Precision 180 Manual

Installation/Service Manual

General Purpose Water Baths

Models 180, 181, 182, 183,

184, 185, 186, 188

Precision

170 Marcel Drive

Winchester, VA

USA

Phone: 540-869-8623

Toll Free: 800-621-8820

FAX: 540-869-8626

ManualP/N36100124(34002480)

RevBDated08NOV01

10

2

1

0

3

46

5

882

1

9

0

9

10 Off

73

5

4

7

6On

NOTICE

THE MATERIAL IN THIS MANUAL IS FOR INFORMATION PURPOSES ONLY. THE CONTENTS

AND THE PRODUCT IT DESCRIBES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

PRECISION MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THIS

MANUAL. IN NO EVENT SHALL PRECISION BE LIABLE FOR ANY DAMAGES, DIRECT OR

INCIDENTAL, ARISING OUT OF OR RELATED TO THE USE OF THIS MANUAL.

For repair information or replacement parts assistance from the manufacturer,

call Customer Service using our toll free telephone number.

800-621-8820

(FAX) 540-869-0130

Initialrelease

6/99A

INDEX DATE AMENDED PAGES NOTES

REVISION STATUS

Update specs

11/01B2

Contents

1. Introduction .................................................................................................................... 1

2. Unpacking and Damage................................................................................................. 1

3. Specifications ................................................................................................................. 2

4. Installation ...................................................................................................................... 3

5. Operation ........................................................................................................................ 3

6. Maintenance.................................................................................................................... 6

7. Service ............................................................................................................................ 8

8. Replacement Parts List................................................................................................ 10

9. Assembly and Schematic Drawings ........................................................................... 11

10. Warranty ...................................................................................................................... 14

1

1. INTRODUCTION

Precision General Purpose Water Baths are

designed for a wide variety of serological research

procedures as well as a broad range of other

general laboratory applications. Operation and

maintenance of these baths are covered in this

manual; unless specifically noted otherwise, the

informationprovided appliestoall availablemodels.

Precision water baths feature a one-piece, deep-

drawn stainless steel chamber with welded and

painted galvanized steel outer body. Depending

onthe model,eitherone ortwoheaters areattached

to the bottom of the bath chamber. For faster

temperature recovery and reduced power

consumption, the baths are equipped with a

stainless steel cover (except Model 181, which is

equipped with a plastic cover). This cover must be

in place to reach and maintain 100°C.

All units (except Model 180) also feature an

adjustable support shelf which may be set at three

different height levels by simply changing the

position of the legs. Model 180 is equipped with a

non-adjustable diffuser shelf.

As the ultimate user of this apparatus, it is your

responsibility to understand its proper function and

operationalcharacteristics. Thisinstruction manual

should be thoroughly read and all operators given

adequate training before attempting to place this

unit in service. Awareness of the stated cautions

and warnings, and compliance with recommended

operating parameters - together with maintenance

requirements - are important for safe and

satisfactory operation. The unit should be used for

itsintended application; alterations ormodifications

will void the warranty.

WARNING

AS A ROUTINE LABORATORY PRECAUTION,

ALWAYS WEAR SAFETY GLASSES WHEN

WORKING WITH THIS APPARATUS.

2. UNPACKING AND DAMAGE

This merchandise was carefully packed and

thoroughly inspected; save all packing material if

apparatus is received damaged.

Responsibility for its safe delivery was assumed by

the carrier upon acceptance of the shipment;

therefore, claims for loss or damage sustained in

transit must be made upon the carrier by the

recipient as follows:

Visible Loss or Damage: Note any external

evidence of loss or damage on the freight bill, or

express receipt, and have it signed by the carrier's

agent.Failure to adequately describe suchexternal

evidence of loss or damage may result in the

carrier's refusing to honor your damage claim. The

form required to file such a claim will be supplied by

the carrier.

Concealed Loss or Damage: Concealed loss or

damage means loss or damage which does not

become apparent until the merchandise has been

unpacked and inspected. Should either occur,

make a written request for inspection by the

carrier's agent within 15 days of delivery date; then

file a claim with the carrier since the damage is the

carrier's responsibility.

If you follow these instructions carefully, we

guarantee our full support of your claim to be

compensated for loss from concealed damage.

DO NOT, FOR ANY REASON , RETURN THIS

UNIT WITHOUT FIRST OBTAINING

AUTHORIZATION. In any correspondence to

Precision Scientific, please supply the nameplate

data, including catalog number and serial

number.

2

3. SPECIFICATIONS

Precision General Purpose Water Baths feature the following parameters. Volume calculations are

based using water level approximately 1" (25mm) from the chamber top.

Catalog

Number Model

Number

Electrical Characteristics Capacity

Volts Watts Amps Liters Gallons

51221070

51221071 180 120

230 225 1.9

1.0 1.5 0.4

51221064

51221211 181 120

230 225 1.9

1.0 2.5 0.7

51221073

51221068 182 120

230 300 2.5

1.3 5.5 1.5

51221060

51221062 183 120

230 400 3.3

1.7 12.0 3.2

51221075

51221069 184 120

230 600 5.0

2.6 19.5 5.2

51221065

51221066 185 120

230 600 5.0

2.6 18.0 4.9

51221072

51221074 186 120

230 1200 10.0

5.2 43.0 11.4

51221061

51221063 188

Dual 120

230 800 6.7

3.5

12.0

Both

Pans

3.2

Both

Pans

3

4. INSTALLATION

4.1 Location

To obtain the most uniform operating conditions

and results, place the bath in an area remote from

drafts,ventilationoutlets, radiators,and otherrapidly

changing ambient conditions.

To assure proper ventilation, allow at least 4" clear-

ance between the rear, top, and sides of the unit and

adjacentwall.Iftwo ormoreunitsarepositioned side-

by-side, allow at least 8" between them.

4.2 Electrical Connections

IMPORTANT : PLEASE READ CAREFULLY.

WARNING:

FOR PERSONAL SAFETY, THIS APPARATUS

MUST BE PROPERLY GROUNDED.

CAUTION:

BE SURE THAT THE POWER SUPPLY IS OF

THE SAME VOLTAGE AS SPECIFIED ON THE

NAMEPLATE.

The power cord of this instrument is equipped with

a three-prong (grounding) plug which mates with a

standard three-prong (grounding) wall receptacle

to minimize the possibility of electric shock hazard.

The user should have the wall receptacle and

circuit checked by a qualified electrician to make

sure the receptacle is properly grounded. Where a

two-prong receptacle is encountered, it is the

personal responsibility and obligation of the user to

have it replaced with a properly grounded three-

prong receptacle.

WARNING:

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM

THE POWER CORD. DO NOT USE A TWO-PRONG

ADAPTER PLUG.

Determine the total amount of current presently

being used by other equipment connected to the

circuit that will be used for this unit. It is critical that

the added current demand by this appliance and

other equipment on the circuit not exceed the

rating of the fuse or circuit breaker in use.

5. OPERATION

CAUTION:

EXERCISE CARE WHEN USING ACIDIC OR

CAUSTIC SOLUTIONS AS THEY WILL ATTACK

THE GALVANIZED STEEL BATH BODY IF SPILLED

INTO THE BATH. IF SPILLS DO OCCUR, THE

BATH LIQUID SHOULD BE IMMEDIATELY

DRAINED AND THE UNIT THOROUGHLY

FLUSHED. SPILLS AND CONDENSATION SHOULD

BE CLEANED/REMOVED FROM ALL METAL

SURFACES AFTER EACH USE.

5.1 Shelf Placement

Place the stainless steel metal shelf also called

diffuser shelf, (corners facing downward) inside

the bath chamber. The shelf provides a sample

base and protects samples from touching the hot

metal bath bottom.

If it is necessary to increase the height of the

diffuser shelf, a Leg Extension Kit is included for

this purpose. Model 180 (Catalog #'s 51220070 &

51220071) are excluded.

