PREISING PASA I Series User manual

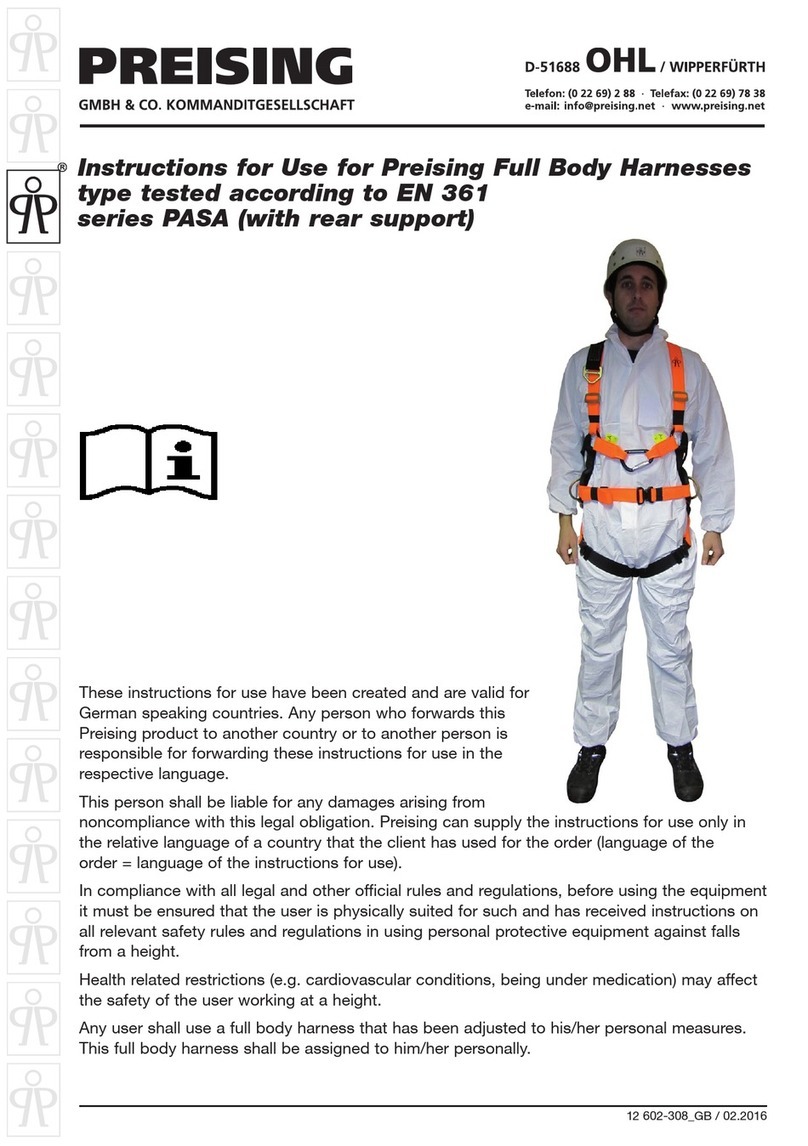

Instructions for use for Preising full body harnesses type tested

according to EN 361 series PASA

These instructions for use have been created and are valid for English speaking countries. Any person

who forwards this Preising product to another country or to another person is responsible for forwarding

these instructions for use in the respective language. This person shall be liable for any damages

arising from noncompliance with this legal obligation. Preising can supply the instructions for use only in

the relative language of a country that the client has used for the order (language of the order =

language of the instructions for use).

General Information

Any user shall use the full body harness that has been adjusted to his/her personal measures. This full

body harness shall be assigned to him/her personally.

It is very important to put on the full body harness correctly, therefore, read these instructions for use

very carefully before using your full body harness.

The proper and designated use of the full body harness is very important, therefore, read these

instructions for use carefully before using your full body harness.

In compliance with any legal and other official rules and regulations, before using the equipment it must

be ensured that the user is physically suitable and has received instructions on all relevant safety rules

and regulations with regard to the use of personal protective equipment against falls from a height. The

user must wear protective clothing suitable and appropriate for the work.

The series PASA I (1), PASA III (3) and PASA V (5) are equipped only with shoulder straps and leg

straps with integrated fall arrest attachment element on the back and/or front.

PASA I (1) PASA V (5) PASA 51 PASA II (2) PASA X (10)

The series PASA II (2), PASA IV (4), PASA X (10), PASA 51 are furthermore equipped with a waist belt

with integrated attachment elements for work positioning or restraint (=work positioning harness),

optional attachment element for guided type fall arrester and D-rings to attach belt pouches (not for

PASA IV(4) for the transportation of material.

