BN Products DBD-Series User manual

DBD-25H Bender ManualPage | 1

October 9, 2018 (Updated)

DBD-25H

PORTABLE REBAR BENDER

Tool Manual

DBD-Series 0-180 degree Rebar Benders

BN Products-USA, LLC.

3450 Sabin Brown Road

Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813

FAX: (928) 684-7041

mail@bnproducts.com • www.bnrebartools.com

DBD-25H

DBD-25H Bender ManualPage | 2

October 9, 2018 (Updated)

NOTE: When using electric tools, basic safety

precautions should always be followed to

reduce the risk of electric shock and personal

injury, including the followings items:

READ ALL INSTRUCTIONS AND SAVE

THEM FOR FURTURE REFERENCE

1. Keep hands away. From all moving parts and rollers

while operating.

2. Dress properly. Loose clothing or jewelry can get

caught in moving parts. Wear sturdy boots with non-

skid soles. Steel toed boots and safety glasses are recom -

mended.

3. Keep children and bystanders away. Distractions can

cause you to lose control.

4. Do not overreach. Keep proper footing and balance at

unexpected situations.

5. Stay alert. Watch what you are doing and use common

sense when operating a power tool. Do not use a power

or alcohol. A moment of inattention while operating

power tools may result in serious personal injury.

6. Do not exceed the maximum number of bars that can

7. When positioning the bar between rollers, make sure to

8. Do not expose tool to rain or use in damp locations..

gases. Keep work area well lit. If the tool is used out -

doors, keep it covered when not in use and protect it

from rain or water.

9. Do not try to bend materials harder than “Grade 60

cause machine failure.

10. Disconnect tool from receptacle when not in use. Dis -

connect when servicing or changing rollers to prevent

accidents.

11. Keep tool clean at all times for best and safest perfor -

mance. Follow instructions for lubricating and chang -

ing parts. Keep hands dry and free of oil or grease.

Inspect switches, tool cords periodically and have them

repaired or replaced by an authorized service center

if damaged. Check moving parts for alignment and

binding as well as for breakage and improper mounting.

Damaged parts should be repaired or replaced by an

authorized service facility unless otherwise indicated in

this instruction book.

