PRECITEC Lasermatic LightCutter User manual

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

LightCutter

Lasermatic®

Cutting head for fibre-coupled lasers

Operating Instructions

Imprint

LightCutter

ii

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

This documentation is protected by copyright law for

Precitec GmbH & Co. KG

and must not be reproduced without the prior written consent of

Precitec

or used

against the due interest of Precitec. It is intended exclusively for internal use

associated with setup and service work. Any other use is not permitted. Any

communication of this documentation to a third party requires the prior express

written permission of

Precitec

.

We reserve the right to change technical details of the descriptions, information

and illustrations in this documentation.

All in Light, Lasermatic, LaserPathFinder, LWM, the Precitec logo and precitec

are registered trademarks in Germany and/or other countries.

This product group is protected by the following patents:

Printed in the Federal Republic of Germany.

Precitec GmbH & Co. KG

Draisstraße 1

D - 76571 Gaggenau - Bad Rotenfels

Tel.: +49 (0)7225 684-0

Fax: +49 (0)7225 684-900

E-mail: [email protected]

DE 10006691 EP 1130361 US 6469523

Further patents pending.

Responsible for the content

Translation of the original operating instructions

Document History

D 159195 © Precitec GmbH & Co. KG • EN 09/2019

iii

Document History

Date Chapter / page Topic, revision, action taken

08/2017 -- revision - technical data

01/2018 -- revision - versions

05/2018 -- revision - nozzle electrodes

11/2018 -- revision - head version

09/2019 -- revision

Notes

LightCutter

iv

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

Notes

Table of contents

D 159195 © Precitec GmbH & Co. KG • EN 09/2019

v

Table of contents

1 Basic safety notes 1 - 1

1.1 Warranty and liability 1 - 1

1.2 Meaning of symbols and notes 1 - 1

1.3 Intended use 1 - 3

1.4 Basic standards 1 - 3

1.5 Obligations of operator and personnel 1 - 4

1.6 Normal operation safety measures 1 - 4

1.6.1 Protection against electric shock

1 - 4

1.6.2 Risk of injury from moving parts

1 - 5

1.6.3 Risk of injury from explosion

1 - 5

1.6.4 Risk of injury from laser radiation

1 - 5

1.6.5 Residual risk from uncontrolled laser beam escape

(angled laser head)

1 - 6

1.6.6 Corrosion in the water cooling circuit

1 - 6

1.6.7 Noise occurring during the laser cutting process

1 - 7

1.7 Storage and transport 1 - 7

1.8 What to do in emergency situations 1 - 7

2 Product description 2 - 8

2.1 Product - overall view 2 - 8

2.1.1 Design and functions

2 - 9

2.1.2 Distance controller

2 - 10

2.1.3 Protective equipment

2 - 10

2.2 Technical specifications 2 - 11

2.3 Specific versions

(focal lengths, collimators)

2 - 12

2.4 Straight versions

without protective window COL

(dimensions/ straight design)

2 - 13

2.4.1 Focal lengths 100/125

2 - 13

2.4.2 Focal length 150

2 - 14

2.4.3 Focal length 200

2 - 15

2.5 Straight versions

with protective window COL

(dimensions/ straight design)

2 - 16

2.5.1 Focal lengths 100/125

2 - 16

2.5.2 Focal length 150

2 - 17

2.5.3 Focal length 200

2 - 18

2.6 Angled versions

(dimensions, angled design)

2 - 19

2.7 Media connections 2 - 20

2.8 LightCutter 3D version 2 - 21

2.9 Accessories 2 - 22

2.9.1 Analysing electronics

(EG8030)

2 - 22

2.9.2 Optics service case

(storage box)

2 - 22

Table of contents

LightCutter

vi

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

3 Fitting and installing 3 - 23

3.1 Safety notes 3 - 23

3.2 Checking package contents 3 - 24

3.3 Fitting 3 - 25

3.3.1 Fitting the ceramic part

and nozzle

(only in the case of individual parts delivery)

3 - 25

3.3.2 Connecting the laser fibre to the laser head

(trained personnel only)

