SealMaster CRACK PRO 125 User manual

S:\Engineering\13-Operator Manuals\Current\CRACKPRO_HEATEDHOSE_V2.0_OCT2019.docx

CRACK PRO HEATED HOSE

Owner’s Manual

Version 2.0

Issue Date: Oct. 2019

Effective Date: May 2019

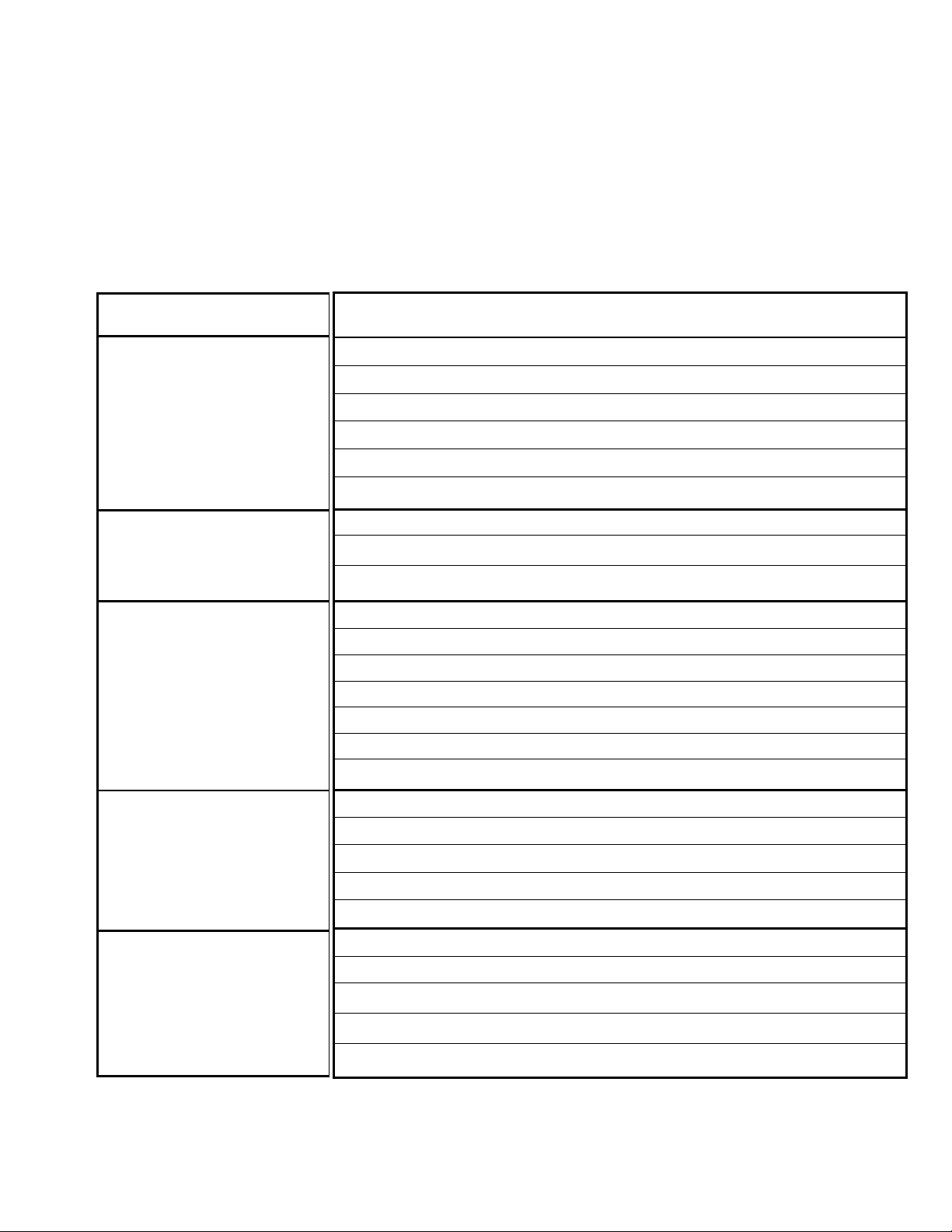

Version

Date

Changes

Approval

1.0

Original Issue

2.0

8/19

New Format and Updates

DS

3

Table of Contents

CORRESPONDENCE .......................................................................................................................................................5

