PRACHT ALPHA User manual

State: März 2023

(NRG1006)

1

NOTES ON THIS DOCUMENT ............................................................................................................Fehler! Textmarke nicht definiert.

SAFETY, INSTALLATION AND USE.......................................................................................................Fehler! Textmarke nicht definiert.

OTHER USE INSTRUCTIONS..........................................................................................................Fehler! Textmarke nicht definiert.

SCOPE OF DELIVERY ..........................................................................................................................Fehler! Textmarke nicht definiert.

TECHNICAL DATA...............................................................................................................................Fehler! Textmarke nicht definiert.

ASSEMBLY..........................................................................................................................................Fehler! Textmarke nicht definiert.

REQUIREMENTS...........................................................................................................................Fehler! Textmarke nicht definiert.

WALL MOUNTING........................................................................................................................Fehler! Textmarke nicht definiert.

ELECTRICAL CONNECTION.................................................................................................................Fehler! Textmarke nicht definiert.

CONNECTION TO THE MAINS......................................................................................................Fehler! Textmarke nicht definiert.

WIRING OF THE RFID MODULE....................................................................................................Fehler! Textmarke nicht definiert.

SETTING THE MAXIMUM CURRENT.............................................................................................Fehler! Textmarke nicht definiert.

VALUES FOR ALPHA NRG1002 (MAX. 11KW PER VEHICLE)..........................................................Fehler! Textmarke nicht definiert.

VALUES FOR ALPHA NRG1012 (MAX. 22KW PER VEHICLE)..........................................................Fehler! Textmarke nicht definiert.

INITIAL COMMISSIONING.................................................................................................................Fehler! Textmarke nicht definiert.

OPERATION........................................................................................................................................Fehler! Textmarke nicht definiert.

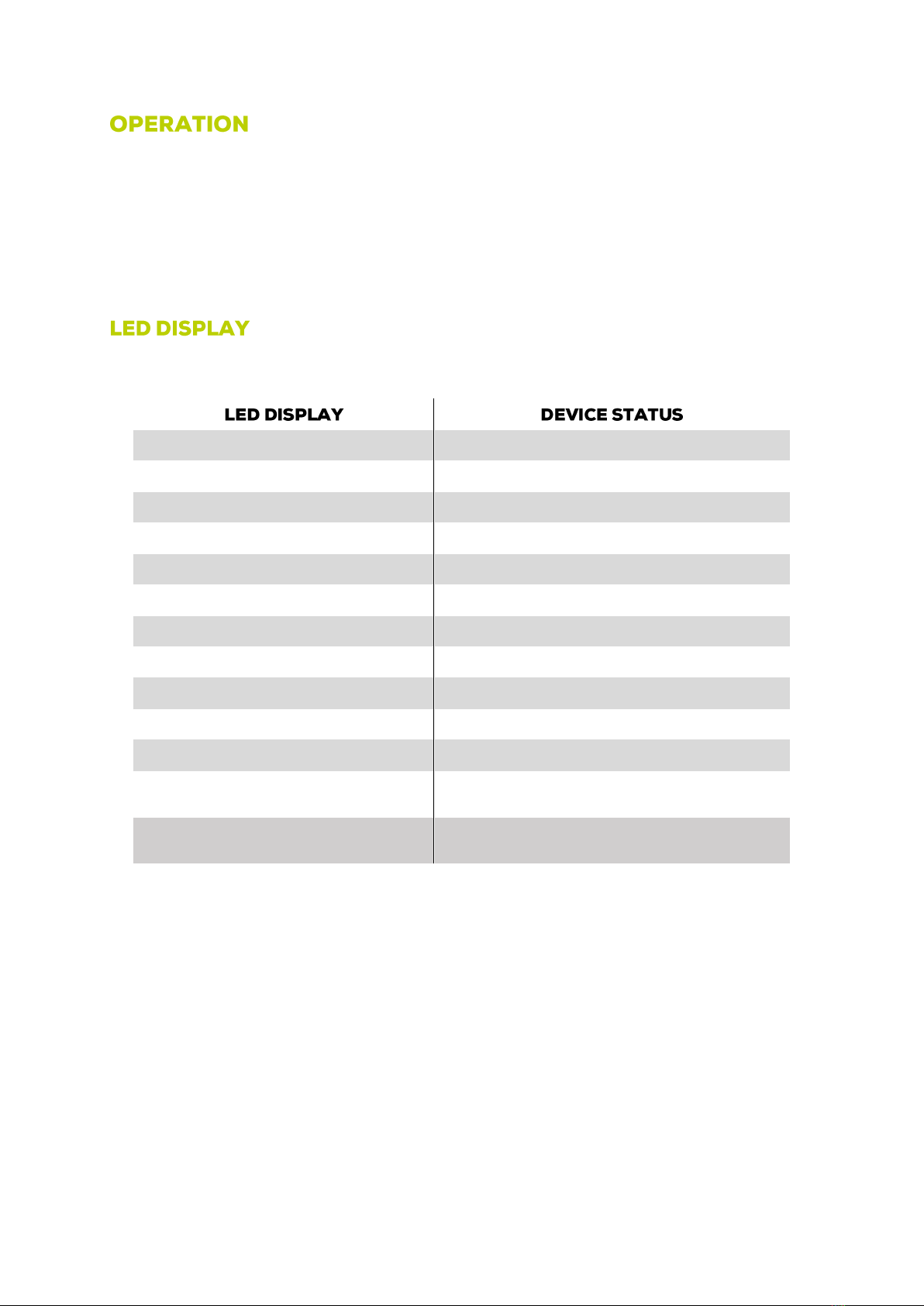

LED DISPLAY .................................................................................................................................Fehler! Textmarke nicht definiert.

RFID CARD TEACH-IN....................................................................................................................Fehler! Textmarke nicht definiert.

RFID CARD DELETION...................................................................................................................Fehler! Textmarke nicht definiert.

ACTIVATION OF THE WALLBOX.....................................................................................................Fehler! Textmarke nicht definiert.

LOAD.............................................................................................................................................Fehler! Textmarke nicht definiert.