3 - 26

3.3.3 Optimum sealing

(e.g. QBH)

3 - 27

3.3.4 Fitting the cutting head to the machine

(trained personnel only)

3 - 28

3.3.5 Grounding of the laser head

3 - 29

3.3.6 Checking the protective window COL

for contamination

(fibre replacement, trained personnel only)

3 - 30

3.4 Installation 3 - 31

3.4.1 Connecting the cutting gas system

(trained personnel only)

3 - 31

3.4.2 Connecting the cooling water system

(trained personnel only)

3 - 32

3.4.3 Connecting the distance sensor system

(trained personnel only)

3 - 33

4 Commissioning 4 - 34

4.1 Safety notes 4 - 34

4.2 Adjusting the laser beam 4 - 35

4.2.1 Centring and adjusting the laser beam

4 - 35

4.2.2 Setting the focal position

4 - 37

4.3 Checking the standoff distance 4 - 39

5 Maintenance 5 - 40

5.1 Safety notes 5 - 40

5.2 Maintenance work

(summary)

5 - 41

5.3 Maintenance recommendations 5 - 42

5.4 Replacing the ceramic part and nozzle

(sensor area)

5 - 43

5.5 Care and maintenance of the protective window cartridge 5 - 44

5.5.1 Replacing the protective window

5 - 45

5.5.2 Replacing axial gaskets

5 - 46

5.6 Maintaining the sensor insert 5 - 47

5.6.1 Cleaning the inside of the sensor insert

(removing short circuits)

5 - 47

5.6.2 Replacing the sensor insert

5 - 49

Table of contents

D 159195 © Precitec GmbH & Co. KG • EN 09/2019

vii

LightCutter3D

6 Specific characteristics of the 3D version 6 - 51

6.1 LightCutter 3D 6 - 51

6.1.1 Product view

6 - 51

6.1.2 Technical specifications

6 - 52

6.1.3 Mechanical dimensions

QBH version (F150)

6 - 53

6.1.4 Media connections

6 - 54

6.2 Installation

(integration into the machine)

6 - 55

6.2.1 Fitting the ceramic part

and nozzle

(only in the case of individual parts delivery)

6 - 55

6.2.2 Connecting the laser fibre to the laser head

(trained personnel only)

6 - 56

6.2.3 Fixing the cutting head to the machine

(trained personnel only)

6 - 57

6.2.3.1 Laser head - hole pattern

6 - 57

6.2.3.2 Grounding the laser head

6 - 58

6.2.3.3 Aligning the sensor insert

(HF socket, sensor system)

6 - 59

6.3 Maintenance 6 - 60

6.3.1 Replacing the ceramic part and nozzle

(sensor area)

6 - 60

6.3.2 Maintaining and replacing the sensor insert (SE)

6 - 61

6.4 Parts available

(LightCutter 3D only)

6 - 62

7 Error analysis and diagnostics 7 - 63

7.1 Safety notes 7 - 63

7.2 Malfunctions 7 - 63

7.2.1 Electrical malfunctions

7 - 63

7.2.2 Mechanical malfunctions

7 - 64

8 Appendix 8 - 65

8.1 Basic technical information 8 - 65

8.1.1 Conversion of Units

8 - 65

8.1.2 Compressed air quality

(ISO 8573-1)

8 - 65

8.1.3 Cooling water - Dew point temperature

8 - 65

8.1.4 Running cables

(notes)

8 - 66

8.2 Parts available 8 - 67

AM YW30 CL R / P0253-1406-00001

List of illustrations

LightCutter

viii

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

List of illustrations

Fig. 2-1 Laser head, overall view

2 - 8

Fig. 2-2 Specific versions

2 - 12

Fig. 2-3 Mechanical dimensions, focal lengths 100/125

(straight)

2 - 13

Fig. 2-4 Mechanical dimensions, focal length 150

(straight)

2 - 14

Fig. 2-5 Mechanical dimensions, focal length 200

(straight)

2 - 15

Fig. 2-6 Mechanical dimensions, focal lengths 100/125

(straight with OG-COL)

2 - 16

Fig. 2-7 Mechanical dimensions, focal length 150

(straight with OG-COL)

