Precisa prepASH User manual

Precisa Gravimetrics AG

8953 Dietikon

Switzerland

prepASH

Drying

and Ashing Device

Serial Number S/N:

Installation Date:

_________________________

_________________________

prepASH Operating Instructions Precisa

Ref01.i 1

Contents

1INTRODUCTION.........................................................................................................................................3

1.1 GENERAL INFORMATION ABOUT THE OPERATING INSTRUCTIONS ............................................................3

2SAFETY.........................................................................................................................................................3

2.1 REPRESENTATION AND SYMBOLS.............................................................................................................3

2.2 SAFETY INSTRUCTIONS.............................................................................................................................3

3DESCRIPTION OF THE DEVICE.............................................................................................................4

3.1 PROPER USE .............................................................................................................................................4

3.2 STRUCTURE AND FUNCTION .....................................................................................................................4

3.2.1 Structure of the Ashing Device........................................................................................................4

3.2.2 Functions of the Ashing Device.......................................................................................................5

3.3 TECHNICAL DATA.....................................................................................................................................5

3.4 CONTROLS AND CONNECTIONS.................................................................................................................6

3.4.1 Front controls..................................................................................................................................6

3.4.2 Rear controls and connections ........................................................................................................7

3.5 FURNACE CHAMBER.................................................................................................................................8

3.6 OPTIONAL ACCESSORIES..........................................................................................................................8

4COMMISSIONING ......................................................................................................................................9

4.1 UNPACKING..............................................................................................................................................9

4.2 SCOPE OF DELIVERY ...............................................................................................................................10

4.3 CHOOSING A SUITABLE LOCATION.........................................................................................................10

4.4 ASSEMBLY AND CONNECTION................................................................................................................11

4.5 GRAVIMETRIC CALIBRATION..................................................................................................................12

4.6 GAS ADJUSTMENT..................................................................................................................................12

4.7 MECHANICAL CALIBRATION...................................................................................................................12

4.8 INSERTING THE TURN-TABLE..................................................................................................................12

5SOFTWARE: FIRST STEPS.....................................................................................................................13

5.1 PROGRAM START....................................................................................................................................13

5.2 PREPASH CONTROLS .............................................................................................................................13

5.2.1 Buttons...........................................................................................................................................13

5.2.2 Numerical Entry ............................................................................................................................14

5.2.3 Text Entry ......................................................................................................................................14

5.3 PREPASH USER INTERFACE ...................................................................................................................15

5.3.1 Display Bar....................................................................................................................................15

5.3.2 Flow Chart.....................................................................................................................................16

5.3.3 Program Selection.........................................................................................................................18

5.3.4 Program Editor..............................................................................................................................18

5.3.5 Program Execution........................................................................................................................18

6PROGRAM SELECTION..........................................................................................................................19

7PROGRAM EDITOR .................................................................................................................................19

7.1 PROGRAM LEVEL....................................................................................................................................19

7.1.1 Parameter selection.......................................................................................................................19

7.1.2 Graphical setting...........................................................................................................................21

7.2 CALCULATING LOSSES AND RESIDUE......................................................................................................22

7.3 EVENTS ON COMPLETION OF THE PROGRAM ...........................................................................................22

7.4 PROGRAM MEMORY................................................................................................................................23

8PROGRAM EXECUTION.........................................................................................................................23

8.1 SAMPLE CHAMBER HOOD ......................................................................................................................23

8.2 DEFAULTS ..............................................................................................................................................23

8.3 SAMPLE DATA........................................................................................................................................24

8.4 WEIGHING IN..........................................................................................................................................25

8.5 SELECTING THE PARAMETER DISPLAY IN THE DIAGRAM .......................................................................26

8.6 STARTING AND EVALUATING THE TEMPERATURE PROGRAM.................................................................27

8.6.1 Starting Drying/Ashing..................................................................................................................27

prepASH Operating Instructions Precisa

Ref01.i 2

8.6.2 During the Measurement...............................................................................................................27