SealMaster® LIMITED WARRANTY ...............................................................................................................................6

INTRODUCTION .............................................................................................................................................................7

CRACK PRO® HEATED HOSE ......................................................................................................................................7

SAFETY PRECAUTIONS AND CAUTIONS........................................................................................................................8

PRECAUTIONS............................................................................................................................................................8

CAUTIONS..................................................................................................................................................................8

FIRST AID ...................................................................................................................................................................9

CHECK IT OUT ..........................................................................................................................................................10

KNOW YOUR MACHINE ...........................................................................................................................................10

FIRE PREVENTION....................................................................................................................................................10

DRESS FOR SAFETY ..................................................................................................................................................11

LEARN TO BE SAFE...................................................................................................................................................11

WALK AROUND INSPECTION ...................................................................................................................................12

TRAFFIC CONTROL ...................................................................................................................................................12

PRE-OPERATION INSTRUCTIONS ................................................................................................................................13

CHECK LIST...............................................................................................................................................................13

CAUTIONS................................................................................................................................................................14

CLOTHING................................................................................................................................................................14

THINGS TO KNOW ...................................................................................................................................................15

FLUID SPECIFICATIONS ............................................................................................................................................16

SERVICE TIP FOR ENGINE START PUSHBUTTON ......................................................................................................18

A. ENGINE START-UP...........................................................................................................................................18

B. ENGINE SHUT DOWN ......................................................................................................................................18

MACHINE MAINTENANCE...........................................................................................................................................19

TROUBLE SHOOTING GUIDE....................................................................................................................................19

MAINTENANCE SCHEDULE ......................................................................................................................................21

OPERATING INSTRUCTIONS - DIESEL FUEL BURNER ..................................................................................................30

CHECK LIST...............................................................................................................................................................30

STARTING THE ENGINE............................................................................................................................................31

THE TEMPERATURE CONTROL ................................................................................................................................32

ADDING MATERIAL..................................................................................................................................................33

MATERIAL TEMPERATURE.......................................................................................................................................33

AUTOMATIC SAFETY INTERLOCKS ...........................................................................................................................34

APPLICATION OF MATERIAL ....................................................................................................................................35

SETTING TEMPERATURE CONTROL .........................................................................................................................36

4

POURING MATERIAL................................................................................................................................................37

BURNER INFORMATION CHART ..............................................................................................................................38

WIRING DIAGRAMS ....................................................................................................................................................39

TEMPERATURE CONTROL BOX ................................................................................................................................39

HEATED HOSE MAIN CONNECTOR J1 AND HEATED HOSE J2 ..................................................................................40

ELECTRIC BRAKES AND RUNNING LIGHTS ...............................................................................................................41

MACHINE PICTURES AND PARTS LIST.........................................................................................................................42

PARTS LIST PICTURE-1 .............................................................................................................................................43

PARTS LIST PICTURE-2 .............................................................................................................................................45

PARTS LIST PICTURE-3 .............................................................................................................................................47

PARTS LIST PICTURE-4 .............................................................................................................................................50

PARTS LIST PICTURE-5 .............................................................................................................................................52

PARTS LIST PICTURE-6 .............................................................................................................................................54

PARTS LIST FOR TEMPERATURE CONTROL BOX.........................................................................................................55

PARTS LIST PICTURE-7 .............................................................................................................................................55

PARTS LIST PICTURE-8 .............................................................................................................................................56

WIRELESS WAND CONTROL BOX OPTIONAL..............................................................................................................57

PARTS LIST PICTURE-9 .............................................................................................................................................57

PARTS LIST FOR DIESEL BURNER .............................................................................................................................59

PARTS LIST FOR AIR COMPRESSOR..........................................................................................................................60