2 - 17

Fig. 2-8 Mechanical dimensions, focal length 200

(straight with OG-COL)

2 - 18

Fig. 2-9 Mechanical dimensions (angled)

2 - 19

Fig. 2-10 Media connections, laser head

2 - 20

Fig. 2-11 Cutting head, view

(LightCutter 3D version)

2 - 21

Fig. 2-12 Accessories: Adjust box EG8030

2 - 22

Fig. 2-13 Accessories: Optics service case

2 - 22

Fig. 3-1 Fitting: Ceramic part, nozzle

(e.g. LightCutter 100)

3 - 25

Fig. 3-2 Fitting: Laser fibre

(e.g. QBH socket)

3 - 26

Fig. 3-3 Fitting: Sealing the fibre coupling

(e.g. QBH)

3 - 27

Fig. 3-4 Fitting: Laser head to the machine

3 - 28

Fig. 3-5 Installation: Laser head - Grounding

3 - 29

Fig. 3-6 Fitting: Protective window COL

(first-time installation/ fibre replacement)

3 - 30

Fig. 3-7 Installation: Connections - Cutting gas

3 - 31

Fig. 3-8 Installation: Water connections

(collimator)

3 - 32

Fig. 3-9 Installation: Connection diagram

(analysing electronics)

3 - 33

Fig. 4-1 Commissioning: Laser beam - Beam position

4 - 35

Fig. 4-2 Commissioning: Laser beam - Focal position

4 - 37

Fig. 4-3 Commissioning: Laser beam - Reference adjustment

4 - 38

Fig. 4-4 Commissioning: Laser beam - Standoff distance

4 - 39

Fig. 5-1 Maintenance: Maintenance recommendations

5 - 42

Fig. 5-2 Maintenance: Ceramic part, nozzle

(e.g. LightCutter 100)

5 - 43

Fig. 5-3 Maintenance: Protective window cartridge

5 - 44

Fig. 5-4 Maintenance: Protective window

(protective window cartridge)

5 - 45

Fig. 5-5 Maintenance: Seal

(protective window cartridge

)

5 - 46

Fig. 5-6 Maintenance: Sensor insert

(removing short circuits)

5 - 47

Fig. 5-7 Maintenance: Sensor insert

(replacement)

5 - 49

Fig. 6-1 Cutting head, view

(LightCutter 3D version)

6 - 51

Fig. 6-2 Mechanical dimensions

(QBH 3D version)

6 - 53

Fig. 6-3 Connections - Media connections

(3D version)

6 - 54

Fig. 6-4 Installation: Ceramic part, nozzle

(LightCutter 3D)

6 - 55

Fig. 6-5 Installation: Laser fibre

(e.g.QBH socket, 3D)

6 - 56

List of illustrations

D 159195 © Precitec GmbH & Co. KG • EN 09/2019

ix

Fig. 6-6 Installation: Laser head to machine

(3D version)

6 - 57

Fig. 6-7 Installation: Laser head - grounding

(3D version)

6 - 58

Fig. 6-8 Installation: Sensor insert - Alignment

(HF socket, 3D version)

6 - 59

Fig. 6-9 Installation: Sensor insert - Alignment

(4x90°, 3D version)

6 - 59

Fig. 6-10 Maintenance: Ceramic part, nozzle

(e.g. LightCutter 3D version)

6 - 60

Fig. 6-11 Maintenance: Sensor insert

(replacement, 3D version)

6 - 61

List of tables

LightCutter

x

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

List of tables

Table 2-1 Technical Data

2 - 11

Table 6-1 Technical Data

(LightCutter 3D)

6 - 52

Table 6-2 Appendix: Parts available

(LightCutter 3D)

6 - 62

Table 7-1 Error analysis: Electrical malfunctions

7 - 63

Table 7-2 Error analysis: Mechanical malfunctions

7 - 64

Table 8-1 Appendix: Units - Conversion table

8 - 65

Table 8-2 Appendix: Compressed air quality - Purity classes

8 - 65

Table 8-3 Appendix: Cooling water - Dew point temperature

8 - 65

Table 8-4 Appendix: Parts available

8 - 67

Table 8-5 Appendix: Nozzles available

8 - 68

1 Basic safety notes

D 159195 © Precitec GmbH & Co. KG • EN 09/2019

1-1

1 Basic safety notes

These operating instructions contain the most important notes for operating

the product in compliance with safety regulations.

