ASSEMBLY

5

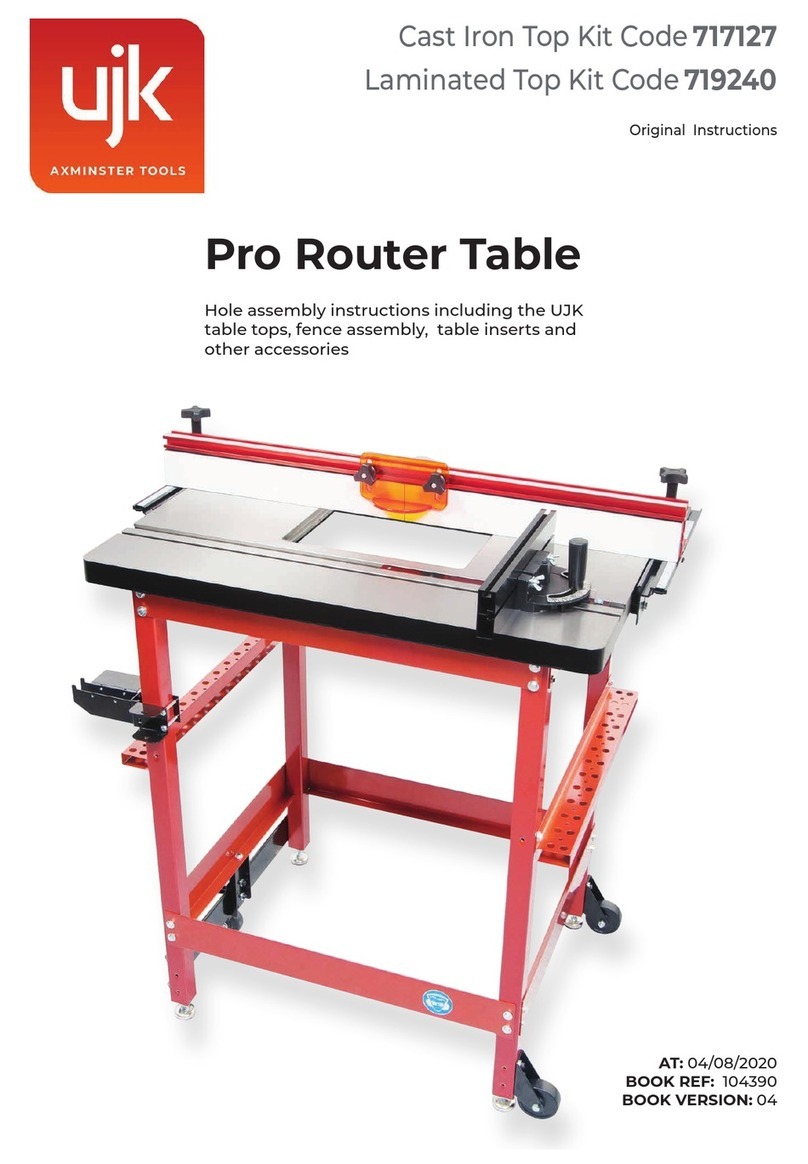

Fitting the Angle Gauge

Fitting the Angle Gauge Sliding Table Fence

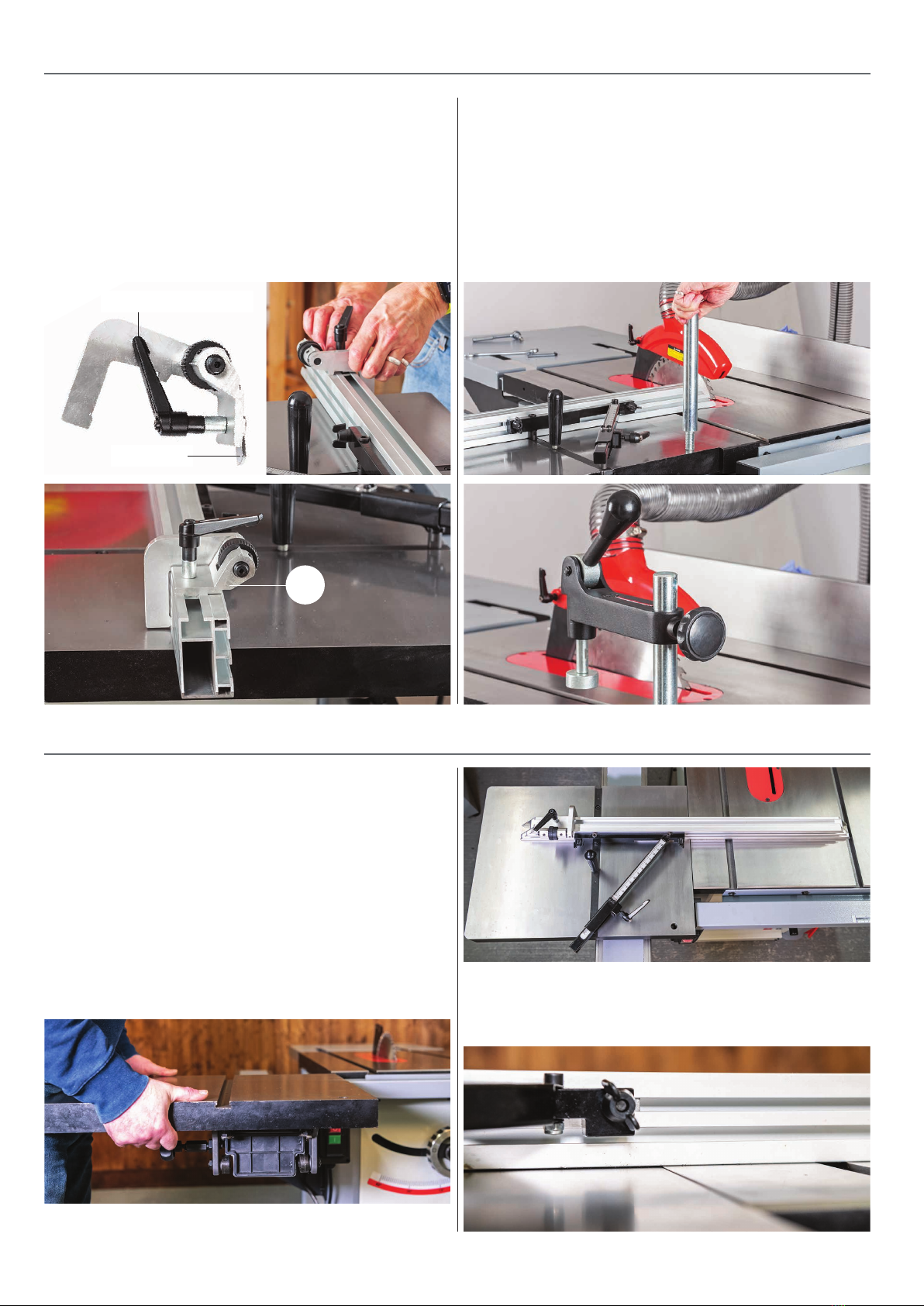

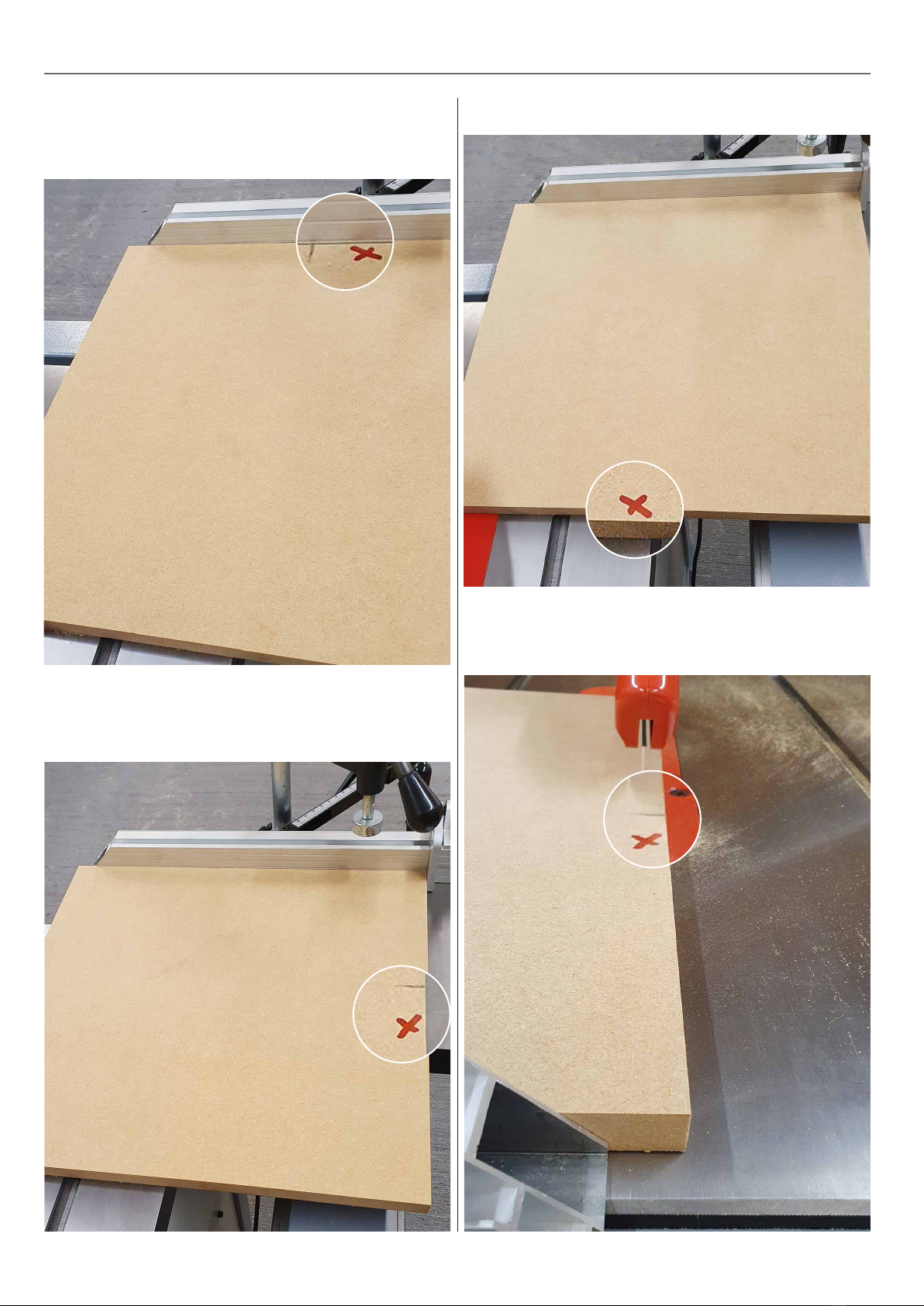

2. Place a straight edge a crossed both tables, see fig 12.

Loosen the support rail (B) locking nuts below the angle

brackets (A), see fig 09 and adjust the four upper nuts

above angle brackets to raise or lower the support rail

assembly, see fig 13. NOTE: make small adjustments

until the sliding table (C) is 0.5mm above the main table.

Once complete tighten the locking nuts to secure the

support rail in place. See set up / alignment on page 6

for levelling the sliding table to the main table in more

detail.