PARTS LIST FOR ROPER 2” PUMP ............................................................................................................................61

DIESEL ENGINE PARTS LIST .........................................................................................................................................63

PARTS LIST FOR 1505 DIESEL ENGINE .....................................................................................................................63

PARTS LIST FOR 902 DIESEL ENGINE .......................................................................................................................64

PARTS LIST FOR 602 DIESEL ENGINE .......................................................................................................................65

OPERATING INSTRUCTIONS –DOUBLE PUMPER .......................................................................................................66

TEMPERATURE CONTROL........................................................................................................................................66

WIRING DIAGRAM ...................................................................................................................................................68

HEATED HOSE MAIN CONNECTOR J1 AND HEATED HOSE (J2-TIMES 2) .................................................................69

MACHINE PICTURES AND PARTS LIST DOUBLE PUMPER ...........................................................................................70

PARTS LIST PICTURE-10 ...........................................................................................................................................70

PARTS LIST PICTURE-11 ...........................................................................................................................................72

PARTS LIST PICTURE-12 ...........................................................................................................................................73

RECOMMENDED SPARE PARTS LIST ...........................................................................................................................74

LIST FOR: DIESEL ENGINE ........................................................................................................................................74

LIST FOR: CRACK PRO HEATED HOSE.......................................................................................................................74

5

ThorWorks Industries, Inc.

Purchased by __________________________ Model NO. _______________________

Company Name _______________________ Serial NO. _______________________

Address ________________________________ Acceptance Date ________________

City _____________ State______ Zip _______

CORRESPONDENCE

All Correspondence regarding this equipment, as well as general correspondence should be addressed to:

ThorWorks Industries, Inc.

PO Box 2277

Sandusky, OH 44870

In referring to the equipment, kindly state the Model Number, Serial Number and any part number involved

`

6

SealMaster® LIMITED WARRANTY

SealMaster warrants that its products are of quality material and workmanship. SealMaster

agrees to replace, within a period of one (1) year from date of delivery, or at its option, repair,

without charge, any part of their manufacture which proved defective. The repair or

replacement will be free of charge F.O.B. Sandusky, Ohio, proving the damaged part or parts

are returned, freight prepaid, to SealMaster and investigation show such repair or replacement

is made necessary by an inherent defect of material or workmanship.

It is hereby understood that engines, motors, pumps, or other components purchased by

SealMaster for use on its equipment are not warranted by SealMaster and are sold only with

the standard warranty of the manufacturer of that component.

SealMaster will make no allowances for repairs or alterations completed by outside sources

unless authorization is in writing and approved by an authorized SealMaster representative.

Any claims for defective material or workmanship must be made prior to the expiration of thirty

(30) days from the date failure occurs, and in all cases prior to the expiration of the warranty

period of one (1) year. It is the intent of this paragraph to limit SealMaster’s liability solely to

the cost of replacement parts, F.O.B. factory, or at the option of SealMaster to repair of the

defective part or parts. No allowances for damages, lost time, or any other claim will be

recognized.

This warranty is null and void if other than genuine SealMaster parts are used.

SealMaster is constantly striving to improve their products. Changes in design and

improvement will be made whenever the manufacturer believes the efficiency of the product

will be improved, without incurring any obligation to incorporate such improvements in any

machines which have been shipped or are in service.

In an effort to continue to improve product quality, SealMaster reserves the right to change

specifications without notice.

Any modification or alteration of this machine without prior approval of the manufacturer may

void this warranty.

7

CRACK PRO® HEATED HOSE MACHINE

APPLIES TO ALL DIESEL FUEL BURNER

INTRODUCTION

CRACK PRO® HEATED HOSE

This manual covers the oil jacketed CRACK PRO® model sizes 125, 200, 260 & 400

- gallon models.

Included also is the oil jacketed CRACK PRO® model size 260 double pumper.

Congratulations on the purchase of your new CRACK PRO® HEATED HOSE joint

sealing machine. This machine is manufactured with the commitment of quality

the CRACK PRO® is known for. It is manufactured for high speed melting of joint

sealing material and the shortest melting time for all hot pour materials.