1.1 Warranty and liability

Precitec GmbH & Co. KG

's General Terms of Delivery apply to our products.

We reserve the right to modify designs to improve quality or extend the fields

of use and to make modifications for manufacturing reasons.

If the product / unit is operated incorrectly or if processes are carried out

wrongly, reflections can be caused when laser cutting highly reflective

materials such as copper, brass or aluminium that would damage the laser

head and other system components.

Precitec shall not be liable for any damage or injury caused by incorrect

operation or improper handling of our products / units.

Dismantling the product / unit may result in warranty claims becoming null and

void. However, this does not apply to the replacement of components that are

subject to normal wear and tear and require maintenance or setup work,

unless expressly stated otherwise in this documentation.

We cannot accept any warranty claims or liability if unauthorised modifications

are made to the product / unit or if unsuitable spare parts are used. We

urgently recommend that only spare parts

(hereinafter referred to as "original spare

parts")

supplied by Precitec be used and that these parts be installed by

Precitec or by a specialist designated by Precitec.

1.2 Meaning of symbols and notes

In these operating instructions, the following designations and symbols are

used to indicate hazardous situations and for notes.

Observe all instructions and guidelines in this documentation.

In addition, accident prevention regulations and instructions applicable to the

area of use must be observed.

Warning!

This symbol indicates an imminent or potential danger to the life and health of

individuals. Not observing these notes may result in serious effects on health or

life-threatening injuries.

Caution!

This symbol indicates a potentially hazardous situation. Not observing these

notes may result in personal injury or damage to equipment.

1.2 Meaning of symbols and notes

LightCutter

1-2

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

Caution!

Dangerous electrical voltage

- indicates a risk of electric shock and warns of

imminent danger to the life and health of individuals or of significant damage to

equipment.

Caution!

Laser beam

- means that the laser machine may operate in laser class 4 when

commissioning the laser head. Warns of damage to eyes or skin caused by

direct or scattered radiation.

Caution!

Danger of crushing

- indicates a potentially hazardous situation. Not observing

these notes may result in personal injury or damage to equipment.

Attention!

ESD-sensitive components

- indicates that touching the contact surfaces can

result in damage or destruction of electronic components.

Attention!

Clean workplace

- indicates that any work on the product or any fitting or

maintenance work must only be carried out in a clean workplace as dust and

firmly adhering dirt can damage or destroy the components.

Attention!

Do not touch

- indicates that touching the contact surfaces or optics can result in

damage or destruction of components.

Important:

Information the user must observe or know to avoid process

disruptions or malfunctions when using the product.

Tip:

Gives the user the information needed to achieve the objective directly and

without problems.

Prerequisite:

Describes all components and conditions that have to be available

or fulfilled so that an action can be performed successfully.

Further information:

Indicates to the user that additional information on the

subject is available.

1 Basic safety notes

D 159195 © Precitec GmbH & Co. KG • EN 09/2019

1-3

1.3 Intended use

The

laser head

has been designed for integration into a laser cutting machine.

The laser head is used for cutting metals with solid-state and diode lasers.

Only use the product in dry working environments. The products / units must

only be operated in compliance with the specifications stated in the Technical

Data sheet.

Electromagnetic

compatibility (EMC)

Both as a standalone device or in combination with the relevant devices and

cables stated in this documentation, the

laser head

complies with the

EN 61000-6-2 and EN 61000-6-3 standards as specified in the current EMC

Directive. It is intended for industrial use.

It is possible that these standards may not be met when using units or cables

provided by the client. Only use the parts / units supplied or original spare

parts and adhere to the instructions in the accompanying manuals relating to

EMC-compliant installations.

If the product / unit is integrated into a system and operated together with

other units, the whole system must comply with the current EMC Directive so

that a general operating permit can be granted.