SEQUENTIAL LOADING.................................................................................................................Fehler! Textmarke nicht definiert.

RESTARTING THE BOX ..................................................................................................................Fehler! Textmarke nicht definiert.

INTERFACE RS 485.............................................................................................................................Fehler! Textmarke nicht definiert.

MAINTENANCE AND CLEANING........................................................................................................Fehler! Textmarke nicht definiert.

ENVIRONMENT..................................................................................................................................Fehler! Textmarke nicht definiert.

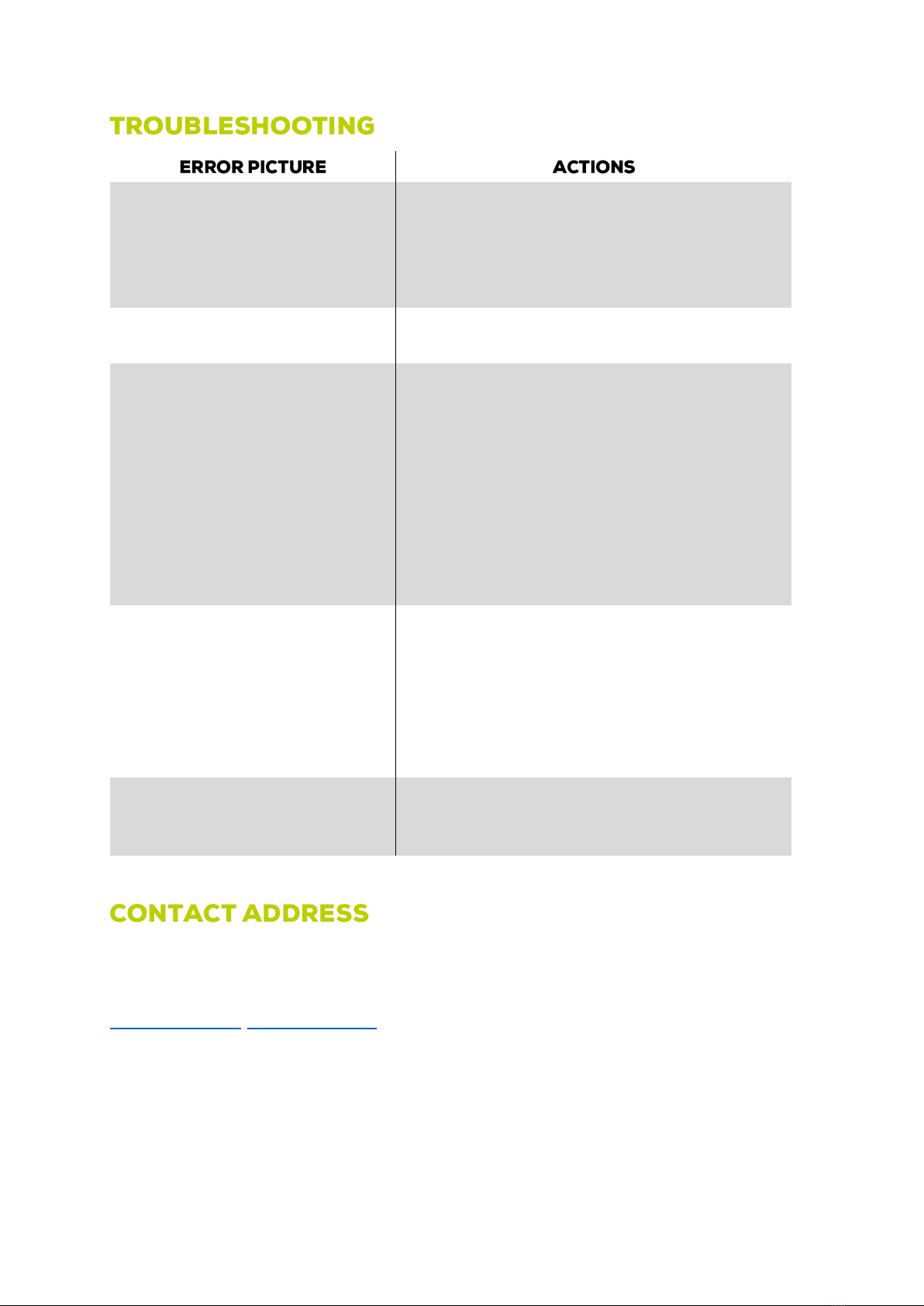

TROUBLESHOOTING..........................................................................................................................Fehler! Textmarke nicht definiert.

CONTACT ADDRESS ...........................................................................................................................Fehler! Textmarke nicht definiert.

2

Before installing and using the wallbox, the instructions must be read and understood in full by the installer and each user.

Please keep the manual for the entire service life of the wallbox in order to be able to access it later.

Also observe the operating instructions for your electric vehicle.

The wallbox is only suitable for use in private and semi-public areas (e.g. company parking lots).

The wallbox must not be installed in areas with an explosive atmosphere (EX area) or where flammable liquids or objects are

stored.

The wallbox is only suitable for stationary installation. Minimumdistances of 50cm to all neighboring objects must bemaintained.

Installation in a closed box is not permitted. Likewise, the wallbox must not be installed in areas at risk of flooding.

The wallbox may only be installed and put into operation for the first time by a trained electrician.

The electrical connection must be made in accordance with nationally applicable standards, as well as other national and

international regulations regarding accident prevention and personal protection, as well as fire protection.

The wallbox may only be connected to and operated on TT, TN-C and TN-C-S networks. Operation on an IT network is not

permitted.

Work on the wallbox may only be carried out when it is de-energized. There is a risk of fatal electric shock due to the

components inside the box!

Modifications or conversions to the wallbox are not permitted and will result in the loss of any warranty and guarantee claims

against the manufacturer.

The box and all associated components may only be used for their intended purpose. The manufacturer assumes no liability for

personal injury or property damage resulting from improper use.

Defective or damaged wallboxes must not be put into operation. In this case, contact your installer.

Check the function of the RCD switch regularly in accordance with national regulations.

