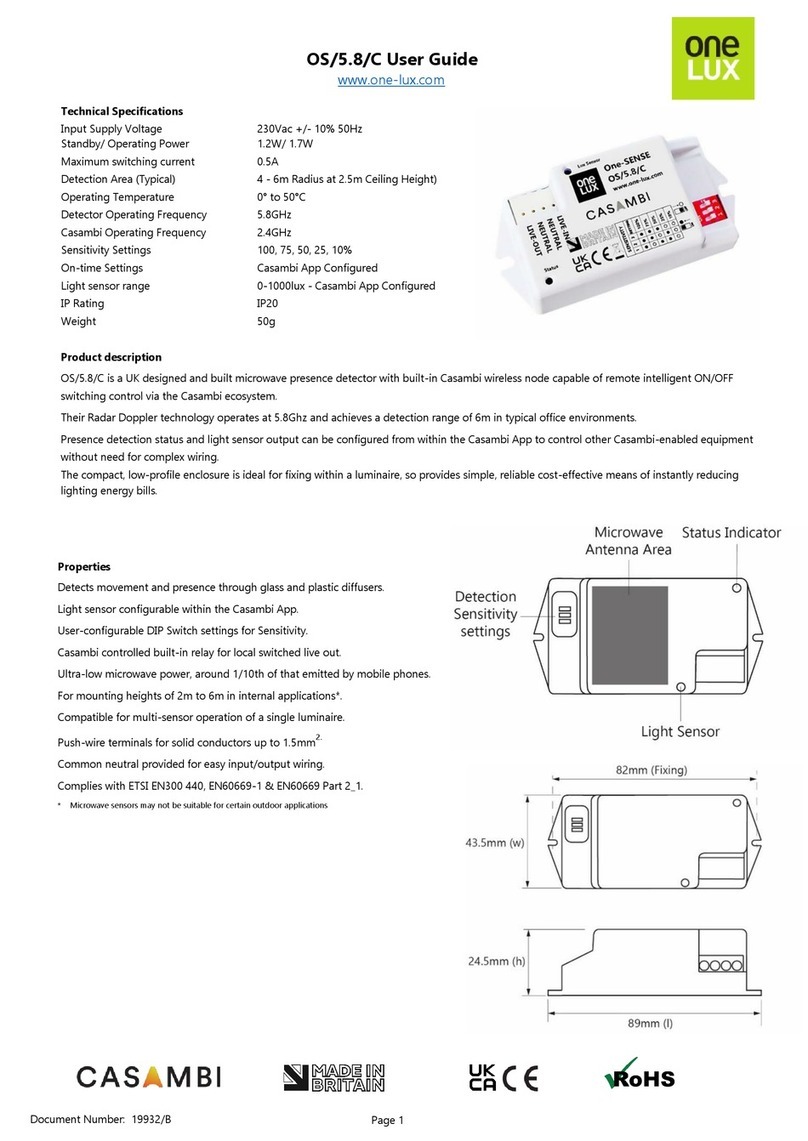

11.2 EMERGENCY STOP BUTTON AND EARTH CLAMP

Items Description

18 Earth clamp connection

19 Emergency stop button

Connect the unit to the earth, through the clamp (18).

The unit must be connected to earth using a copper cable with a minimum cross-section of 6 mm².

The manufacturer is not responsible for any damage caused by failure of the earthing.

Make sure that the emergency stop button (19) is rearmed. If it doesn’t, turn the grip handle in

clockwise direction.

In emergency case it is possible to stop the generating set by pressing the stop button (19).

18 19

PR4000 9mt 4x1000W METAL HALIDE

20

TL073-11-02-03

01-02-2011

11.3 BATTERY SWITCH

Items Description

20 Lockable battery insulator switch

The machine is supplied with the battery switch disconnect (20).

Connect the battery switch (20).

If the machine has to be stopped for a long period, we suggest to disconnect the battery switch

(20).

20

Table of contents

Other PR POWER Lighting Equipment manuals