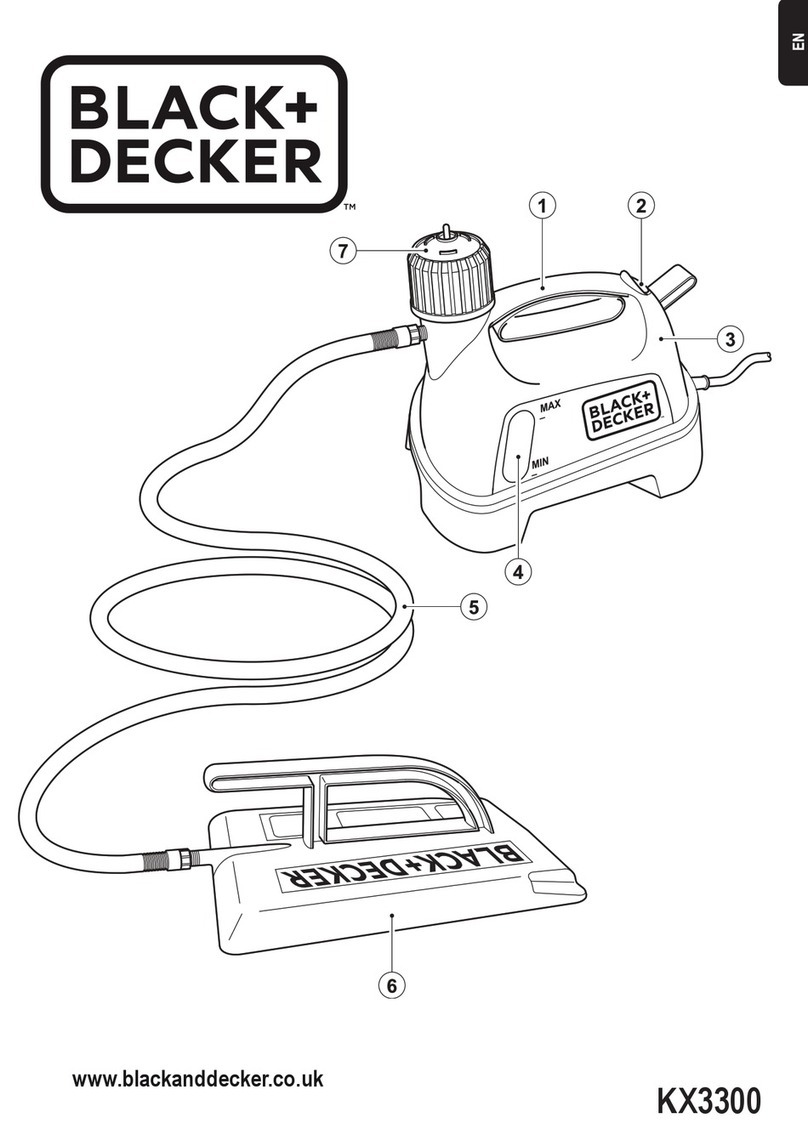

DBD-25X Portable Rebar Bender

1. Moving bending roller

2. Center roller

3. Adjustable stopper

4. Main switch

5. Pilot lamp

6.

7. Angle setter (lever type) 2-stops

8. Angle stopper (two)

9. Emergency stop button

10. Plug-in for foot switch

11. Roller set

12. Foot Operated Switch

DBD-25H

DBD-25H Bender ManualPage | 3

October 9, 2018 (Updated)

Recommended Bending Roller Selection Chart

for DBD-25H Bender on Standard Hook Details

Combination of Center Roller and Moving Roller according to the bar size:

Bar Diameter Size

Max. Grade 60

Center

Roller #

Center Roller Outside

Diameter

CRSI Recommended Inside

Bend Diameter

Moving

Roller

No. of bars that

can be bent

1” (25mm) #8 No. 7 5.97” (153mm) 6.00” (155mm) No. 1 1 -Piece

7/8” (22mm) #7 No. 6 5.15” (132mm) 5.25” (135mm) No. 3 1 -Piece

3/4” (19mm) #6 No. 4 4.45” (114mm) 4.50” (115mm) No. 5 2 -Pieces

5/8” (16mm) #5 No. 3 3.63” (93mm) 3.75” (95mm) No. 6 2 -Pieces

1/2” (13mm) #4 No. 2 3.09” (79mm) 3.00” (80mm) No. 8 3 -Pieces

3/8” (10mm) #3 No. 1 2.54” (65mm) 2.25” (60mm) No. 9 4 -Pieces

** Use a second No. 4 Roller on moving roller to produce a complete 180° Bend.

Recommended Bending Roller Selection Chart

for DBD-25H Bender on Stirrup Hooks

Combination of Center Roller and Moving Roller according to the bar size:

Bar Diameter Size

Max. Grade 60

Center

Roller #

Center Roller

Outside Diameter

*ACI Recommended

Inside Bend Diameter

Moving

Roller

No. of bars that

can be bent at

one time

5/8” (16mm) #5 No. 1 2.54” (65mm) 2.50” (51mm) No. 8 2 -Pieces

1/2” (13mm) #4 Special * 1.95” (50mm) 2.00” (51mm) No. 9 3 -Pieces

3/8” (10mm) #3 ** 1.57” (42mm) 1.50” (38mm) No. 9 4 -Pieces

* Requires optional roller #1BR5140 used on DBD-25X bender

** Use roller shaft only with no roller, shaft outside diameter 1.57”

Bending Roller Sizes for DBD-25H Rebar Bender

Part Number -Roller Number Outside Diameter

#1BR4212500 -No. 1 2.54” (65mm)

#1BR4212600 -No. 2 3.09” (79mm)

#1BR4207000 -No. 3 3.63” (93mm)

#1BR4207201 -No. 4 4.45” (114mm)

#1BR4207101 -No. 5 4.45” (114mm)

#1BR4207300 -No. 6 5.15” (132mm)

#1BR4212800 -No. 7 5.97” (153mm)

#1BR4209600 –No. 8 6.48” (166mm)

#1BR4212900 –No. 9 7.14” (183mm)

Information from CRSI -Concrete Reinforcing Steel Institute, www.crsi.org

DBD-25H

DBD-25H Bender ManualPage | 4

October 9, 2018 (Updated)

WARNING:

ALWAYS UNPLUG THIS TOOL

BEFORE ATTACHING OR

REMOVING ROLLERS OR

ACCESSORIES.

