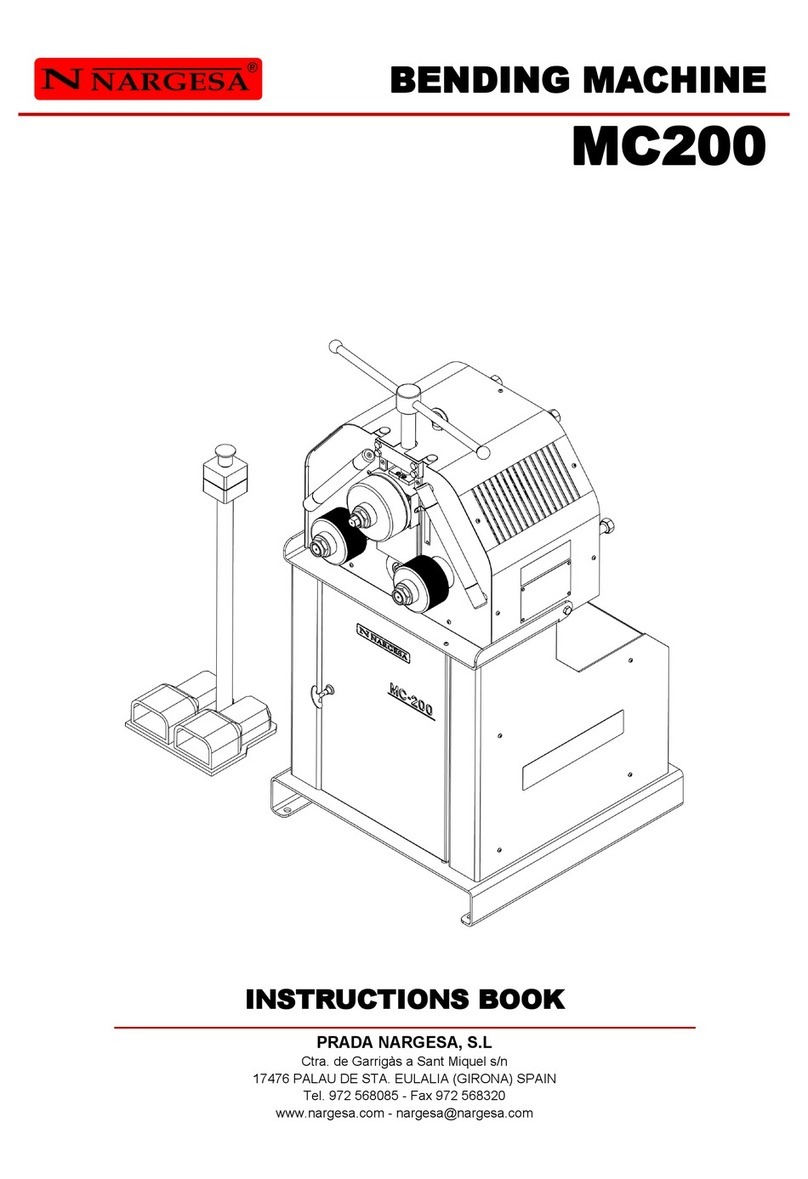

PRADA NARGESA CC90 User manual

INSTRUCTIONS BOOK

PRADA NARGESA, S.L

Ctra. de Garrigàs a Sant Miquel s/n · 17476 Palau de Santa Eulàlia (Girona) Spain

Tel. +34 972568085 · [email protected] · www.nargesa.com

NON-MANDREL TUBE AND PIPE BENDER

CC90

Thank you for choosing our machines

www.nargesa.com

CONTENTS

1. MACHINE DETAILS ………....................................................................................................... 3

1.1. Machine Identification………......................................................................................... 3

1.2. Dimensions ................................................................................................................... 3

1.3. Description of the Machine ........................................................................................... 3

1.4. Machine Parts ............................................................................................................. 4

1.5. General Characteristics ….......................................................................................... 5

1.6. Description of the Guards ............................................................................................. 6

2. TRANSPORT AND STORAGE ……....................................................................................... 7

2.1. Transport …................................................................................................................... 7

2.2. Storage Conditions ………..…………............................................................................ 7

3. MAINTENANCE ……................................................................................................................. 8

3.1. Greasing Moving Parts …........................................................................................... 8

4. INSTALLATION AND START UP ……….................................................................................. 9

4.1. Machine Location ….................................................................................................... 9

4.2. Dimensions and Work Area ......................................................................................... 9

4.3. Acceptable External Conditions .................................................................................... 9

4.4. Instructions for Electrical Connection .......................................................................... 10

5. INSTRUCTIONS FOR USE ..................................................................................................... 11

5.1. Assembling the Roller and Counter-Die ............................................................. 11

5.2. Assembling the Radius Arm …………………..……..…………….……………………... 13

5.3. Changing Rotation Direction ………………………………………………………………. 14

5.4. Control Panel .............................................................................................................. 16

5.5. Manual Mode .............................................................................................................. 17

5.6. Angle Correction ……….……………………………………………………..……………. 20

5.7. Radius Arm ………………………………………………………………………………….. 20

5.8. Part Counter ………………………………………………….…………………………...… 21

5.9. Rotation Direction …………………………..………………………………………………. 22

5.10. Adjustment Tables ……………………………………………………………………… 24

5.11. Automatic Mode …………………………………………………………………………... 26

5.12. Remote Service …………………………………………………………………………. 29

5.13. Import/Export Parameters, Materials and Programs ………………………………..… 30

5.14. Touchscreen Calibration ……………………………………………………………...….. 32

6. ACCESSORIES ....................................................................................................................... 33

6.1. Optional Accessories .................................................................................................. 36

7. TROUBLESHOOTING.............................................................................................................. 42

TECHNICAL ANNEXES

- 3 -

1. MACHINE DETAILS

1.1. Machine Identification

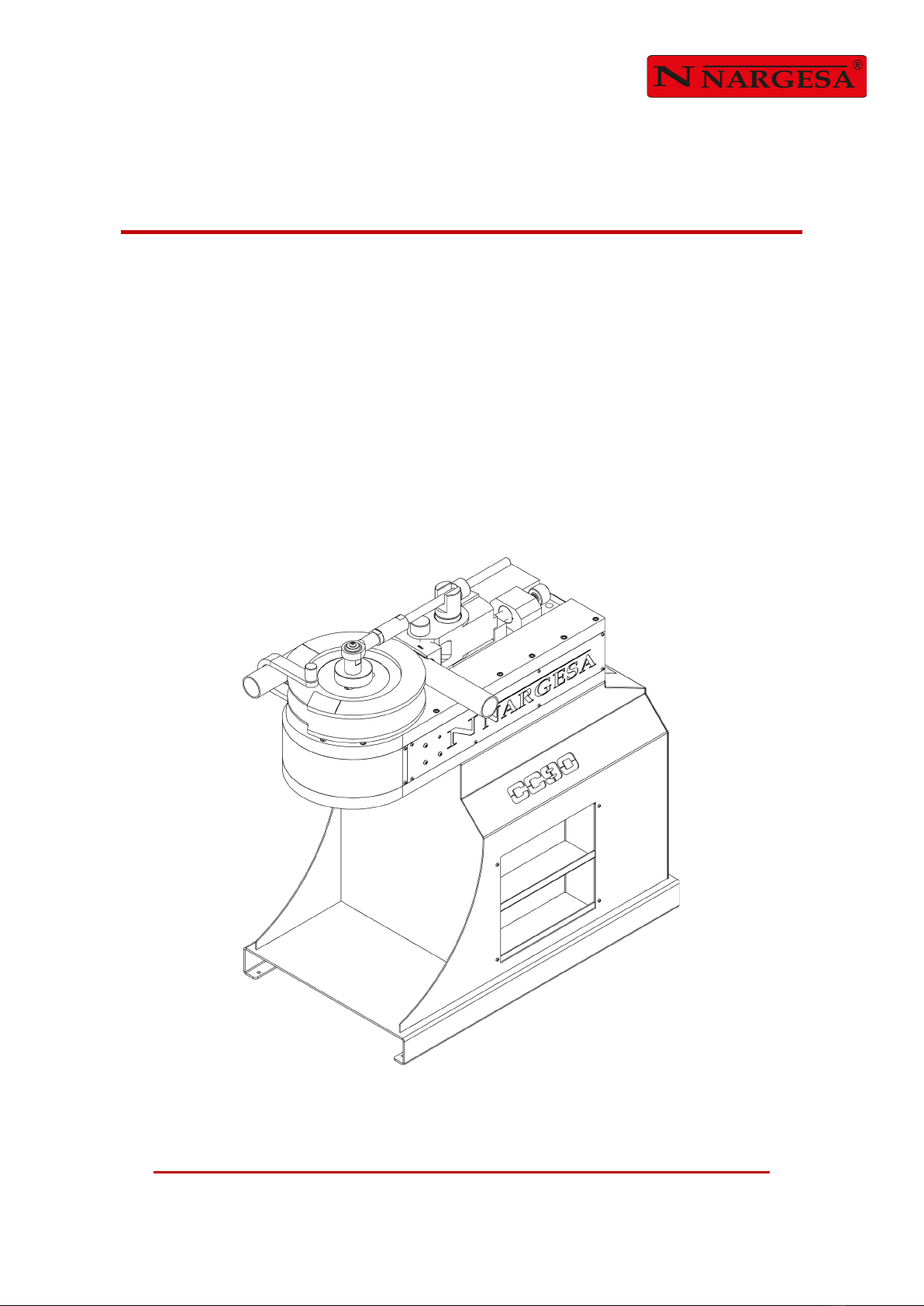

1.2. Dimensions

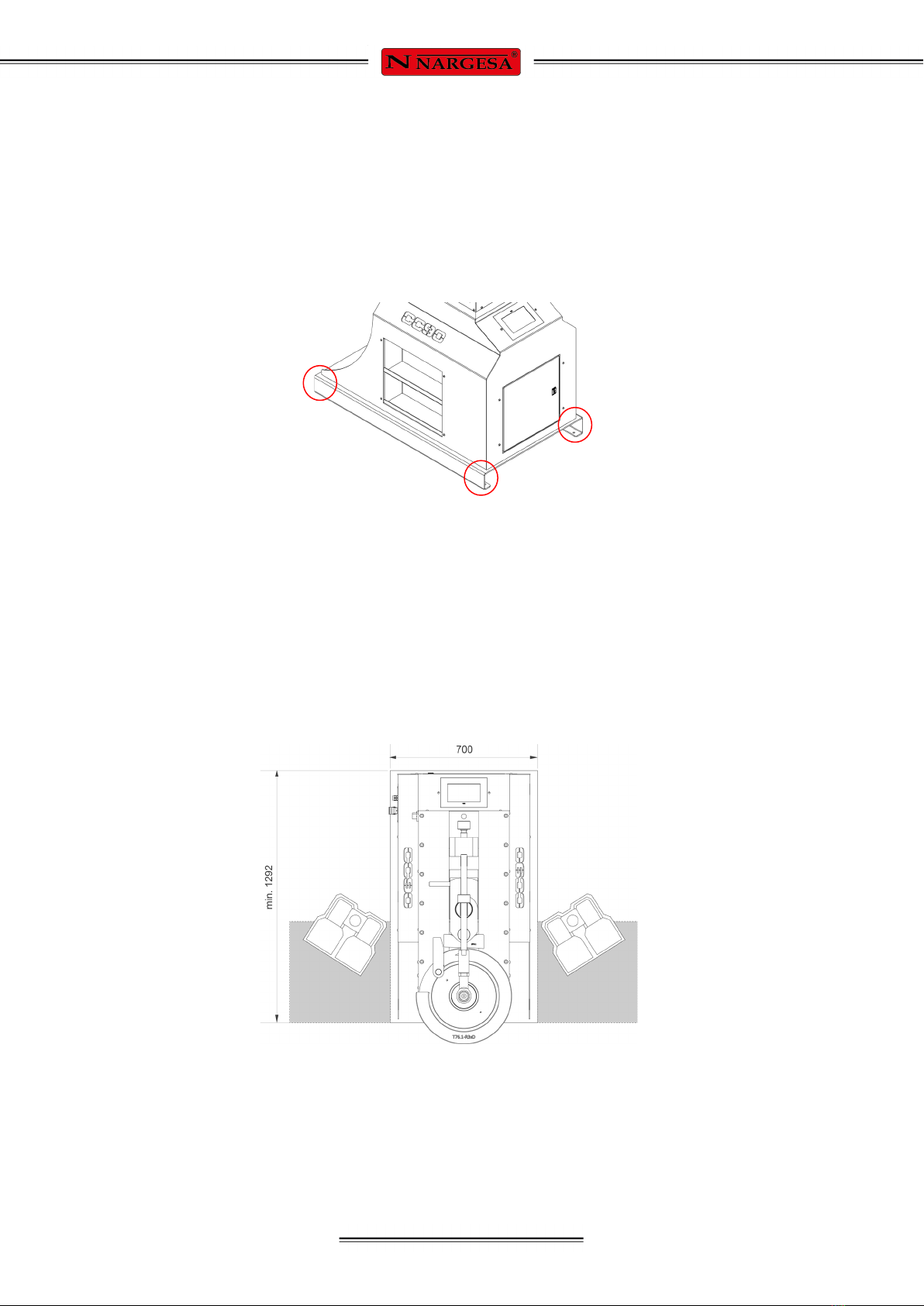

Figure 1. Outside Dimensions of Bender CC90

1.3. Description of the Machine

The non-mandrel pipe bender CC90 is a machine specifically designed to bend profiles, mainly metal ones,

of different thicknesses and configurations: pipes, solid profiles, T-profiles, angles...

The bender comes standard with a radius arm that must be used to bend thicker pipes of larger diameters.

Besides standard rollers, PRADA NARGESA manufactures different types of additional rollers for all types

of bending based on the configuration of the material to be worked.

PRADA NARGESA S.L. is not liable for any damages that may be caused due to improper use or

a breach of the safety rules by users.

Make NARGESA

Type Non-Mandrel Pipe Bender

Model CC90

- 4 -

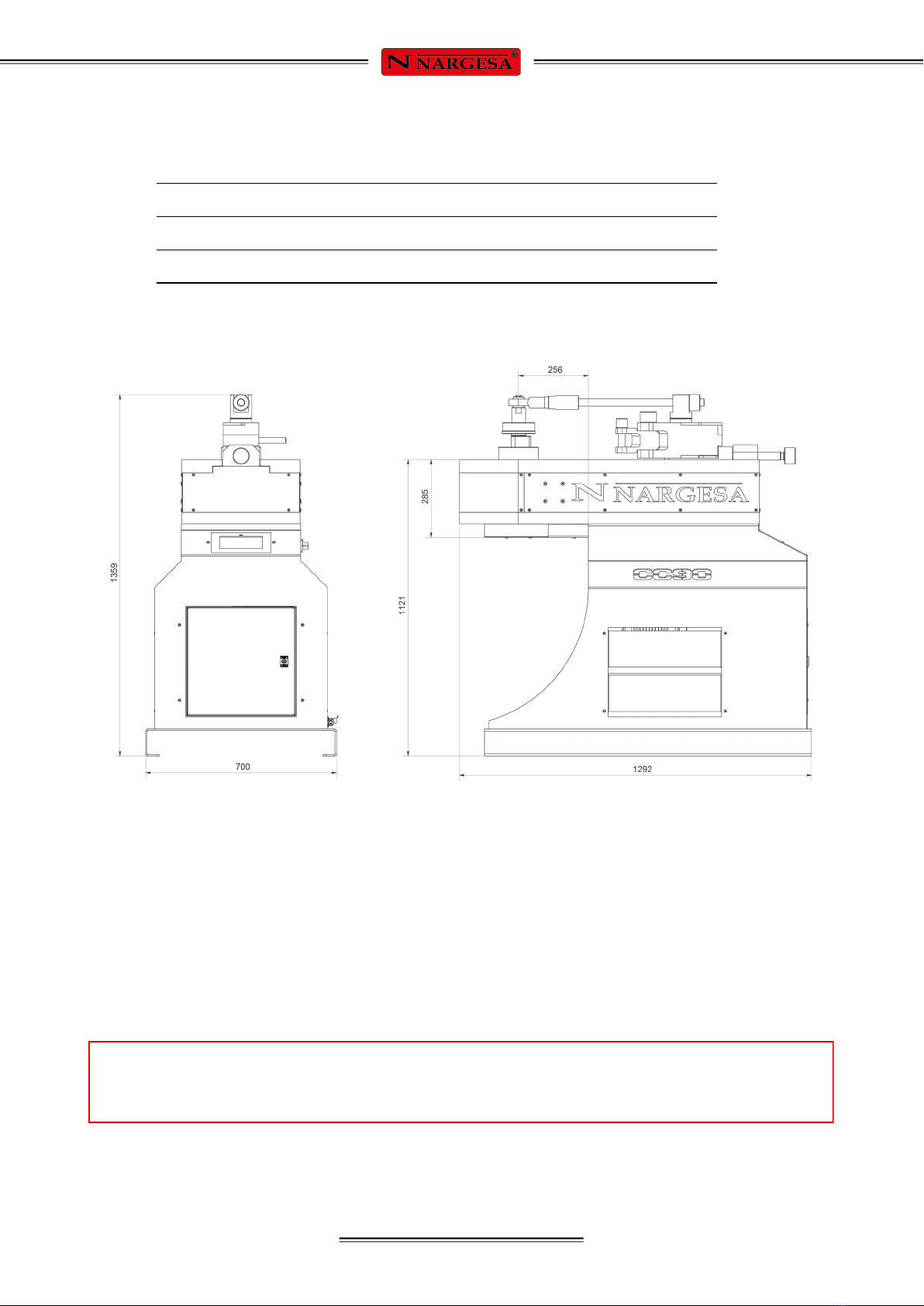

NON-MANDREL TUBE AND PIPE BENDER CC90

1.4. Machine Parts

Roller Radius arm

Spindle

Drag Clamp

Counter-die

Positioner

CNC Control

Shelving

- 5 -

Figure 2. Characteristics plate

1.5. General Characteristics

Reference 100-17-02-001

Engine power 2,2 Kw / 3 HP

Tension 230/400V 50/60Hz Three-Phase

230V 50/60Hz Single-Phase

Automatic rotation speed 0,7 to 1,8 r.p.m.

Intensity 9/5 A

Minimum radius of curvature 3 times the pipe diameter

Maximum radius of curvature 375 mm

Max. cap. round steel pipe 88,9mm or 3" Schedule or 3" 1/2 x 6mm.

Max. angle of curvature 180º

Dimensions 700x1292x1359 mm

Weight 965 Kg

- 6 -

NON-MANDREL TUBE AND PIPE BENDER CC90

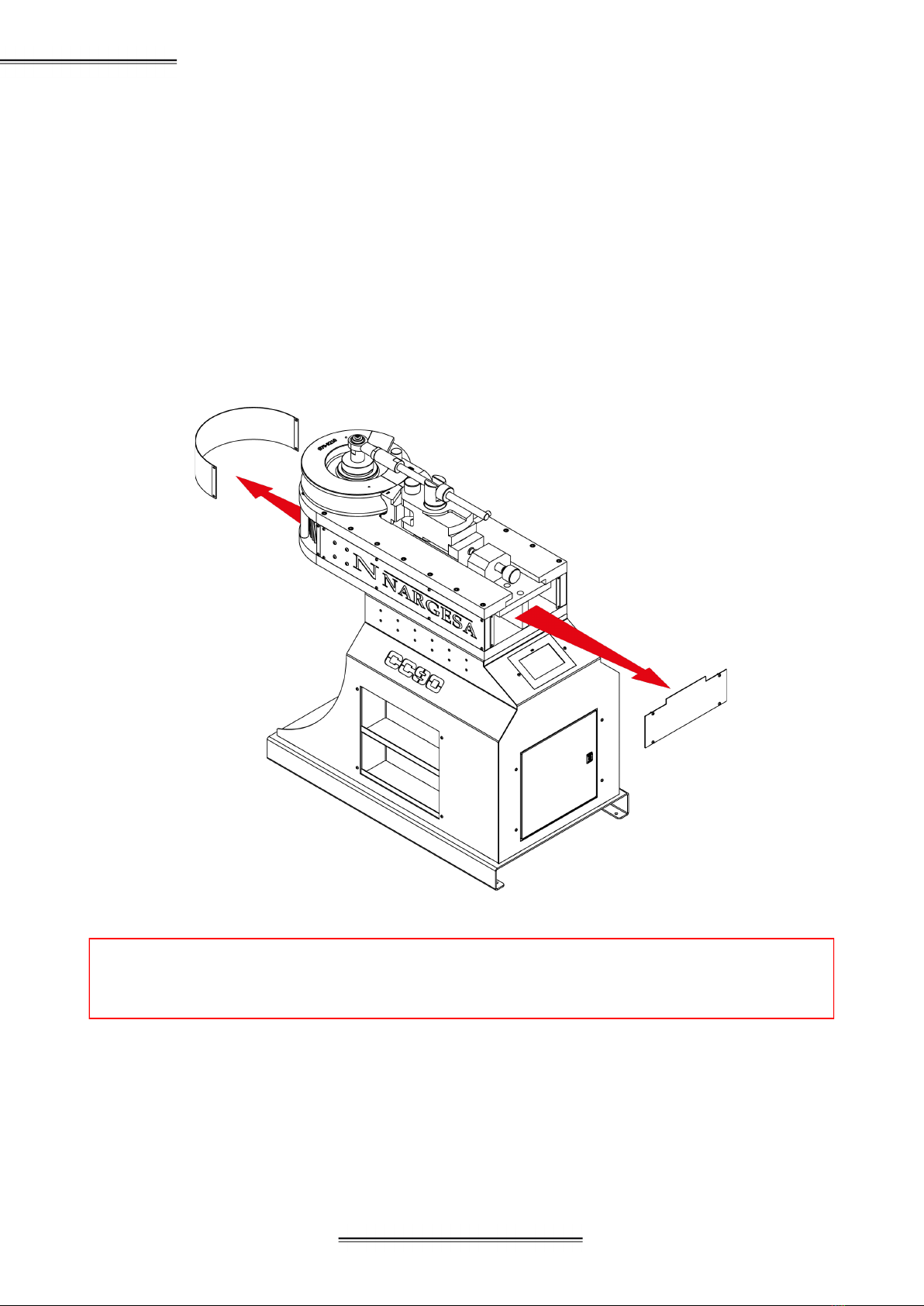

1.6. Description of the Guards

The gear box and all the gears enabling the machine to operate are inside the main structure which pro-

tects the mechanisms.

Despite the fact the main moving parts are protected by the front cover, special precaution must be taken

when bending to prevent entrapment between the die, counter-die and part.

Figure 3. Mechanism Protection Guards

Front guard

Rear guard

- 7 -

2. TRANSPORT AND STORAGE

2.1. Transport

The machine should be transported as follows:

- Along the bottom at the base of the machine using a forklift or lift truck as indicated in the illustration.

Never raise the machine more than 200 mm off the ground or it may tip over.

Figure 4. Moving the machine

2.2. Storage Conditions

The pipe bender may not be stored anywhere that does not meet the following requirements:

- Humidity of 30% to 95%

- A temperature of -25ºC to 55ºC or 75ºC over periods not to exceed 24 hours (please remember these

temperature are for storage conditions)

- Do not pile machines or place any heavy objects on top

- Do not dismantle for storage

- 8 -

NON-MANDREL TUBE AND PIPE BENDER CC90

ATTENTION: To grease the machine, you must stop the machine and press the “Emergency Stop”

button.

3. MAINTENANCE

3.1. Greasing the Moving Parts

Keeping the moving parts on the machine clean whenever possible is recommended to ensure proper

operation and extend the service life.

To grease the pinions on the CC90, do as follows:

- Remove the front guard and rear guard to access the pinions.

- Apply grease to the teeth of the pinions using a brush or spatula.

- Distribute the grease evenly without creating any excess or accumulation.

- Grease the machine periodically depending on the use. Recommended by the manufacturer: once a year.

- 9 -

4. INSTALLATION AND START UP

4.1. Machine Location

Try to position the machine in the proper location so that it does not have to be moved; otherwise, following

the steps described in the transport section (no. 2). Position over a smooth, level surface to prevent vibra-

tions and movements during bending operations.

The machine can be secured with bolts as it comes with a base or pedestal on the bottom with four holes

as shown in the following figure.

Figure 5. Anchoring points on the machine

4.2. Dimensions and Work Area

Take the dimensions, operator work area and the lengths of any materials to be worked into consideration

when positioning the machine.

The pipe bender may be used by a single operator who must stand on one of the two sides of the machine

to control the materials during processing.

Before starting the bending process, the operator shall adjust the roller and counter-die to the material

while the machine is off.

Figure 6. Operator’s work area

4.3. Acceptable External Conditions

- A room temperature of between +5 ºC and +40 ºC without exceeding an average temperature of +35 ºC

over 24 hours.

- Moisture between 30% and 90% without water condensation.

- 10 -

NON-MANDREL TUBE AND PIPE BENDER CC90

The pipe bender CC90 is equipped with a 230 V 1.1 kw engine for operation with the Roller. The machine

must be connected to 220 V compatible supply voltage compliant with the requirements specified.

IMPORTANT

This machine must be connected to an earthed socket.

Before making any change in the wiring or the electric panel,

you need to make sure the machine is not connected to the power supply system.

4.4. Instructions for Electrical Connection

- 11 -

5. INSTRUCTIONS FOR USE

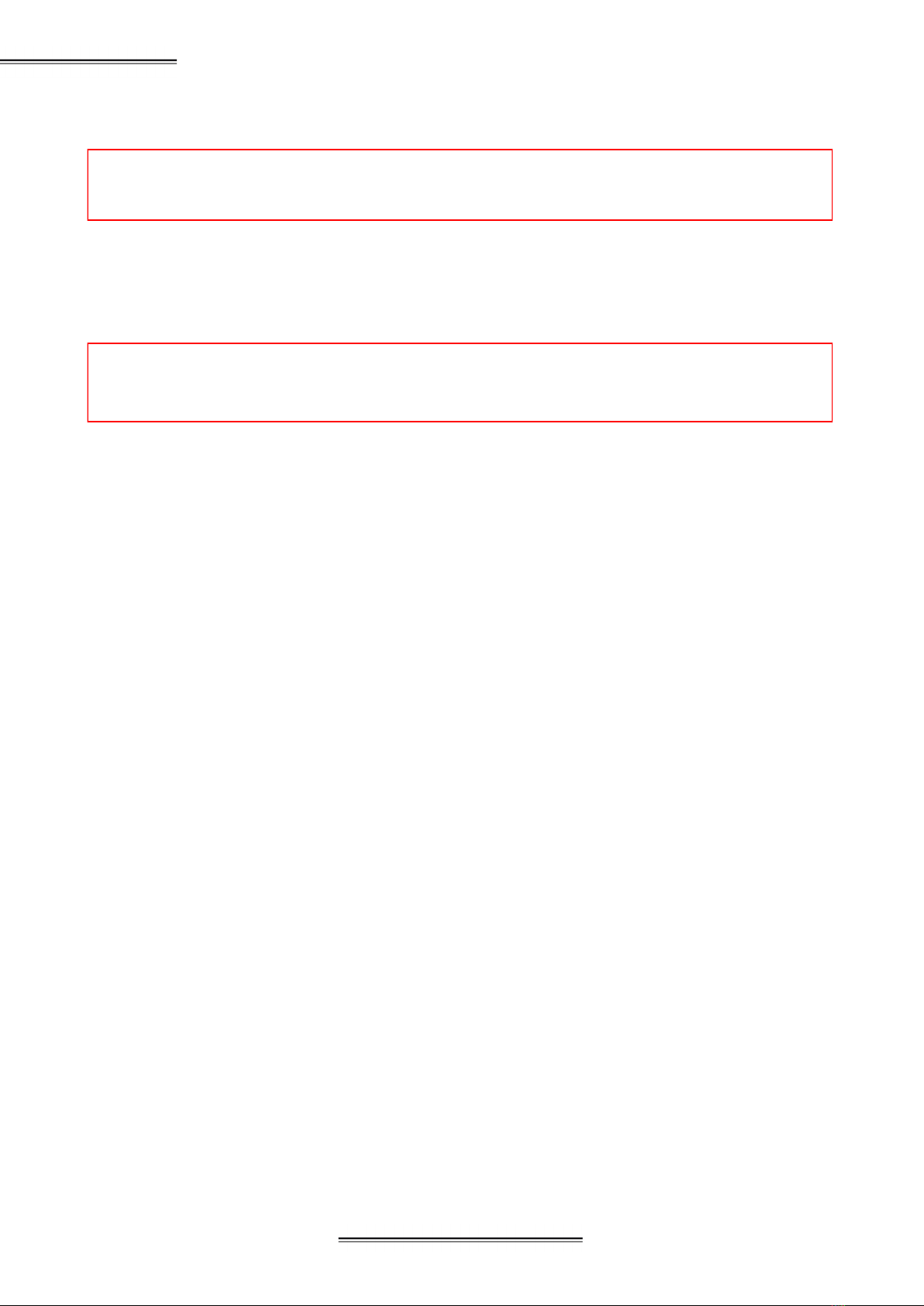

5.1. Assembling the Roller and Counter-Die

The roller shall be assembled as follows:

1. Place the roller in the machine axis. The built-

in centring pin will prevent an incorrect position.

2. Secure the roller with the washer and screw.

3. Put the counter-die or support rollers in the

positioner and secure.

4. Put the material in the roller guide and

secure to the drag clamp.

- 12 -

NON-MANDREL TUBE AND PIPE BENDER CC90

5. Lubricate the pipe and the counter-die with

BEND8 spray.

7. Secure the positioning spindle with your

hands to the machine table.

6. Slide the counter-die positioner until adjusted

to the material.

- 13 -

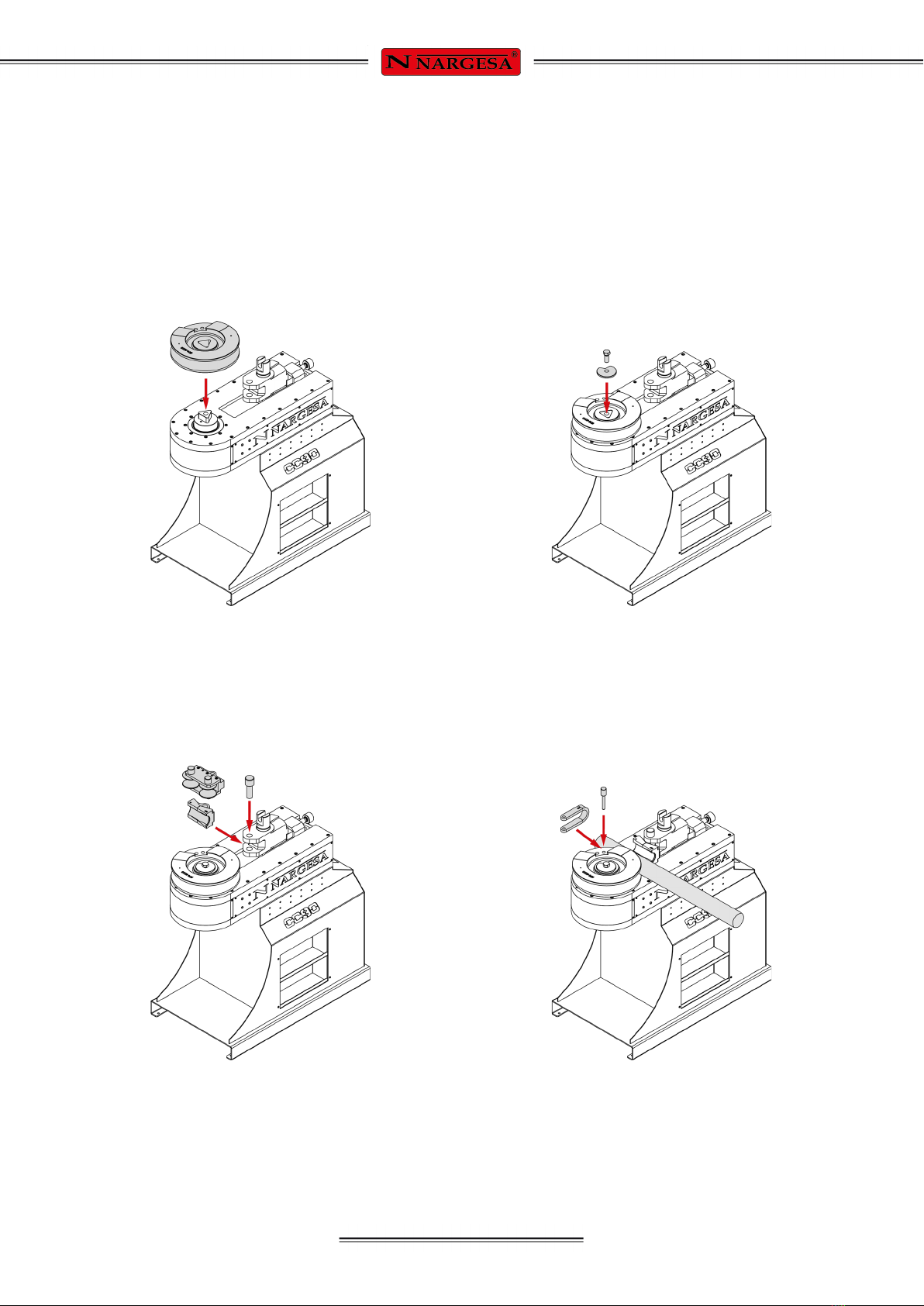

2A. Secure the roller with the radius arm. 8. Place the radius arm in the positioner

channel and adjust the nut with your hands

until secure and fixed.

5.2. Assembling the Radius Arm

If the radius arm must be used, switch step 2 with 2A as explained below.

And follow step 7 with number 8 as explained below.

- 14 -

NON-MANDREL TUBE AND PIPE BENDER CC90

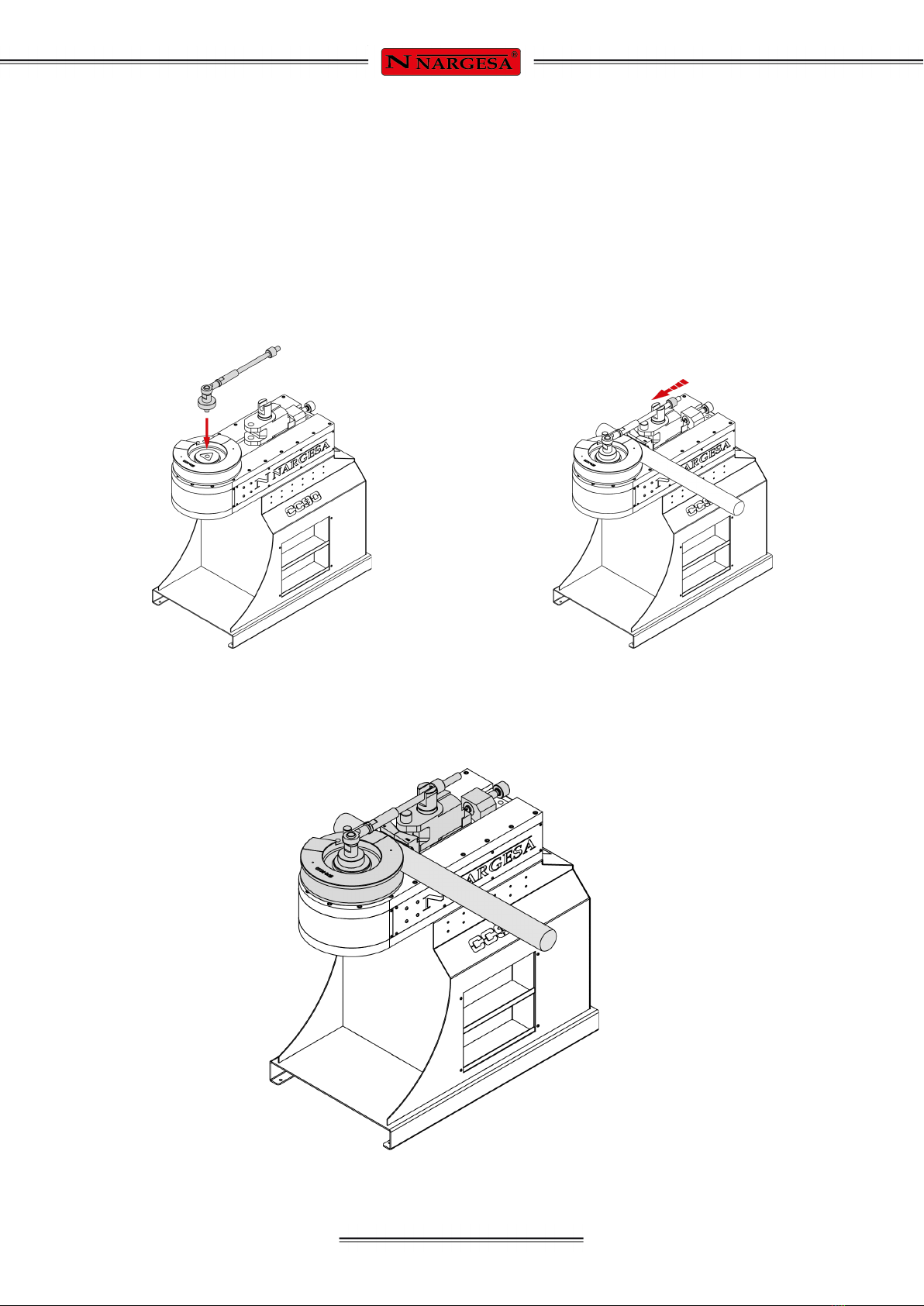

1. Remove the positioning spindle. 2. Remove the positioner and counter-die.

5.3. Changing the Rotation Direction

The non-mandrel pipe bender CC90 is programmed to rotate counter-clockwise. When the rotation direc-

tion must be changed, make the following position changes:

IMPORTANT

Remove the material from the machine to make this change.

3. Remove the drag clamp. 4. Remove the counter-die.

- 15 -

5. Position the roller with the CNC. See section

5.8. Rotation Direction.

6. Turn the positioner 180º degrees and insert it

back in the carriage.

8. Put the drag clamp back on.7. Rotate the counter-die 180º and secure with

the pin.

- 16 -

NON-MANDREL TUBE AND PIPE BENDER CC90

5.4. Control Panel

On

Automatic

Manual

Menu

Manual rotation to the right

Rotation direction to the left

Rotation direction to the right

Automatic unlocking

Manual rotation to the left

Diameter of the material

Roller Radius

Operating speed

Thickness of the material

Corrector

Part counter

Repetitions

- 17 -

5.5. Manual Mode

To turn on the machine, place the Start Switch in the Connected position. The initial interface appears on

the screen:

The machine is now in Standby; in other words, the machine is active yet at rest waiting for any operation

order.

The CC90 is already started and in Standby. To activate it, follow the steps indicated below.

Enter the following operating details:

- Diameter of the material

- Roller radius

- Thickness of the material

- Bending angle

Press each of the items on the screen to enter all these parameters.

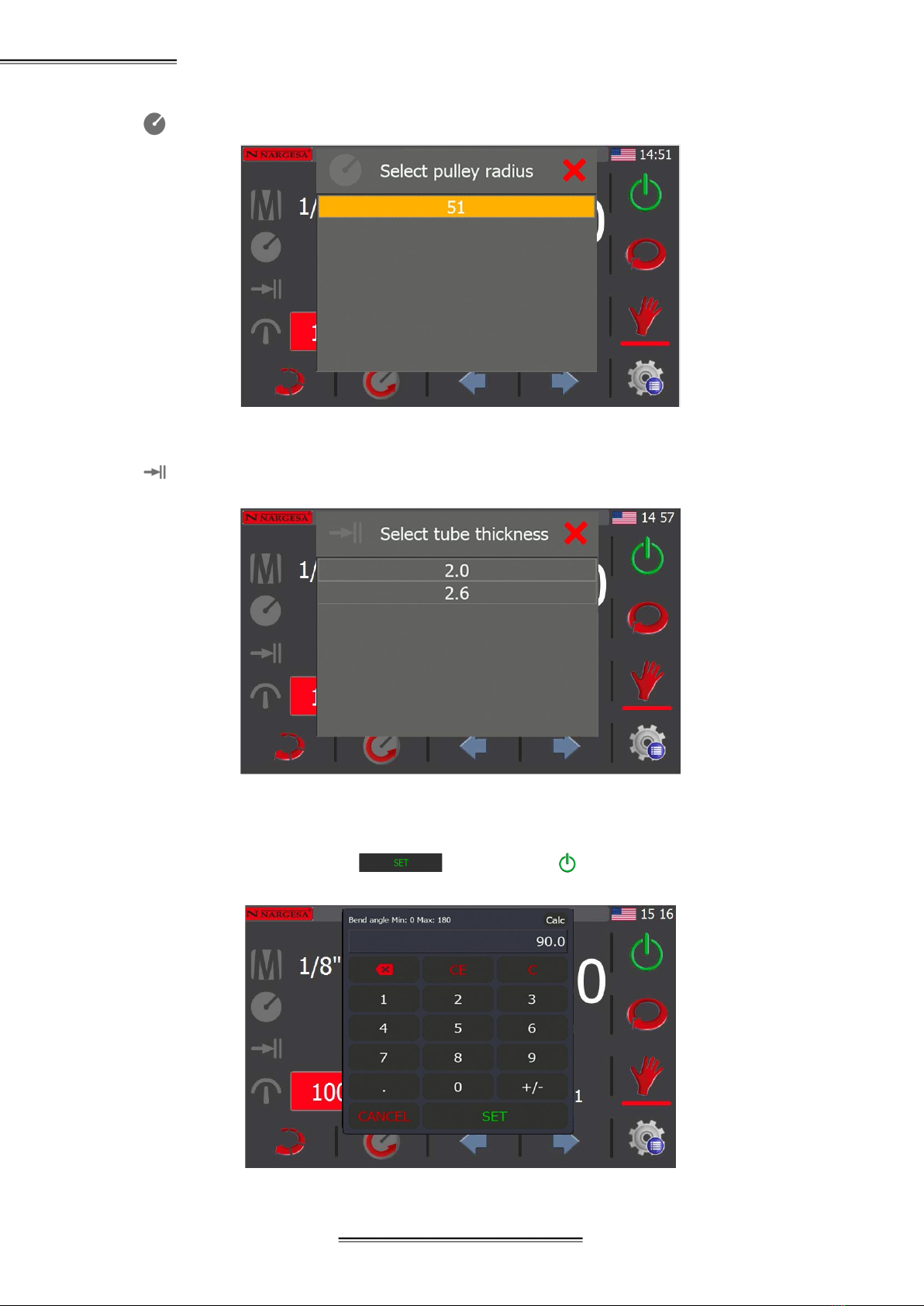

Press the key to choose the diameter of the material to be curved:

- 18 -

NON-MANDREL TUBE AND PIPE BENDER CC90

Press to choose the roller radius.

Press to choose the thickness of the material:

To determine the bending angle, press the number that appears at the top right of the screen and enter the

value; in this case, 90 degrees. Press to accept and to start the machine.

- 19 -

The machine will work at minimum speed based on the parameters entered.

If necessary, enable the automatic unlocking option by pressing the icon . This means the machine

will automatically unlock by rotating in the opposite direction of the bending a few degrees to unlock the

material. If it is not necessary, disable this icon.

Table of contents

Other PRADA NARGESA Construction Equipment manuals