Prebena KT-3500 Installation instructions

PREBENA Wilfried Bornemann GmbH & Co. KG

Seestraße 20 –26, 63679 Schotten, Germany

Tel.: +49 (0) 60 44 / 96 01 –0, Fax: +49 (0) 60 44 / 96 01 –820

Email: info@prebena.com

www.prebena.de, www.kartuschen-tausch.de

Original Operating Manual for the

Cartridge

PREBENA KT-3500

PREBENA KT-300

PREBENA KT-470

PREBENA KT-690

PREBENA KT-900

98678703

Preamble

This operating manual helps you with the

intended,

safe and

economic

use of the cartridges KT-3500, KT-300, KT-470, KT-690 and KT-900,

short cartridge.

We assume that every cartridge user possesses knowledge in

handling pressure containers and compressed air-driven devices.

Persons without such knowledge must be instructed in cartridge

usage by an experienced user.

Every person who

uses,

fills,

cleans

or disposes of

the cartridge, must take note of this operating manual.

This operating manual is part of the product. Always keep it near the

cartridge. Pass this operating manual on if you sell the cartridge or

hand it down in another way.

3

Table of Contents

Design Elements..............................................................................4

General design elements .............................................................4

Safety information features ..........................................................4

Basic Safety Information ................................................................5

Intended use.................................................................................5

Avoiding explosion hazards..........................................................6

Avoid damaging the cartridge.......................................................6

Description.......................................................................................7

Scope of delivery..........................................................................7

Specification on the type label for KT-3500 .................................7

Specifications on the type label for KT-300, KT-470, KT-690 and

KT-900..........................................................................................8

Using the Cartridge .........................................................................9

Checking the condition.................................................................9

Connecting the cartridge..............................................................9

Separating the cartridge from the device...................................10

Transporting and Storing the Cartridge......................................11

Servicing the Cartridge.................................................................11

Cleaning the cartridge ................................................................11

Filling the cartridge.....................................................................12

Having the cartridge checked.....................................................13

Troubleshooting ............................................................................14

Cartridge Disposal.........................................................................15

Technical Data ...............................................................................15

Manufacturer Address ..................................................................18

Warranty.........................................................................................19

Design Elements

4

Design Elements

General design elements

Various elements of the operating manual are furnished with defined

design elements. This way you can easily differentiate if it is a

normal text,

A list or

Action step.

These notes contain additional information such as special

details about the economic use of the cartridge.

Safety information features

All safety information in this operating manual is structured in the

same way. On the left you find a hazard symbol. Right next to it you

see a signal word indicating the severity of danger. Below this, you

see a description about the source of danger and information about

how you can avoid this hazard.

WARNING

Information with the word WARNING warns of

hazards that could possibly lead to severe or

fatal injuries.

CAUTION

Information with the word CAUTION warns of

hazards that could possibly lead to minor or

moderate injury as well as damage to property

or the environment.

Basic Safety Information

5

Basic Safety Information

Note and observe all warnings and information in this operating

manual and on the cartridge when handling the cartridge. The

attached Declaration of Conformity is part of this operating manual.

Intended use

The cartridges are solely for supplying those types of PREB ENA

devices with compressed air that are expressly stipulated in their

respective cartridge operating manual. The use of other devices is

only permitted after consulting with the manufacturer. Part of the

intended use is observing the accident prevention regulations and

the provisions and standards applicable on site. Any other use is

deemed as not intended and can lead to damage to property and

even to damage to persons.

The following items are particularly deemed as not intended

Operation on not permitted devices,

Operation with oxygen or other flammable gases or gas mixtures

or

Operation by persons without knowledge of the use of pressure

containers and devices driven by compressed air.

The PREBENA WILFRIED BORNEMANN GMBH & CO. KG is not

liable for damages that occur due to non-intended use.

Basic Safety Information

6

Avoiding explosion hazards

Fill the cartridge with the PREBENA compressors of the PKT

FILLMASTER series only.

Fill the cartridge with compressed air only.

Fill the cartridge only to the maximum filling pressure of 300 bar.

Do not fill a damaged cartridge.

Do not expose the cartridge to temperatures above 60 °C or

direct sunlight.

Use the cartridge only up to the date of the maximum operating

life specified on the type label.

Separate the cartridge from the fastener driving tool and the

controller before transport.

Keep the cartridge inaccessible for children and other

unauthorised persons.