This manual will assist you in the maintenance and operation of your joint sealing

machine for many years.

8

SAFETY PRECAUTIONS AND CAUTIONS

PRECAUTIONS

Always wear eye and ear protection, long sleeve shirt, face shield

and gloves.

Be aware of all CAUTION, WARNING, and DANGER signs on the

unit.

The high operating temperatures of your joint sealing machine

and materials require special training and maintenance of your

equipment.

Read and follow these operating instructions to every detail.

Make sure the operator is familiar with the units’ operation.

CAUTIONS

Keep hands, feet, and clothing away from moving parts.

Do not operate the machine without all guards in place.

Never fill the fuel tank with a lit burner.

WARNING! When checking oil levels, never check when HOT!

WARNING! When the burner is on DO NOT exceed 10 mph while

towing, or damage to the burner or machine may occur.

9

SAFETY PRECAUTIONS AND CAUTIONS

FIRST AID

10

SAFETY PRECAUTIONS AND CAUTIONS

CHECK IT OUT

Know what protective devices your machine is equipped with and see that

each item is securely in place and in operating condition.

For example:

1. Warning Decals

2. Guards

3. Material hose connections and protective sleeve

4. Grounding wires

KNOW YOUR MACHINE

Have all of the repairs been made that you reported? The most minor

malfunction could be the result of more serious trouble.

FIRE PREVENTION

Avoid fire hazards such as:

1. Always stop the engine when refueling, do not refuel while smoking

or when near an open flame or sparks.

2. Always wipe up any spills immediately.

3. Batteries produce explosive gases, keep open flame or sparks away.

4. Remove all trash or debris from the machine, make sure that oily

rags or other flammable materials are not stored in or on the

machine.

5. Check for fuel, engine oil, and hydraulic leaks, replace worn or

damaged hoses.

6. Inspect electrical wiring for worn or damaged insulation, replace as

needed.

WARNING: LETHAL FUMES!

Engine and burner exhaust gases contain carbon monoxide. Carbon

monoxide is odorless, colorless and can cause death if inhaled. Avoid

inhaling exhaust fumes, and never run the burner or engine in an enclosed

building or confined area. Symptoms of poisoning are:

1. Dizziness

2. Headache

3. Weakness, Sleepiness and Vomiting

11

SAFETY PRECAUTIONS AND CAUTIONS

DRESS FOR SAFETY

When operating your Crack Pro equipment always wear the following:

1. Long pants

2. Long sleeved shirt

3. Heat resistant gloves

4. Eye protection (face shield is preferred)

5. Work shoes

6. Safety Vest

WARNING: MOVING PARTS

Keep hands, feet, hair, and clothing away from all moving parts.

Never operate the machine with covers, shrouds, or guards removed.

Do not wear loose or dangling clothing or jewelry near the

equipment. It could become caught and possibly cause serious injury

or death.

LEARN TO BE SAFE

1. STUDY THE OPERATORS MANUAL and other pertinent information

furnished with the equipment. Learn your machines operating and

maintenance characteristics, capacities, and limitations.

2. Learn the location and function of all controls, indicators, and

warning devices.

3. Be familiar with the safety devices on your machine.

4. Learn to recognize the machines warning and safety signals, they will

alert you to conditions that may make it hazardous to continue

operating.

5. Carefully read and follow all safety signs and instructions on the

machine.

6. Keep safety signs and instructions in good condition, replace missing

or damaged signs immediately.

7. Do not open the tank lid and put your head directly over the opening.

Besides not being good to breathe, there may be enough oxygen

introduced into the tank to cause the sealant to self-ignite.

12

SAFETY PRECAUTIONS AND CAUTIONS

WALK AROUND INSPECTION

Before each day, walk around the machine and inspect for leaks, loose or

missing parts, damaged parts, or parts out of adjustment. Perform all

recommended daily maintenance.