Legend for full body harnesses made by Preising:

1. Fall arrest attachment element on the back

2. Fall arrest attachment element on the front

3. Attachment element for guided type fall arrester

EN 353-1 (not for all models)

4. Attachment elements for work positioning (not for

all models)

a) Adjustment vertical shoulder straps

b) Adjustment leg straps

c) chest buckle (not for all models)

d) Adjustment and buckle of work positioning

harness (not for all models)

Upon special client request individual

models can be manufactured and delivered

without attachment element on the back

(e.g. for skylifts).

In this case straps are still crossed over on

the back!

The model PASA IV (4) can be equipped with

waist belt and attachment element No. 3 (for

guided type fall arrester), but without

restraint attachment element No. 4.

This fall arrest attachment element of type Amay be used in connection with

(1) hinged guided type fall arresters in accordance with EN 353-2

(2) guided type fall arresters in accordance with EN 353-2

(3) lanyards EN 354 with energy absorber

(4) rectractable type fall arresters EN 360

(5a) band energy absorbers EN 355

(5b) friction energy absorbers EN 355

(6) abseilingr devices EN 341, also with integrated rescue function

in accordance with EN 1496 or specific rescue devices in accordance with EN 1496.

Always observe the instructions for use for any personal protective equipment which

is used together with the Preising full body harnesses, in particular the given

minimum distances to danger areas as well as the safety instructions!

Fall arrest equipment as per EN 353-2, connectors with energy absorber as per EN

354, energy absorbers as per EN 355 and retractable type fall arresters as per EN

360 require e.g.

- defined minimum clearances below the user between the underlying danger area

- anchor points with defined position in relation to the user (e.g. above) with

instructions and restrictions e.g. regarding horizontal or inclined use.

The full arrest attachment element characterized with A/2 consists of 2 belt loops

which must always be connected with the included karabiners as per EN 362 in order

to form a functional full arrest attachment element. This functional unit may be used

in connection with

(7) fall arrest equipment EN 353-1 – „guided-type fall arresters“

(1) hinged guided type fall arresters in accordance with EN 353-2

(2) guided type fall arresters in accordance with EN 353-2

(3) lanyards EN 354 with energy absorber

(4) rectractable type fall arresters EN 360

(5a) band energy absorbers EN 355

(5b) friction energy absorbers EN 355

(6) abseiling devices EN 341, also with integrated rescue function

in accordance with EN 1496 or respective rescue devices in accordance with EN

1496.

Always observe the instructions for use for this equipment used together with the

Preising full body harnesses, in particular the respective safety instructions.

Fall arrest equipment as per EN 353-2, connectors with energy absorber as per EN

354, energy absorbers as per EN 355 and retractable type fall arresters as per EN

360 require e.g.

- defined minimum clearances below the user

- anchor points with defined position in relation to the user (e.g. above) with

instructions and restrictions e.g. regarding horizontal or inclined use.

The integrated work positioning or restraint attachment elements without rear support

(e.g. PASA IV (4) or with rear support (e.g. PASA II (2), PASA X (10), PASA 51 my

be used only in connection with 8work positioning ropes EN 358 or lanyards with

energy absorber EN 354 (design in accordance with figure 8) which are suitable for

the joint use of both work positioning attachment elements (= work positioning ropes)

- can be adjusted so that a free fall is limited to at maximum 0.5 m.

Work positioning rings are not suitable for fall arrest purposes!

One-sided use of a work-positioning ring is not permitted!

All Preising full body harnesses with integrated work positioning or restraint rings can

be equipped with an attachment element for guided type fall arrester (no upgrades –

available only when manufacturing).

These attachment elements for guided type fall arresters may only be used in

connection with 7fall arrest equipment in accordance with EN 353-1, so called

guided type fall arresters.

Attachment possibilities for belt pouches are limited to models with attachment

elements for work positioning and rear support (e.g. PASA X (10), PASA II (2),

PASA 51.

Design features and proper and designated use of the full body harnesses

Fall arrest attachment

element on the back A

Front mounted fall arrest

attachment element A/2

Attachment possibilities for belt pouches are only available with models with

restraint function and rear support (e.g. PASA X (10), PASA II (2), PASA 51.

How to put on the full body harness

Prior to each use, a visual inspection of the full body harness must be carried out in order to ensure its impeccable

condition. Particular attention should be made regarding the following: cuts, wear, damage due to heat, chemicals and

similar, undamaged seams and fittings (no corrosion, no mechanical deformation or cuts as well as inspection regarding

impeccable function). Check the impeccable function of the karabiners as per EN 362 which are included in the scope of

supply of the full body harness, i.e. snap safety catch closes without problem and clicks in completely, the locking screw

element can be operated smoothly and correctly, self-locking twist fasteners and Trilock fasteners latch in completely as

envisaged and lock impeccably.

All fasteners are free from any contamination which might impair their function.

