Precision 51221076 Supplement

Installation/Service Manual

Dubnoff & Shallow Form

Shaking Water Baths

Precision

170 Marcel Drive

Winchester, VA

USA

Phone: 540-869-8623

Toll Free: 800-621-8820

FAX: 540-869-8626

ManualP/N36100126(34002554)

Rev.BDated08NOV01

High Temp.

Off

On

NOTICE

THEMATERIALINTHISMANUALISFORINFORMATION PURPOSESONLY. THECONTENTS

AND THE PRODUCT IT DESCRIBES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

PRECISION MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THIS

MANUAL. IN NO EVENT SHALL PRECISION BE LIABLE FOR ANY DAMAGES, DIRECT OR

INCIDENTAL, ARISING OUT OF OR RELATED TO THE USE OF THIS MANUAL.

For repair information or replacement parts assistance from the manufacturer, call Customer Service using our toll

freetelephonenumber.

800-621-8820

(FAX) 540-869-0130

INDEX DATE NOTES

REVISION STATUS

Initial release

A

AMENDED PAGES

6/99

B NOV01 Add caution "acidic & caustic

substance....."

7

Contents

INTRODUCTION.......................................................................................................................1

UNPACKING AND DAMAGE ...................................................................................................1

GENERAL INFORMATION.......................................................................................................2

PERFORMANCE ......................................................................................................................2

INSTALLATION ........................................................................................................................3

WATER LEVEL REGULATOR .................................................................................................4

EXPLANATION OF CONTROLS..............................................................................................6

OPERATION .............................................................................................................................7

MAINTENANCE........................................................................................................................8

TROUBLESHOOTING ..............................................................................................................9

PARTS REPLACEMENT ........................................................................................................14

TEMPERATURE CALIBRATION ...........................................................................................17

REPLACEMENT PARTS LIST ...............................................................................................18

ASSEMBLY & SCHEMATIC DWGS ......................................................................................20

WARRANTY ...........................................................................................................................29

1

INTRODUCTION

Your satisfaction and safety are important to

PRECISION and a complete understanding of

this unit is necessary to attain these objectives.

As the user of this apparatus, you have the

responsibility to understand the proper function

andoperationalcharacteristicsofyourbath. This

instructionmanualshouldbethoroughlyreadand

all operators given adequate training before

attemptingtoplacethisunit inservice. Awareness

of the stated cautions and warnings, and

compliance with recommended operating

parameters — together with maintenance

requirements — are important for safe and

satisfactoryoperation. Theunitshouldbeusedfor

itsintendedapplication;alterationsormodifications

will VOID THE WARRANTY.

WARNING

AS A ROUTINE LABORATORY PRECAUTION,

ALWAYS WEAR SAFETY GLASSES WHEN

WORKING WITH THIS APPARATUS.

Thisproductisnotintended,norcanitbeused,

as a sterile or patient connected device. In

addition,thisapparatusisnotdesignedforuse

in Class I, II or III locations as defined by the

NationalElectricalCode.

UNPACKING AND DAMAGE

Save all packing material until unit is put into

service. Thismerchandisewascarefullypacked

andthoroughly inspectedbefore leavingourfac-

tory.

Responsibility for safe delivery was assumed by

the carrier upon acceptance of the shipment;

therefore,claimsforlossor damagesustained in

transit must be made upon the carrier by the

recipient as follows:

Visible Loss or Damage: Note any external

evidence of loss or damage on the freight bill, or

expressreceipt,andhaveitsignedbythecarrier's

agent. Failuretoadequatelydescribesuchexter-

nal evidence of loss or damage may result in the

carrier's refusing to honor your damage claim.

Theformrequiredtofilesuchclaimwillbesupplied

by the carrier.

ConcealedLossorDamage: Concealedlossor

damage means loss or damage which does not

becomeapparentuntilthemerchandisehasbeen

unpacked and inspected. Should either occur,

make a written request for inspection by carrier's

agentwithinfifteen(15)daysofthedeliverydate;

thenfileaclaimwiththecarriersincethedamage

is the carrier's responsibility.

If you follow the above instructions carefully, we

will guarantee our full support of your claim to be

compensated for loss or concealed damage.

DO NOT — FOR ANY REASON — RE-

TURN THIS UNIT WITHOUT FIRST

OBTAINING AUTHORIZATION. In any

correspondence to

PRECISION,

please

supply the nameplate data, including cata-

log number and serial number.

2

GENERAL INFORMATION

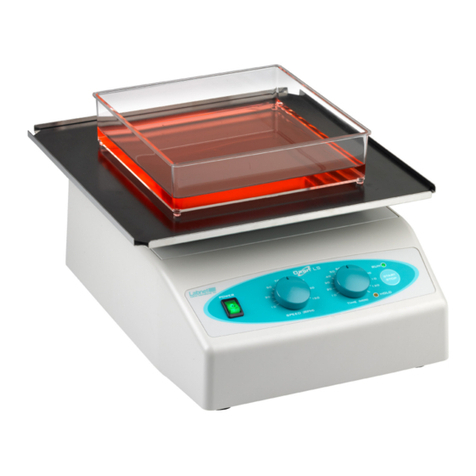

ThePrecisionDubnoffMetabolicShakingIncubator

Bath and the Precision Shallow-Form Shaking

Bathhavebeendesignedprimarilyfortheincubation

of tissue and homogenates.

The microprocessor control panel houses all

functions necessary to operate the bath. The five

push-button switches and single display window

allow the operator to adjust bath temperature,

motor speed, and calibration via a single set of

controls.

The proportional integral derivative temperature

control allows precise temperature control from

5°C above ambient to 55°C without cover and to

99.9°C with use of the gable cover provided.

A high limit thermostat is provided and can be set

to prevent heater runaway in the event of

temperature control failure.

Trayshakingspeed is easily adjusted between 30

and 200 cycles per minute at 5 cpm intervals.

The tray stroke can be adjusted to three different

lengths: .5", 1" and 1.5". The drive mechanism

containsself-lubricatingbearingswhichrequireno

maintenance.

The tray is easily removable and rides silently on

four plastic balls.

The interior of the bath is constructed of stainless

steel and is designed for operation with distilled

water or water solutions, such as water/ethylene

glycol. Donot use deionizedwater. Ifdeionized

is the only water available, a mixture with a 50/50

ratio of deionized and tap water should be used.

Deionized water (18 MEG) will damage metals.

The body is made from galvanized steel and is

painted for added protection. A drain is located at

the far left hand end of the bath. A stainless steel

gable cover is also provided with the bath.

The230voltunitsareidenticalinappearancetothe

115voltunitsexceptfortheadditionofastep-down

transformer for the motor.