8.6.3 Program End .................................................................................................................................28

8.6.4 Saving the Results..........................................................................................................................29

8.6.5 Printing the Results .......................................................................................................................29

8.6.6 Log.................................................................................................................................................30

8.7 REMOVAL OF SAMPLE .............................................................................................................................31

9CALCULATIONS.......................................................................................................................................32

10 SCREEN SETTINGS / LANGUAGUE SELECTION.........................................................................33

11 FORMATTING.......................................................................................................................................34

12 CONFIGURATION / CALIBRATION.................................................................................................35

12.1 BALANCE CALIBRATION.........................................................................................................................35

12.2 GAS ADJUSTMENT AND HOOD CONTROL.................................................................................................36

12.3 VIEW CONTROL AND SAMPLE COLORS ...................................................................................................37

12.4 USER CONTROL ......................................................................................................................................37

12.5 CALIBRATION REPORT............................................................................................................................38

12.6 TEMPERATURE CALIBRATION .................................................................................................................38

13 MAINTENANCE AND SERVICE ........................................................................................................38

13.1 HOUSING.................................................................................................................................................38

13.2 SAMPLE CHAMBER .................................................................................................................................38

13.3 AIRING....................................................................................................................................................39

prepASH Operating Instructions Precisa

Ref01.i 3

1 Introduction

1.1 General Information about the Operating Instructions

The prepASH 129 ashing and drying device is simple to use. Please read the operation manual

carefully and thoroughly in order to understand and make the most optimum use of the many features

and possibilities offered by prepASH 129 in your daily routine.

This operation manual contains reproductions of the screen and switch surface icons, which are

intended to make it easier to find information.

Dangers and notices are indicated in Chapter 2 Safety page 3

2 Safety

2.1 Representation and Symbols

Important safety-related instructions are highlighted visually at the appropriate points below:

DANGER

Warning of a possible danger which may lead to death or to serious injury

CAUTION

Warning of a possible danger which may lead to minor injury or damage

NOTE

Tips and important rules on how to use the ashing unit correctly.

2.2 Safety instructions

•When using the ashing device in surroundings with increased safety requirements, pay careful

attention to the appropriate regulations.

•Only set it up in a room which is adequately spacious, dry and well ventilated.

•Only operate the device upright on its stand and on a stable, level base.

•Atmospheric contamination may only be non-conductive. Short-term conductivity caused by

condensation may only arise occasionally.

•The device may not be operated or stored in a corrosive or explosive atmosphere (dust,

steam, gas).

•Never operate the device with a faulty mains lead.

•Never lay the mains cable over sharp corners and edges or hot surfaces.

•If there is any reason to believe that it is no longer possible to operate the device safely,

unplug it immediately from the electricity supply (pull out the mains cable) and secure it so that

it cannot be operated inadvertently.

•During operation and maintenance work, take particular care with hot parts, in particular in the

area of the furnace chamber (risk of burning).

•When the furnace chamber is opened whilst the machine is in operation or after the end of the

trial, very hot air will escape, and the furnace chamber will radiate intense heat.

•Do not place or stand objects of any kind on the lid of the ashing device. Do not subject the lid

to any mechanical pressure. Heat must be allowed to radiate freely from the machine during

operation.

•Sample type: do not ash any explosive samples.

•Have an electrician check that the entire electrical system is working properly before the

ashing device is first commissioned, after maintenance and servicing work on the electrical

system and at intervals of at least every four years.

prepASH Operating Instructions Precisa

Ref01.i 4

3 Description of the Device

3.1 Proper Use

The ashing device should only be used for weighing, drying and ashing of solid materials and liquids.

The max. permissible load of the integrated balance should never be exceeded, otherwise the balance

may be damaged.

If the ashing device is used in combination with other Precisa devices or with other makes of devices,

it is imperative that you follow the instructions for the safe and proper use of the auxiliary devices.