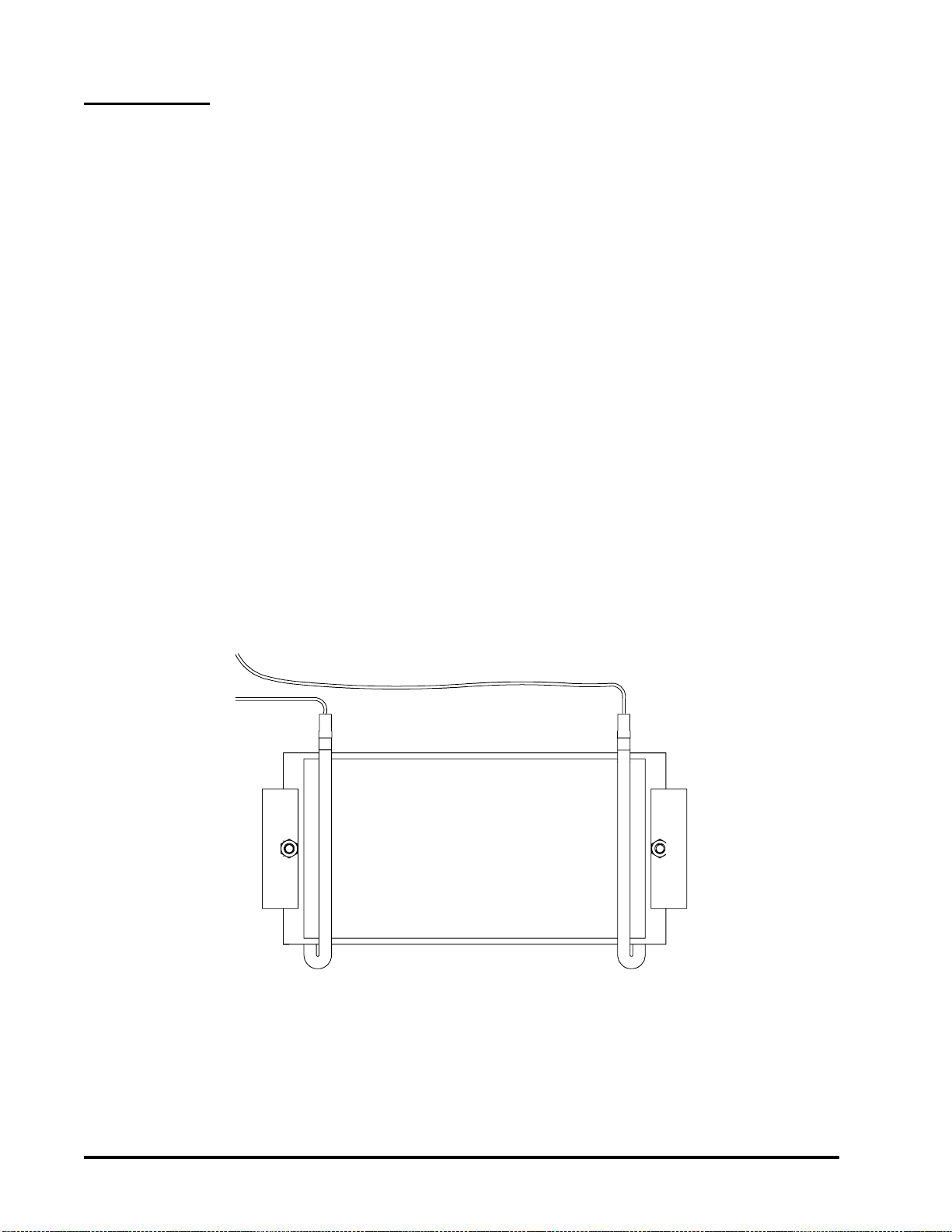

Following the figure shown below, attach the four

extension legs to each of the four corners of the

diffuser shelf.

DIFFUSER SHELF

LEG EXTENSION KIT

4

5. OPERATION (CONT.)

5.2 Filling Bath

NOTE:

DISTILLED WATER IS RECOMMENDED; IT WILL

NOT CORRODE THE BATH CHAMBER

AND IT REDUCES THE NEED FOR FREQUENT

BATH CLEANING.

DO NOT USE 18 MEG DEIONIZED WATER.

NOTE: If this is the only source of treated water

available; mix 50% with regular tap water.

Before filling, check the power switch and make

sure that it is in the "OFF" position.

Fill the bath with distilled water, making allowance

for displacement by the sample(s) being immersed

and for expansion of the media upon reaching

operating temperature.

For Model 181 and above, the maximum liquid

level should be 1-1/2" from the top surface of the

bath after sample(s) are immersed. For the Model

180, the maximum liquid level should be 3/4" from

the top of the bath.

5.3 Bath Cover

To conserve energy and reduce evaporation, use

the cover supplied with the bath throughout the

temperature range of the bath. This cover must be

in place to reach and maintain 100°C.

CAUTION:

DO NOT USE ALUMINUM FOIL AS A COVER; IT

MAY CAUSE CORROSION OF THE STAINLESS

STEEL AS A RESULT OF AN ELECTROLYTIC

REACTION.

NOTE:

AS WATER BATHS ARE OPERATED,

ESPECIALLY AT ELEVATED TEMPERATURES,

CONDENSATION WILL FORM ON THE

UNDERSIDE OF THE GABLE COVER. THE

AMOUNT OF CONDENSATION CAN BE

CONSIDERABLE. CARE SHOULD BE

EXERCISED WHEN REMOVING THE COVER

SO THAT WATER WILL FALL BACK INTO THE

BATH CHAMBER, AND NOT ON THE BATH

SURFACE. THE COVER SHOULD BE PLACED

UPSIDE DOWN WHEN REMOVED TO MAINTAIN

A DRY WORK AREA.

5.4 Bath Thermometer

Eachbathis suppliedwithathermometer and O-ring

(packed separately).The thermometer isattached to

the bath via a metal clip on the top of the bath.

Slip the O-ring onto the thermometer; insert this

assemblythrough the metal clip until theimmersion

depth indicator line is at or below the water surface.

The thermometer bulb should always be located

above the diffuser shelf.

CAUTION:

CARE SHOULD BE TAKEN TO PROTECT THE

THERMOMETER FROM ACCIDENTAL

BREAKAGE AND SPILLAGE OF CONTENTS.

5.5 Power ON

Insert the line cord into the proper receptacle and

turn the power switch to the "ON" position. This

action will energize the heater and cause the

amber pilot lamp to light. The pilot lamp will stay lit

as long as the heater(s) is energized.

5.6 Setting Thermostats

NOTE:

DIAL NUMBERS ON FRONT PANEL ARE FOR

REFERENCE ONLY; THEY ARE NOT VALUES

FOR WATER TEMPERATURE WITHIN THE UNIT.

WARNING:

DO NOT LEAVE THE BATH UNATTENDED DUR-

ING THE SETTING PROCEDURE.

A. Turn both the Temperature Control and High

Temperature Limit thermostat knobs fully

clockwise. The Temperature Control Pilot lamp

should illuminate.

B. When the bath temperature reaches the desired

temperature, slowly turn the High Temperature

Limit Thermostat counterclockwise and stop

when the High Temperature Limit Pilot Lamp

illuminates.

C. Turn the High Temperature Limit Thermostat

Knobclockwisetonexthighestreferencenumber.

The High temperature Limit light should go off.

The High Temperature Limit thermostat is now

set approximately 5° above the desired bath

temperature.

5

D. Turn the Temperature Control Thermostat

counterclockwise until both pilot lamps are off.

E. Turn the Temperature Control thermostat

clockwise until the Temperature Control pilot

lamp just lights. Allow the unit to stabilize,

readjust/fine tune the Temperature Control

thermostat as necessary.

2II

2Q

Figure 5.1 Controls

6

6. MAINTENANCE

WARNING:

UNIT MUST BE DISCONNECTED FROM POWER

SOURCE PRIOR TO SERVICING. IT IS

RECOMMENDED THAT ALL SERVICE BE

PERFORMED BY QUALIFIED SERVICE

PERSONNEL.

CAUTION:

ELECTROLYSIS CAN DAMAGE STAINLESS

STEEL. THIS CAN OCCUR IF AN OBJECT IS

ALLOWED TO REST DIRECTLY ON THE

SURFACE, TRAPPING MOISTURE THAT

BECOMES OXYGEN STARVED BUT IS

SURROUNDED BY WATER CONTAINING

OXYGEN. THE RESULTING ELECTROLYTIC

ACTION WILL PIT OR CORRODE THE

STAINLESS STEEL.

Background

Stainless steel is an alloy of steel with chromium

and nickel which increase the metal's resistance to

rust and corrosion. However, if not properly cared

for it can rust and corrode. Exposure to air provides

the passivations for clean stainless steel. This

exposureproduces a thin, durable chromium-oxide

film that forms rapidly on the alloy surface and

gives stainless steel its characteristic "stainless"

quality. Exposure of the surface to water other

oxidizing environments also produces this

passivating film. However, if free oxygen is not

available due to scale or contamination buildup the

metal surface may become vulnerable to attack.

Maintaining a neutral pH and frequent cleaning

with detergent and water will give you years of

trouble free service for your water bath. The follow-

ing are some guidelines to keep in mind.

Water

Distilled water is recommended. Maintain pH

between 7 and 9 to minimize corrosion of the

stainless steel.

De-ionizedor reverse-osmosis water may be used.

However, if this water is very pure it may be

corrosive to stainless steel; and in such cases

always add 20-40 ppm (20 to 40 mg/liter)

disodium phosphate or sodium bicarbonate.

Adjust dosage to give a pH of 7 to 9. See "pH

Control" below.

If the above water is not available you may use

clean, aerated soft tap water provided the total

solids concentration is <500 ppm.

pH Control

Be sure to check pH regularly. If pH is <6.0, add

disodium phosphate to increase pH to a 7 to 9

value. Sodium carbonate or sodium bicarbonate

may be used but tend to form scale which must be

rinsed out regularly. If pH is >10.0 add sodium

bisulfate to decrease pH to a 7 to 9 value. Avoid

adding harsh alkalines or acids since they may

cause localized corrosion and result in unstable pH.

Anti-Fungal -- Anti-Bacterial Additives

These additives are permissible to use as long as

the pH of the aqueous solution is kept within the

range of 7 to 9. Some of these are available

through your supply dealer. Be sure they are not

harmful to stainless steel.

Prevention of Scale Buildup

Additives commonly available for use in swimming

pools and spas may be acceptable in circulating

baths only. In static baths these are generally not

effective. This is why it is best to use distilled,

deionized or RO water treated as described in

"WATER" above. If scale buildup is detected

(especially around immersion heaters) clean the

bath and replace water as soon as practical.

Other Water Additives

Proper maintenance of the stainless steel bath

chamber will help assure many years of service.

It should be cleaned regularly with mild soapy

water and rinsed with distilled water.

IMPORTANT: If it is necessary to use the following

chemicals, limit the exposure time to a maximum of

four hours. Clean surfaces immediately after use

by rinsing with distilled water.

Aluminum Chloride Barium Chloride

Bichloride of Mercury Calcium Chloride

Carbolic Acid Chlorinated Lime

Citric Acid (boiling) Dakin's Solution

Ferrous Chloride Mercury Salts

Lysol Mercuric Chloride Phenol

Potassium Permanganate

StannousChloride

Sodium Hypochlorite Tartaric Acid

Potassium Thiocyanate Lysol

7

NEVER USE THE FOLLOWING

Aqua Regia Ferric Chloride Iodine

Sodium Azide Sulfuric Acid

6.1 Cleaning

Spillsof any chemical, especially thoselisted above

should be removed as soon as possible and the

stainless steel surface cleaned with mild soapy

water followed by copious rinse with clean water.

Do not use soap filled or any metallic pads. Even

stainless steel pads are to be avoided as they may

destroy the passive film on the surface of the metal

andcreate crevices thatmay harbor contamination.

If stubborn stains persist use a plastic light duty

cleansing pad and rub gently in the direction of the

metal grain. If stains continue to persist use one of

the following methods.

WARNING:

THE FOLLOWING CHEMICAL METHODS HAVE

PROVEN SUCCESSFUL BUT EXTREME CARE

MUST BE TAKEN WHEN HANDLING THESE

MATERIALS. ALWAYS WORK IN AN AREA WITH

ADEQUATE VENTILATION. USE THE

PRECAUTIONS OUTLINED IN THE MATERIAL

SAFETY DATA SHEET (MSDS) AND

MANUFACTURER'S INSTRUCTIONS FOR THE

PRODUCT YOU ARE WORKING WITH. FOLLOW

THE PERSONAL PROTECTION INDEX FOUND

IN THE HAZARDOUS MATERIALS

IDENTIFICATION SYSTEM (HMIS) SECTION OF

THE MSDS.

THE USE AND DISPOSAL OF THESE

CHEMICALS MAY BE REGULATED BY YOUR

LOCAL MUNICIPALITY. CONSULT THE

REGULATIONS BEFORE DISPOSING OF THESE

MATERIALS.

1. Bathroom tub and tile cleaners. Available at

supermarkets.

2. Any of a variety of "scale removers" available at

your local supermarket or hardware store.

Generally sold for cleaning coffee makers,

humidifiers and vaporizers.

3. Citric acid based cleaners. Contact your lab

supply dealer.

4. A 15 to 35% phosphoric acid solution. Available

from chemical supply dealers for scale and rust

removal. Allow solution to soak the surface

affected until rust and scale is loosened.

Immediatelyrinse withcopious amounts ofclean

water.

5. Oxalic Acid 2% to 5% in warm water. Swab

solution on surface allowing it to remain until

rust is loosened. Immediately flush with copious

amounts of clean water.

6.A mixture of20% nitric acid and1.5% hydrofluoric

acid (or hydrochloric acid). Swab solution on

surface allowing it to remain until rust is

loosened. Immediately flush with copious

amounts of clean water.

The above are ranked in order of mild to strong

cleaning agents. Items 5 and 6 should only be

used if severe rust and scale stains have devel-

oped and cannot be removed by any other method.

In any case the chemical should be allowed to do

the cleaning with minimal scrubbing. Always fol-

low the manufacturer's instructions.

6.2 Chamber Disinfecting

Materials known to be effective in disinfecting:

*Household Bleach

*Glutaraldehyde

*Alcohol

Consult with your staff chemist for advice on

using these chemicals.

CAUTION:

ALWAYS RINSE WITH COPIOUS AMOUNTS OF

CLEAN WATER. AIR DRY AND/OR FILL WITH

FRESH WATER AND FOLLOW THE GUIDELINES

IN "WATER" ABOVE.

DISCLAIMER:

The above information is the result of limited inves-

tigation and Precision Scientific makes no claims

as to the suitability to your particular application.

These are intended to be GUIDELINES ONLY.

Consult your staff chemist to determine what works

best in your lab.

8

7. SERVICE

WARNING:

UNIT MUST BE DISCONNECTED FROM POWER

SOURCE PRIOR TO SERVICING. IT IS

RECOMMENDED THAT ALL SERVICE BE

PERFORMED BY QUALIFIED SERVICE

PERSONNEL.

7.1 General Information

To service the water bath, turn it on its side or top

and remove the bottom plate and insulation. To

prevent scratching of the enameled surface, place

protective material (such as cardboard, cloth, or

newspaper) under unit.

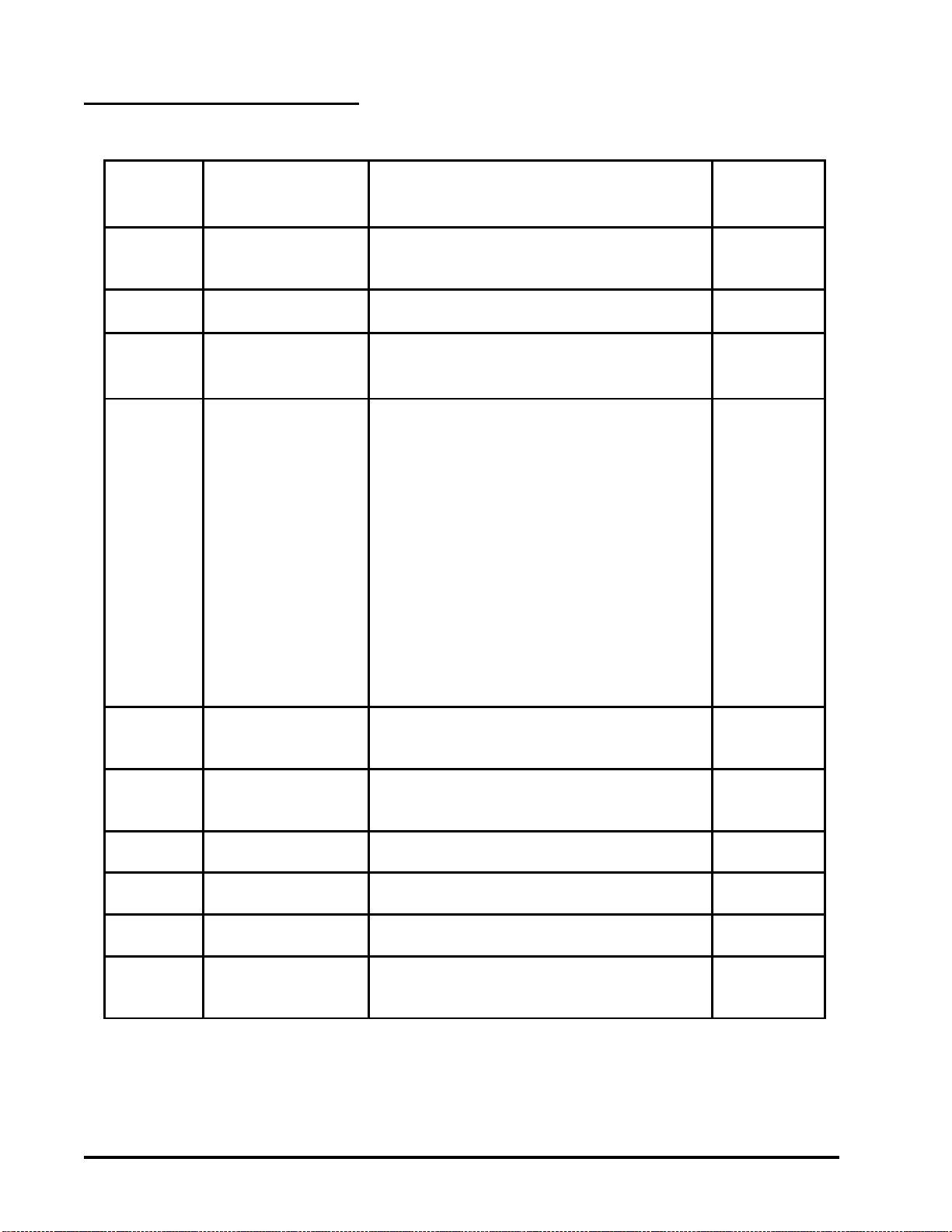

7.2 Heater Element Replacement

A. Put the power switch in the "OFF" position and

disconnect power to the bath.

B. Turn bath upside down and remove bottom plate

& fiberglass insulation

C. Disconnect the two leads from heater element.

D. Remove the two hex nuts that fasten the heater

element to the pan and remove element.

E.Remove FiberFaxinsulation from theold element

and insert it into the new element.

F. Fasten the new heater element to the pan and

connect the two leads.

CAUTION:

BE SURE THE WIRE LEADS DO NOT TOUCH

THE HEATER ELEMENT.

G. Replace insulation and install bottom plate.

NOTE:

USE NO THERMAL COMPOUNDS OR PASTE

ON HEATER.

Figure 7.1 Heater element

9

7.3.1 Thermostat Replacement

Use the following thermostat replacement proce-

dure when the sensing bulb is located WITHIN the

bathpan. Some models only have externally

mounted sensing bulbs on the underside of the

pan, if this is the case follow procedure 7.3.2.

CAUTION:

CARE MUST BE EXERCISED WHEN HANDLING

THE THERMOSTAT CAPILLARY, SINCE A

SHARP BEND WILL CRIMP OFF THE FLOW OF

THE HYDRAULIC OPERATING MEDIUM. TO

AVOID TWISTING THE CAPILLARY OR

DAMAGING O-RING, HOLD THE FITTING

UNDER THE BATH STATIONARY, AND FIRMLY

TIGHTEN LOCKNUT INSIDE BATH CHAMBER.

DO NOT OVER-TIGHTEN, AS O-RING

COULD BE SQUEEZED OUT OF POSITION,

CAUSING BATH TO LEAK. UNDERTIGHTENING

WILL ALSO CAUSE THE BATH TO LEAK.

A. Put switch in "OFF" position and disconnect

power to bath.

B. Remove shelf and drain bath.

C. Remove thermostat control knob by loosening

two set screws on knob.

D. Place bath on its side and remove bottom plate

and insulation to gain access to thermostat

fitting.

E. Remove two screws fastening thermostat to

control panel.

F. Remove wires from thermostat terminals. Mark

location of wire leads.

G.Hold thefittingunder thebath stationary,unscrew

locknut inside bath chamber, and remove from

capillary.

H. Feed thermostat capillary out through hole in

bottom of chamber.

I. Replace O-ring on bottom side of chamber with

new Viton O-ring.

J. Complete installation by reversing above

procedure. Be certain all wiring is away from

heater. Insulation must be replaced between

heater and bottom plate to prevent possible

wire shorting.

7.3.2 Thermostat Replacement

Use the following procedure when the sensing

bulb is located UNDER the pan.

A. Put the power in the "OFF" position and

disconnect power to the bath.

B. Turn bath upside down and remove bottom plate

and fiberglass insulation.

C. Mark the location of the wire leads on the

thermostat and disconnect.

D. Remove thermostat control knob by loosening

two set screws on knob.

E. Remove two screws fastening thermostat to

control panel.

F. Loosen the two hex nuts holding thermostat bulb

bracket and pull the thermostat and bulb out

from behind the control panel.

G. Mount the new thermostat by reversing steps A

through G.

CAUTION:

MAKE SURE THE WIRE LEADS DO NOT TOUCH

THE HEATER ELEMENT.

10

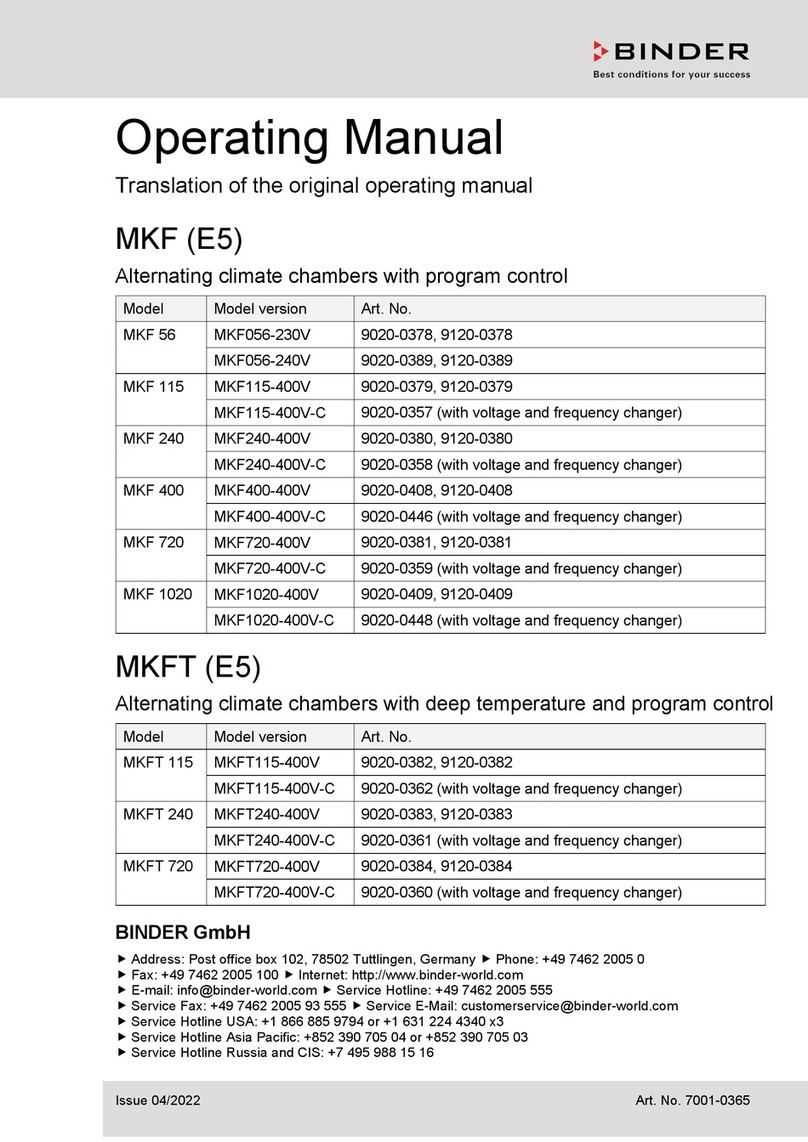

8. REPLACEMENT PARTS

Item

Number Symbol Wiring

Diagram Description Part

Number

1 DS1/DS2 Pilot Light Assembly-Amber (120 VAC)

Pilot Light Assembly-Amber (240 VAC) 34541927

34002320

2 S1 DPST Switch - Amber (115 & 230 VAC) 34240618

3 S2/S3 Thermostat (120/240 VAC) under pan

Thermostat (120/240 VAC) in pan 34239186

34001584

4 HR1/HR2 Heater - Model 180 (120 VAC)

Heater - Model 180 (240 VAC)

Heater - Model 181 (120 VAC)

Heater - Model 181 (240 VAC)

Heater - Model 182 (120 VAC)

Heater - Model 182 (240 VAC)

Heater - Model 183 (120 VAC)

Heater - Model 183 (240 VAC)

Heater - Model 184 (120 VAC)

Heater - Model 184 (240 VAC)

Heater - Model 185 (120 VAC)

Heater - Model 185 (240 VAC)

Heater - Model 186 (120 VAC) QTY2

Heater - Model 186 (240 VAC) QTY2

34247411

34247399

34247411

34247399

34247412

34247346

34247413

34247347

34247414

34247348

34247414

34247348

34247414

34247348

5 n/a Heater Model 188 equal pans 120v (qty2)

Heater Model 188 equal pans 220v (qty2) 34247413

34247347

6 n/a Thermometer - Model 180

Thermometer - All Other Models 34307058

34307059

7 n/a O’Ring, Thermometer 34232070

8 n/a Knob, Thermostat 34220199

9 n/a Bracket, Heater Retaining (2/Heater) 34542262

10 n/a Cord and plug (120 VAC)

Cord and plug (240 VAC) 36353081

34353046

11

WIRING DIAGRAM

MODELS 180-185

9. WIRING DIAGRAMS

12

WIRING DIAGRAM

MODEL 186

13

WIRING DIAGRAM

MODEL 188

14

WARRANTY

PRECISION warrants its products against defects in material and workmanship when used

under appropriate conditions and in accordance with appropriate operating instructions for a

period of no less than one (1) year from the date of delivery of the products.

Sole obligation of PRECISION shall be to repair or replace at our option, FOB factory or locally,

without charge, any part(s) that prove defective within the warranty period, provided the

customer notifies PRECISION promptly and in writing of any such defect. Compensation for

labor by other than PRECISION employees will not be our obligation. Part(s) replacement does

not constitute an extension of the original warranty period.

PRECISION MAKES NO WARRANTY OR MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, OR ANY OTHER WARRANTY, EXPRESSED OR IMPLIED, AS

TO THE DESIGN, SALE, INSTALLATION, OR USE OF ITS PRODUCTS, AND SHALL NOT

BE LIABLE FOR CONSEQUENTIAL DAMAGE RESULTING FROM THE USE OF ITS

PRODUCTS.

PRECISION SCIENTIFIC will not assume responsibility for unauthorized repairs or failure as

a result of unauthorized product modifications, or for repairs, replacement, or modification

negligently or otherwise improperly made or performed by persons other than PRECISION

employees or authorized representatives.

While our personnel are available to advise customers concerning general applications of all

manufactured products, oral representations are not warranties with respect to particular

application and should not be relied upon if inconsistent with product specification or the terms

stated herein.

In any event, the terms and conditions contained in PRECISION formal sales contracts shall

be controlling; and any changes must be in writing and signed by an authorized executive of

PRECISION .

All defective components will be replaced without charge one (1) year from the date of delivery.

There will be no charge for labor if the apparatus is returned to the factory prepaid.

Conditions and qualifications of the warranty statement shall prevail at all times.

This manual suits for next models

23

Table of contents

Other Precision Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Ovation

Ovation QS Cleaning instructions

Beckman Coulter

Beckman Coulter Optima XE Series user guide

Binder

Binder MKF 400 operating manual

TA Instruments

TA Instruments DISCOVERY XENON FLASH Getting started guide

HACH LANGE

HACH LANGE BUHLER 3010 Short manual

Metrohm

Metrohm 930 Compact IC Flex SeS Manual - Short Instructions