Do not use a cartridge if its periodic check dates back more than

5 years.

Avoid damaging the cartridge

Never open the cartridge. Always leave repair works to qualified

experts.

Do not use the cartridge if it has been dropped or damaged. Have

the cartridge checked by qualified experts before putting it into

service again.

Avoid contact of the cartridge with the following substances:

-Aggressive solvents

-Fuel and lubricants

-Acids

-Cleaning agents

-Chemicals of all kinds.

Description

7

Description

Scope of delivery

The cartridge is delivered in a metal transport case for two cartridges

(KT-3500-S) and one cartridge (KT-300-S,

KT-470-S, KT-690-S and KT-900-S) respectively or is enclosed to

the device. The scope of delivery includes protective caps for the

valves on the cartridge, the operating manual and the conformity.

Specification on the type label for KT-3500

A label is attached to the cartridge. You can find the following

important information about the cartridge on it:

No.

Explanation

1

End of operating life

2

Serial number of the cartridge

3

Manufacturing date (month and year)

4

Year of the first periodic check

5

Type designation of the cartridge

6

Country of origin

7

Company name

8

Date of the last periodic check that was carried out

Description

8

Specifications on the type label for KT-300, KT-470,

KT-690 and KT-900

A label is attached to the cartridge. You can find the following

important information about the cartridge on it:

No.

Explanation

1

End of operating life

2

Serial number of the cartridge

3

Manufacturing date (month and year)

4

Year of the first periodic check

5

Type designation of the cartridge

6

Country of origin

7

Company name

8

Date of the last periodic check that was carried out

Do not remove or cover the type label.

Using the Cartridge

9

Using the Cartridge

Checking the condition

WARNING

There is risk of explosion when using a

damage cartridge.

Check the cartridge’s condition before

every single connection.

Connect the cartridge in sound condition

only.

Particularly check the following items:

-The valve must not be damaged or contaminated or loose.

-The cartridge must not show any external damage such as

scrapes or dents.

-The last periodic check of the cartridge must not date back

more than five years.

-The cartridge’s operating life must not be exceeded.

Do not connect a damaged cartridge to a device.

Have the damaged cartridge repaired by PREBENA experts

before connecting it.

Connecting the cartridge

Take the cartridge from the transport case.

Keep the transport case for transporting the cartridge.

Transport of the cartridge is only permitted in the transport

case.

Using the Cartridge

10

WARNING

There is risk of explosion when exceeding the

maximum operating pressure (see operating

manual of the fastener driving tool).

In this case, separate the cartridge from

the device immediately.

Unscrew the sealing cap from the valve.

Check the valve for foreign objects and contamination.

Clean the valve, if necessary (see page Fehler! Textmarke nicht

definiert.).

Check the condition of the cartridge (see page 9).

WARNING

Operation on unsuitable devices can cause

damage to the cartridge and the device.

Connect the cartridge to devices approved

by the manufacturer only.

Slide the cartridge with the valve at the head into the brackets on

the device.

Screw the cartridge hand-tight into the thread at the device

connection.

Separating the cartridge from the device

Conduct the following steps after the operation or after service

interruption:

Unscrew the cartridge from the connection thread.

Pull the cartridge back from the brackets on the device.

Screw the sealing cap onto the cartridge’s valve.

Store the cartridge in the delivered transport case protected

against shock and blows.

Transporting and Storing the Cartridge

11

Transporting and Storing the

Cartridge

CAUTION

Damage due to chemicals or shock possible.

Transport and store the cartridge protected

against shock.

Transport and store the cartridge protected

against chemicals.

Leave a little pressure on the cartridge (between 2 and 3 bar).

Pack the cartridge in the transport case or a durable shipping

carton before transport or storage.

Transport the cartridge to the desired location.

Store the cartridge at room temperature in a dry and dust-proof

location.

Servicing the Cartridge

The cartridge must only be serviced by persons having the required

knowledge, skills and experience for that. All works not described

here must only be conducted by the manufacturer’s customer service

or at the manufacturer’s premises.

Cleaning the cartridge

Clean the hull and the valve of the cartridge after every single

use.

CAUTION

Damage to the cartridge due to wrong cleaning

agents.

Use a dry or slightly moistened cloth or a

cloth slightly moistened with mild soap

solution for cleaning only.