1.4 Basic standards

Below you will find a summary of basic German and international standards

and regulations that apply to Precitec products.

Precitec does not guarantee that this summary is complete.

DIN VDE 0100

Regulations for setting up power current installations with rated voltages

up to 1000 V

DIN EN 207

Personal eye protection: Filters and eye protectors against laser radiation

(laser goggles)

DIN EN ISO 12100

Safety of machinery - General principles for design - Risk assessment and risk

reduction

DIN EN 60204-1

Safety of machinery: Electrical equipment of machines,

Part 1: General requirements (IEC 60204-1)

DIN EN 60825-1

Safety of laser machines: Part 1 (IEC 60825-1)

DIN EN 61000-6-2/ -6-3

Electromagnetic compatibility

(EMC)

(IEC 61000-6-2/ -6-3):

Generic standards on interference emission/immunity, Part 2: Industry

BGV A3

Accident prevention regulation: Electrical systems and equipment

BGV B2

Accident prevention regulation: Laser radiation

Any use which deviates from that which was originally intended is regarded as

improper use. Precitec shall not be liable for any damage caused by the

improper use of the unit.

1.5 Obligations of operator and personnel

LightCutter

1-4

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

1.5 Obligations of operator and personnel

The operator of the system / machine is obliged to ensure that the personnel

working at the machine

• are familiar with the basic safety at work and accident prevention regulations

and have been instructed on how to operate the machine.

• have read and understood the basic safety notes and the operating

instructions and have confirmed this with their signature.

Personnel must be instructed according to the regulations and safety notes

and informed of potentially hazardous situations.

Precitec shall not be liable for any damage caused by not complying with or

having insufficient knowledge about the information contained in the operating

instructions.

Manufacturer's and supplier's regulations must be observed. The prescribed

protective equipment must be used.

1.6 Normal operation safety measures

Only use the parts supplied or original spare parts and do not connect any

other units or cables.

If it has been decided that safe operation is no longer possible, the product /

unit or machine must be switched off. The unit or the machine must be

protected against unintended use.

1.6.1 Protection against electric shock

For operational reasons, components of the laser head such as nozzle body,

sensor body, sensor inserts and nozzle electrodes as well as the

accompanying fitting parts such as union nuts etc. cannot all be connected to

a protected earth. These components can carry low voltage.

When installing the unit, make sure that the electrical equipment is designed

in such a way that individuals are protected against electric shock.

The regulations contained in EN 60204-1, especially those included in

Sections 6 'Protection against electric shock' and 6.4 'Protection by PELV'

(Protective Extra Low Voltage)

must be met.

Recommendation

Use a safety transformer in compliance with DIN EN 61588-2 (IEC 61558-2).

Attention – Grounding the system!

Make sure the system is earthed according to regulations.

1 Basic safety notes

D 159195 © Precitec GmbH & Co. KG • EN 09/2019

1-5

1.6.2 Risk of injury from moving parts

When lowering the linear drive / robot hand to which the laser head is fitted,

there is a risk of injury or damage to equipment.

Never put your hands or other parts of the body under the laser head.

Repair or maintenance work must only be carried out with the power supply

switched off.

1.6.3 Risk of injury from explosion

According to their designated use, laser heads are loaded with gas under

pressure. The specified maximum pressure must never be exceeded. To

ensure that individuals are not harmed, the laser head must always be kept in

perfect condition.

Any connecting elements such as screws and nuts must be tightened firmly.

1.6.4 Risk of injury from laser radiation

The laser head does not emit any laser radiation. However, laser radiation is

guided through the laser head. The machine must be switched off when

carrying out any installation or maintenance work.

If it has been decided that safe operation is no longer possible, the product/

device must be switched off. The unit or the machine must be protected

against unintended use.

Caution - Laser beam!

During commissioning the machine may operate in

laser class 4

:

• Avoid radiation to eyes or skin caused by direct or scattered radiation.

• Do not look directly at the laser beam even using optical instruments.

• Use laser goggles in compliance with DIN EN 207 and BGV B2 that are

designed for the wavelength of the connected laser.

