SPARE BENDING FORMERS

OF DOUBLE FRAME OPEN BENDING

(For short radius heavy & thin wall thickness bending upto 180°)

PROD. I.D. O.D. RADIUS MIN.WALL N.W.T

NO. INCHES MM MM THICKNESS MM (Kgs)

225A 3/8 16.7 80 2.65 5.100

225B 1/2 21.0 80 2.65 5.000

225C 3/4 26.4 80 2.65 4.500

225D 1 33.2 110 3.25 9.500

225E 1.1/4 42.0 160 3.25 11.550

225F 1.1/2 47.8 160 3.25 12.000

225G 2 60.3 200 3.65 19.600

FEATURES

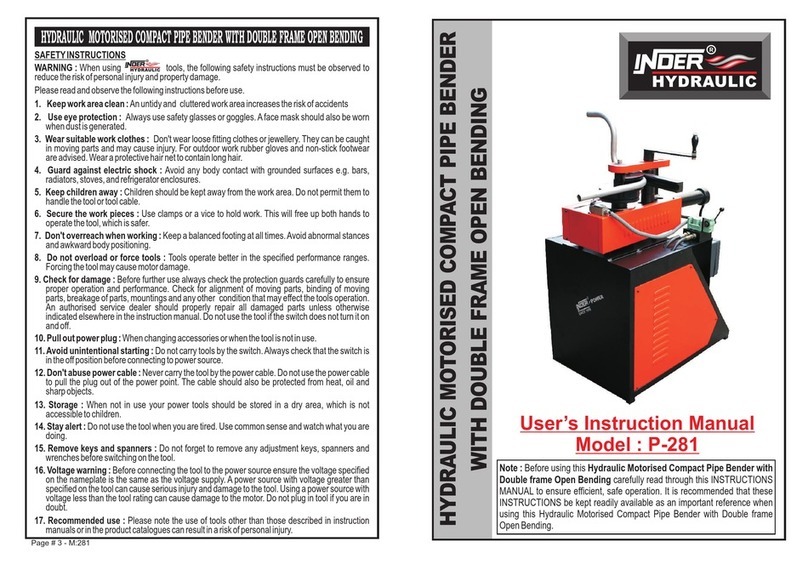

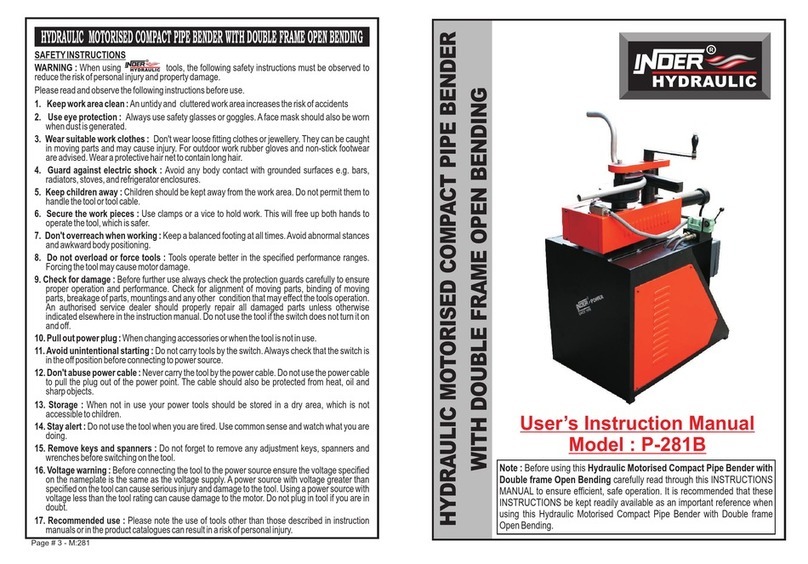

"INDER" HYDRAULIC MOTORISED PIPE BENDERS WITH DOUBLE FRAME OPEN

BENDING is specially self designed for short radius heavy & thin wall thickness bending

3/8" - 2" Gas, Water, Steam & stainless steel pipe upto 180° "U" bending. In this version

providing extra pump force 15 tons, well Grinding/Hardcrome Ram/Piston with automatic

return will spring to release of valve.