Damaged full body harnesses must not be used, also not when there are doubts regarding their safe condition Îpass on

to a competent person or to the manufacturer for inspection (address see page 1 of these instructions for use)!

Only use original parts made by Preising!

A full body harness which has been used for an arrest fall, must be immediately put out of service and sent to the

manufacturer for inspection (address see page 1 of these instructions for use)!

Your full body harness is supplied with the following documentation:

1. Identity card indicating manufacturer, serial number, model, date of being put into service (to be filled in by the user) etc.

2. These instructions for use.

Both documents must be stored carefully and should be available at all time.

Alternative solutions are within the responsibility of the company.

Remove the full body harness from

the packaging, hold it at the shoulder

straps so that the harness is

completely spread out.

Open the leg straps amd put on

the full body harness by placing

the shoulder straps over the

shoulders as shown

Fix the full body harness by

closing first the front chest

buckle (if available for the

respective model).

Then close the leg straps. And finally the waist belt.

If your model is equipped with a fall arrest

attachment element on the front, both belt loops

must be connected using a karabiner as per EN

362. Make sure that the snap safety catch has

been closed according to the instructions!

Operation of the various fittings

The plastic snap buckle

consists of 2 parts - fit together

until both latch in.

Fasteners with friction buckles:

Guide the loose strap end

through the friction buckle from

the backside, insert between

the movable part and the fixed

end of the strap and pull to the

front.

Now, guide the strap end which

has been pulled to the front,

around the movable part and

reinsert to the back.

Finally, pull tightly.

Metal snap buckle: Place both

ends into each other until they

latch. View of the closed and tightly

adjusted snap buckle of the waist

belt.

Compact snap buckle: Place

both ends into each other until

they latch. View of the closed and tightly

adjusted snap buckle of the

waist belt.

Tighten with the buckle closed by

pulling the free strap end, loosen

only in the open condition (pull at

the buckle).

For changing the strap length:

Open the buckle, hold at right-

angles and pull at the strap end

(to tighten) or at the buckle (to

loosen).

loosen

fasten

Pass-thru buckles:

Insert the smaller frame from

the back through the larger one.

Then, pull tightly (to tighten) at

the free strap end; loosen only

in the open condition (pull at

the frame).

Open the compact snap buckle:

Press simultaneously both

release levers and pull the other

buckle half in direction of the

arrows.

Fasteners with friction buckles in the

leg area: Guide the loose strap end

through the friction buckle from the

backside, insert between the

movable part and the fixed end of the

strap and pull to the front.

Now, guide the strap end which

has been pulled to the front,

around the movable part and

reinsert to the back. Finally, pull

tightly.

Front mounted fall arrest

attachment element:

The right and left strap loops are

connected with each other by

means of a karabiner as per EN

362 – then close the safety

mechanism on the snap safety

catch according to the

instructions!

Leg strap snap buckle PASA 51:

The two black snap buckle parts

must be placed on to the pegs of

the silver part such that they latch

in.

PASA 51:

Adjust waist belt more tightly/

Tighten waist belt: position both

frames at a right-angle and pull

tightly the loose strap end.

PASA 51:

Loosen waist belt: position

both frames at a right-angle

and pull back the loose strap

end.

Leg straps horizontal on the thighs.

Safety and risk instructions to be observed after the full body harness has been put on

The leg straps are adjusted

correctly when it is possible

to place only the flat of one

hand underneath.

much too loose! not cool!

Danger to life The sit strap is

underneath the

buttocks.

Attention: Leg straps put on

incorrectly!

Readjust according to the

previous explanations!0

Shoulder straps

adjusted too

tightly – risk of

injury and

tiredness!

Readjust

according to the

previous

explanations!

Pull straps in direction of the arrows and conforming to the sequence 1-4 in order to lower

the breast fastener. It can be positioned higher when proceeding in the reverse sequence. Thisiscorrect!

Particular safety instructions:

Always observe the relevant instructions applicable for the work to be carried out by the user (regulations for

the prevention of accidents.)

The anchor point should be above the user and have a minimum load bearing capacity conforming to EN 795

(min. 10 kN).

Front mounted fall arrest attachment element A/2: the following applies for connection of the 2 belt loops (see

page 3) (provided that the included karabiner is not used): karabiner EN 362 of type B may be loaded only in the

main axis (EN 362:2005). If this cannot be ensured by the user, karabiners EN 362 of type M (EN 362:2005) must be

used. If in doubt, consult the manufacturer prior to use of the full body harness!

The equipment should personally belong to the user.

The equipment should be used only by trained and qualified persons.

Strictly observe the cleaning instructions.

The full body harness is approved for securing only one person.

It is forbidden to make any modification to the personal protective equipment.

Modifications as well as repair work must be carried out only by the manufacturer!

Use of the Preising full body harnesses: -20°C up to +60°C.