3

•Vessels containing liquids must not be placed on the charging station

•Kinking or running over of the charging cable must be avoided

•The charging cable must be wound up on the device provided for this purpose when the charging station is not in use

•Fix the charging coupler in the charging coupler receptacle provided when not in use.

•Before using the charging coupler, check it visually for damage or dirt on the contacts.

•The charging coupler must not be disconnected from the vehicle during the charging process

•The insertion of objects into the charging coupler is prohibited

•Do not wash the vehicle with a garden hose or high-pressure cleaner when the charging coupling is plugged in, in order

to prevent water from entering the charging coupling or the connecting device of the vehicle.

•The vehicle must be parked at a suitable distance from the charging station to ensure that the charging cable can be

plugged in without tensile stress

•Avoid direct sunlight

•Do not open charging station mounted outdoors during rain or snowfall

•The charging cable must not be connected to extension cords or adapter cables

•Do not allow children to play unsupervised in the vicinity of the charging station

•The charging station must always be closed during operation

•The key for opening the charging station should be kept in a place to which unauthorized persons have no access

•For persons with a pacemaker or defibrillator, despite compliance with all European directives and standards on

electromagnetic compatibility, no statement can be made regarding the suitability of use, maintenance or repair work

of the charging station. Please contact the manufacturer of the defibrillator or pacemaker for further information.

•Improper use can cause serious injury or death, as well as destroy the vehicle or the charging station

•Wallbox ALPHA DUO with RFID module and RS 485 interface

•Key

•Jumper, pre-assembled

•Instruction manual

•Drilling template

•Fastening material, consisting of:

1x mounting lug left

1x mounting bracket right

8x self-tapping screws for mounting straps

•2 pieces RFID card (more cards available - NRG9003)

Check the scope of delivery for completeness.

4

ALPHA –NRG1006

Charging power mode 3 [kW] per

output

Charging power mode 3 [kW] total

3.7 (1-phase) / 11 (3-phase)

7.4 (1-phase) / 22 (3-phase)

Nominal voltage UN [V] 50Hz

230 (1-phase) / 400 (3-phase)

max. line protection [A]

20

Residual current

protection/disconnecting device

30

AC [mA]

6

max. current consumption [A]

(adjustable)

10, 13, 16, 20

max. charging current [A] per vehicle

16

Protection type

IP 65

Protection class

I

Impact resistance box

IK08

Number of charging ports

2

Charging port/coupling

Typ 2

Charging cable length [m]

5,5

Mounting location

Indoor, protected outdoor, no direct sunlight

Mounting type

Wall mounting, column mounting (optional)

Ambient temperature

-20°C to +40°C for connected load < 11kW

-25°C to +35°C with connected load > 11kW

Altitude

max. 2000m a.s.l.

Relative humidity [%]

max. 95 (non-condensing)

Dimensions [mm] (W x H x D)

299 x 425 x 180 (without coupling)

299 x 425 x 380 (with coupling)

Material

ABS, Aluminum

Weight [kg]

11

optionally available

NRG9000 - Stand with roof

NRG9001 - Roof for mounting in unprotected outdoor area

NRG9003 - RFID cards

NRG9004 - Wall cable holder

5

The wallbox may only be installed by a trained electrician.

Before installation, the device must be thoroughly checked for damage.

The wallbox is only suitable for vertical installation.

The box may be mounted indoors or in protected outdoor areas, such as under canopies. The ambient temperature at the

installation site must be in the range of -20°C to +40°C. The wallbox must be mounted away from easily flammable parts.

Sufficient ventilation must be ensured during operation. The mounting location must be selected so that the connected charging

cables cannot come into contact with water. To prevent the ingress of water, the proper fit of the cover and the tight fit of the

cable glands must be checked after installation.