1.6 Normal operation safety measures

LightCutter

1-6

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

1.6.5 Residual risk from uncontrolled laser beam escape

(angled laser head)

The laser head does not emit any laser radiation. However, laser radiation is

guided through the laser head.

To ensure that individuals are not harmed by the laser beam, the manufacturer

of the system / machine must take

(or provide written information on)

relevant

measures regarding the maximum permissible exposure limit for the laser

machine

(laser class 4)

. These measures must be monitored by the operator.

If it has been decided that safe operation is no longer possible, the product /

unit or machine must be switched off. The unit or the machine must be

protected against unintended use.

1.6.6 Corrosion in the water cooling circuit

To avoid any corrosion the instructions and maintenance intervals prescribed

by the machine manufacturer, laser source manufacturer or cooling unit

manufacturer must be observed.

To protect the water cooling circuit

(stainless steel)

against electro-chemical

corrosion, copper or brass connections

must not

be used. Only stainless steel

or plastic connections can be used.

Warning – Uncontrolled laser beam escape!

If the bending mirror is defective due to improper handling during operation

(mechanical or thermal shock, wrong wavelength range)

, the bending mirror cover

may be damaged, causing the laser beam to escape. This can lead to laser

radiation

(horizontal to the processing area)

in the laser machine.

Technical and organisational measures

must

be taken to ensure that personnel

is not exposed to laser radiation above the maximum permissible exposure

(MPE)

limit during normal operation.

For pure stainless steel circuits

use only

water with a conductivity value

prescribed by the laser manufacturer

.

1 Basic safety notes

D 159195 © Precitec GmbH & Co. KG • EN 09/2019

1-7

1.6.7 Noise occurring during the laser cutting process

With high cutting gas pressure the noise level is >75 dB(A). Noise emitted by

the cutting gas depends on the operating conditions.

To ensure that individuals are not harmed by noise, the manufacturer of the

system / machine must implement or provide written information on relevant

safety measures which must be observed by the operator.

1.7 Storage and transport

To prevent damaging the unit during storage or transport the

following basic rules must be observed:

• Keep the storage temperature within the range specified in

the Technical Data sheet.

• Adopt suitable measures to avoid damage due to humidity,

vibration or impact.

• Do not store the unit within or in the vicinity of magnetic fields

(e.g. permanent magnet or strong alternating field)

.

1.8 What to do in emergency situations

• Disconnect the machine from the power supply; set the main switch

to AUS

('OFF')

.

• Only use

Class B

extinguishers to extinguish fires,

e.g. CO

2

extinguishers

(carbon dioxide)

.

2.1 Product - overall view

LightCutter

2-8

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

2 Product description

2.1 Product - overall view

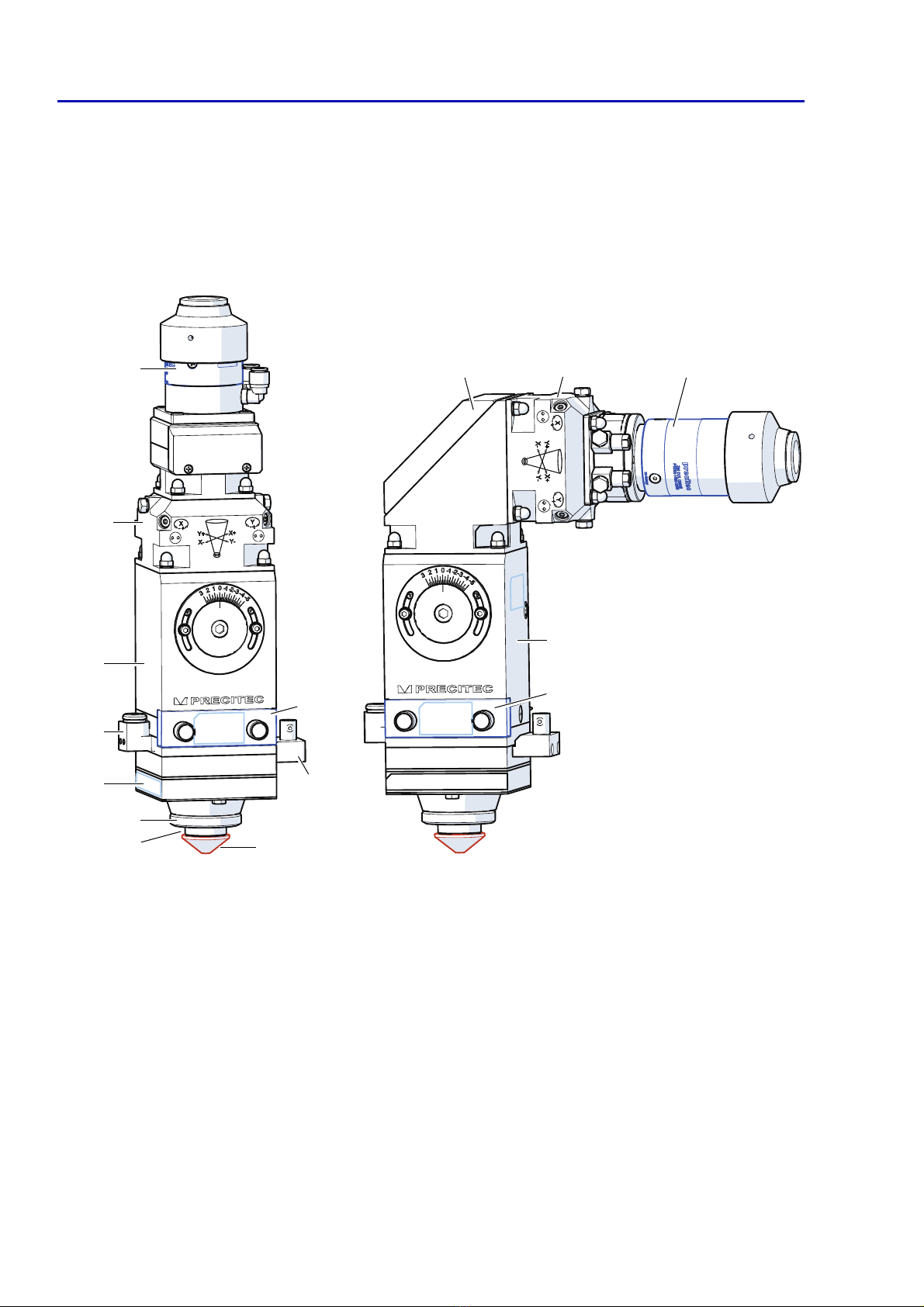

Fig. 2-1 Laser head, overall view

LC-BA-oAs / -oAa

5

2

6

7

3

10

1

9

8

11 2 1

3

10

(straight design)

(angled design)

4

1

Fibre socket

(e.g. QBH)

7

Ceramic part

KT

2

Collimating module

COL

8

Nozzle

DE

(nozzle electrode)

3

Adjustment module

(focal position)

9

BNC connection

(sensor system)

4

G1/8 connection, left

(cutting gas)

10

Protective window cartridge

5

Sensor insert

SE

11

Beam bender module

(COL 90°)

6

Nut

MU

2 Product description

D 159195 © Precitec GmbH & Co. KG • EN 09/2019

2-9

2.1.1 Design and functions

The laser head is used for the distance-controlled laser cutting of metals

using fibre-coupled lasers on flat bed machines.

It is precisely worked, rugged, service-friendly and can be adjusted easily.

All media connections are located at the laser head.

The laser head includes capacitive distance sensors that constantly record

the standoff distance between the nozzle

(nozzle electrode)

and the workpiece.

The system electronics analyses the sensor signal that is used to control a

linear drive.

Collimator

The collimator is permanently mounted on the laser head and mainly consist

of a fibre socket and the collimator housing with a water cooling device for the

collimating lens

(f

C

75 / f

C

100 focal length)

.

Water cooling device

All water-conducting parts in the module-integrated cooling system are made

of stainless steel. Fittings with M5 threaded holes for hoses

(ø6 mm external/

ø4 mm internal)

are used for cooling water outflow and inflow.