Fig 12-13

Adjusting nut

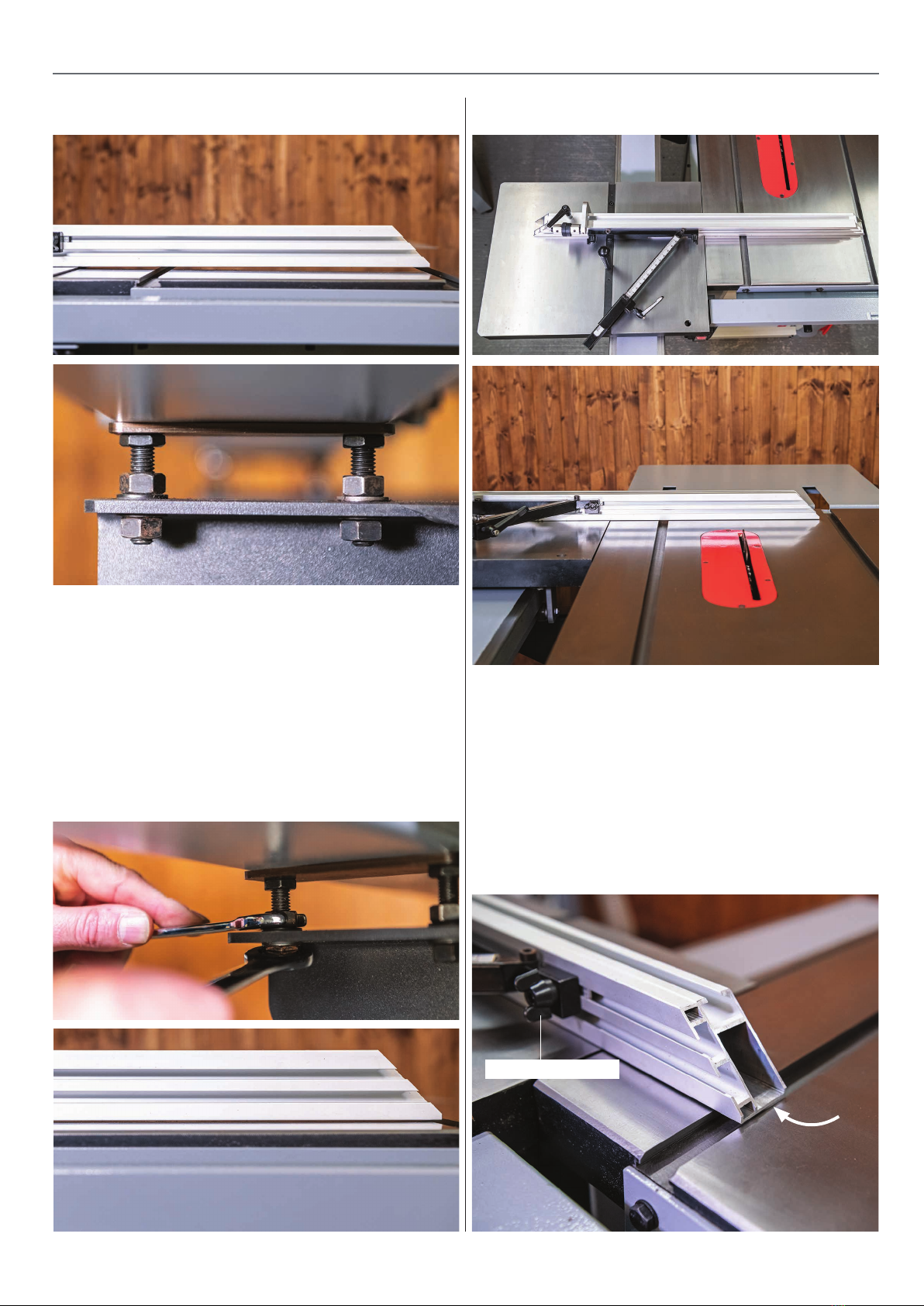

1. Locate the angle gauge (H), using a hex key remove the

cap head bolt in the sliding tables ‘T’ slot and place safely

to one side, see fig 14.

2. Slide the angle gauge (H) into the sliding tables ‘T’ slot.

Note: there are two threaded holes in the tables ‘T’ slot,

enabling the angle gauge to be set in two positions,

see fig 15. This gives extra support for different lengths of

timber.

Fig 14

Cap head bolt

Fig 15-16

3. Line up the recessed hole in the angle gauge support

bar with one of the threaded holes in the table and

replace the cap head bolt you removed earlier, see fig 16.