3.2 Structure and Function

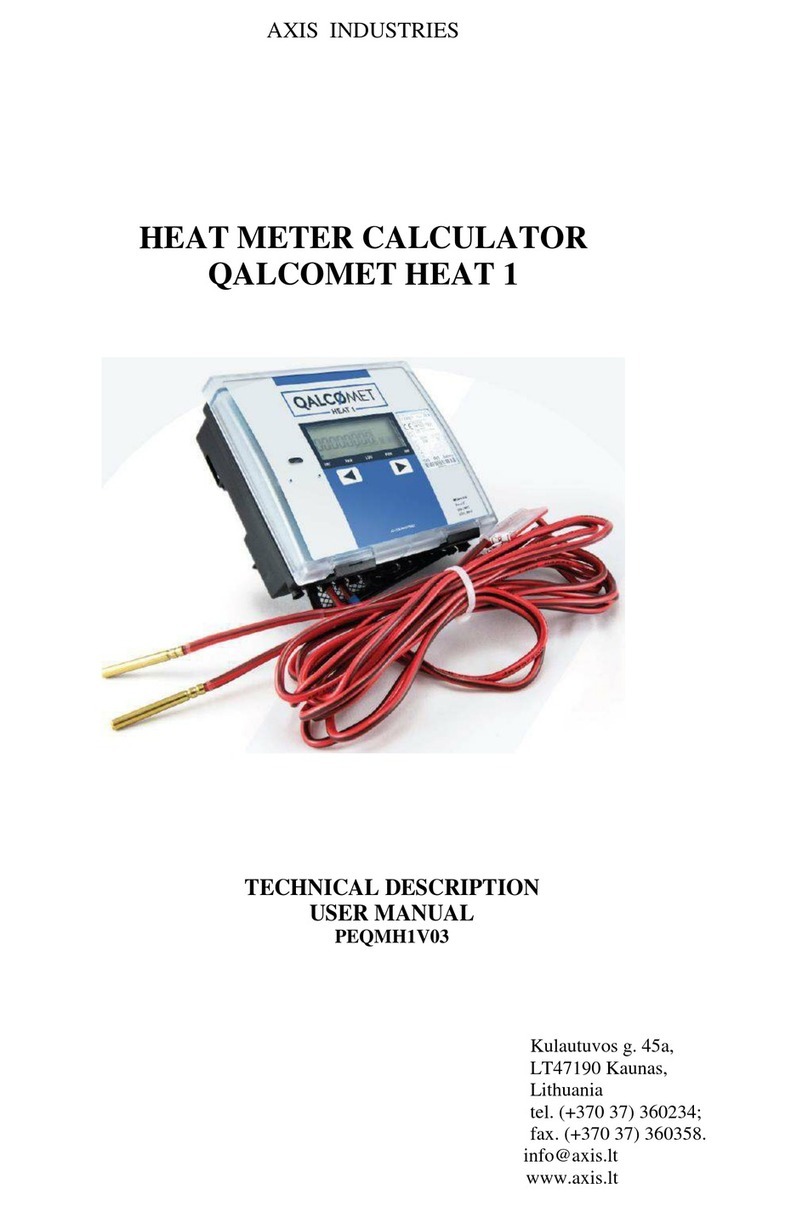

3.2.1 Structure of the Ashing Device

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1 Crucible 9 Exhaust gas nozzle

2 Plate holder 10 Process gas flow control

3 Sample plate 11 Inlet for temperature sensor

4 Balance pan 12 Miniature circuit breaker

5 Touch screen 13 Mains connection

6 Flash card 14 Process gas and compressed air connections

7 Master switch 15 PC / printer ports

8 Maintenance unit with a compressed air

connection

prepASH Operating Instructions Precisa

Ref01.i 5

3.2.2 Functions of the Ashing Device

The prepASH 129 ashing device is simple to operate. It facilitates the quick and reliable drying /

ashing of liquid, porous or solid materials. The device works using thermo gravimetric principles.