Laser beam position

The focal position adjustment device is integrated into the collimator.

Two Allen

(socket)

head screws

(size 2)

at the front of the collimator are used

for centring.

The horizontal adjustment range is ±1.5 mm.

Focusing lens

Focusing lenses with focal lengths from

F100

to

F200

can be used.

The maximum clear optical diameter

(clear aperture)

is 24 mm.

Focal position

(adjustment module)

The vertical adjustment range lies between -5 and +3 mm for all focal lengths.

A large indicating dial

(graduation of 0.5 mm)

enables the focal position to be set

using an Allen key

(size 5)

.

Protective window cartridge

The protective window cartridge is located underneath the beam shaping

optics. The protective window

(OG)

is pressure-proof and can withstand

maximum laser head pressure.

Cutting gas

The laser head can be operated at a cutting gas pressure of up to 25 bar

(2.5 MPa)

. The connection

(G1/8)

is located on the left-hand side of the

protective window module

(a module where the connection (G1/8) is on the

right-hand side is also available).

The cutting gas also cools the protective window.

Precitec offers fibre sockets for its high-performance collimators for connecting

conventional fibre optic cables

Collimators OG-COL

(straight design)

can also be equipped with a protective

window

(protective window cartridge COL)

which protects the collimating lens from

dust and dirt when the fibre is being installed or removed.

Cutting gas quality in compliance with ISO 8573-1:2010; Solid particles -

Class 2, Water - Class 4, Oil - Class 3 (see

Tab. 8-2, page 8-65

). The purer the

cutting gas is the longer the protective window's life will be.

2.1 Product - overall view

LightCutter

2-10

© Precitec GmbH & Co. KG • EN 09/2019 D 159195

Sensor insert

The sensor insert

(SE)

is fitted firmly to the laser head. It can be removed by

undoing four screws. A ceramic part

(KT)

is fitted to the sensor insert from

below. It locks into place firmly as it can only be fitted in one direction and is

secured by a nut

(MU).

Nozzle

(nozzle electrode)

The nozzle is screwed into the ceramic part and can be replaced easily if

worn. Precitec nozzles and ceramic parts are very precisely worked. Because

of the minimum concentricity tolerance any re-adjustment work can be

reduced or avoided when replacing these parts.

Fixing to the machine

Four M6 threaded holes

(14.5 mm deep)

at the back of the laser head are used

for fixing it to the machine. Two pin holes ø4

F7

(8 mm deep)

are used to position

the unit precisely and in such a way that this position can be reproduced.

2.1.2 Distance controller

Distance sensor system

(Lasermatic®)

For distance-controlled cutting, the laser head is equipped with the capacitive

Lasermatic®

distance sensor system

(sensor cable, max. 20 m)

.

Together with the other control loop components the system guarantees a

constant standoff distance

(focal position)

between the nozzle electrode and the

workpiece during laser beam cutting if there are no edges or large workpiece

surface bulges in the sensor's scanning range.

2.1.3 Protective equipment

Cooling the collimating lens

The collimating lens must be water-cooled. Fittings with M5 threaded holes for

hoses

(ø6 mm external/ ø4 mm internal)

are used for cooling water outflow and

inflow. The cooling water is conveyed around the collimator housing in a

(stainless steel)

circuit, indirectly cooling the collimating area.

Collision detection

When

Precitec

analysing electronics are used, an electronic collision signal is

emitted when the sensor insert or the nozzle contacts the machine mass. The

signal either stops the drive or enables the laser head to take evasive action.

Please refer to

chapter 8.2 „Parts available“, page 8-67

for the nozzle

(DE)

diameters that can be supplied.

This manual suits for next models

1

Table of contents

Popular Cutter manuals by other brands

Hilti

Hilti NCT 45 S-22 manual

Universal Laser Systems

Universal Laser Systems X-660 Safety, installation, operation, and basic maintenance manual

Guarda

Guarda FTR095 Operator's manual

Marshalltown

Marshalltown 28847 manual

Husqvarna

Husqvarna TS 230 I operating instructions

Yueming

Yueming CMA1325 owner's manual