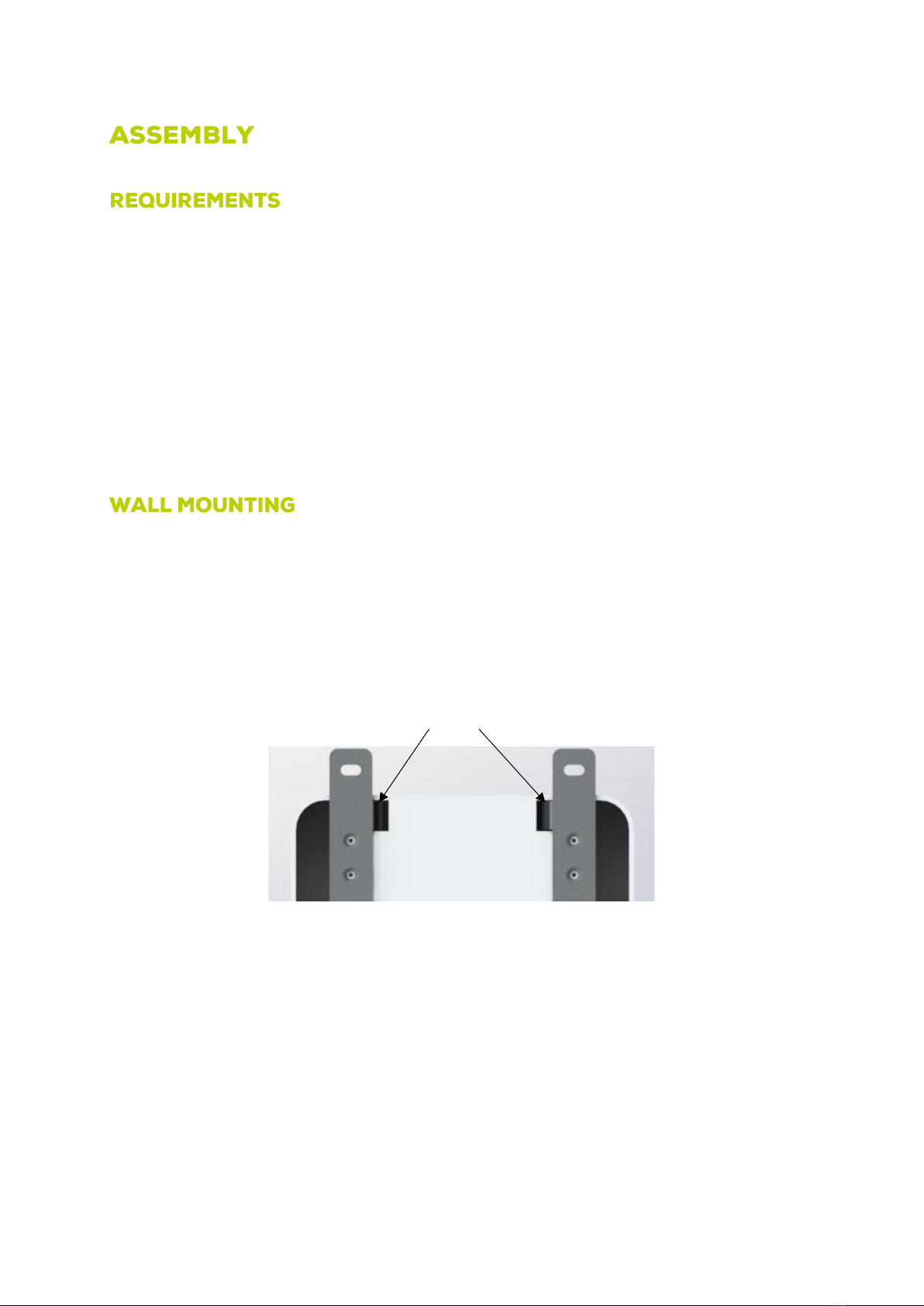

1. The enclosed mounting plates (left/right) are to be mounted on the back of the wallbox with four self-tapping screws

each. Make sure that the beveled tabs are oriented towards the center of the housing (cf. Figure 1).

2. The drilling distances for wall mounting are to be transferred to the wall with the aid of the enclosed drilling template.

3. Drill holes in the wall.

4. Insert four dowels (not included in the scope of delivery) according to the wall condition.

5. Screw the two lower screws into the dowels and place the wallbox on the screws using the screw holes.

6. Screw the upper screws into the dowels, align the wallbox and finally fasten it using the total of four screws.

Figure 1 Arrangement of the mounting plates

The next step is the electrical connection of the wallbox.

Straps

6

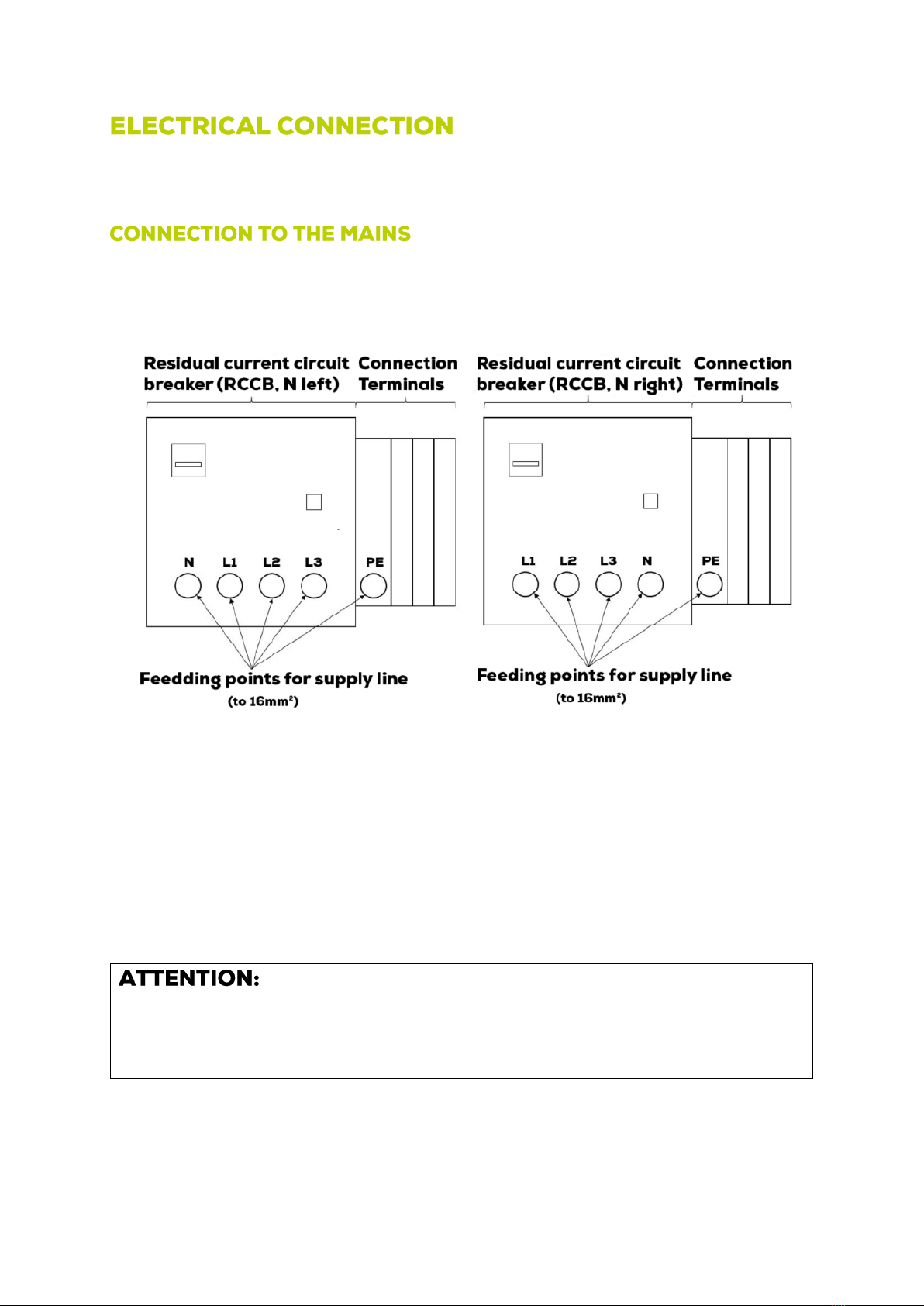

The supply line of the wallbox must be disconnected from the power supply during installation work.