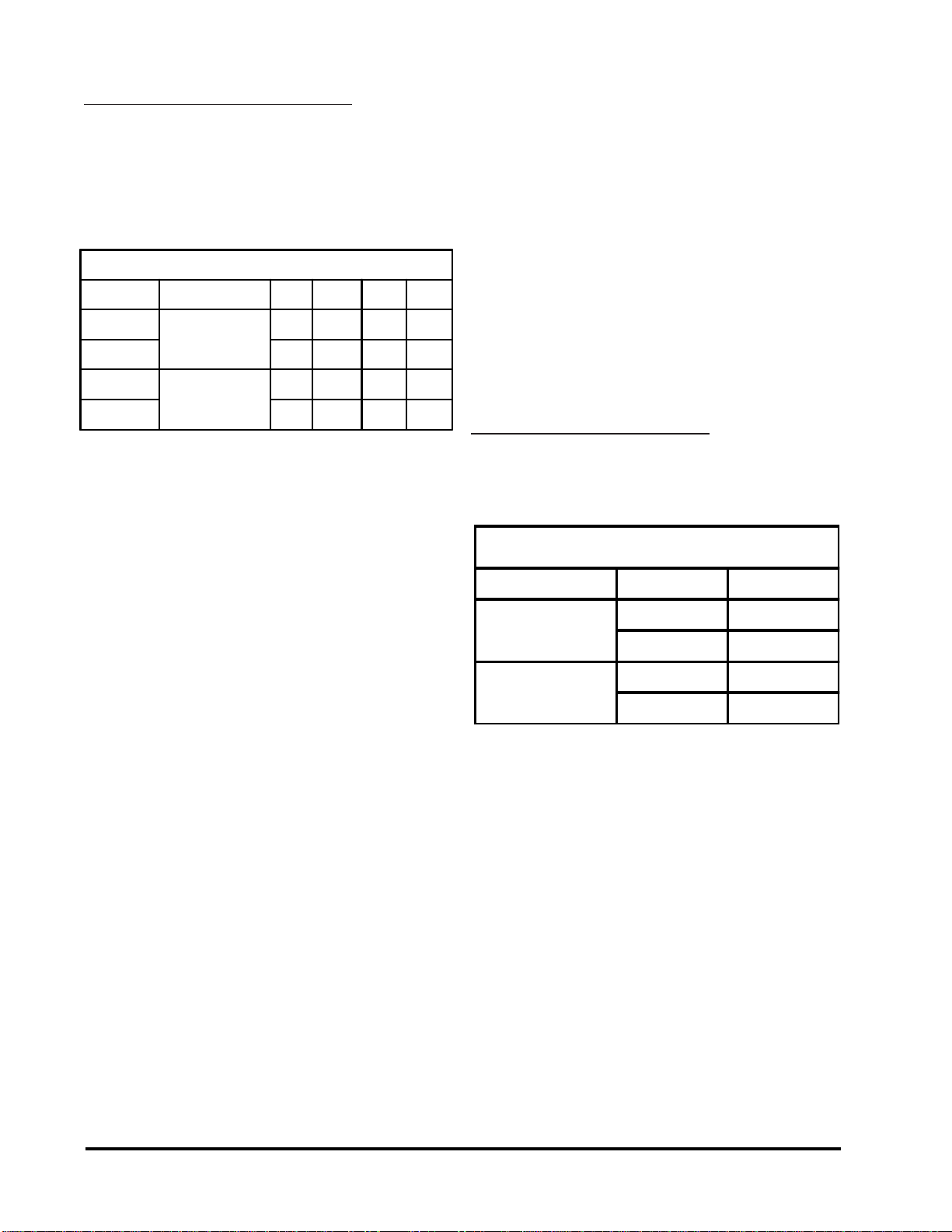

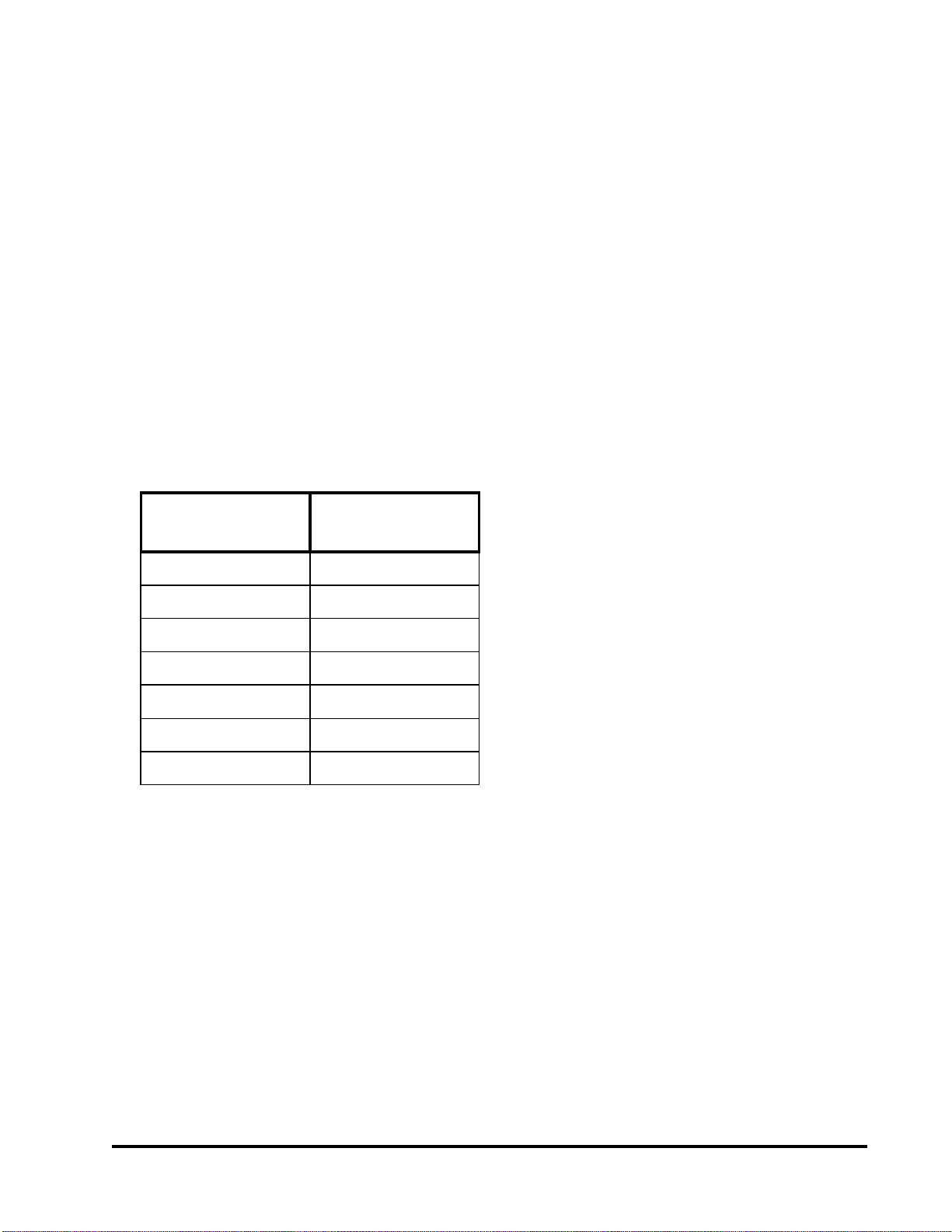

PERFORMANCE DATA

Thefollowing table identifies thespecificationsfor

the Shallow Form and Dubnoff Shaking Baths.

Performance Data

With Cover Without Cover

Uniformity 37°C ±.05 ±.15

56°C ±.05 ±.2

Sensitivity 37°C ±.05 ±.1

56°C ±.05 ±.1

Listing of Models included in this Manual

Cat.No. Description Volts Hertz Watts Amps

51221076 Dubnoff Metabolic

Shakin

g

Incubator

Bath

120 50/60 1000 8.3

51221077 230 50/60 1000 4.3

51221079 Shallow Form

Shakin

g

Bath

120 50/60 1000 8.3

51221078 230 50/60 1000 4.3

3

INSTALLATION

WARNING

INSTALLATION SHOULD BE COMPLETED BY

QUALIFIEDPERSONNELONLY.

Location - The most uniform operating conditions

willbeobtainedbyplacingthebathonalevelsurface

in an area remote from drafts, ventilating outlets,

radiators, and other rapidly changing ambient

conditions.

Electrical Connections -

IMPORTANT

FOR PERSONAL SAFETY, THIS APPARATUS

MUSTBEPROPERLY GROUNDED.

1. Thepowercordprovidedonthisunitisequipped

withathree-prong(grounding)plugwhich mates

with standard three-prong grounding wall

receptacletominimizethepossibilityofelectric

shockhazardfromthisapparatus. Ifindoubtthe

usershouldhavethewallreceptacleandcircuit

checkedbyaqualifiedelectriciantomakesure

the receptacle can provide adequate current

andisproperly grounded.

2. Whereastandardtwo-prongwallreceptacleis

encountered, it is the personal responsibility

andobligationoftheusertohaveitreplacedwith

aproperlygroundedthree-prongwall

receptacle.

Do not, under any circumstances, cut or remove

the third (ground) prong from the power cord. Do

not use a two-prong adapter plug.

Determinethetotalamountofcurrentbeingusedby

otherapparatusconnectedto the circuit that will be

used for this apparatus. It is critical that the added

current demand (see nameplate) of this and other

equipmentusedonthesamecircuitdoesnotexceed

theratingof the fuse or circuit breaker.

CAUTION

BESURETHATTHEPOWERSUPPLYISOFTHE

SAME VOLTAGE AS SPECIFIED ON THE

NAMEPLATE.

Shaker Clip Installation - The spring retainers

providedaredesignedtofirmlyholdflaskclipsinthe

shakingtrayholes.

1. It is important that these retainers be inserted

into tray holes before inserting optional flask

clips.

Stroke Length Adjustment - The length of the

shakerstrokeissetatthefactoryfora1"stroke. The

following procedure should be observed when

changingstrokelengths.

WARNING

TURN OFF POWER TO THE BATH AND

DISCONNECT THE BATH FROM ITS POWER

SUPPLY.

1. Togainaccesstothemotordrivehub,remove

four screws in upper side panel corners, and

carefullyopenthecontrolpanel.Onceopened,

the 3-position drive hub will be immediately

visibleattop-centerofcontrolhousing.

2. Toalterthestrokelength,unscrewthebearing

mounting screw from its present position and

rethread the screw firmly into the hole that will

provide the desired stroke length. The hole

closestto the hub centerprovidesthe shortest

stroke;theonefurthestaway,thelongest. The

threethreadedopeningsprovidestrokelengths

of 0.5", 1.0", and 1.5".