The most important basic features of the ashing device include:

•Simultaneous automatic drying, ashing and weighing of up to 29 samples.

•Simultaneous measuring and logging of all samples throughout the entire measurement

procedure.

•Automatic compensation for lift.

•5.7“ VGA color touch screen for simple operation and clear display.

•Temperature range of 50 °C to 1000 °C.

•Connection to an external balance for weighing in the samples.

•Flash card for storage of results.

3.3 Technical data

•Mains connection

- 230 VAC (+15/-20 %); 50 to 60 Hz

- 15 A

•Power consumption

- 3300 VA

•Balance system

- Weighing range: 120 g

- Number of samples: 1 - 29

- Resolution: 0.0001

- Unit: g

•Heating system

- Ceramic infrared radiator

- Temperature range: 50 °C – 1000 °C

- Temperature stability: ± +/- 2%

- Temperature curves are individually configurable

- Time to steady-state: 0 – 6 h

- Dwell time: 0 – 20 h

- Auto stop: 0.1-100 mg/min, mg/30min, mg/60min

•Results

- Weight loss in %, ‰, g

- Weight loss to the pre-interval in %, ‰, g

- Residual weight in %, ‰, g

- Residual weight to the pre-interval in %, ‰, g

•Monitoring

- Acoustic

- Alarm output for external monitoring

•Gas requirements

- Oxygen: 99.5 % purity, 3 bar (± 10 %), 0 – 9 l / min

- Nitrogen: 99.5 % purity, 3 bar (± 10 %), 0 – 9 l / min

- Compressed air, oil-free and without condensation, 6 bar (± 10 %)

•Furnace atmosphere

- Oxygen, nitrogen or compressed air

- Flow rate is measured electronically

•Data outputs

- RS232 port for a PC (COM1)

- RS232 port for an external balance (COM2)

- Centronics port for a printer (LPT1)

- Alarm output (floating double-throw contact)

•Operation and display

- 5.7“ VGA color touch screen

- Menu-guided operation

prepASH Operating Instructions Precisa

Ref01.i 6

•Printout via an optional printer

- Graphics

- Table

•Memory capacity

- EEPROM (internal): 15 method memory

- Flash card (external): 100 method memory and 100 measured data memory

•Weight and dimensions

- Weight 57 kg

- Dimensions H(H)xWxD / 620(980)x590x830 mm

(H) Height with the sample chamber open

•Requisite footprint

- WxD / 590x830 mm

(Requires a margin of 15 cm for safety)

•Permissible ambient conditions

- Temperature: 5 °C – 35 °C

- Relative humidity: 25 % - 85 %, non-condensing

If you have any questions regarding the technical data or require detailed technical information about

your ashing device, contact your local Precisa agent.

3.4 Controls and connections

3.4.1 Front controls

1

The touch screen (1) enables simple, menu-guided control.

Both tables and graphics are displayed in color. All device

settings can be changed easily via the touch screen display.

2

3

The master switch is located on the underside of the control

panel (3).

The flash card (2) can be used to transfer settings and results

to another prepASH.

prepASH Operating Instructions Precisa

Ref01.i 7

3.4.2 Rear controls and connections

DANGER

The ashing device is operated from a 230 V AC supply. The electrical wiring work should

be carried out by a qualified electrician.

The exhaust gas hose must be fed outdoors in order to discharge harmful waste gases

from the furnace chamber safely.

CAUTION

The pneumatic system for the prepASH must not be operated on pure oxygen (danger of a

strong reaction between oxygen and oil).

1

2

3

4

5

6

The oil-free compressed air can be connected to the

maintenance unit (3). You are advised to use a compressed-air

hose with an inner diameter of 6 mm.

Use the controller (1) and the pressure gauge (4) to adjust the

pressure in line with the pneumatic supply to the device.

Check the filter (5) at regular intervals for dirt and condensation.

The filter must be emptied manually to ensure that no

condensation enters the device (6).

The pneumatic system can be vented or disconnected from the

compressed air network via the switch-on valve (2).

7

The process gases can be fed in via the terminal connections

(7) with hoses (DxTh. / 4x0.75mm). The compressed air inlet

(AIR) is connected to the maintenance unit in the factory.

CAUTION working with oxygen and nitrogen.

8

9

10

11

The supplied hose is fitted to the exhaust gas nozzle (8) using

the clip, and the other end is fed into an exhaust system.

A PC can be connected to the COM1 serial port (9), and an

external balance can be connected to COM2 (10).

A printer can be connected via the parallel port LPT1 (11).

12

13

The supplied plug must be fitted by an electrician. The pre-

assembled mains cable can be inserted into the plug connector

(12).

The miniature circuit breaker (13) causes the device to cut out

in the event of an overload. Once the fault has been

investigated and rectified, the miniature circuit breaker can be

pushed back in.

A

IR

prepASH Operating Instructions Precisa

Ref01.i 8

3.5 Furnace Chamber

CAUTION

The parts inside the furnace chamber and the metal covers will become hot. Take care

when opening and loading the furnace chamber.

Always use the supplied holder for removing the sample plate from the device. If you are

removing individual crucibles, always use the supplied tongs (this will also help you to

avoid rogue measurements).

NOTE

Handle the sample plate, crucible and balance pan with care. These parts are made from

ceramic and can be damaged easily.

Take care not to damage the insulation when you load the device.

1

2

3

The entire furnace chamber is lined with insulating

inserts (2).

The suction device (3) is in the back left.

The circlip (1) prevents jamming when the lid is closed.

CAUTION: Watch out for hot parts when you are

handling the device.

4

5

6

7

When the sample plate is removed, the following parts

are visible.

The process gases (N2, O2or compressed air) are fed

inside the sample chamber by means of the lance (4).

The sample plate sits on the rotary axle (5).

The temperature sensor (6) measures the temperature

inside the furnace chamber.

The balance pan (7) is inserted into a protective pipe.

3.6 Optional Accessories

Part Number Designation Quantity Comments

PN 3950-066 Printer 1 For printing out prepASH data

PN 3950-065 Printer cable 1 Connecting a printer to prepASH

PN 3950-067 PC cable 1 Connecting a computer to prepASH

340-7204 Flash card 1 2 MB

340-5001 Crucible 1

prepASH Operating Instructions Precisa

Ref01.i 9

4 Commissioning

4.1 Unpacking

Observe the following points when you unpack the ashing device in order to avoid damage:

•Check the ashing device for any external visible signs of damage immediately after you

unpack it. If you find that it has been damaged in transit, notify your Precisa service agent

immediately.

•Read these Operating Instructions carefully before starting to work with the ashing device and

pay particular attention to the safety instructions (see section 2 "Safety" on page Fehler!

Textmarke nicht definiert.).

1

2

Unpacking the prepASH

1. Open the box (1) at the top

2. Remove all the padding and accessories

3. Undo the 4 screws (2) on the base of the cardboard box

4. Lift off the cardboard box

NOTE

Retain the packaging. If the device is delivered to the factory by a transport firm for repair after a

lengthy period of use, this may only be done in the original packaging. If devices are not properly

packaged, they may sustain considerable damage in transit.

prepASH Operating Instructions Precisa

Ref01.i 10

4.2 Scope of delivery

Once you have unpacked all the parts, check that the delivery is complete.

Designation present yes / no

Ashing device

Sample plate

30 crucibles

Balance pan

2 sample holders

Crucible tongs

Mains plug

Plug alarm

Flash card

Exhaust gas hose

Clip for the exhaust gas hose

Calibration weight 50 g (± 0.1 mg)

4.3 Choosing a Suitable Location

In order to ensure that your ashing device functions properly and safely, select a location that complies

with the permissible ambient conditions (see section 3.3 "Technical Data" on page 5) and also fulfils

the following criteria:

•The room in which it is installed must be adequately spacious (minimum room capacity of 10

m3) and must be well ventilated.

•Observe the following safe distances from neighbouring devices, equipment and walls: space

of at least 15 cm around the sides and at least 1.5 m from the ceiling.

•Put the ashing device on a solid, firm horizontal base, where it is not exposed to vibration.

•Ensure that the ashing device cannot be knocked over.

•Do not expose the ashing device to direct sunlight.

NOTE

The ashing device is a precision instrument. Ensure that the device is not badly shaken.

Vibrations from neighbouring devices can corrupt the ashing device's measurements.

prepASH Operating Instructions Precisa

Ref01.i 11

4.4 Assembly and Connection

NOTE

All the parts must be attached without exerting undue force. Do not apply any undue force. If you

have any problems, the Precisa customer service representative will be happy to assist.

The ashing device does not come fully assembled. Carry out the steps in the sequence outlined

below:

1. Arrange to have an electrician assemble the plug: L →Phase 230 VAC

E →Earth

N →Neutral

2. If necessary, have the alarm plug made up (e.g. connect a pilot lamp). Use pins 1 and 3.

3. Remove the protective stoppers from the requisite connections (process gases and waste gas

nozzle) on the back of the device.

4. Attach the compressed air, the process gases, the mains cable, the waste gas hose and, if

necessary, the alarm plug to the designated connection points (see section 3.4.2 "Rear Controls

and Connections" on page 7).

5. Regulate the pressure of the compressed air supply using the attached maintenance unit (see

section 3.4.2 "Controls and Connections on the Back" on page 7).

DANGER

The ashing device is operated with a 230 V AC supply. The electrical wiring work should

be carried out by a qualified electrician.

Have the electrician check that existing electrical installations are in good working order

and that fuses and cable cross sections are sufficient for the connection data on the

rating plate for the ashing device.

The exhaust gas hose must be fed into an exhaust system in order to discharge harmful

waste gases from the furnace chamber safely.

In order to continue the assembly process, you need to start the ashing device and open the furnace

chamber.

6. Press the master switch on the front device (see section 3.4.1 Front controls on page 6)

7. As the weighing pan is not in place, the unit cannot start properly. Wait until the error message

appears and confirm. Now, in the service mode, the hood may be opened. (Administrator

password: 83710).

8. Remove the balance protection plug and slide in the weighing pan support. Restart the device

(on-off main switch). The start-up screen appears.

prepASH Operating Instructions Precisa

Ref01.i 12

1

2

3

4

Touch button (1) to enter the user interface for drying

and ashing (see section 5"Software: First Steps" on

page 13).

Button (2) takes you to service mode for the device.

Button (3) takes you to the formatting page.

Settings can be defined on-screen via button (4).

Access authorization is required for service mode and

for the screen settings.

4.5 Gravimetric calibration

Before use, the balance must be adjusted according to acceleration of the earth specific to the place

of use. It is recommended to calibrate the balance regularly. The procedure is described in the section

marked 12.1 Balance Calibration page 35

4.6 Gas Adjustment

The gas flow must be regulated after adjustment of pressure. This procedure is described in chapter

12.2 Gas adjustment and hood control page 36

4.7 Mechanical calibration

Mechanical adjustment is made at the factory. The lifting and turning movements of the turntable are

tested by the technician installing the device.

4.8 Inserting the turn-table

Carefully place the sample plate on the rotary axis.

NOTE

The small hole in the sample plate must lie to the

left of the balance pan (refer to figure on the

right).

The ashing device is now ready to be used.

prepASH Operating Instructions Precisa

Ref01.i 13

5 Software: First Steps

5.1 Program Start

You can also switch the terminal on by pressing the mains switch on the ashing device. The start page

appears on the screen.

The software is started by touching the prepASH button.

The other three buttons lead to screen and service and calibration settings. Users must be authorized

to access these (12 ”Configuration / Calibration” page35)

5.2 prepASH Controls

5.2.1 Buttons

You can switch between the main menu pages in the prepASH user interface by

touching the arrow buttons. Unless otherwise described, these program instructions

move along one page to the right every time.

Open files

Save files

Delete files, groups

prepASH Operating Instructions Precisa

Ref01.i 14

5.2.2 Numerical Entry

Numerical values need to be entered at various points in the program. The Numerical Entry window

appears when you tap the relevant field or number which needs to be changed.

The number entered appears in the white box.

The numbers to the left and right of it show the

maximum and minimum entries in this entry

range. Incorrect entries can be corrected using

the arrow and DEL buttons.

5.2.3 Text Entry

The Text Entry window appears when you tap the text entry field.

The entered text appears in the white field.

Corrections can be made using the arrow and

DEL buttons. ESC ends the text entry without

saving the entry; OK ends the text entry and

saves the text.

prepASH Operating Instructions Precisa

Ref01.i 15

5.3 prepASH User Interface

An existing program can be opened or new programs created on the prepASH user interface.

5.3.1 Display Bar

The display bar appears at the very top of the user interface and always remains visible on the main

menu pages.

It shows the current temperature and power values, as well as the gas flow rate.

prepASH Operating Instructions Precisa

Ref01.i 16

5.3.2 Flow Chart

The sequence of the main menu pages is illustrated in the flow chart.

User interface

Open Program

new or edit

Select and open program

Edit program steps

Define results calculation

Events after program-end

Save

prepASH Operating Instructions Precisa

Ref01.i 17

Sample information

Initial weighing/Group assignment

Graphics setting

Start page/Results printout

Numerical control

Pro

g

ram Execution

Automatic saving and printing

prepASH Operating Instructions Precisa

Ref01.i 18

5.3.3 Program Selection

If you touch the Open icon, the program selection appears.

Select the program you require and open it by pressing the Open icon.

5.3.4 Program Editor

The choice of control parameters for each stage of the program is described in detail

in the Program Editor section (see section 6 "Program Editor" on page18).

5.3.5 Program Execution

The first page that appears is the sample data acquisition, followed by graphics settings and, finally,

the program execution page with the Start icon.

The individual steps are described in the section on program executions (see section 7 "Program

Execution" on page 21).

prepASH Operating Instructions Precisa

Ref01.i 19

6 Program Selection

If you touch the Open icon, the program selection appears.

Select the desired program by touch. The chosen program will be highlighted in blue. The program is

opened by again touch the Open symbol.

prepASH is now ready to operate (see Ch. 8 Program Executionpage 23).

7 Program Editor

The program editor is opened by tapping on in the prepASH user interface.

Here you may adjust the temperature program. The temperature program consists of several program

steps in which the parameters may be defined.

7.1 Program level

When you create a program, first of all select the program step in which the parameter settings are to

be active. A program supports up to 10 steps.

Switch from one step to another by touching the Step buttons. The program step

currently set is shown in the graphic in a red box.

During the program sequence, prepASH processes all the steps in order in which parameter settings

have been edited and then automatically switches to the cool-down step.

7.1.1 Parameter selection

Every section of the program contains, among other things, time and temperature settings, which are

defined via the parameter selection control fields.

The values can either be set by drawing lines in the diagram or by entering numerical values.

The Number Entry window appears when you tap in the relevant number. Alternatively, the value can

be entered.

There is a sample program contained in section 8.6.6 Log, page 30.

Table of contents

Other Precisa Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics IMI SENSORS 604M25 Installation and operating manual

Siemens

Siemens SIMATIC ST-1500 Function manual

kruss

kruss M5000 user manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS OAKTON WD-35413-21 instruction manual

Drexelbrook

Drexelbrook 401-10-9 Installation and operating instructions

Hanna Instruments

Hanna Instruments HI 96822 instruction manual