Servicing the Cartridge

12

In order to remove slight contamination on the hull, proceed as

follows:

Wipe the cartridge with a cloth slightly moistened with mild soap

solution.

Then wipe the cartridge with a cloth slightly moistened with tap

water.

Then scrub it with a soft and dry cloth.

To clean the valve, proceed as follows:

WARNING

Risk of explosion if the valve is damaged.

Do not clean the valve with hard or pointed

objects.

Blow out the inside of the valve.

Wipe the outside of the valve with a cloth slightly moistened with

soap solution.

Then wipe the outside of the valve with a cloth slightly moistened

with tap water.

Then scrub it with a soft and dry cloth.

It is not permitted to clean the cartridge with means other than the

stated means.

If you are unable to clean the cartridge as described, send it to

the manufacturer.

Filling the cartridge

You can fill the cartridge with the compressor of the PKT

FILLMASTER series available as accessory.

Observe the compressor operating manual here.

You can also buy a full cartridge at a specialist shop in exchange for

an empty cartridge.

Servicing the Cartridge

13

Having the cartridge checked

WARNING

Risk of explosion due to unchecked cartridges.

Use properly checked cartridges only.

The cartridge must be inspected at Prebena at intervals specified in

national regulations every five years. This check must be

documented in the intended field on the label of the cartridge.

Check the date of the last periodic check on the type label.

If it dates back 5 years or more, proceed as follows:

Pack the cartridge in a sturdy shipping carton (see page 11).

Send the cartridge to PREBENA for inspection.

Troubleshooting

14

Troubleshooting

Symptom

Possible cause

Remedy

Air escapes audibly at the

fastener driving tool’s

safety valve.

The operating pressure

is too high; the fastener

driving tool is damaged.

Separate the cartridge from

the fastener driving tool

(see page 10).

Send cartridge and device

to PREBENA via a

specialist dealer

(see page 18).

Air escapes audibly at the

connection for the

cartridge.

The cartridge was

loosened by shock.

Screw the cartridge hand-

tight into the connection

(see page 9).

The gaskets on the

connections for the

cartridge are defective.

Connect new cartridge

(see page 9).

Send cartridge to

PREBENA via a specialist

dealer (see page 18).

If the problem persists:

Send the fastener driving

tool to PREBENA via a

specialist dealer

(see page 18).

No release possible

The operating pressure

is too low.

Connect new cartridge (see

page 9).

If the malfunction still cannot be remedied, contact your specialist

dealer or the manufacturer (see page 18).

Cartridge Disposal

15

Cartridge Disposal

CAUTION

Damage to the environment if disposed of

incorrectly.

Clean the cartridge before disposal.

Observe applicable regulations for

disposing of oil.

Never throw the cartridge into the normal

household waste.

Send the cartridge to the manufacturer for

disposal (see page 18).

Technical Data

KT-3500

Length:

410 mm

Diameter:

87 mm

Packaging dimensions (L × W × H):

KT-3500-S: 270 × 115 × 435 mm

Weight, empty cartridge:

1.3 kg

Weight, full cartridge:

1.7 kg

Weight KT-3500-S,

with transport case:

7 kg

Content:

1.5 l compressed air

Maximum container air pressure:

300 bar

Operating temperature:

–5 to +45 °C

Storage / transport temperature:

Room temperature, maximum of 60 °C

Maximum operating life:

15 years from the date of manufacture

Technical Data

16

KT-300

Length:

465 mm

Diameter:

115 mm

Packaging dimensions (L × W × H):

KT-300-S: 600 x 290 x 195 mm

Weight, empty cartridge:

2.0 kg

Weight, full cartridge:

3.06 kg

Weight KT-3500-S,

with transport case:

9.52 kg

Content:

3.0 l compressed air

Maximum container air pressure:

300 bar

Operating temperature:

–5 to +45 °C

Storage / transport temperature:

Room temperature, maximum of 60 °C

Maximum operating life:

15 years from the date of manufacture

KT-470

Length:

505 mm

Diameter:

140 mm

Packaging dimensions (L × W × H):

KT-470-S: 600 x 290 x 195 mm

Weight, empty cartridge:

2.9 kg

Weight, full cartridge:

4.54 kg

Weight KT-3500-S,

with transport case:

11.1 kg

Content:

4.7 l compressed air

Maximum container air pressure:

300 bar

Operating temperature:

–5 to +45 °C

Storage / transport temperature:

Room temperature, maximum of 60 °C

Maximum operating life:

15 years from the date of manufacture

Technical Data

17

KT-690

Length:

540 mm

Diameter:

160 mm

Packaging dimensions (L × W × H):

KT-690-S: 675 x 310 x 235 mm

Weight, empty cartridge:

3.9 kg

Weight, full cartridge:

6.22 kg

Weight KT-3500-S,

with transport case:

14.04 kg

Content:

6.9 l compressed air

Maximum container air pressure:

300 bar

Operating temperature:

–5 to +45 °C

Storage / transport temperature:

Room temperature, maximum of 60 °C

Maximum operating life:

15 years from the date of manufacture

KT-900

Length:

575 mm

Diameter:

175 mm

Packaging dimensions (L × W × H):

KT-900-S: 675 x 310 x 235 mm

Weight, empty cartridge:

5.0 kg

Weight, full cartridge:

8.1 kg

Weight KT-3500-S,

with transport case:

15.94 kg

Content:

9.0 l compressed air

Maximum container air pressure:

300 bar

Operating temperature:

–5 to +45 °C

Storage / transport temperature:

Room temperature, maximum of 60 °C

Maximum operating life:

15 years from the date of manufacture

Manufacturer Address

18

Manufacturer Address

PREBENA

Wilfried Bornemann GmbH & Co. KG

Fastening technology

Seestraße 20–26

D-63679 Schotten

Telephone: +49 (0) 60 44 / 96 01 - 0

Telefax: +49 (0) 60 44 / 96 01 - 820

Email: [email protected]

Homepage: www.prebena.de

www.kartuschen-tausch.de

Warranty

19

Warranty

PREBENA warrants 1 year of warranty for the specified device from

the date of purchase according to the following warranty conditions.

PREBENA warrants the corrections of defects attributable to material

or fabrication defects free of charge. Functional defects and

damages caused by improper handling are not considered within the

scope of this free warranty.

Furthermore, only original PREBENA fixtures must be used and

product liability and thereby the warranty claim does not apply upon

non-compliance. The warranty does not extend to wear parts such

as O-rings, etc. It is at PREBENA’s discretion to undertake the

warranty by exchanging the defective part or by substitute delivery.

There are no further claims.

In order to make claims under the warranty, the properly filled out

warranty certificate with dealer stamp and date of purchase or an

invoice stating the data and specifications to be executed according

to the warranty certificate must be attached.

Shipping: The faulty device must be packed carefully and shock-

proved and sent to PREBENA sufficiently stamped.

Warranty certificate

Model designation:

Date of purchase:

Dealer:

(stamp)