3. After selecting desired stroke length, close

control panel and replace the four screws.

Reconnectthebathtopowersource.

Dubnoff Flowmeter Assembly (Optional) -

1. Theoptionalflowmeterassemblyisinstalledby

placingthedovetailonthefrontoftheflowmeter

intothematingbracketlocatedonthebackright

sideofthebath.Theflowmeteriscalibratedfor

use with oxygen, nitrogen, and CO2 and is

scaledtoreaddeliveryrates upto10standard

cubicfeet perhour.

2. Connect the bottom hose barbs to the gas

sources. The top hose barbs connect to the

gassing hood(s) with the tubing provided. A

valveisconnectedtoeachoftheflowmetersfor

moreprecisecontroloftheatmosphere.

4

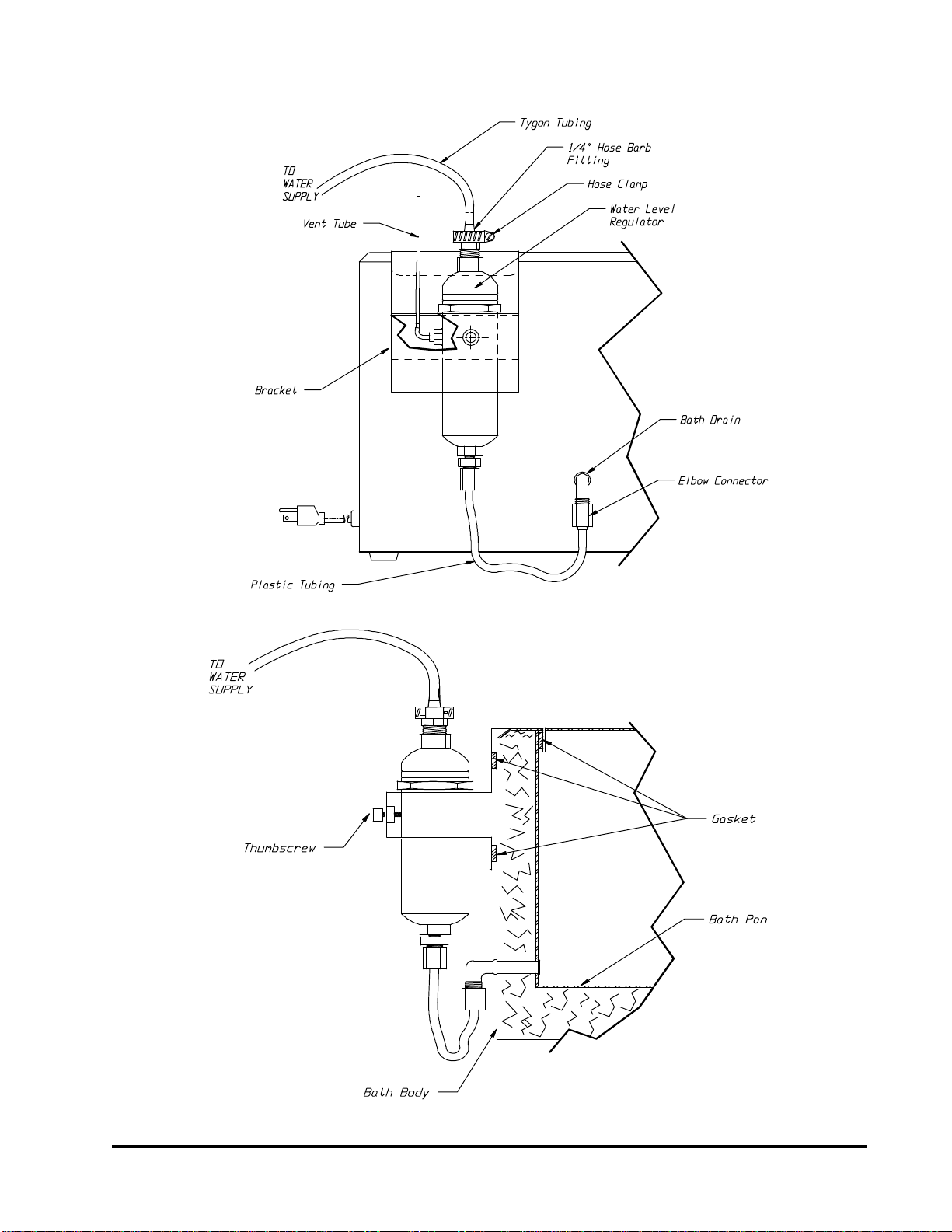

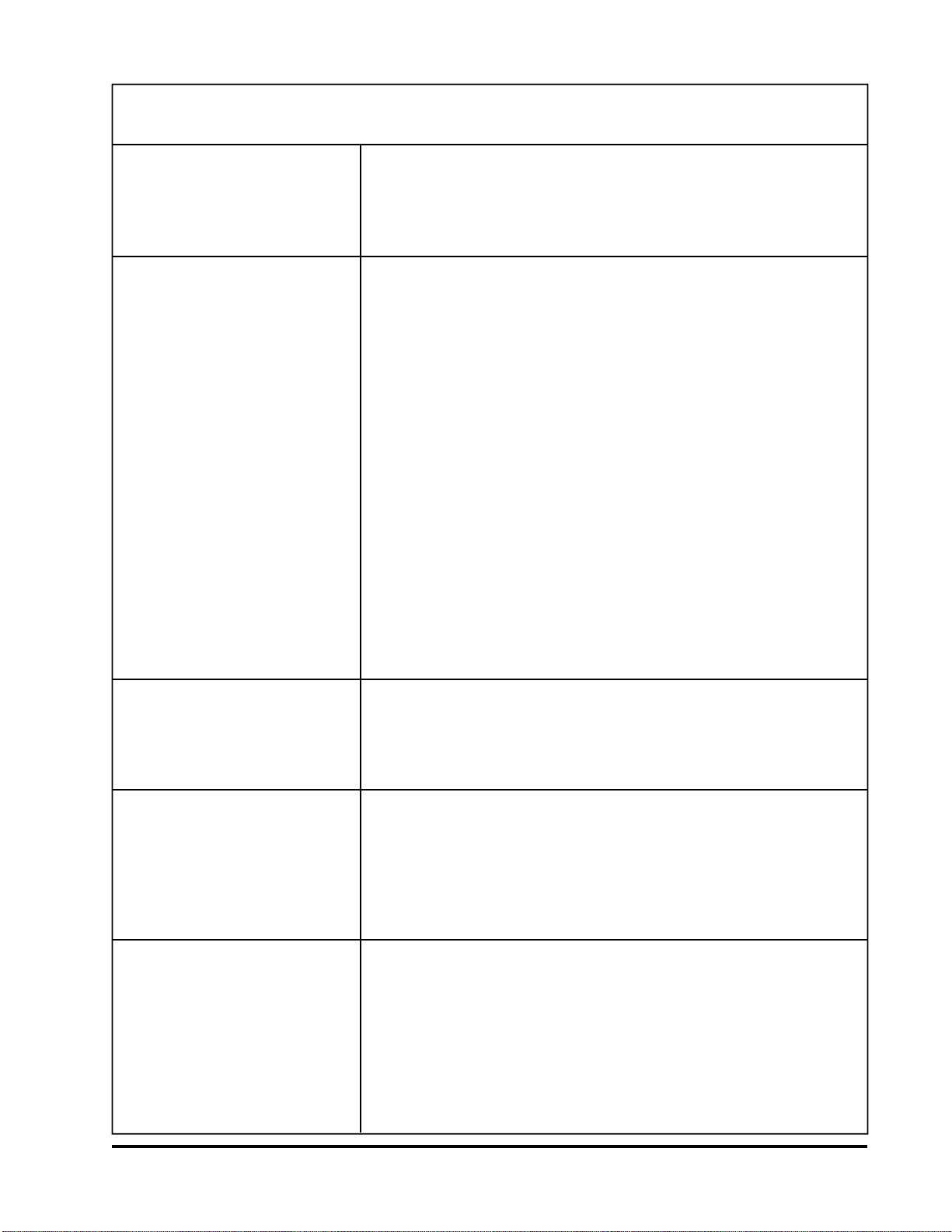

WATER LEVEL REGULATOR

(OPTIONAL)

INSTALLATION INSTRUCTIONS - Use the

followingstepsalongwithFig.1&2shownonthe

followingpage.

1. Turn off unit, disconnect power & drain water

fromthe bath.