The supply line must be correctly fused.

1. Pull the supply line into the box

2. Connect the supply line as shown in Figure 2 and then relieve the strain and seal it using the cable gland.

Figure 2 Connection position of the supply line

Check the electrical connection and voltages using a measuring device.

Also make sure that neutral (blue) and ground (PE, yellow/green) are connected correctly.

The sequence of L1, L2, L3, N may differ depending on the type. Please observe the imprint next to the connection terminals.

Switch off the RCD during insulation resistance tests (according to DIN VDE 0100-600) to avoid

damage to the electronics!

7

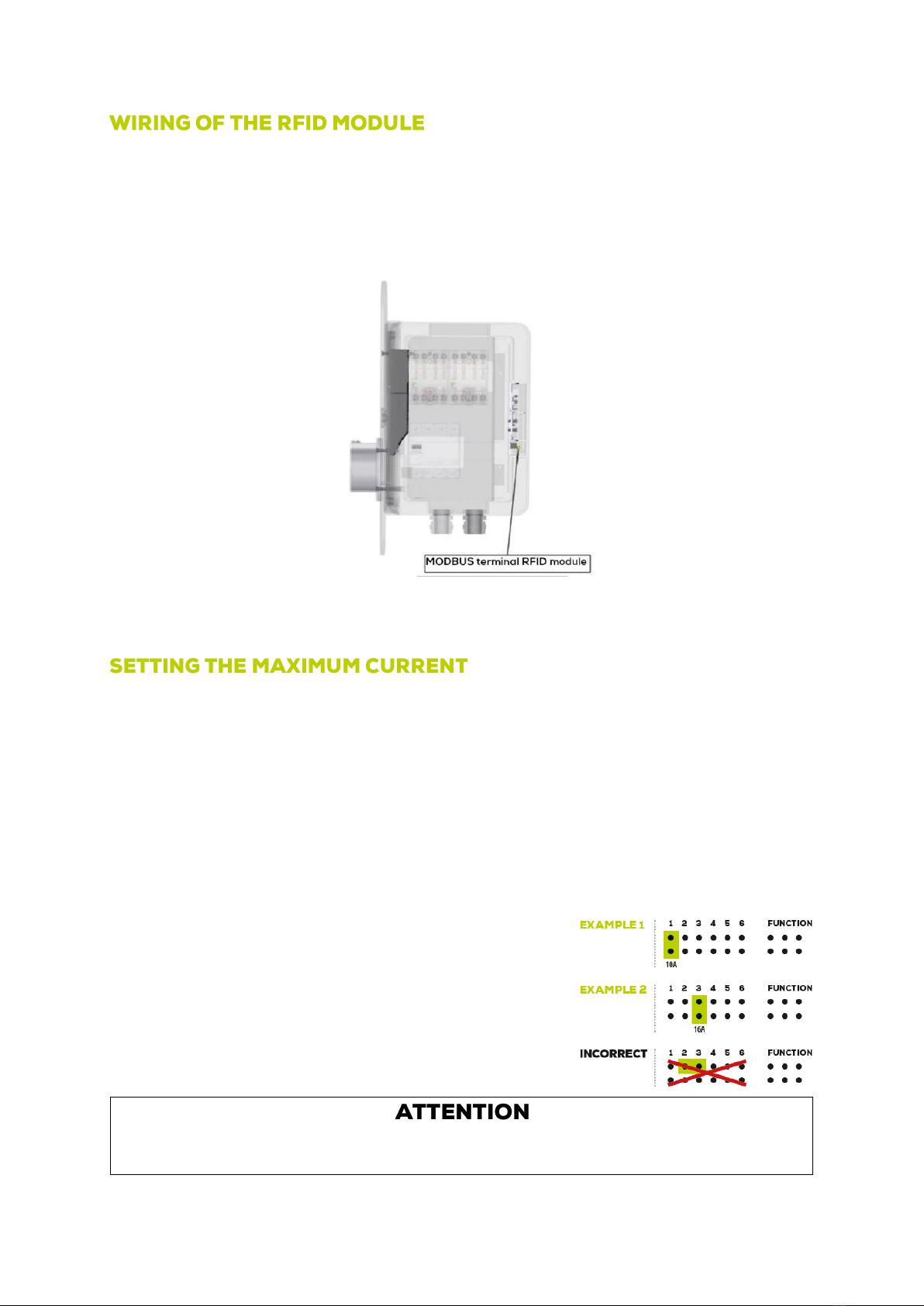

When using RS485, a double line with a characteristic impedance of 120 Ohm must be used. Since this is a data bus, it must be

terminated with a resistor at the end or beginning. This can be done with the resistor pre-mounted in the interface or with the

termination functions of other Modbus accessories. When using our PCC, it must always be mounted at the beginning or end of

the bus as it has an integrated termination resistor. The GND connection must be carried on a separate wire (or pair of wires) in

the cable to avoid interference effects.

Figure 3 Modbus cable connection

It should be noted that the loading speed depends mainly on two factors:

1. amount of the maximum power output of the wallbox.

2. maximum charging power of the electric vehicle

Preferably, the wallbox should be connected with three phases.

Before commissioning, the maximum current that the wallbox draws via the supply line must be set using the enclosed jumper

on the control board.

When setting the maximum current, it must not be higher than the fuse or the cable cross-section and the length of the supply

line allow.

The setting is made by plugging the jumper into the corresponding position on the

control unit. The slots on the control unit can be found by means of the inscription

"I max". The assignment of the slots is shown in the following tables:

Slot 5 to 8 are not to be used!

8

By setting an additional jumper to FUNCTION 1, simultaneous loading of the vehicles is prevented. Loading now takes place one

after the other. The vehicle that first makes the request to load is served first. The second vehicle can only be charged after the

charging request has been dropped.