PREBENA Wilfried Bornemann GmbH & Co. KG

Seestraße 20 –26, 63679 Schotten, Germany

Tel.: +49 (0) 60 44 / 96 01 –0, Fax: +49 (0) 60 44 / 96 01 –820

Email: info@prebena.com

www.prebena.de, www.kartuschen-tausch.de

Other manuals for KT-3500

1

This manual suits for next models

4

Table of contents

Other Prebena Power Tools Accessories manuals

Popular Power Tools Accessories manuals by other brands

3M

3M 3M-Matic 800r3 Instructions and parts list

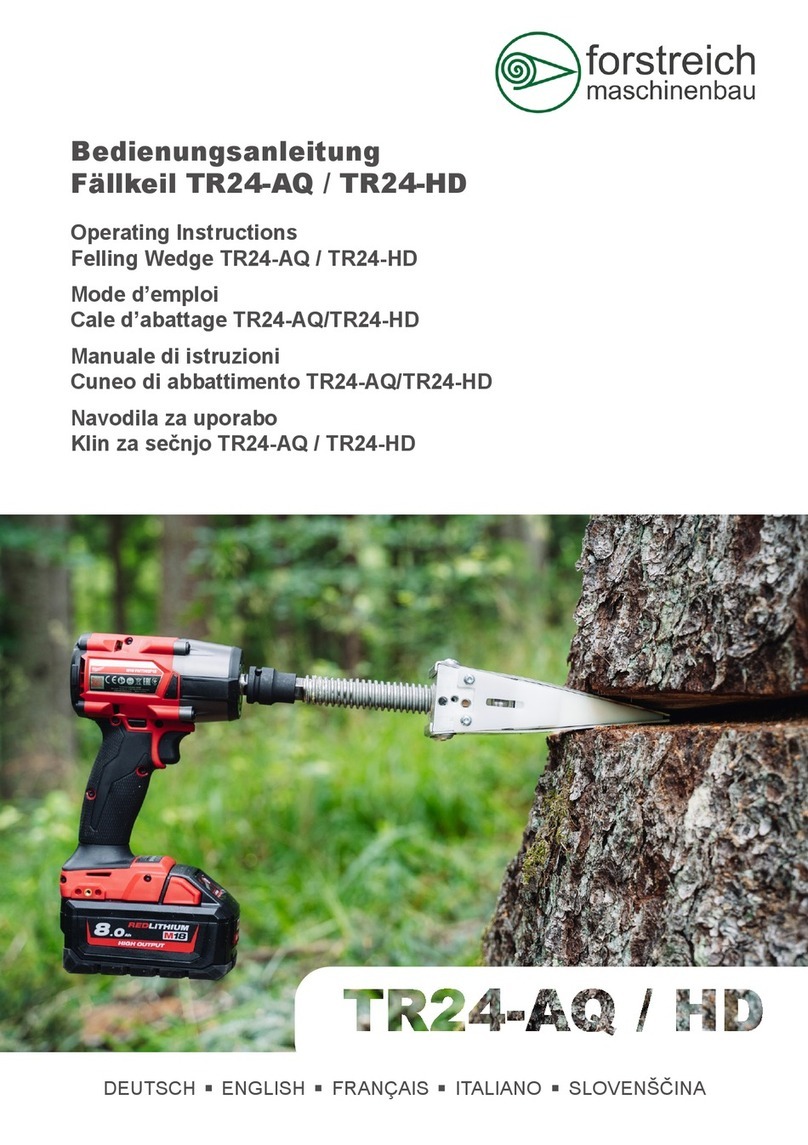

Forstreich Maschinenbau

Forstreich Maschinenbau TR24-AQ operating instructions

Rousseau

Rousseau 5000 owner's manual

SUHNER ABRASIVE

SUHNER ABRASIVE WH 13 Technical document

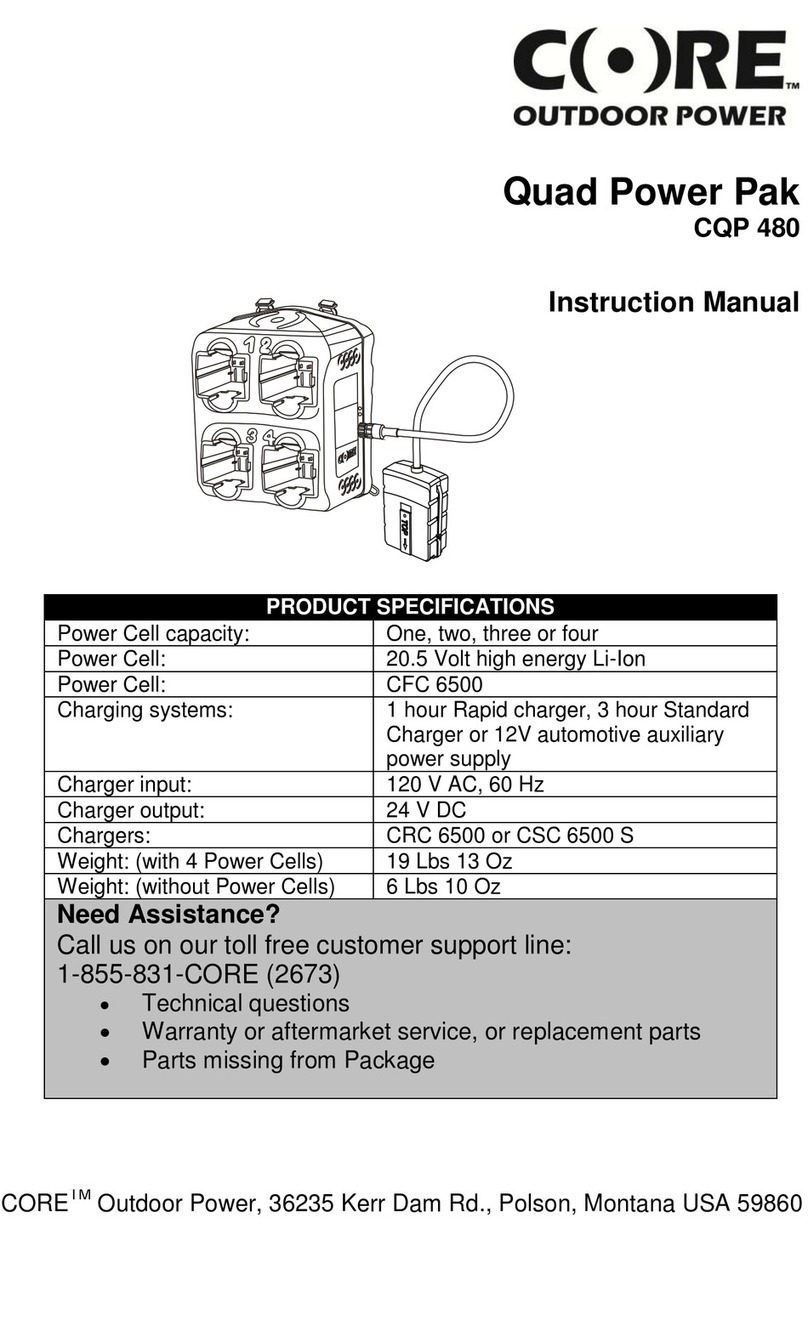

Core

Core Quad Power Pak CQP 480 instruction manual

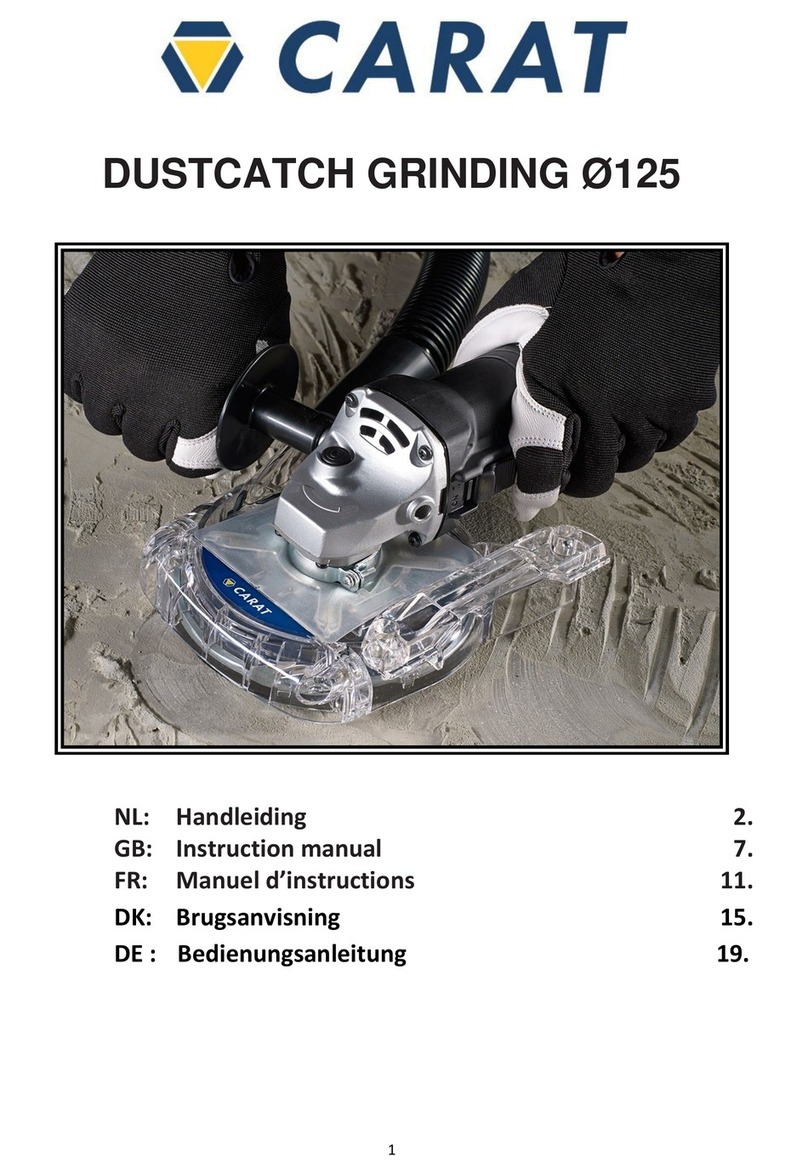

Carat

Carat Dustcatch 125 Grinding instruction manual