2. Unscrew drain plug from side of bath body.

3. Replacewithelbowconnector(shippedloose).

NOTE

TO INSURE GOOD SEAL, WRAP THREADS

WITHTEFLONTAPEOREQUIVALENTSEALER.

4. Tighten elbow connector so open end (tube

fitting)facesstraightdown.

5. PlaceWaterLevelRegulatorBkt.Ass'yonthe

lip of the bath pan (drain side of the bath

towardstherearoftheunit).Thesmallflange

with gasketing near the top of the bracket

shouldrestagainsttheinsideofthebathpan.

Theother2flangeswithgasketingshould rest

againsttheoutsideofthebathbody.

6. Insert the plastic tubing (coming from the

bottom of the water level regulator) into the

elbow connector (at the drain) & tighten the

elbowconnectorfittingfirmlytoinsureagood

seal.

7. Uncoil Tygon tubing & press onto 1/4" Hose

Barb Fitting (located at the top of water level

regulator).

8. Hook-upotherendofthetygontubingtowater

supply&turnonwater.(Waterpressureshould

fall within the following range: MIN is approx.

15 PSI, MAX is approx 75 PSI)

NOTE

WATERLINEMARKINGONTHEWATERLEVEL

REGULATOR IS AN INDICATOR OF THE

APPROX. WATER LEVEL THAT WILL BE

MAINTAINED IN BATH. THE ASS'Y HAS BEEN

SETTOMAINTAINAPPROX.1-3/4"OFWATER.

TO RAISE THE SET WATER LEVEL, LOOSEN

THUMBSCREW & RAISE WATER LEVEL

REGULATOR TO DESIRED LEVEL (COINCIDE

WITH WATER LINE MARK) & TIGHTEN

THUMBSCREW TO HOLD WATER LEVEL

REGULATORINPLACE.

NOTE

DO NOT OVER-TIGHTEN THUMBSCREW

5

WATER LEVEL REGULATOR ASSEMBLY

FIGURE 2

CUTAWAY FRONT VIEW OF BATH

FIGURE 1

SIDE VIEW OF BATH

6

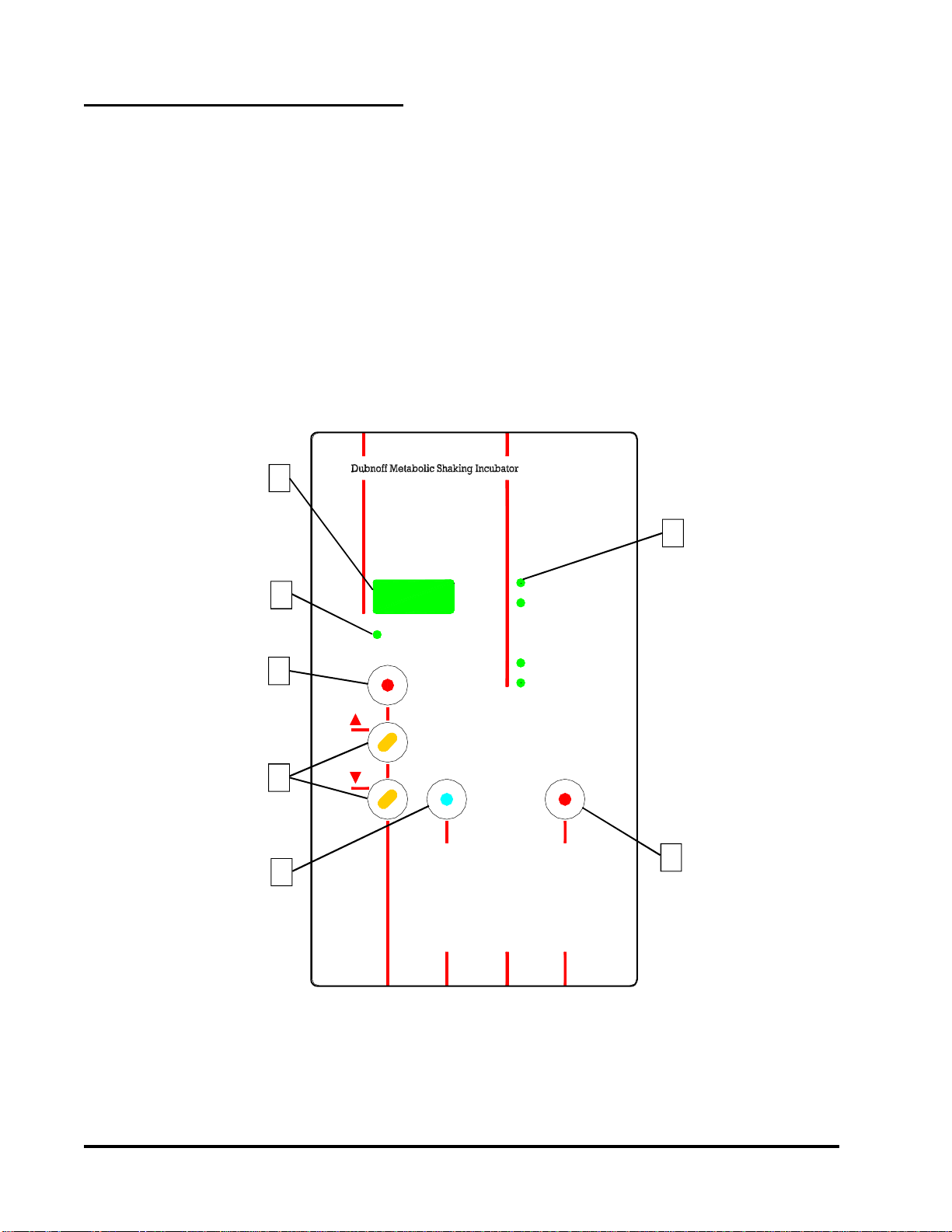

pq

Set Point

Actual

BathTemp., °C

Speed,RPM

Speed,RPM

BathTemp., °C

START/STOP

SELECT/ENTER

Temp.

Offset

HeaterOn

Shaker

PressSELECT/ENTERagain to setthenew value.

PressSELECT/ENTER button toset point.

PressSTART/STOP tobegin or end shaking.

Press or untilvalue is displayed.

Toadjust temperature orshaking speed :

FIGURE A

3

7

5

4

6

2

1

EXPLANATION OF CONTROLS

Power Switch - The power switch is located on

the lower right hand side of the bath, it provides

power for the entire unit.

Hi-LimitThermostat-TheHi-LimitThermostatat

is located immediately to the left of the power

switchonthelowerrighthandcornerofthebath.

The high limit thermostat provides prevention of

heaterrunawayintheeventoftemperaturecontrol

failure.

The Control Panel

islocatedontop

ofthe bath.

1. LEDDisplay-The

three-digit LED

display is used

toshowboththe

actual and

setpoint values

for temperature

and shaking

speed.

2. HeaterOnLamp-

The "Heater

ON" lamp is

illuminated

when power is

applied to the

heater.

3. Indicator Lamps - These lamps indicate

which of 4 parameters (Actual Temp, Actual

Speed,SetpointTemp,andSetpointSpeed)

is displayed in the LED window.

4. Enter Key - The Enter Key is used to choose

which parameter is displayed in the LED window,

and is also used to store a new setpoint value.

5. UP & DOWN Keys - are used to adjust

temperature

andspeed

setpointvalues.

Pressing &

holdingthese

keys will

increment/

decrementthe

displayvalue

slowly at first,

and then rapidly

ifheld.

6. Offset Key-

is used to

adjustthe

temperature

to match a

calibrated

reference

thermometer.

7. Shaker

Start/ Stop Key

-This key is

usedto toggle

the tray shaking

motion on or

off.

7

OPERATION CAUTION

EXERCISE CARE WHEN USING ACIDIC OR

CAUSTIC SOLUTIONS AS THEY WILL ATTACK

THEGALVANIZEDSTEELBATHBODYIFSPILLED

INTOTHEBATH.IFSPILLSDOOCCUR,THEBATH

LIQUIDSHOULDBEIMMEDIATELYDRAINEDAND

THE UNIT THOROUGHLY FLUSHED. SPILLS AND

CONDENSATION SHOULD BE CLEANED/

REMOVED FROM ALL METAL SURFACES AFTER

EACH USE.

Whenfillingthebathwithwater,allowancemustbe

madeforthedisplacementofwateruponimmersion

of samples. Also make allowance for splashing of

water from tray oscillation movement.

CAUTION

WATER LEVEL REQUIREMENTS:

MINIMUMLEVEL-ONEINCHOFWATERSHOULDBE

MAINTAINED AT ALL TIMES. THIS LEVEL WILL

KEEP HEATERS COVERED AND WILL HELP

PREVENTHEATERFAILURE.