TRAFFIC CONTROL

Proper traffic control is your responsibility. Never place sealant in an

uncontrolled area. Protect vehicles and pedestrians from the workplace

until the sealant has thoroughly cooled (100°F or the pavement surface

temperature)

REMEMBER:

ONLY YOU CAN PREVENT INJURY TO YOURSELF AND OTHERS!

SAFETY IS YOUR RESPONSIBILITY!

13

CRACK PRO® HEATED HOSE MACHINE

PRE-OPERATION INSTRUCTIONS

CHECK LIST

THE ENTIRE UNIT SHOULD BE CHECKED

Even though your Crack Pro joint sealing machine is ready for

operation when you receive it, certain items should be checked before

putting it to use.

If you have any questions on the operation of this machine discontinue

operation of the machine and call the factory immediately.

(419-626-4375)

Most important items to check are listed below:

Check nuts, set screws, and bolts to assure that no loosening

occurred doing shipment.

Check tightness of all heat transfer oil HTO hoses. (steel braided

hoses)

Check to be sure the HTO vent pipe is clear and open for venting,

located on the HTO expansion tank.

Check wheel lug nuts after first 100 miles of travel.

Never operate machine unattended.

Never exceed heat transfer oil limit of 500°F when operating.

Do not expose material hose to direct flame.

Close tank lid before transporting.

14

CRACK PRO® HEATED HOSE MACHINE

PRE-OPERATION INSTRUCTIONS

CAUTIONS

Caution should be used when loading blocks to prevent possible splash

of hot material. Set material block (one at a time) on the lid. Close lid

allowing the block to drop into the material tank.

Do not breathe joint sealing material fumes.

Do not load more than four boxes of material into the machine

at one time.

Do not exceed 10 mph when towing with the burner on.

Do not operate the machine in the rain.

Do not pressure wash the burner area in front of the machine.

Do not work on the machine while it is in operation.

Do not work on the machine when heat transfer oil has been

heated over 90°F.

Never expose material tank to an open flame.

CLOTHING

Proper clothing should be worn at all times.

long sleeve shirt

face shield

high-temperature gloves

long pants

15

CRACK PRO® HEATED HOSE MACHINE

PRE-OPERATION INSTRUCTIONS

THINGS TO KNOW

The heated hose on this machine operates at 90 - 110 volts ac. Every

caution has been taken to ensure a safe operating the machine.

The information listed here needs to be told to anybody who uses or

works on this machine.

Never operate when conditions are wet. Allow the machine to

dry completely before using.

The digital temperature control box houses both 120 volts ac

and 12 volts dc.

While they are separated, anybody doing diagnostic testing

needs to be made aware of the dual voltages.

DO NOT MOVE THE HOSE WHEN IT IS COLD!

Doing so may kink the inner tube resulting in a hose that will be

destroyed, and will have to be replaced. It will not be covered by the

machines standard warranty.

Should the protective sleeve become cut or damaged in any way, do not use.

Electrical wires are wound around the inner hose, any exposed wires are an

electrocution hazard. Replace the hose immediately.

16

CRACK PRO® HEATED HOSE MACHINE

OPERATING INSTRUCTIONS

FLUID SPECIFICATIONS

Diesel engine crankcase oil:

The break-in oil should be changed after the first 50 hours of operation.

Oil change intervals:

Temperature Oil type Interval

Above 77°F SAE 30 or 10w-30 with filter 100 hours

Between 32°F to 77°F SAE 20 or 10w-30 with filter 100 hours

32°F or below SAE 10 or 10w-30 with filter 100 hours

Hydraulic oil:

The hydraulic system should be drained, cleaned, and refilled every

two years.

If the oil becomes contaminated at any time, flush the system

immediately. The oil filter should be changed yearly.

System capacity is 30 gallons.

Change the hydraulic oil filter after the first 20 hours of operation.

