1-800-255-5387 • www.premier-mfg.com

premier manufacturing company Page 2

pull sideways, removing it from the body. When the

896 Handle is removed, the 895 Latch and 895A

Spring are also free to be removed. Please note that

Thread Locker is used to secure the 895C Set Screw.

Therefore it may be necessary to slightly heat-up the

part with a torch, in order to remove the set screw.

CAUTION: Do Not apply heat to the 895A Spring or

permanent damage will occur.

12) If the 891P Pin & Cable are damaged, you can

now remove them. Using a chisel or flat-bladed

screwdriver placed at the base of the 16DS Drive

Screw, tap with a hammer to wedge the 16DS up and

out of the hole it resides in, and remove the 891P Pin

& Cable.

13) Disassembly is now complete. Clean and inspect

parts and body for wear and/or damage. If wear

exists or damage is noted, replace affected

part. NEVER ATTEMPT WELD REPAIR OF ANY

DAMAGED OR WORN COMPONENT.

DISASSEMBLY IS COMPLETE

IMPORTANT NOTES TO CLEAN,

INSPECT & LUBRICATE:

► Use only genuine PREMIER replacement parts on

any repairs. Use of other parts, which can have

different specifications or tolerances, may fail to alert

you to non-obvious damage to the hitch which can

lead to hitch failure.

► All body holes, part holes and pins need to be

thoroughly cleaned and lubricated with a heavy

grease before the parts are reassembled. If a bushing

resides in a part, lubricate the hole prior to installing

the bushing. (DO NOT LUBRICATE PINTLE HOOK

WEAR SURFACE).

► Clean, inspect and lubricate latch components

every 90 days or sooner if required by the operating

environment.

► Clean and inspect the coupling for damage and

excessive wear prior to each and every use.

► Do not over-tighten fasteners as this may cause

damage.