MAXIMUMLEVEL-WATERLEVELSHOULDBEKEPT

LOWER THAN THE TRAY SHAFT FITTING. WATER

FILLED BEYOND THIS LEVEL COULD POSSIBLY

SEEPINTOCONTROLPANELANDCAUSEDAMAGE.

To conserve energy, reduce evaporation, and

increase temperature control accuracy, use the

gablecover provided.Donot usealuminumfoil as

a cover, as it may cause corrosion due to an

electrochemical reaction.

1. Add distilled water to bath. Use water levels

as instructed above.

2. Power up: Depress the power switch located

atthelower righthandcorner ofthebath. The

unit is fully operational upon application of

power, and the display will read actual bath

temperature.

3. To set temperature control point:

a. PressENTERuntilsetpointtemperatureis

displayed.

b. Press UP or DOWN until desired setpoint

is displayed.

c. Press ENTER again to set the new value.

d. Display will return to actual temperature.

e. If ENTER is not pressed, new values will

not be set and display will return to actual

temperature.

4. To set new speed:

a. Press ENTER until setpoint speed is

displayed.

b. Press UP or DOWN until desired speed is

displayed.

c. Press ENTER again to set new speed.

d. Display will show actual speed for 10

seconds,thenreturntoactualtemperature.

e. If ENTER is not pressed, new values will

not be set and display will return to actual

temperature.

5. To begin or end shaking motion:

a. Press START/STOP key.

6. To set temperature offset:

a.Temperatureoffsetshouldbeusedtomatch

a stable bath's actual temperature display

to a calibrated thermometer. The offset

valueisenteredasthe

difference

between

the two values.

b. Press ENTER until actual temperature is

displayed.

c.WhilepressingOFFSET,pressUPorDOWN

keys to desired value. Continue holding

offset and press ENTER to set new value.

d. IfENTERisnotpressed,newvalueswillnot

be set and display will return to previous

temperature value.

e. Display should now match your calibrated

thermometer.

f. Temperature setpoint will now control at

previous setpoint plus offset value.

g. Repeatstep3toreadjustsetpointtodesired

value.

h. Example:Setpointis37°andactualdisplay

bathtemperatureisstableat37°.Calibrated

referencethermometerreads37.2°.Press

OFFSETandtheUPkeyuntildisplayreads

.2.PressENTERwhilestillholdingOFFSET

key. Release keys. Display and Setpoint

willnowbe 37.2. Readjust setpoint to 37°.

NOTE

AS WATER BATHS ARE OPERATED, ESPECIALLY

AT ELEVATED TEMPERATURES, CONDENSATION

WILL FORM ON THE UNDERSIDE OF THE GABLE

COVER.THEAMOUNTOFCONDENSATIONCANBE

CONSIDERABLE. CARE SHOULD BE EXERCISED

WHEN REMOVING THE COVER SO THAT WATER

WILL FALL BACK INTO THE BATH CHAMBER, AND

NOTONTHEBATHSURFACE.THECOVERSHOULD

BE PLACED UPSIDE DOWN WHEN REMOVED TO

MAINTAIN A DRY WORK AREA.

8

CAUTION

Never use the following chemicals.

-Aqua Regia -Ferric Chloride

-Iodine -Sodium Azide

-Sulfuric Acid

Removing Discoloration: Should the stainless

steeleverbecomediscoloredbyironrust,usethe

followingproceduretoremovealltracesoftherust

and restore the stainless steel.

WARNING

OBSERVE THE FOLLOWING SAFETY

PRECAUTIONS! USE HEAVY GLOVES OR

OTHER ADEQUATE HAND PROTECTION.

WEARGOGGLESOROTHERADEQUATEEYE

PROTECTION. WORK ONLY IN AREAS WITH

ADEQUATEVENTILATION.

Prepare a solution of 20% nitric and 1.5%

hydrochloricacid(ifpreferred,a2%to5%solution

ofwarm oxalicacid maybeused). Swab solution

over surface, allowing it to remain until all rust is

loosened. This will usually take 1 to 2 minutes.

Assoonasrustisloosened,immediatelyflushwith

clean distilled water until all acid is removed.

MAINTENANCE

OPTICAL DISC - Check the optical disc monthly.

Verifythattheopticaldiscisfreeofforeignmaterial.

Ifnot,wipediscclean.Rotatediscbyhandoneturn

clockwiseandverifythatdiscdoesnotrubagainst

optical sensor; loosen 2 set screws on eccentric

and reposition disc, if required.

CLEANING -Stainless steel will resist corrosion;

however, it is not impervious to it. Proper

maintenance of the stainless steel bath chamber

willhelpassuremanyyearsofservice. Itshouldbe

cleanedregularlywithmildsoapywaterandrinsed

with distilled water. Should algae or other

undesirablemicroorganismsformonthetopofthe

bathmedia,addalittleformaldehydeorquaternary

ammonium germicide available from Precision,

P/N51200912.

CAUTION

AVOID SPILLING HARSH CHEMICALS ONTO

THEBATHASCORROSIONOFTHESTAINLESS

STEELMAY RESULT.

IMPORTANT

IFITISNECESSARYTOUSETHEFOLLOWING

CHEMICALS, LIMIT THE TIME TO A MAXIMUM

OF FOUR HOURS. CLEAN SURFACES

IMMEDIATELYAFTERUSE.

-Aluminum Chloride -Barium Chloride

-Bichloride of Mercury -Calcium Chloride

-Carbolic Acid -Chlorinated Lime

-Citric Acid (boiling) -Dakin's Solution

-Ferrous Chloride -Mercury Salts

-Lysol Mercuric Chloride -Phenol

-Potassium Permanganate -SodiumHypochlorite

-Potassium Thiocyanate -Tartaric Acid

-Stanous Chloride

9

TROUBLESHOOTING 4. Turn ON the main power.

5. The voltmeter should be reading

approximately 14 volts DC ±2.

6. Connect the positive lead to TP3 ±5V. The

voltmetershouldbereading+5voltsDC±0.5.

7. Turn OFF main power. Change the scale of

the voltmeter to 200 VDC. On later versions

of the POWER SUPPLY board there is a

jumper JP1, located near the transformer,

thatmustbeinstalledtomeasurethefollowing

voltage.

8. Connect the negative lead of the meter to

anode (non-stripped end) of CR6 and the

positiveleadtothecathode(strippedend)of

CR7.

9. Turn ON the main power and measure the

voltage. The measured voltage should be

between 140 and 150 VDC.

10. Turn OFF the main power.

11. Connect the display board ribbon connector

to the power supply board at J102 and then

repeat steps 3 thru 6. Do not connect the

connectortotheCPUboardatthistime.Ifthe

above voltages are not measured again, the

displayboard has a badcomponentwhich is

loadingdownthevoltages.Ifthevoltagesare

still present, continue on to step 12.

12. Connect the display board ribbon connector

totheCPUboardJ310andrepeatsteps3thru

6. If the above voltages are not measured

again, the CPU board has a bad component

whichisloadingdownthevoltages.Thisboard

will have to be replaced.

WARNING

SERVICESHOULDBEPERFORMEDONLYBYA

QUALIFIEDTECHNICIAN.BEFOREREPLACING

ANY ELECTRICAL OR MECHANICAL

COMPONENTS, UNPLUG THE LINE CORD. IF

ELECTRICAL POWER IS REQUIRED FOR

SERVICE,USEEXTREMECARE.

RefertoProblemsandSolutionsfortroubleshooting

information on the baths. This guide provides the

basic information required to repair the bath.

The following is a list of the tools and instruments

requiredtoperformtheproceduresoutlinedinthe

Troubleshooting"Problems&Solutions"section.

Tools Needed:

•Phillips or Flat Blade Screwdriver

•7/16" Socket or adjustable wrench

•Ohmmeter

•DCVoltmeter

•ACVoltmeter

•5VDC Power Supply

When changing circuit boards, please use

CAUTION when re-installing the flat cable

connectors that come from the display board.

MakesurethepinsareNOTbentorbroken. Circuit

boardswillnotoperatecorrectlyifthesepinshave

been abused because they will not receive the

necessary signals from other boards.

Before attempting any troubleshooting for a

particular problem, it is good practice to verify

power supply voltages of the POWER SUPPLY

board #34372501. Read these steps to get

acquaintedwiththeprocedure.

1. BesurethatthemainpowersourceisOFFor

disconnected.

2. Insure that J101 and J105 are connected to

the POWER SUPPLY BOARD. Disconnect

J102 that comes from the CPU and the

DISPLAY at this time.

3. Connectthenegativeleadofthevoltmeterto

TP2-COM. SelectaVDCof20. Connectthe

positive lead to TP1 - UNREG.

