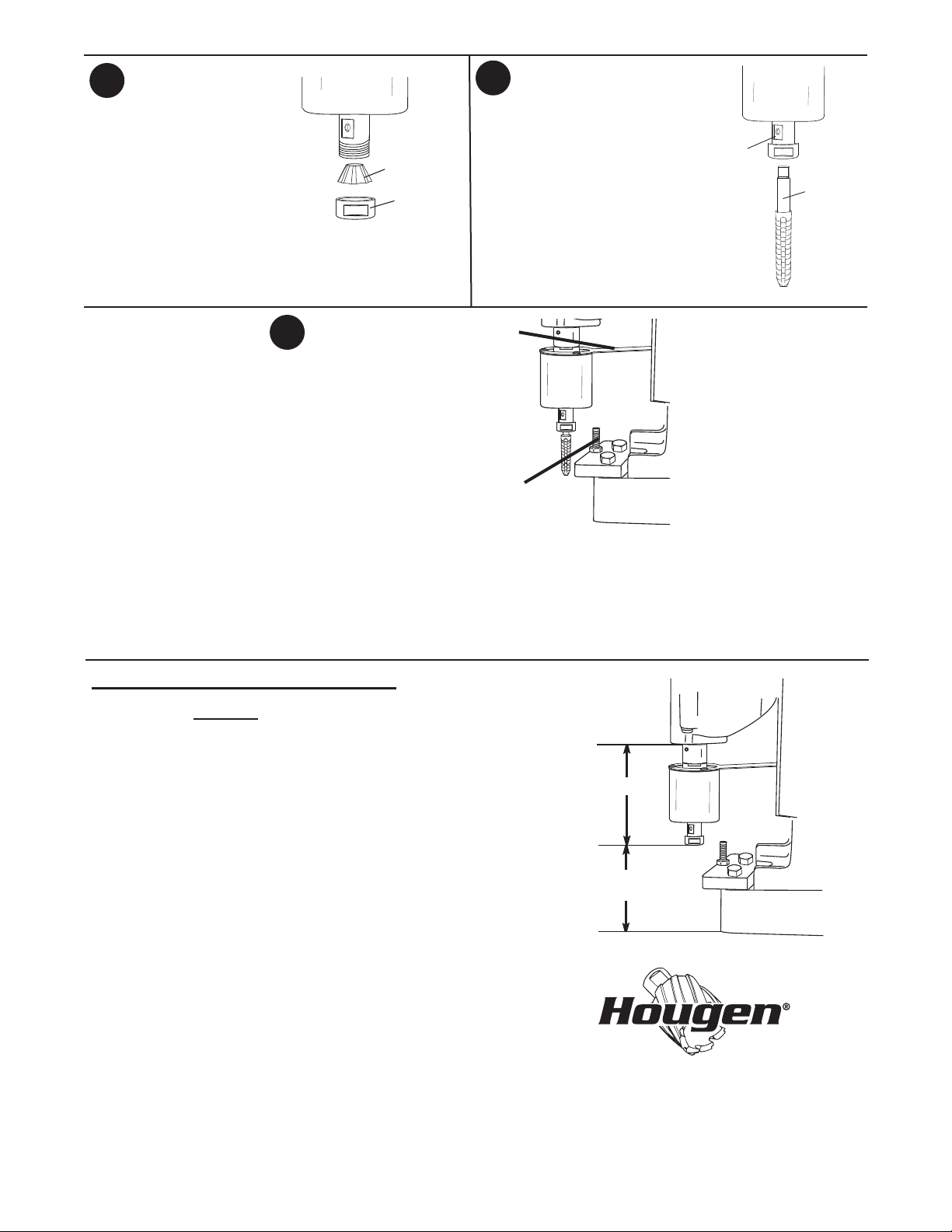

Collet

Collet Retainer Tap

Jaws

Select the correct size Collet

for the Tap that will be used

and install it into the bottom

of the Tap-Matic.

Collet 02495 - Taps #6 thru 1/4”

Collet 02496 - Taps 1/4” thru 1/2”

Thread the Collet Retainer onto

the Tap-Matic holding the Collet

in place. Do not tighten the Col-

let Retainer until the next step.

Install the appropriate Tap up

thru the Collet Retainer until the

at sides of the Tap are in the

Jaws of the Tap-Matic. Tighten

the Jaws so the Tap is held.

Then tighten the Collet Retainer

with the supplied wrenches.

Adjust the long Stop Screw

to the appropriate depth and

lock in place with the lock

nut.