Threaded holes

recessed hole

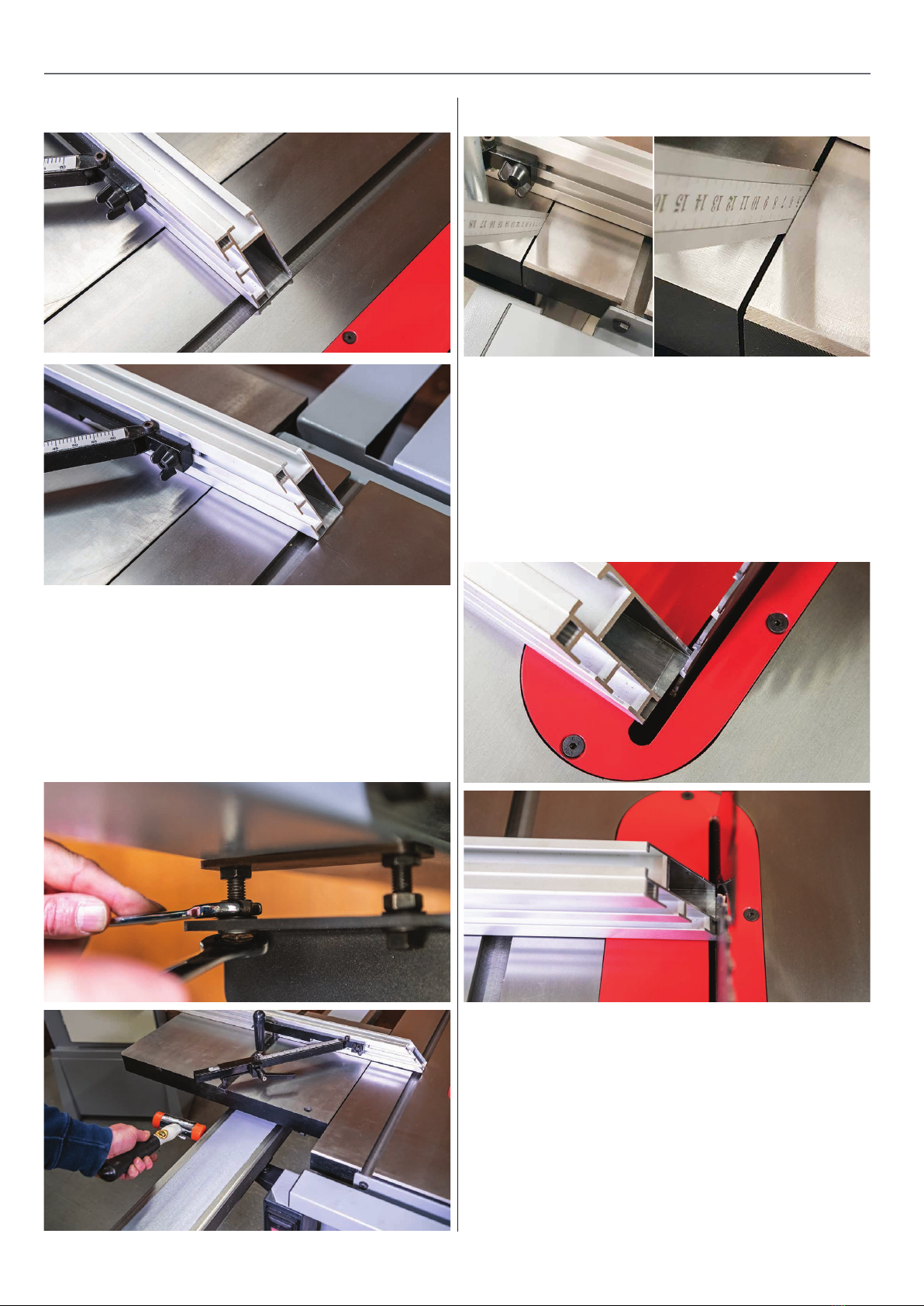

1. Find the sliding table fence (G), loosen the two

thumb screws on the angle gauge (H) to give sufficient

clearance to the ‘T’ bolt clamps, see fig 17.

2. Line up the ‘T’ slot in the aluminium fence (G) with the

first ‘T’ bolt clamp and slide on the fence. Repeat for the

remaining ‘T’ bolt clamp, see 18-19. Nip-up the thumb

screws to lock the fence in place.

H

Fig 17-18-19

‘T’ Bolt clamp

Thumb screw

G

Continues over...