10

TP1-COMtestpoint. Measurethevoltageat

U7-pin2. Itshouldbeapproximately14volts

DC. ThenmeasurethevoltageatU7-Pin6.

Itshouldbeapproximately5voltsDC. Ifthe

14voltsispresentbutnotthe5volts,theCPU

boardmust bereplaced.

4. Checktemperatureprobe.

a. Measure the bath water temperature and

makenoteofit. Makesureitwillnotchange

drasticallyduringthischeck.

b. WithaDCvoltmeter,measurethesupplyof

thetemperaturesensoratJ302pins1&3. It

shouldbeapproximately5volts. Ifitis,then

continue on to step C. If not, see Step 3a.

c. Measuretheoutputofthetemperaturesensor

atJ302pins2&3.Pin3beingthereference

orground.Theoutputrelationshipofvoltage

to degrees centigrade is listed in the table

below. Compare the measured voltage to

the temperatures listed to determine if the

probe is working.

5. The bath is not heating when it should be

requesting heat. Voltage measurements are

made on the POWER SUPPLY BOARD

#34372501.

a. Select a setpoint temperature at least 10°

above what the actual temperature is. The

bathshouldberequestingheatasindicated

bytheheater"ON"indicatorlamponthefront

panel. It should be on continuously, not

flashing.

b. MeasurethevoltageatU1-PIN2withrespect

toTP2-COM. Itshouldbenogreaterthan4

VDC.

c. MeasuretheDCvoltageacrossR4,sincethe

bath is requesting heat, there should be

currentflowing through this resistor making

the voltage drop equal to 3 vdc ±0.5.

GENERALINFORMATION-ThePOWERSUPPLY

PCB ASSEMBLY #34372501 has the triac (solid

state AC voltage switch) on it which supplies the

power to the heater. This triac is "told" to operate,

whenneed be, by the microprocessor.

There is another device known as an octo-coupler

whichservesasthehigh/lowvoltageisolatorbetween

thetriac and themicroprocessor.

When the bath starts experiencing temperature

problem and/or variations, due to known controller

malfunctioning,thesetwocomponentsbecomeprime

suspects. The reason being they are under higher

operatingstressthanothercomponents.

If thebathstartsexperiencingtemperatureproblems

such as no heat, or "creeping" upward heat, then

follow thetroubleshootinginstructionsbelow. These

instructionsrequiretheuseofavoltmeterbeingable

tomeasureDCandACvoltages(preferablyadigital

voltmeter).

WARNING

THE FOLLOWING TROUBLESHOOTING

INSTRUCTIONSREQUIRETHATPOWERBEON.

ONLY QUALIFIED SERVICE PERSONNEL

SHOULDPERFORMTHESEPROCEDURES.

Openthecontrolcoverandfamiliarizeyourselfwith

thePOWERSUPPLYassembly#34372501. Locate

the triac (Q2), the opto-isolater (U1), the resistor

(R4), andlocatethetestpoint#2(TP2-COM). The

firstmeasurementswillbeDCvoltagemeasurements,

a DC scale of at least 10 volts should be selected.

PROBLEMS & SOLUTIONS

*********** Problem A : No Heat *************

1. Verify that the setpoint temperature is greater

thantheactualwatertemperature.

2. VerifythattheHIGHTEMP lightis"OFF". Ifthe

light is "ON", turn the HIGH LIMIT CONTROL

fullyclockwise.

3. Check temperature probe voltage reference.

These measurements are on the CPU board

#34372801.

a. PlacethenegativeleadofaDCvoltmeteron

Temp

Degrees C Volt Temp

Degrees C Volt

10 0.500V 60 1.400V

20 0.680V 70 1.580V

30 0.860V 80 1.760V

40 1.040V 90 1.940V

50 1.220V 99 2.218V

11

d. If the last two steps are not as stated, then

most likely the CPU board is bad and it will

havetobereplaced.Iftheyare,continueon.

e. Switch the voltmeter to an AC volts scale

capableofreading120volts.

f. MeasurethevoltagebetweenU1-PIN4and

U1-PIN 6. It should be less than 1 VAC.

g. Ifitisnot,thenmostlikelytheopto-couplerU1

isbadand the POWER SUPPLY board will

have to be replaced. If it is, continue on.

h. Measure the voltage directly across the

heater. Itshouldbelinevoltage 110VACto

120VAC.

iIfitisnot,thenmostlikelythetriacQ2isbad,

andthePOWERSUPPLYboardwillhaveto

bereplaced.

6. Checkheater.

a. Disconnectthebathfromitselectricalsupply.

b. Isolate the heater from any circuitry by

disconnectingoneoftheheaterleads.

c. Using an ohmmeter, check the heater

resistance. Appropriate heater resistance

valuesare listedbelow:

If the resistance reads 0 or infinity, then

replacetheheater.

d. Check the resistance between the heater

leads and ground (green wire). If the

resistancereads0ohms,replacetheheater.

********* Problem B: Constant Heat **********

1. Bathis heating when it isnotrequesting heat.

a. Select a setpoint temperature at least 10°

below the actual temperature. The bath

should not be requesting heat as indicated

by the HEATER ON indicator lamp on the

frontpanel. ItshouldNOTbeoncontinuously

orevenflashing.

b. MeasurethevoltageatU1-PIN2withrespect

to TP2-COM. It should be no less than 4

VDC.

c. Measure the DC voltage across R4. The

voltageshouldbeapproximatelyzerovolts.

d. IfthelasttwostepsareNOTasstated,then

most likely the CPU board is bad and it will

havetobereplaced,otherwise,continueon.

e. Switch the voltmeter to an AC volts scale

capableofreading120volts.

f. MeasurethevoltagebetweenU1-PIN4and

U1-PIN6. Itshouldbelinevoltage110VAC

to120 VAC.

g. If it is not, most likely the opto-coupler U1 is

bad and the POWER SUPPLY board will

have to be replaced. If it is, continue on.

h. Measure the voltage directly across the

heater.It should beapproximately0 VAC.

i. Ifitisnot,thenmostlikelythetriacQ2isbad,

andthePOWERSUPPLYboardwillhaveto

bereplaced.

2. Check Temperature Probe. Problem A, Step 4.

115 VOLT 230 VOLT

Dubnoff &

Shallow Form

Shaking Baths 15 OHMS 57 OHMS

12

*** Problem C: Unstable Temperature ***

Control or Display

1. Use gable cover provided to improve

temperaturecontrol.

2. Ifcontrol isstablebutnotatdesiredtemperature,

thenchecktemperaturecalibration.Re-adjustif

necessary.