1 Car 1 Car 1 Car

(1Ph supply line, 1Ph

car)

(3Ph supply line,

2Ph car)

(3Ph supply line,

3Ph car)

1 10 A 1,5 mm² 2,3 kW 2,3 kW 0,0 kW 4,6 kW 4,6 kW 0,0 kW 6,9 kW 6,9 kW 0,0 kW

2 13 A 1,5 mm² 3,0 kW 1,6 kW 1,4 kW 6,0 kW 3,2 kW 2,8 kW 9,0 kW 4,8 kW 4,2 kW

3 16 A 2,5 mm² 3,7 kW 1,8 kW 1,8 kW 7,4 kW 3,7 kW 3,7 kW 11,0 kW 5,5 kW 5,5 kW

4 20 A 4,0 mm² 3,7 kW 2,3 kW 2,3 kW 7,4 kW 4,6 kW 4,6 kW 11,0 kW 6,9 kW 6,9 kW

*After the end of the charging process, the power at the other connection point corresponds to the charging power with only one vehicle.

Nominal values with tolerance +-10%

(1Ph supply line,

1Ph car)

(3Ph supply line,

2Ph car)

(3Ph supply line,

3Ph car)

Position connector

(Jumper)

Current raiting

Min. cross section

supply line

1-PHASE LOADING

2-PHASE LOADING

3-PHASE LOADING

2 Car

2 Car

2 Car

Before commissioning, check that the jumper is seated correctly.

No settings are required to divide the charging current between two vehicles. The charging current is regulated by the controller.

Due to increased cable length of the supply line, it may also be necessary to compensate for the resulting voltage drop by using

a larger cable cross-section.

1. Before commissioning the wallbox, all vehicles must be disconnected from the system.

2. Turn on the fuse in your house power box.

3. Turn on the RCD switch located in the box.

The microcontroller now starts automatically. Within 2 seconds, the box reports the preselected settings by flashing all

LEDs. The number of flashes indicates the presetting. For example, if the LEDs flash ten times, the presetting is 10A.

After successful commissioning, the red LED on the control board goes out. The green LED, on the other hand, lights up

permanently.

4. The door must be locked with the enclosed triangular key.

If the red LED remains permanently lit, there is a fault in the system.

In this case, the wallbox must not be put into operation.

9

This charging station is suitable for electrically charging one or two vehicles with type 2 charging couplings.

By programming an RFID card (see "Programming RFID cards"), charging is only possible for authorized persons. If no RFID card

is programmed, the wallbox is freely accessible.

Pay attention to your safety when operating inside the wallbox and do not touch any live components. Also observe the

operating instructions for your electric vehicle.

The wallbox is equipped with a separate LED indicator light for each charging cable, which shows the current status during

operation. From software V12 (see door inside)

green

No vehicle connected, wallbox ready for operation

blue

Box unlocked via RFID module

yellow

Vehicle connected, waiting state, charging process completed

green, slowly flashing

Vehicle is charging (more than 16A available)

red, flashing

Charging cable has short circuit, plug very dirty

red, 2x flashing

CP signal not stable, connector dirty

red, 3x flashing

Diode in vehicle defective, plug dirty

3 seconds flashing pink

RFID card not known / all RFID cards successfully deleted

3 seconds white

RFID card was taught

yellow flashing

Total power of the box limited via digital interface

light blue flashing

Power of a charging point limited via digital interface

red luminous

DC fault current >6mA, fault current sensor error or

connection error (from V12 restart of ALPHA required)

red and yellow flashing (from V12)

Ventilation requested by the vehicle therefore no charging

allowed

The LED indicator lights also show the preset current consumption every time the box is restarted.

