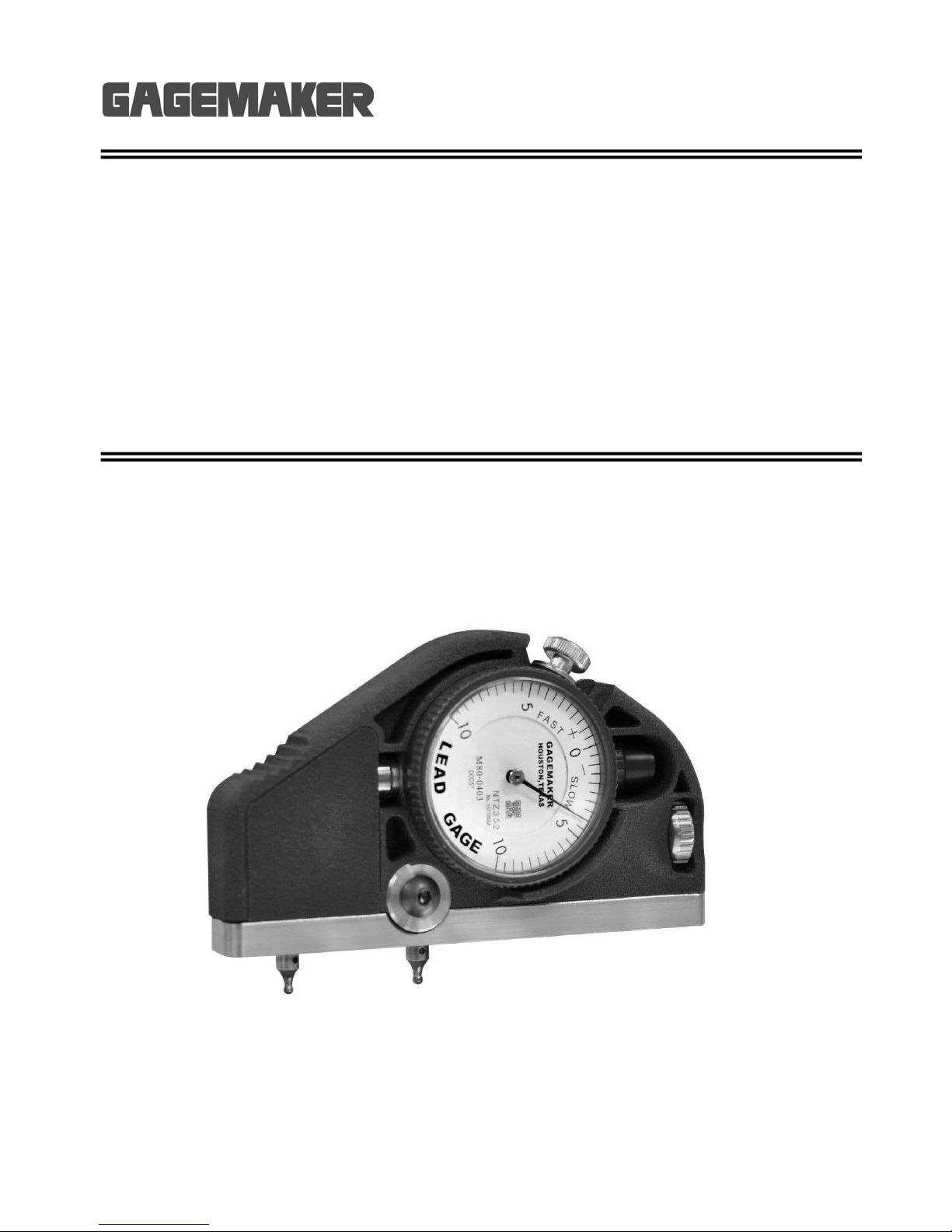

Lead Gage Operation Manual Model LG-6001

Copyright © 2016 Gagemaker. All rights reserved

10

Setup Procedures

Setting Up the Lead Gage

Materials Needed:

Lead gage Calipers

Contact points (2) Paper clip

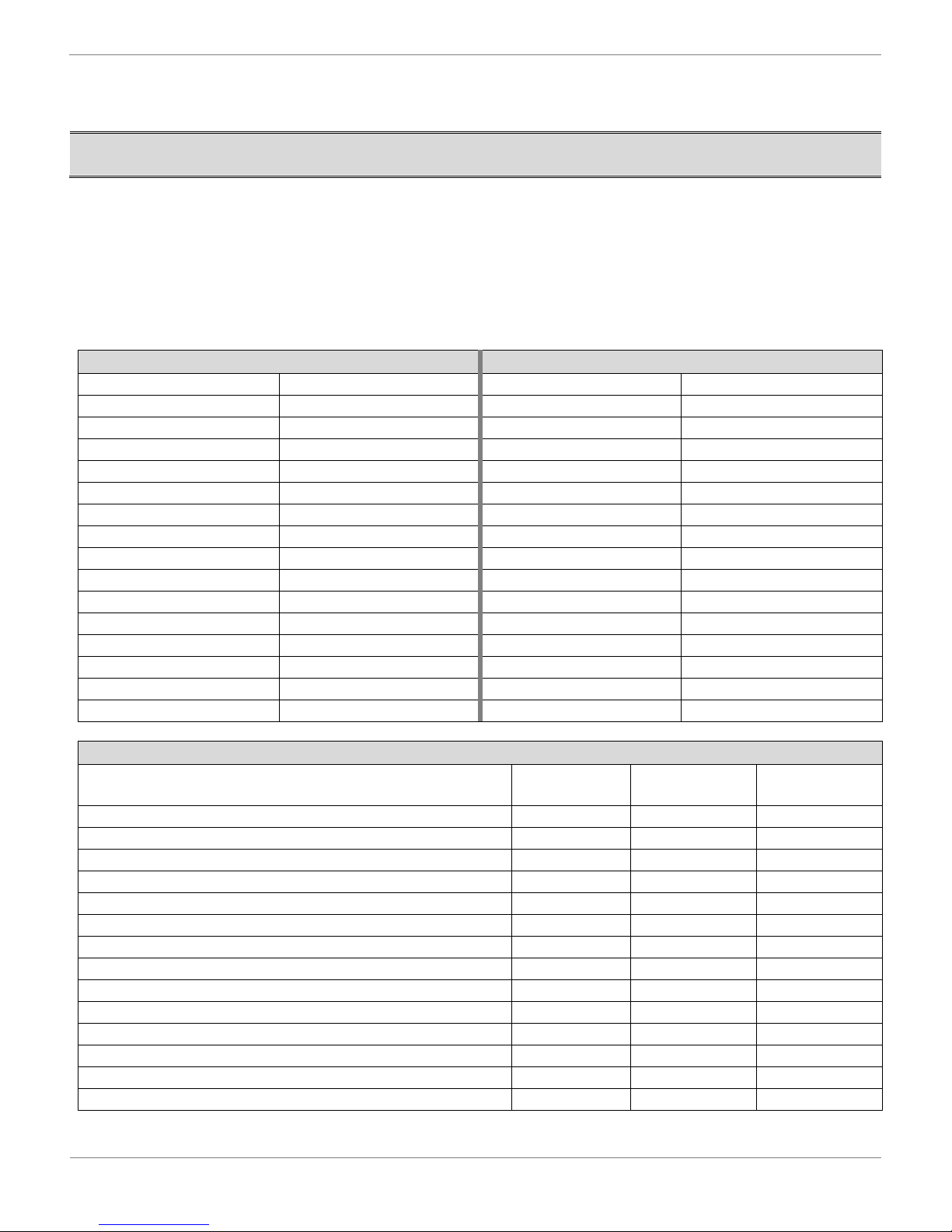

Setting up the lead gage, involves installing the proper size contact points for the application (refer to the

table below for selecting the proper model contact point for ACME, Stub ACME, UN threads or API

threads).

ACME or Stub ACME Threads

1 pitch T531T 1 pitch T562

1.5 pitch T344T 2 pitch T288

2 pitch T266T 3 pitch T188

2.5 pitch T219T 3.5 pitch T188

3 pitch T188T 4 pitch T144

3.5 pitch T144T 4.5 pitch T128

4 pitch T128T 5 pitch T115

5 pitch T105T 5.5 pitch T105

6, 7 pitch T090T 6 pitch T096

8 pitch T062T 8 pitch T072

10 pitch T050T 10 pitch T057

12 pitch T041T 12 pitch T050

14 pitch T041T 14 pitch T041

16 pitch T032T 16 pitch T041

18 pitch T032

Connection Type Point

Diameter Thread Pitch Contact Point

Model Number

All Hughes H-90 0.200” 3 ½ T200

API Rotary Shouldered Connections 0.144” 4 T144

API Rotary Shouldered Connections

API Rotary Shouldered Connections

Truncated for Extreme Line 0.105” 5 ½ T105T

API Rotary Shouldered Connections

API Tubing, Casing and Line Pipe 0.072” 8 T072

Buttress Casing - Lead 0.062” 5 T062

API Line Pipe 0.050” 11 ½ T050

API Line Pipe 0.041” 14 T041

API Line Pipe 0.021” 27 T021