3. Check Temperature Probe, Problem A, Step 4.

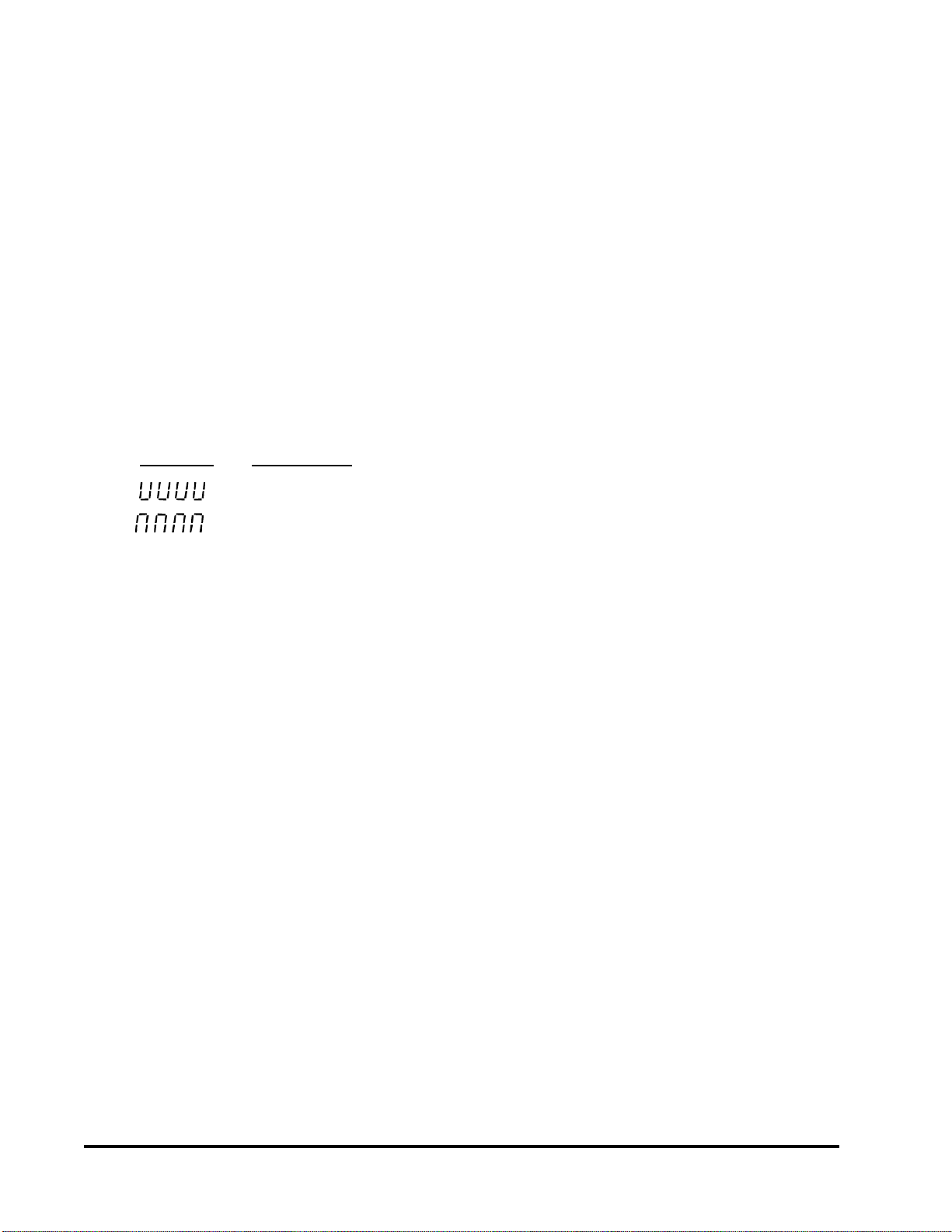

** ProblemD: Display Reads NNNN orUUUU **

The control boards have the ability to detect an

OPENorSHORTEDtemperaturesensor. These

twoconditionsareshownonthedisplayasfollows:

DISPLAY CONDITION

Before coming to the conclusion that the probe is

badwhenoneofthesedisplaysappear,checkthe

connection of the probe to the circuit board for

polarityandalignment.

**ProblemE: DisplayReadsallEights(8888) **

1. Themostcommoncauseof thisproblemisthe

failure of the driver integrated circuit on the

DISPLAY/KEYBOARD board (#34373101).

Replaceit.

*** ProblemF: MotorDoesNotShakeTray ***

1. Verify that the speed setpoint is greater than 0.

2. Later versions of the POWER SUPPLY board

haveajumperJP1locatednearthetransformer.

Verify thatthis jumper isinstalledif applicable.

3. Press the Start/Stop key. If the tray shakes

violentlyforafewmomentsthenstops,replace

theoptical sensor.

4. Check tray linkage for binding.

a. Remove tray from the bath.

b. Disconnectthepushrodfromeccentricby

removingthe bolt.

SHORT CIRCUIT

OPEN CIRCUIT

c. Slidethepushrodbackandforth. Thepush

rodshouldslideveryeasilyinitshousing. If

not, replace the push rod and the bearing

housing.

5. Checkmotor.

a. Disconnect motor connector J103 from the

powersupplyboard.

b. Usinganohmmeter,measuretheresistance

between the black leads (Pins 3 & 4). The

resistance should be approximately 1300

ohms.

c. Usinganohmmeter,measuretheresistance

between the blue leads (Pins 1 & 2). The

resistance should be approximately 130

ohms.

d. Ifneitheroftheaboveresistancesarenotas

stated,replacethemotor.

e. Checktomakesurethereisanopencircuit

between any combination of black and

blue leads. If a resistance is measured

between any black and blue combination,

replace the motor.

6. Check the DISPLAY board #34373101. Even

thoughthischeckisfortheDISPLAYboard,the

voltage measurements will be made on the

POWERSUPPLYboard. Thecommandsignal

thatdrivestheoutputcircuitforthemotorcomes

fromthe displayboard.

a. Be sure the main power is "OFF".

b. PlacethenegativeleadofaDCvoltmeterto

TP2-COM and the positive lead of the

voltmeter to the lead of R6 closer to J102.

Disconnect the motor from the POWER

SUPPLYboardbydisconnectingJ103.

c. Turn"ON"themainpowerandselectaspeed

of200.

d. During normal operation, the voltage at R6

shouldbe about4.4volts DCwith the motor

"OFF". Press the START/STOP key. For

normal operation, this voltage will start to

reducetoabout2.3voltsDCinapproximately

15 seconds and then jump back to 4.4 volts

DCandremainthereuntiltheSTART/STOP

key is pressed again.

13

e. Ifthissignal is NOT changing as mentioned

above when the START/STOP key is

pressed,thenmostlikelytheproblemisinthe

DISPLAYboardanditwillhavetobereplaced.

f. Re-connect the motor back to J103 on the

POWERSUPPLYboard.

7. Check Power Supply Board #34372501.

a. If Step 6 has checked out fine, then possibly

the power circuit for the motor has failed.

Locate the diode CR11 on the POWER

SUPPLY board and place a DC voltmeter

acrossitwiththepositiveleadonthecathode

(band side) and the negative lead on the

anode. The listed voltages appear across

the diode for different speeds. Select a

couple of these speeds and verify the

voltages.

*Problem G: Motor Speed Erratic or Fully on *

1. Check Optical Disc.

a. The optical disc should be free of foreign

material. Ifnot,cleandisc.

b. The disc should be parallel to the bottom of

thebath and centeredin the opticalsensor.

If not, loosen the 2 set screws on eccentric

andreposition thedisc.

c. Thediscshouldbesmoothandflat. Ifthedisc

is bent or warped then replace the disc.

d. Whilethemotorisoperating,thediscshould

NOTcomeincontactwiththeopticalsensor

at any time.

2. CheckOpticaltransmitter.

a. ConnectthenegativeleadofaDCvoltmeter

to TP1-COM on the CPU board.

b. Withthebath"ON"andmotor"OFF"or"ON",

use the positive lead of the voltmeter to

measure the voltage at J303-Pin 1 of the

CPU board. The correct reading should

approximatelybe1.2voltsDC. Ifthereading

deviatesconsiderablyfromthis,replacethe

opticalsensor.

3. CheckOpticalSensor.

JustastheOpticalDisccanbedirty,thelenses

of the optical transmitter and sensor can also

accumulate dust and dirt. It would be good

practice before making the following voltage

measurements to be sure these lenses are

clean. Thelensesarelocatedontheinnerwalls

ofthesensor.

a. ConnectthenegativeleadofaDCvoltmeter

to TP1-COM on the CPU board.

b. ConnectthepositiveleadoftheDCvoltmeter

totheleadofR4whichisclosertotheedge

ofthe circuitboard.

c. Turn the bath power "ON" and the motor

"OFF".

d. Turn the optical disc slowly by hand until a

darkportionofthedisciscenteredbetween

the optical sensor. The voltmeter reading

should be greater than 4 volts DC.

e. Repeat Step D so a clear portion of the disc is

centered between the optical sensor. The

voltmeter reading should be less than 1 volt DC.

f. If the last two steps did not read correctly,

thenreplacetheopticalsensor.

4. Check Display Board #34373101; Problem E,

Step6.

5. Check Power Supply Board #34372501;

Problem E, Step 7.

SPEED SELECTED VOLTAGE ACROSS

CR11

VOLTS DC

30 20

50 30

70 40

90 50

110 60

130 70

150 80

14

Beforeremovinganypartsforreplacement,verify

partinquestionbyfollowingtheinstructionslisted

inthetroubleshootingguide.

Refer to Parts Replacement Table below for

appropriate replacement procedures. Failure to

follow parts replacement procedures may cause

damagetothe bath.