ASSEMBLY

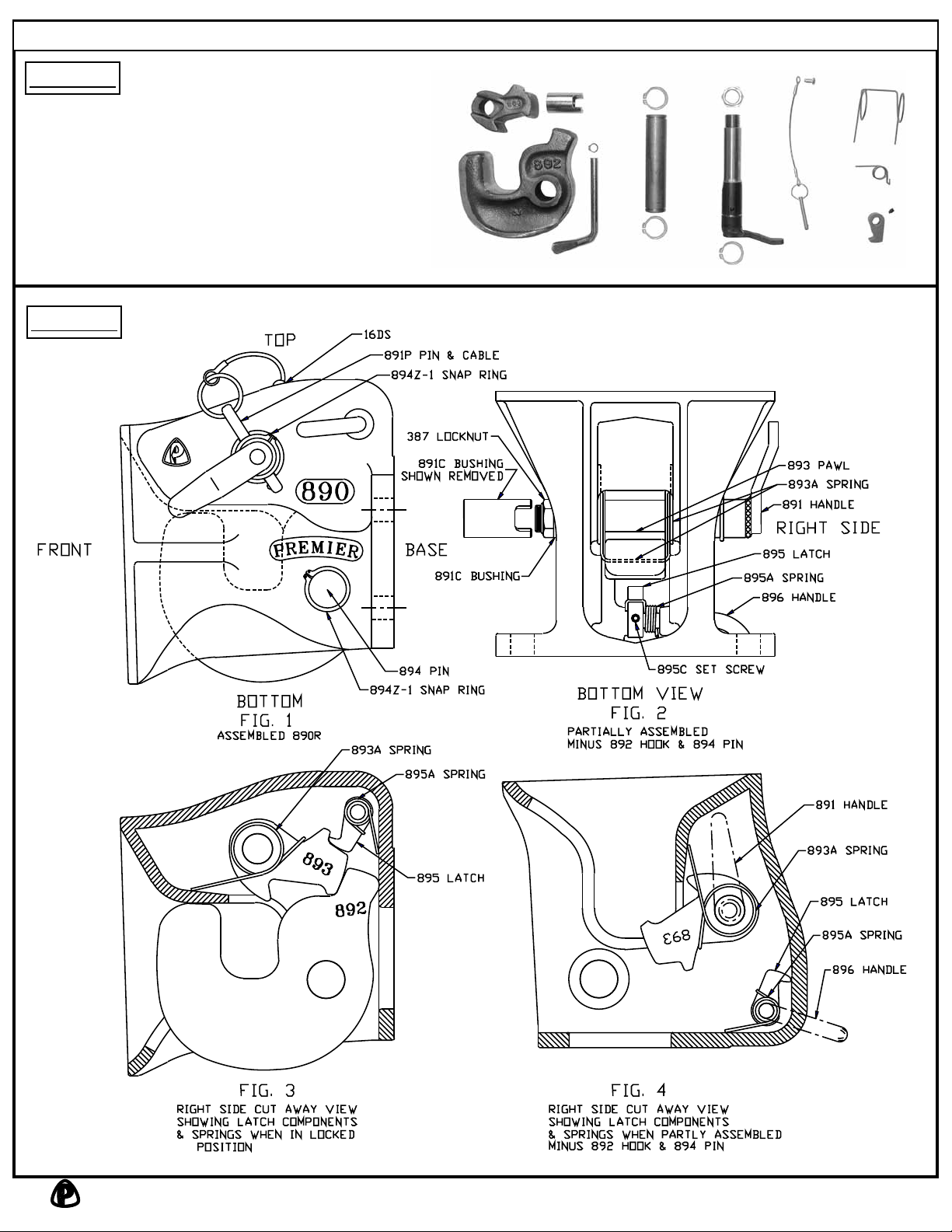

1) With the coupling body positioned on its topside as

shown in Image #2, Fig. 2. Slide 896 Handle into

the body from the right side until approx. 1/2” of the

handle is protruding past the inside surface of the

body.

2) Place the 895A Spring inside body onto the

protruding portion of the 896 Handle, to temporarily

hold the 895A Spring in position. Straight spring leg

will be pointing towards you. (See Image #2, Fig. 2

for spring position.)

3) Place 895 Latch into position, making certain that

the spring catch on the spring is located on the long

flat side of the part. While holding the 895 Latch in

position, slide 896 handle thru the 895 Latch and

continue thru the other body sidewall until snap ring

groove is exposed. (See Image #2, Figs. 2 & 4 for

spring and latch position.)

4) Locate counter-drilled hole in 896 Handle and align

it with the tapped hole in 895 Latch. Install 895C Set

Screw into 895 Latch, making certain it maintains

alignment with 896 Handle counter-drilled hole, and

then tighten in position. 895C Set Screw should

be flush with the surface of the 895 Latch. If it is

protruding, it is not aligned with the counter-drilled

hole in the 896 Handle. (See Image #2, Fig. 4 for

approx. handle position when completed.) Use a

permanent thread locker to secure the 895C Set

Screw.

5) Rotate the 896 Handle counterclockwise checking

for spring resistance. If the 895A Spring is installed

correctly, a smooth increasing spring resistance

should be felt when handle is rotated. If no

resistance or binding is felt, the spring and/or part is

not installed correctly and must be corrected prior to

proceeding further.

6) Install 275-50 Snap Ring into groove provided on the

end of the 896 Handle. Install the 894Z-1 Snap Ring

into groove provided on 891 Handle.

7) From the left side of the body, insert the 891C

Bushing into the hole (where the 891 Handle will

reside), with the cut out lugs going inward first. Make

sure the 891C Bushing is flush with the interior body

wall.

8) Place 893A Spring into body (opened spring legs

pointing away from you), and align spring with the

hole that the 891C Bushing is resting in. When

aligned, push 891C Bushing into spring loop just

enough to hold spring in position. (See Image #2,

Figs. 2 & 4 for spring position and orientation.)

9) Grasp 893 Pawl and lower into position, making

certain the closed loop of the spring is closest to you

and catch the backside of the 893 Pawl on the spring

as shown in Image #2, Fig. 4. Align the 893 Pawl