10

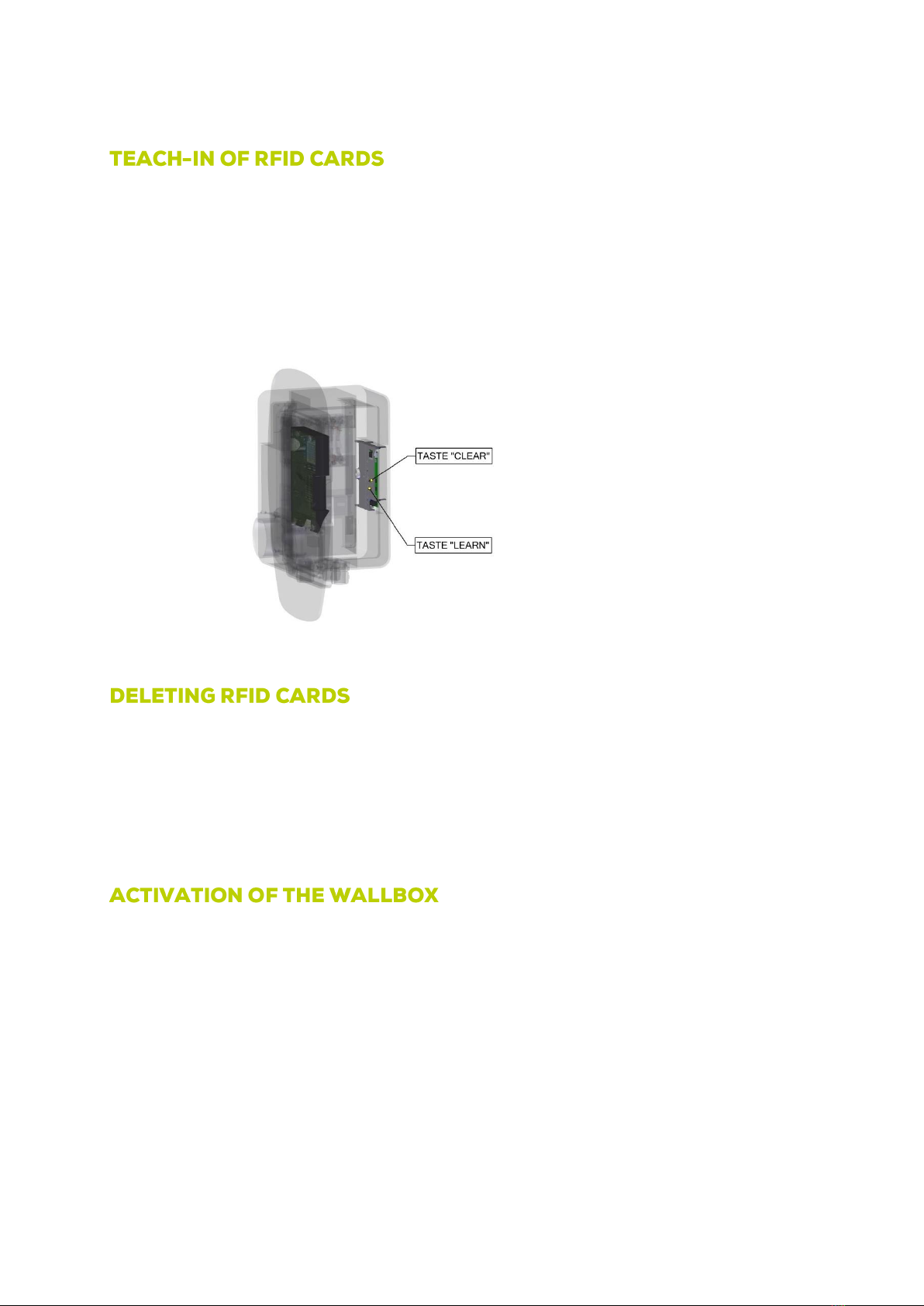

To use the RFID module, it is necessary to teach in at least one RFID card.

RFID cards are taught as follows:

1. Open the wallbox with the key provided for this purpose.

2. Press and hold the Learn button on the RFID module and place the card to be learned on the right outside of the

wallbox. (see Figure 4) A taught-in RFID card is signaled by a white status LED of the wallbox. In this way, up to 100

RFID cards, possibly also from third-party suppliers, can be taught.

Figure 4 Control panel of the RFID module

Note: It is not possible to delete individual RFID cards. The deletion process removes all previously taught-in cards.

1. First open the wallbox with the key provided for this purpose.

2. Start the deletion process by pressing and holding the Clear and Learn buttons on the RFID module until the LED

indicator flashes pink. The memory has been successfully deleted. This process can take up to one minute. (see

Figure 4)

3. Lock the wallbox.

There are two ways to start the charging process or to unlock the wallbox.

Option 1

1. Place a taught-in RFID card on the right-hand outside of the wallbox.

The wallbox signals the unlocking by a blue LED display.

2. Establish the connection between the wallbox and the vehicle to be charged within 30 seconds.

Option 2

1. First connect the wallbox to the vehicle to be charged.

2. Then unlock the wallbox by placing the RFID card on the right-hand side of the wallbox. In this case, too, the blue LED

indicator signals that the wallbox has been successfully unlocked.

11

In both cases, the charging process starts automatically.

Charging points to which no vehicle is connected are locked by the wallbox after 30 seconds.

As long as the connected vehicle is in the waiting or charging state, the connected charging point remains unlocked.

After completion of the charging process, the charging point in use is also locked.

Connect your vehicle to the wallbox.

As soon as the electric vehicle is ready for charging, the charging process starts automatically.

After successful charging, the vehicle ends the charging process automatically. Overcharging" is therefore not possible.

If two vehicles are charged at the same time, the wallbox regulates the available power. For example, the charging current is

divided between the two vehicles. If the charging process of one of the two vehicles is completed, the charging power of the

vehicle still charging is automatically increased.

Note: The time-delayed allocation of the charging current is not supported by all electric vehicles.

A charging current of at least 6A is required for each vehicle to be charged.

If the wallbox has been configured for a low charging current, this may mean that both vehicles cannot be charged at the same

time. In this case, the two connected vehicles are charged one after the other (sequentially).

If the charging process of the second vehicle does not start automatically, it may be necessary to disconnect the vehicle from the

system for a short time first. After reconnection, the charging process starts.

As a preventive measure, observe the connection sequence to the box. First connect the vehicle that does not support sequential

charging. Only then connect the second vehicle (sequential charging is supported by this one).

To restart the box, first disconnect all vehicles from the system.

Switch off the internal FI of the wallbox for 5 seconds.

After switching on the voltage, the microcontroller of the box restarts automatically.

Within 2 seconds, the box reports the preselected setting by white flashing of the LEDs, for example, 10 flashes signal a preset of

10 amps.