PROD. NO. 225

Page # 1 - M:222

Prod. No. Pipe Size Formers Size Formers Size Formers Size

(O.D.) in (O.D.) in Inches (O.D.) in Inches (O.D.) in Inches

Inches FOR GAUGE 18 FOR GAUGE 16 FOR GAUGE 14

209A 1/2 8 7 6

209B 3/4 9 8 7

209C 1 9 8 7

209D 1.1/4 12 12 10

CONDUIT PIPE SIZE

Please state when placing the order for conduit Pipe Bender for furniture pipe

PROD. NO. 222

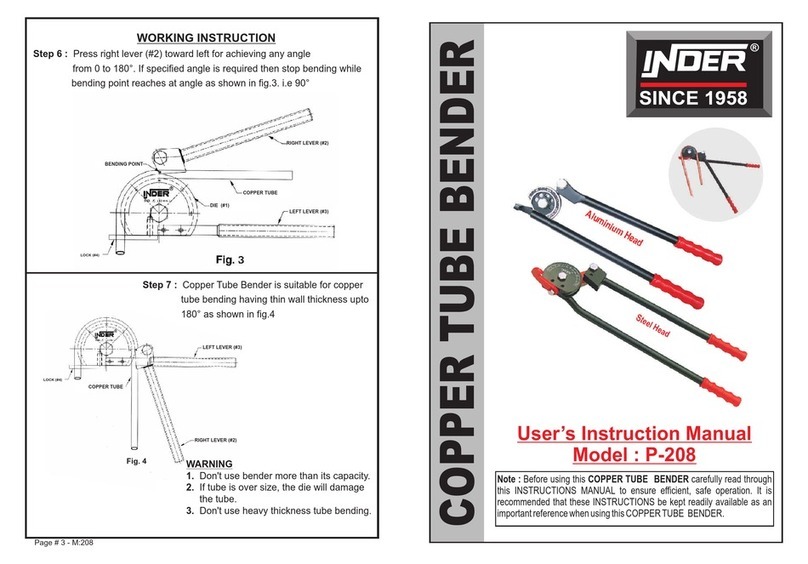

R

Bending radius R

is always calculated

from the middle of

the pipe.

HYDRAULIC MOTORISED PIPE BENDER

WITH DOUBLE FRAME OPEN BENDING

(For short radius heavy & thin wall thickness bending upto 180°)

PROD. SIZE IN PUMP HYDRAULIC MOTOR N.WT. G.WT

NO. INCHES FORCE OIL POWER/KW (Kgs) (Kgs)

IN TONS IN LTR. lll PHASE 440V

222A 3/8 TO 1.1/4 15 1.750 1.5 204.0 269.0

222 B 1/2 TO 2 15 1.750 1.5 244.0 309.0

DEFECT AND REMEDY

DEFECT : Dust particles in filter portion.

REMEDY: Open complete drain plug (#25) as shown in the figure 8 and clean filter (#24)

throughly as shown in the figure 9

DEFECT : If Ram/Piston does not move from the place while pumping and it go and back on

same place.

REMEDY: Loose release valve (#20) in anti clockwise & switch on the machine for 20

seconds & again tight release valve (#20) in clockwise direction & repeat this

operation 4-5 times as shown in figure 10

It results are not satisfied, remove four L - Key bolt (#47) & remove motor & open

screw (#29) & clean its three parts i.e. Ball (Big) (#28), Weight Pin (#27), Ball

(Small) (#26) & again fit all four parts as shown in figure 11

HOW TO REPLACE/FIT PUMP PLUNGER

Step 1 : Open four pieces L- key bolts (#47) & remove motor (#65).

Step 2 : Get the complete plunger (#41 to #45) out & clean.

Step 3 : Replace the damage seals, if found.

Step 4 : Fit all parts of pump plunger again turn by turn as shown in figure 13.

Ball (#41) - Surfacer (#42) - Nylon washer (#43) - Double spring (#44) - Fit bucket

(#45A) on plunger shaft (#45)- Fit oil seal (#45D) in side the plunger (#45B) & O-

ring (#45C) on out side the plunger. Insert plunger shaft (#45) into plunger (#45B)

from the bottom side as shown in figure 13. Otherwise bucket will damage, put the

motor (#65) on the cylinder & hold it with 4 L-Key bolt as shown in figure 12.

Page # 6 - M:215

Figure 8 Figure 9

24

25

25

24

Figure 13

41

45D

45C

45B

45 45A

44

43

42

Back

20

OFF

ON

Figure 10

Figure 11

Figure 12

29

28

Drops

27

26

L - Key

42

47