The factory installed oil meets the following specifications:

Grade 68

Viscosity @ 100°F SUS 306

Approximate SAE grade 20W

Factory installed oil: COMMERCIAL AW Hydraulic Oil

See enclosed MSDS

17

CRACK PRO® HEATED HOSE MACHINE

OPERATING INSTRUCTIONS

FLUID SPECIFICATIONS

Heat Transfer Oil:

Heat transfer oil is specially formulated to withstand high temperature and many

heating and cooling cycles. The normal life cycle is one to two years, depending

on how much the machine is used.

Never leave the oil in the machine for more than two years.

The procedure for checking the oil level is to ALWAYS CHECK IT COLD.

Located on the expansion tank is an oil level dip stick, there is a mark on the dip

stick to designate the full point. When adding oil, it is necessary to remove the oil

thermometer from the top rear curbside corner. Install a funnel here, and check

with the dip stick.

Heat Transfer Oil Gallons per Tank:

Tank Size

Gallons

125

25

200

28

260

30

400

45

DO NOT OVERFILL, OVER FILLING WILL CAUSE OIL TO COME OUT THE OVERFLOW

VENT PIPE AND ONTO THE GROUND WHEN THE MACHINE IS BEING HEATED

Oil coming out of the vent pipe means one of two reasons, overfilling or moisture

is present in the oil jacket.

Immediately shut off the burner if this happens. Let the machine cool

completely.

Water in the oil is extremely dangerous. Never heat the machine if water is

present. Drain and replace.

The factory installed oil meets the following specifications:

Name Industrial turbine oil

Flashpoint >390°F

Auto-ignition temp. >500°F

Factory installed oil: Turbine XL 68 See enclosed MSDS

18

CRACK PRO® HEATED HOSE MACHINE

OPERATING INSTRUCTIONS BEFORE 2017

SERVICE TIP FOR ENGINE START PUSHBUTTON

A. ENGINE START-UP

Red pushbutton on panel must be held in the depressed position while starting engine

until running oil pressure is established to open SWICHGAGE contacts. NBMNBNB

(1) 518-APH pushbutton should remain in the depressed position during normal running.

If pushbutton fails to remain in the depressed position:

(A) Visually check wiring for loose connections, frayed wiring, etc., on all terminals and

switch loop circuit.

(B) Check 14amp fuse connected to “B” terminal.

(C) Check for good ground on “G” terminal.

(D) Disconnect switch loop circuit from SW1 and SW2 terminals. Place temporary jumper

between SW1 and SW2 and restart engine. If pushbutton stays in with engine running, 518-

APH switch is not the problem. This indicates either an open circuit, unwanted ground, or

too high resistance in switch loop circuit wiring, between SW1 and SW2.

(E) Continuity checks power removed from “B” terminal.

(1) With ohmmeter or continuity light, check for good continuity through switch

loop circuit. If good continuity is indicated, proceed to step (2).

(2) Unwanted ground in loop circuit. With SWICHGAGE contact adjusted away

from pointer, check continuity between one end of loop circuit and ground. Good continuity”

indicates an unwanted ground in loop circuit such as a terminal rotated against mounting panel.

Remove ground, restore loop circuit connections to SW1 and SW2, power to (B), restart engine.

(3) Too high resistance in switch wiring

With ohmmeter, check resistance between one end of the loop circuit to the

other. Resistance should exceed 25 ohms. If resistance is too high, recheck

for loose connections in loop circuit. Otherwise select larger size wire for

loop circuit.

B. ENGINE SHUT DOWN

(A) Engine fails to shut down when contacts close on one wire to ground SWICHGAGE controls.

(1) With engine running, jumper SW1 to “G” terminal. If switch trips and engine

shuts down, trouble is failure of SWICHGAGE contacts to make contact or lack of good case

ground on SWICHGAGE. Adjust contacts back and forth to give a wiping and cleaning action on

contacts. Check switch mounting for good ground.