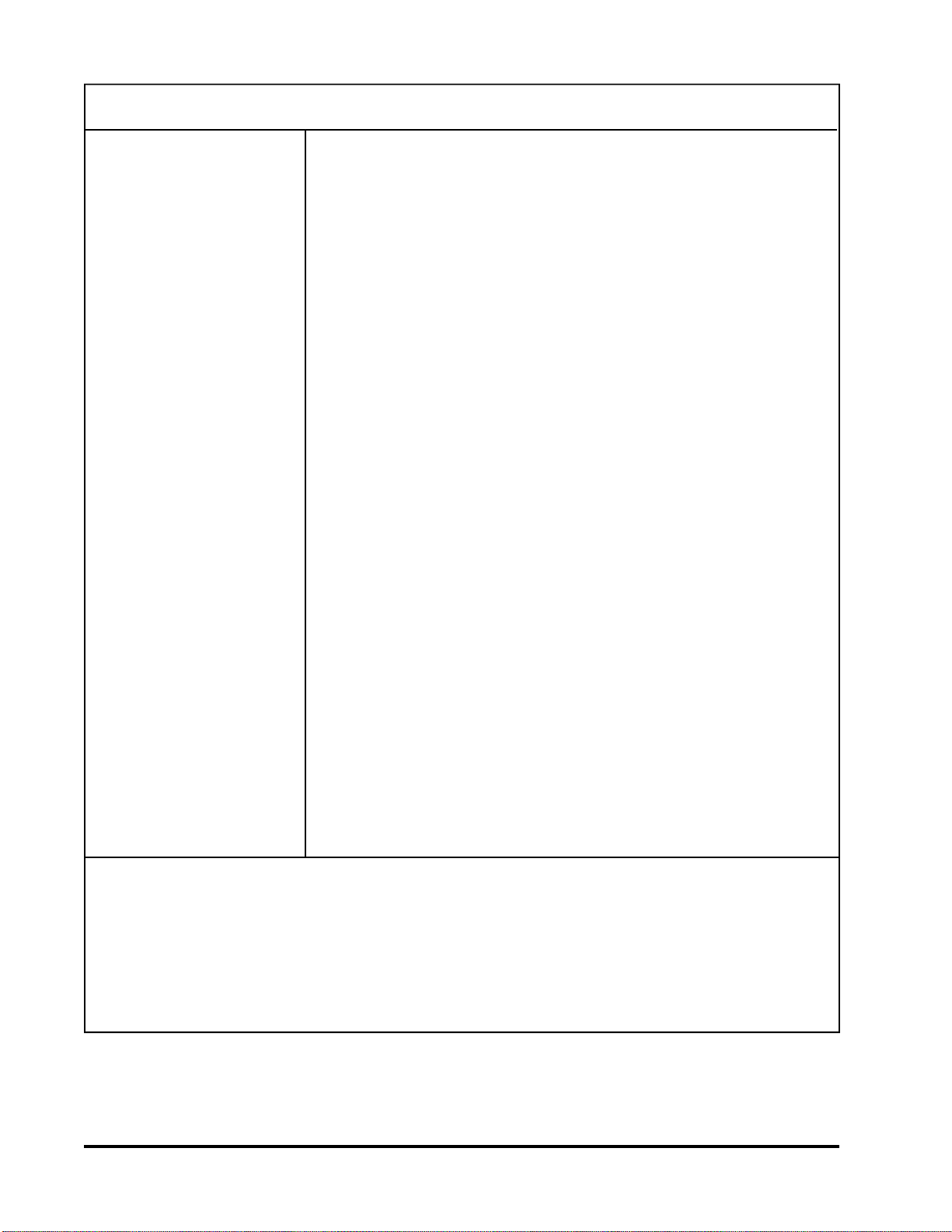

PARTS REPLACEMENT

NOTE: For easiest access to the control housing, place bath on the edge of a bench or table. Remove four

screws on upper side of control housing and carefully lower hinged control panel to the vertical position.

PARTS REPLACEMENT

WARNING

BEFORE REPLACING ANY PART, BE SURE

BATH IS DISCONNECTED FROM POWER

SOURCE. SERVICESHOULDBEPERFORMED

BYAQUALIFIEDTECHNICIAN.

CAUTION

WHENREPLACINGTEMPERATURESENSOROR

HEATER, MAKE SURE ALL SEALS ARE

WATERTIGHTBEFOREAPPLYING ELECTRICAL

POWER.

1. Remove connector J103 from power supply board.

2. Remove bolt on top of plastic bearing and remove bearing.

3. Remove 2 screws from optical sensor and remove sensor.

4. Loosen 2 socket set screws from motor drive eccentric and

remove eccentric from motor shaft.

5. Remove 4 screws holding bracket to wall,

then remove 4 screws holding motor to wall.

6. Reverse above procedure to install new motor.

1. Remove tray from bath.

2. Remove connector J302 from CPU board.

3. Remove temperature sensor fitting from inside bath pan.

-Hold small nut on fitting firmly with a wrench.

-Remove large fitting piece with another wrench.

4. Remove rubber grommet from temperature sensor.

5. Carefully slide sensor through the control housing and remove.

6. Reverse above procedure to install new temperature sensor.

7. Recalibrate new temperature sensor. See Temperature

Recalibrationonpage17.

Replace Temperature

Sensor

1. Remove connector J303 from CPU board.

2. Remove 2 screws holding optical sensor to bracket and remove

sensor.

3. Reverse above procedure to install new sensor.

ReplaceMotor

Replace Optical Sensor

15

PARTS REPLACEMENT (CONT'D)

1. From inside control housing, remove 2 nuts and disconnect

wires from heater leads.

2. Remove two hex nuts from heater ends using a 13/16" socket

and remove heater

3. Reverse above procedure to install new heater.

1. Remove four leads from thermostat terminals.

2. Remove two screws from thermostat bracket and remove

bracket.

3. Carefully tilt bath on its side.

4. Remove eight screws from bottom plate and remove plate.

5. Remove insulation from bottom of pan and between pan

andcontrolpanelwall.

6. Loosen two nuts from thermostat bulb bracket.

7. Carefully remove thermostat from control housing by sliding

bulb through hole in control panel wall.

8. Reverse above procedure to install new Hi Limit thermostat.

Use extreme care when installing new thermostat. A sharp

bend in the thermostat capillary will crimp off flow of

hydraulicfluid.

1. Remove connectors J101, J102, J103, and J105 from board.

Use extra care when removing J102 to not bend connector

pins.

2. Remove five nuts from board and remove board.

3. Reverse above procedure to install new power supply board.

1. Remove bolt on top of plastic bearing and remove plastic

bearing.

2. Disconnect tray from push rod and remove push rod.

3. Remove jam nut from control side of bearing assembly.

4. Slide bearing assembly out and into bath side of unit.

5. Remove bearing cap and wiper seal from assembly.

6. Reverse above procedure to install new bearing assembly.

1. Remove connectors J302 and J303 from CPU board.

2. Remove connector J102 from power supply board. Use

extreme care when removing J102 to not bend connector pins.

3. Remove 4 nuts from CPU board and remove CPU board and

Keyboard/Displayboard.

4. Remove J301 from CPU board. Use extreme care when

removing J301 to not bend connector pins. Remove board.

5. Reverse above procedure to install new board.

Replace Heater

Replace "HI Limit"

Thermostat

Replace Power Supply

Board

ReplaceBearing

Assembly

Replace CPU or Display/

KeyboardBoard

See note on the following

page **

16

PARTS REPLACEMENT (CONT'D)

6. The software must be configured to match the Bath model.

To enter configuration mode, press the upper left pushbutton

while applying power. The upper left push-button is labeled

"Select/Enter." This push-button is used to enter configuration

codes and steps through the different levels of configurations.

When a triangle is shown in the chart, the pushbutton is to be

depressed once for each symbol.

Immediately following power up with the push-button

depressed,the readout will display a 3-digit number. This is

the software revision. The readout will then begin to do a self-

test of digits. Press the "Calibrate" push-button once. The

readout will display 0000. Follow the listing below to complete

theconfiguration.

A. Enter 37 using up/down arrows. Press "Select/Enter"

B. Enter 12 using up/down arrows. Press "Select/Enter"

C. Enter 2.0 using up/down arrows. Press "Select/Enter"

D. Enter 500 using up/down arrows. Press "Select/Enter"

E. Enter 1 using up/down arrows. Press "Select/Enter"

F. Display Not Used. Press "Select/Enter"

G. Display Not Used. Press "Select/Enter"

H. Display will show raw count Press "Select/Enter"

I. LOW TEMP CALIBRATION*

LITTLEc.FactorySetting. Press "Select/Enter"

J. HI TEMP CALIBRATION

BIG C. Factory Setting. Press "Select/Enter"

Configuration is now complete

Replace CPU or

Display/Keyboard Board

See note below **

* Calibration of the low and high end of the sensor input is done at the factory. Field calibration of

the sensor may be performed using the following technique: Enter the configuration routine and

press the top left switch until a little "c" (Item H) is displayed. Add water that is around 10°C to the

bath completely covering the sensor. Insert a calibrated thermometer. After the thermometer

stabilizes, match the display setting to the thermometer reading by pressing the "UP" or "DOWN"

push button switch. Press the top left switch. The readout will now display a big "C" (Item I).

Remove water from the bath and add hot water of about 70 - 80°C. After the unit stabilizes, match

readout display to temperature on thermometer and press the top left switch. Calibration is now

complete.

**Note:

When replacing CPU printed circuit board reprogramming may be necessary.

Follow thoroughly instructions provided with the replacement circuit board.

This manual suits for next models

3

Table of contents

Other Precision Laboratory Equipment manuals