1. Select and set the correct rollers for the bars to be

bent. See the table above.

2. Plug the electrical power cord into an appropriate

outlet.

3. Lay the bar on the machine surface between the

center roller and bending roller. Adjust the stopper

so that the bar is parallel to the front edge of the

machine.

4. Turn the main switch on and check that the pilot

lamp has lit up.

5. Set the angle and make a test bend. If the bent

angle is not exact, adjust the angle setter slightly

duplicate the same angle each time.

6. -

ing bending roller will automatically return to the

start position once the bend has been completed.

7. If it is necessary to stop the machine in an emer -

gency, push the emergency stop button or release

bending roller will return to the start position

automatically.

BENDING ANGLES

CAN BE PRESET

1. Set the angle setter to 135° then tighten the right

angle stopper to lock the 135° position.

2.

stopper to lock the 90° position.

3. Set the angle setter to 135°. Push the operation but -

4. Slide the rebar to the desired length and set the

angle setter to 90°. Push the operation button to

complete your second bend.

For stirrups, cut your rebar to the desired length before

Finally make your (3) 90° bends to connect your ends

together. See below.

WARNING: Never touch any moving parts or roll -

ers while the rebar bender is being operated.

DBD-25H

DBD-25H Bender ManualPage | 5

October 9, 2018 (Updated)

INSPECTION AND MAINTENANCE

WARNING: ALWAYS UNPLUG TOOL BEFORE PERFORMING MAINTENANCE.

DO NOT USE PARTS OR ACCESSORIES THAT ARE NOT

GENUINE DIAMOND BRAND from BN Products-USA

1. At least once a month remove the bottom plate and grease all the visible gears and pinions. At the

same time, check the carbon brushes for wear or damage. Replace with new brushes if they are

worn out.

2. Check that there are no loose nuts and bolts before starting the operation.

3. -

chine surface.

4. In order to empty the metal dust from the bender, (remove side cover DBD-25X and DBD-32X

models) then tilt the machine to one side allowing the debris to fall out of the catch pan. Be sure

to blow out any remaining dirt and dust with compressed air prior to using the tool again (wear

safety goggles to block blowing debris).

1C1961A Carbon Brush

DBD-25H

DBD-25H Bender ManualPage | 6

October 9, 2018 (Updated)

DBD-25H

No. Part No. Part Name Qty

1 1BR5001 GEAR CASE M 1

2 1BR5002 GEAR CASE C 1

3 1BR5206 GEAR CASE PACKING 1

4 7CB06045 CAP BOLT M6X45 2

5 7SW006 SPRING WASHER M6 2

6 7B08050 BOLT M8X50 3

7 7SW008 SPRING WASHER M8 4

8 7PW008 PLATE WASHER M8 1

9 7B08025 BOLT M8X25 1

10 7N008 NUT M8 1

11 7B10100 BOLT M10X100 4

12 7PW010 PLATE WASHER M10 4

13 7SW010 SPRING WASHER M10 4

14 7N010 NUT M10 4

15 7B12020 BOLT M12X20 1

No. Part No. Part Name Qty

16 7WF12 SEAL WASHER WF12 1

17 1BR5023 HELICAL GEAR 1

18 1BR5025 PINION NO.1 1

19 1BR5024 HELICAL GEAR KEY 2

20 1BR5009 NEEDLE BEARING TA1212 1

21 1BR5003 BEARING 6202V 4

22 1BR5026 GEAR NO.1 1

23 1BR5027 PINION NO.2 1

24 1BR5028 GEAR NO.2 1

25 1BR5029 PINION NO.3 1

26 1BR5030 PINION KEY 7X7X20 1

27 1BR5004 BALL BEARING 6204 2

28 1BR5006 BALL BEARING 6005 1

29 1BR5015 OIL SEAL SC22-32-7 1

30 1BR5008 BALL BEARING 6009Z 1

DBD-25H

DBD-25H Bender ManualPage | 7

October 9, 2018 (Updated)