Use only dry full body harnesses when starting work.

Suitable for persons having a weight of max. 150 kg.

The instructions for use for all personal protective equipment used in combination with the full body harness

must be absolutely observed.

Prior to the use of the complete personal protective equipment, the user must find out about possible risks

which may occur at the place of use and then use the personal protective equipment in accordance with the

requirements. Also, a rescue concept should be available for the concrete application case.

Training regarding the use of full body harnesses in accordance with the requirements is offered by the

manufacturer.

Storage: Preferably in dry, well-ventilated rooms; keep away from sources of heat!

Transport: A suitable container protecting the personal protective equipment from contamination and damage during

transport, should be used, e.g. equipment bag No. 5099L, rucksack No. 5099/S4.

Cleaning: Clean the full body harness with lukewarm water by adding standard detergents.

Desinfection: Please contact directly the manufacturer if desinfection of the personal protective equipment should be

required.

Drying: Hang up in warm ventilated rooms, however not near to a fire or any other source of heat >60°C.

Checks and regular inspections: Prior to each use, visual inspection of the full body harness must be carried out

regarding impeccable condition in order to ensure the user’s safety which depends e.g. upon the effectiveness and

durability of the full body harness.

Particular attention should be made regarding the following: cuts, wear, damage due to heat, chemicals and similar,

undamaged seams and fittings (no corrosion, no mechanical deformation or cuts as well as inspection regarding

impeccable function). Check the impeccable function of karabiners as per EN 362 which are included in the scope of

supply of the full body harness, i.e. snap safety catch closes without problem and clicks in completely, the locking screw

element can be operated smoothly and correctly, self-locking twist fasteners and Trilock fasteners latch in completely as

envisaged and lock impeccably.

All fasteners are free from any contamination which might impair their function.

Damaged full body harnesses must not be used, also not when there are doubts regarding their safe condition Îpass on

to a competent person or to the manufacturer for inspection (address see page 1 of these instructions for use)! Only use

original parts made by Preising!

A full body harness which has been used for an arrest fall, must be immediately put out of service and sent to the

manufacturer for inspection.

It may be used again only following written approval by the manufacturer (address see page 1 of these instructions for use)!

The full body harness must be inspected by a competent person as necessary, however at least every 12 months in

compliance with EN 365. An inspection card (attached to these instructions for use) is enclosed in the scope of supply of

each full body harness. A respective inspection plan to be followed by the qualified person, can be obtained from the

manufacturer upon request (address see page 1). Furthermore, it must be verified that the full body harness is provided

with a readable identification.

Training to become a qualified person for carrying out the regular inspection of full body harnesses, is offered by the

manufacturer.

(Basis training for the period inspection).

Service life:

In the case, following inspection

1. through the user prior to each use

2. through the competent person as necessary, at least every 12 months,

no defects forbidding the further use, have been stated, we recommend full body harnesses to be taken

out of service following a service life of 6-8 years maximum.

Any longer use – also when prior to the first use, the full body harness had been stored for several years

in accordance with the regulations – should be agreed upon with the manufacturer.

Each full body harness is provided with the following indication:

A = fall arrest

attachment

element Æsee

page 3)

A/2 = fall arrest

attachment

element

Consisting of 2

strap loops which

must absolutely be

connected by

means of a

karabiner as per

EN 362

Æsee page 3

ÆPreising company logo

Full body harness EN 361:2002ÆType of product / reference to standards

0158 Æreference marking of the test site

performing the production control

Serial number 404672 Æserial number

ÆNote for the user to follow the instructions for use

Model PASA

I(1) II(2) IV(4) V(5) X(10) 51 type identification

Size K-1 S-2 Ü-3

size designation

Year of manufacture

Used materials for full body harnesses of series PASA

Strap: polyamide

Fall arrest attachment elements / attachment elements: made from steel and/or aluminium alloy

Frame fittings: made from aluminum alloy or steel with respect to the model

Snap buckles: made from aluminum alloy or steel with respect to the model

Type test: The product has been approved and certified by the company EXAM BBG Prüf- und

Zertifizier GmbH, Dinnendahlstraße 9, 44809 Bochum conforming to EN 361:2002.

Quality inspection performed by the manufacturer.

Production control performed by the EXAM certification authority.

All Preising full body harnesses are provided with the registered trademark.

Type designation Full body harness as per EN 361 series PASA

I (1) - II (2) - IV (4) - V (5) - X (10) - 51

Serial number

Year of manufacture

Suitable for the use with

Date of purchasing

Date of first use

Name of user

Notes/

Annual Inspection

Lanyards conf. to EN 354

Guided type fall arresters conf. to EN 353

Energy absorbers conf. to EN 355

Retractable type fall arresters EN 360

This manual suits for next models

2

Other PREISING Safety Equipment manuals