19

CRACK PRO® HEATED HOSE MACHINE

MACHINE MAINTENANCE

TROUBLE SHOOTING GUIDE

See oil burner trouble shooting guide for step by step instructions

PROBLEM

MATERIAL PUMP

LEAKING

HOSE

NO PRESSURE

DIESEL BURNER

HAS LOW OPERATING PSI

BURNER

DOES NOT LIGHT

POSSIBLE CAUSES/SOLUTIONS

LEAKING AROUND SHAFT / TIGHTEN & REPLACE PACKING

PUMP GEARS WORN / REPLACE PUMP GEARS

HYDRAULIC MOTOR WORN / REPLACE HYDRAULIC MOTOR

PUMP SHAFT NOT TURNING / CHECK WIRING - FUSE

PUMP WORN / CHECK AND REPLACE

FUEL LINE PLUGGED / CLEAN OR REPLACE

PUMP COUPLER BROKEN / REPLACE COUPLER

BURNER MOTOR WORN / REPLACE MOTOR

ELECTRODES WORN AT TIPS / REPLACE ELECTRODES

ELECTRODES SPACING INCORRECT/ RESET SPACING

CAD CELL DIRTY / CLEAN GLASS LENS

WATER IN FUEL / REPLACE FUEL & FILTER

BURNER IN LOCKOUT / REMOVE NEGATIVE CABLE & REATTACH

FUEL NOZZLE PLUGGED / REFER TO OWNER’S MANUAL

AIR SHUTTER MOVED / REFER TO OWNER’S MANUAL

FUEL FILTER PLUGGED / CLEAN AS NEEDED

AIR IN PUMP / OPEN BLEEDER

TRANSFORMER WORN / REPLACE TRANSFORMER

PRIMARY CONTROL FAILED / REPLACE PRIMARY CONTROL

FUEL SOLENOID FAILED / REPLACE SOLENOID

NO POWER FROM CONTROLLER / TRACE WIRES

HI-TEMP LIGHT IS ON / PUSH RESET

20

CRACK PRO® HEATED HOSE MACHINE

MACHINE MAINTENANCE

TROUBLE SHOOTING GUIDE

PROBLEM

ENGINE

ISSUES

(HTO) HEATED TRANSFER OIL

COMING OUT OF VENT PIPE

(HTO) HEATED TRANSFER OIL

NOT CIRCULATING

CP-400 ONLY

HYDRAULIC SYSTEM

NOT WORKING

AGITATOR

DOES NOT ROTATE

POSSIBLE CAUSES/SOLUTIONS

OIL SPECIFICATIONS / REFER TO OWNER’S MANUAL

OPERATING INSTRUCTIONS / REFER TO OWNER’S MANUAL

DEAD BATTERY / REPLACE BATTERY

LOW ON FUEL / FILL FUEL TANK

PLUGGED FUEL LINE / CLEAN FUEL SYSTEM

PLUGGED FILTER / CHANGE FILTER

OVER HEATED HTO / CHECK TEMPERATURE CONTROL

MOISTURE IN HTO TANK / DRAIN AND REPLACE

HTO PAST OPERATING LIFE / DRAIN AND REPLACE

BROKEN DRIVE COUPLER / REPLACE COUPLER

Y-STRAINER PLUGGED / DRAIN AND REPLACE

HTO LINE VALVES CLOSED / OPEN VALVES

HTO LINE KINKED / REPLACE LINE

LOW ON HTO / CHECK LEVEL AND FILL

HTO PUMP WORN / REPLACE PUMP

DRIVE MOTOR WORN / REPLACE DRIVE MOTOR

LOW OIL LEVEL / CHECK LEVEL AND FILL

HYDRAULIC PUMP WORN / REPLACE PUMP

FILTER PLUGGED / REPLACE FILTER

TANK VALVE CLOSED / OPEN VALVE

KINKED HOSE / REPLACE HOSE

NO POWER AT 12V VDC COIL / CHECK WIRING & FUSE

BROKEN DRIVE COUPLER / REPLACE COUPLER

BROKEN DRIVE MOTOR / REPLACE MOTOR

NOT WORKING LID SWITCH / CHECK LID SWITCH

HYDRAULIC CARTRIDGE / REPAIR OR REPLACE

This manual suits for next models

3

Table of contents

Other SealMaster Construction Equipment manuals