No. Part No. Part Name Qty

31 1BR5016 OIL SEAL SC45-62-9 1

32 1BR5010 NEEDLE BEARING

TA223020

1

33 1BR5011 CIRCLIP AR-30 1

34 7TMF1341 CLUTCH ASS’Y 1

35 1BR5043 SHIM 1

36 1BR5038D CLUTCH ARMATURE

FLANGE

1

37 1BR5007 BEARING 6007ZZ 1

38 1BR5031 BEARING NUT 1

39 1BR5032 BEARING WASHER 1

40 1BR5033 GEAR NO.3 1

41 1BR5035 SHAFT 1

42 1BR5034 GEAR NO.3 KEY 1

43 1BR4206200 PINION NO.4 1

44 1BR5037 PINION KEY 1

45 1BR5017 OIL SEAL SC30-45-8 1

46 1BR5047 FLANGE UNIT UCFL205 1

47 7B14028 BOLT M14X28 2

48 7SW014 SPRING WASHER M14 2

49 1BR5012C ARMATURE 1

50 1BR6200ZZ BALL BEARING 6200ZZ 1

51 1BR5012B STATOR COIL 1

52 1BR5012D MOTOR HOUSING 1

53 1BR5012H BRUSH CAP 2

54 1BR5012A CARBON BRUSH SET 1

55 1BR5012E CARBON BRUSH HOLDER 2

56 1BR5048 MOTOR COVER 1

57 7B08015 BOLT M8X15 WITH

WASHER

1

58 7CB06050 CAP BOLT M6X50 2

59 7CB06070 CAP BOLT M6X70 2

60 7SW006 SPRING WASHER M6 4

61 1BR5044 CLUTCH COVER 2

62 7PB206008 PAN HEAD BOLT M6X8

W/WASHER

4

63 1BR1025600 FRAME 1

64 1BR2062800 BASE 1

65 7CB10020 CAP BOLT M10X20 6

66 1BR5133 DAMPER 1

67 7SW010 SPRING WASHER M10 1

No. Part No. Part Name Qty

68 7N010 NUT M10 1

69 1BR5063 ADJUSTABLE STOPPER 1

70 1BR5064 ADJUSTABLE NUT 1

71 1BR5065 ADJUSTABLE HANDLE 1

72 7SP05008 SPRING PIN Φ5X8 2

73 1BR3110400 SIDE COVER 2

74 7PB06010 PAN HEAD BOLT M6X10 8

75 7SW006 SPRING WASHER M6 8

76 7PW006 PLATE WASHER M6 8

77 1BR3110500 DUST COVER 1

78 1BR7121 DUST COVER STAY 4

79 7SB06050 FLAT HEAD BOLT M6X50 4

80 7SW006 SPRING WASHER M6 4

81 7N006 NUT M6 4

82 1BR5068 MAIN SHAFT 1

83 1BR2062700 SWIVEL ARM 1

84 1BR5070 BALL BEARING 6208Z 2

85 1BR5071 BALL BEARING 6207Z 1

86 7SRH80 SNAP RING C-80 1

87 1BR5073 SPACER 1

88 1BR5074 ROLLER SHAFT 1

89 7RC08060 SPRING PIN Φ8X60 1

90 1BR5079 MAIN SHAFT CLAMP 1

91 7CB10020 CAP BOLT M10X20 2

92 7CB10025 CAP BOLT M10X25 2

93 7SW010 SPRING WASHER M10 4

94 7SS10025 SET SCREW M10X25 1

95 7N010 NUT M10 1

96 1BR3110200 SWIVEL GEAR 1

97 7CB10035 CAP BOLT M10X35 8

98 7SW010 SPRING WASHER M10 8

99 7RC08030 SPRING PIN Φ8x30 1

100 1BR5087 LIMIT SWITCH CAM 1

101 7SS06006 SET SCREW M6X6 1

102 1BR51324 ANGLE SET PINION 1

103 1BR3110600 ANGLE LEVER 1

104 1BR50942 ANGLE STAND 1

105 7B308015 BOLT M8X15 WITH

WASHERS

2

106 1BR5098 DISK SPRING M10 2

DBD-25H

DBD-25H Bender ManualPage | 8

October 9, 2018 (Updated)

No. Part No. Part Name Qty

107 1BR5099 LOCK NUT SET 1

108 1BR5101 SWITCH CAM 1

109 7B308015 BOLT M8X15 WITH

WASHERS

1

110 1BR5107 WIRE CLAMP 1

111 7CB10020 CAP BOLT M10X20 1

112 7SW010 SPRING WASHER M10 1

113 1BR51101 JIB 1

114 7B14060 BOLT M14X60 1

115 7PW014 PLATE WASHER M14 2

116 7NU014 SELF LOCK NUT M14 1

117 1BR4206600 WIRE ROPE 1

118 1BR5117 WIRE CLIP WITH NUT 1

119 1BR5118 SPRING HANGER 1

120 1BR5119 RETURN SPRING 4

121 1BR4206300 CENTER COVER 1

122 1BR5134 CENTER PLATE 1

123 7SB06015 FLAT HEAD BOLT M6X15 1

124 1BR50782 ROLLER STOPPER 1

125 7SSP10 SNAP PIN SSP-10 1

126 1BR5050 SWITCH PANEL 1

127 1BR4206400 ANGLE STOPPER ( R ) 1

128 1BR4206500 ANGLE STOPPER ( L ) 1

129 7CB06018 CAP BOLT M6X18 2

130 7GW006 TEETHED WASHER M6 2

131 7PW006 PLATE WASHER M6 2

132 7PB306015 PAN HEAD BOLT W/

WASHERS

5

133 1BR421250A ROLLER NO.1 Φ65MM 1

133 1BR4212600 ROLLER NO.2 Φ79MM 1

133 1BR420700A ROLLER NO.3 Φ93MM 1

133 1BR4207201 ROLLER NO.4 Φ114MM 1

133 1BR420710A ROLLER NO.5 Φ114MM 1

133 1BR421270A ROLLER NO.6 Φ132MM 1

No. Part No. Part Name Qty

133 1BR4212800 ROLLER NO.7 Φ153MM 1

133 1BR420960A ROLLER NO.8 Φ166MM 1

133 1BR421290A ROLLER NO.9 Φ183MM 1

134 1BT5070 BALL BEARING 6208Z 6

135 7K5B4012 DU BUSH 1

7K5B4025 DU BUSH 1

8P1085 TOOL BOX 1

137 1BL5402000 ROLLER CLAMP 2

138 7B812025 CLAMP BOLT M12X25 2

139 1BR5200 1BR5129 CONTROL BOX

ASSEMBLY

1

139 1BR5406 MAGNET CONTACTOR 1

139 1BR51296 DIODE u05G 1

139 1BR51291K THYRISTER 1

139 1BR5129F FUSE HOLDER 1

139 1BR5129G FUSE 1

139 1BR5200B TRANSFORMER 115V 1

140 1BR5126 PILOT LAMP 1

141 7BN25F10 OPERATION SWITCH 1

1BR5231 EMERGENCY BUTTON 1

142 3CD0151 MAIN SWITCH 1

143 1BR5128 SOCKET FOR FOOT

SWITCH

1

144 1BR5124 LIMIT SWITCH AZ7141 2

145 7PB204030 PAN HEAD BOLT W/

WASHER

4

146 1BR5012G CORD ARMER 1

147 1BR5012F CORD SET 1

1BR2062900 STAND 2

1BR4206700 STAND STAY 1

7B10025 BOLT M10X25 10

7N010 NUT M10 2

7SW010 SPRING WASHER M10 10

1BR5231 EMERGENCY STOP

BUTTON (NOT SHOWN)

1

1BR3100400 HANDLE (NOT SHOWN) 2

DBD-25H

This manual suits for next models

1

Table of contents

Other BN Products Construction Equipment manuals

BN Products

BN Products AIRMATIC DBD Series User manual

BN Products

BN Products BNHC-20 User manual

BN Products

BN Products DIAMOND DBD-20M User manual

BN Products

BN Products DBS-16H Assembly instructions

BN Products

BN Products DBD Series User manual

BN Products

BN Products SIGMA DSX 25 Installation and operation manual

BN Products

BN Products JMB-22 User manual

BN Products

BN Products JMB-22 User manual

BN Products

BN Products BNMS-100B User manual