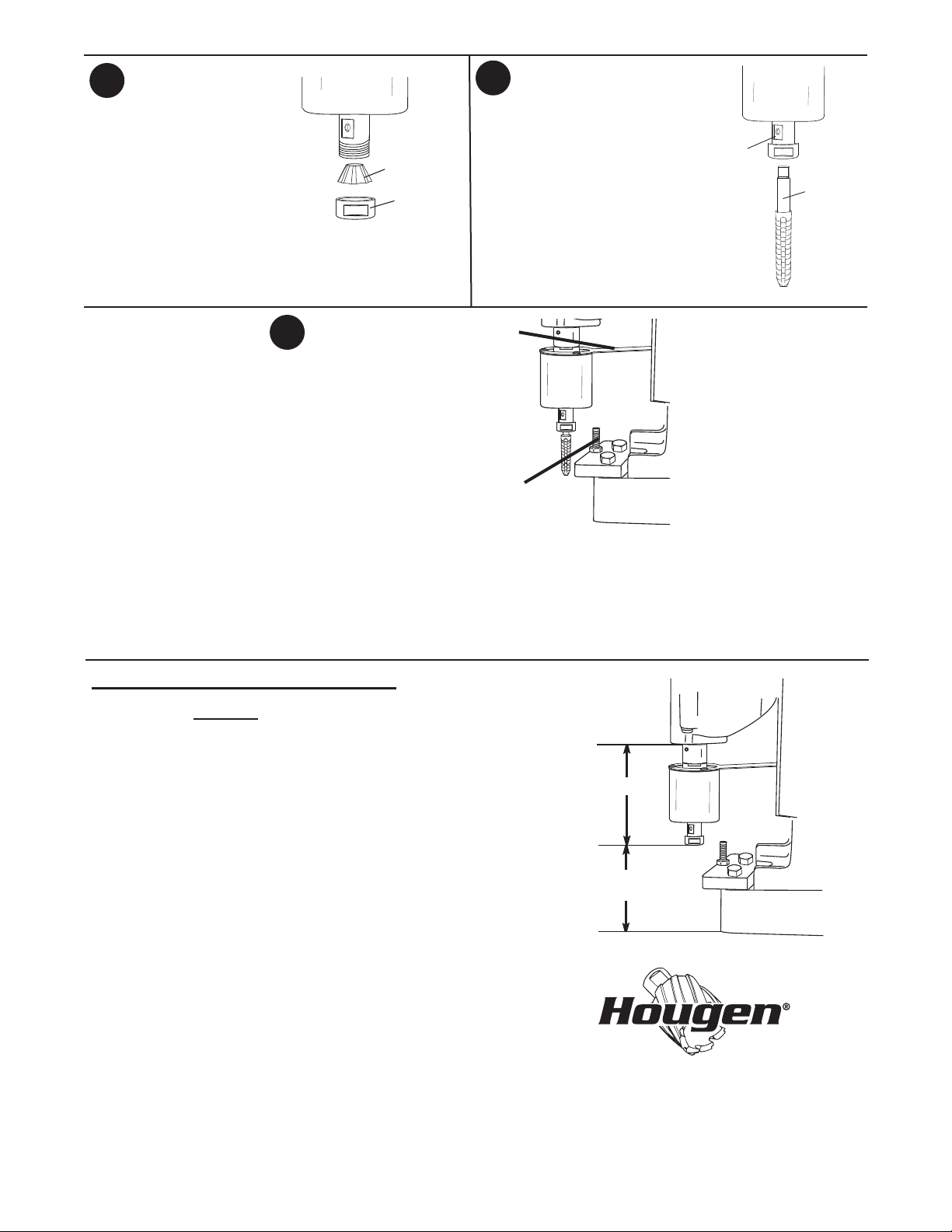

CAUTION

When the Tap is working down into the material the Stop Arm will rotate

and make contact with the Drill Housing on the opposite side that is

shown. When the Tap direction changes and the Tap is working out of

the material it will rotate again to the opposite side. Keeps hands clear of

the Stop Arm while operating.

Stop Arm

Stop Screw

Approx. 6.75”

3.25” in the UP position

with 2.38” of stroke down.

78

9

Hougen Manufacturing, Inc.

P.O. Box 2005 • Flint, MI 48501-2005

3001 Hougen Drive • Swartz Creek, MI 48473

Phone (810) 635-7111 • Fax (810) 635-8277

© 2014 Hougen Manufacturing, Inc.

FORM 08178

Operating the Tapping Attachment

FOR HMD905 ALWAYS TAP IN LOW GEAR 250RPM

1. Produce the correct size hole for the Tap you

are using.

2. Install the Tap-Matic unit using the

instructions above.

3. Position the machine so the Tap is centered and

just above the hole.

4. Apply Slick-Stik Lubricant or an alternative oil

appropriate for tapping.

5. Lock the magnet in position and verify the Tap is

still centered over the hole.

6. Start the motor using the operating instruction in

the Operators manual.

7. Rotate the feed handles down until the Tap pulls

thru the material. Feed handles are not used to

drive the tap down.

8. When the Tap-matic Assembly makes contact with

the Stop Screw the gears will disengage and the

Tap will stop turning.

9. While rotating Feed Handles to bring the Tap-Matic

UP, the Tap will engage and turn counter-clock-

wise.

10. Rotate the Feed Handles until the Tap is clear

of the work piece and push the Motor OFF button.