12

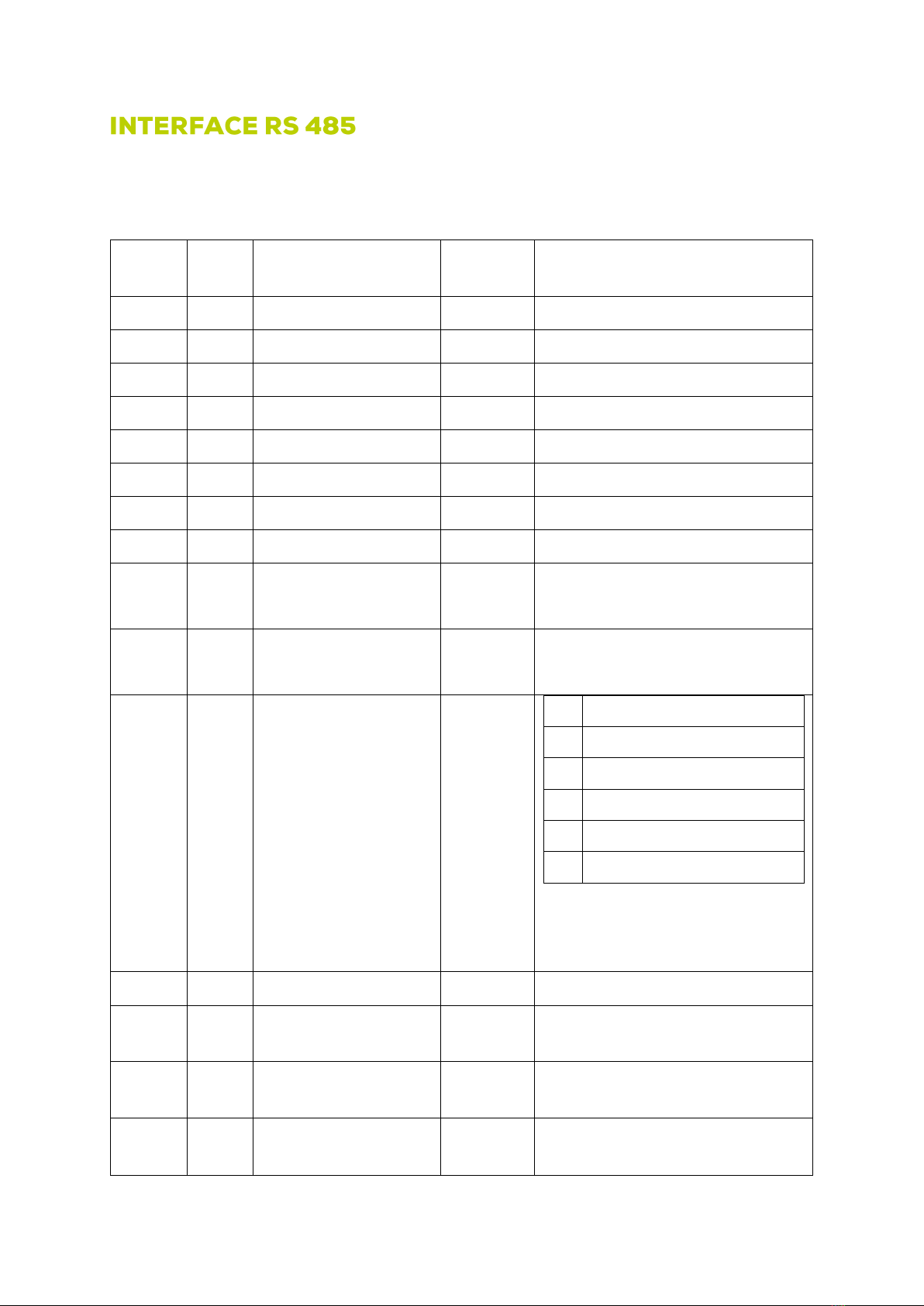

The RS 485 interface communicates with Modbus RTU, 9600 baud, 8 DATA bits, 1 stop bit, parity none, slave ID 1, unsigned

integer 16bit (UINT16, internal values 8 bit). The timeout is less than 2000ms.

Register type 40XXX read and write, register type 30XXX read only.

Modbus

address

Modbus

register

Initial value

Values type

0

40001

Modbus ID

1

1

40002

Modbus baud rate

96

(corresponds to 9600)

2

40003

max. current total limit

255

in A (values below 6 A lead to shutdown)

3

40004

max. current KFZ1 limit

255

in A (values below 6 A lead to shutdown)

4

40005

max. current KFZ2 limit

255

in A (values below 6 A lead to shutdown)

11

30012

Allocated current KFZ1

0

in A

12

30013

Allocated current KFZ2

0

in A

74

30075

taught RFID cards (number)

255

100

30101

Software version RFID and

Modbus module

255

Decimal value Software version

(D3 -> "3")

101

30102

Software version motherboard

255

Decimal value Software version

(V3 -> "3")

102

40103

Release register charge points

1

Share all

2

Lock all

11

Enable charging point 1

21

Lock charging point 1

12

Enable charging point 2

22

Lock charging point 2

Automatic locking takes place ~30 seconds after

release!

(Register available from software D2)

103

30104

Temperature in the box

255

(value register -72)*0.4244= Temp in °C

106

30107

Status KFZ1

255

0 no car, 1 car connected, 2 charging request, 3

charging request with fan, 4 short circuit

107

30108

Status KFZ2

255

0 no car, 1 car connected, 2 charging request, 3

charging request with fan, 4 short circuit

114

30115

Set charging current Supply

line

255

Value in A of the jumper position

13

115

30116

Set charging current Supply

line after corrections

Temperature and setting

255

Value in A that is available for all connected

vehicles in total.

116

30117

Lock status display

0

0

(0b00)

Box released

1

(0b01)

Charging point 1 locked

2

(0b10)

Charging point 2 locked

3

(0b11)

Both charging points locked

Information about RFID cards can be requested depending on the software version at support@pracht.com.

In the event of a defect, please contact the manufacturer directly.

Before cleaning, the wallbox must be disconnected from the power supply for safety reasons.

Dirt can be removed with a damp cloth.

The use of harsh cleaning agents is not permitted.

The wallbox must not be cleaned with a water jet or high-pressure cleaner.

Disposal of the packaging material is carried out via the collection containers for paper and plastics provided for your region.

The disposal of old devices and their accessories is carried out in accordance with the national and regional regulations for the

disposal of electrical and electronic devices. Accordingly, these must not be disposed of with household or bulky waste.

14

No function of the wallbox (LEDs extinguished).

•Check the fuses in the house distribution.

•Check the residual current circuit breaker (FI) in the house

distribution.

•Check the internal fuses.

•Check the internal residual current circuit breaker (FI).

Wallbox no longer responds.

•First disconnect all vehicles from the system. Then restart

the wallbox.

The wallbox signals a fault (red LED display).

•Disconnect the connection to the vehicle.

•Check the charging coupling and charging cable for possible

damage.

•In case of damage, disconnect the box from the power

supply and repair it.

•Check the contacts of the charging coupler for dirt. To do

this, disconnect the box from the power supply.

•After repair or cleaning, the wallboxcanbeconnected to the

mains. Once the fault has been rectified, the box is ready

for operation.

The vehicle suddenly charges with lower charging

current or briefly interrupts the charging process.

•The wallbox is equipped with thermal overload protection.

•From around 40°C outside temperature, the system

gradually reduces the maximum charging current.

•If the ambient temperature continues to rise, the wallbox

may switch off the charging process.

•As the outside temperature decreases, the wallbox

automatically continues the charging process.

The loading process was canceled.

•Restart the charging process. To do this, disconnect the

connection between the wallbox and the vehicle for 10

seconds.

PRACHT Industry GmbH

Am Seerain 3, 35232 Dautphetal-Buchenau, Germany

Tel. +49 6466 9140-900

info@prachtenergy.com, www.prachtenergy.com

Other manuals for ALPHA

2

This manual suits for next models

1

Table of contents

Other PRACHT Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction