Pres Block AFNOR NF S 90-116 Manual

USE AND MAINTENANCE HANDBOOK FOR

AFNOR NF S90-116 /FD S90-119

TERMINAL UNITS /PROBES AND ACCESSORIES

CONFORM TO EN ISO 9170-1 STANDARD

0476

93/42/EEC

1. General information

1.1 Introduction

Pres Block NF S 90-116 / FD S 90-119 terminal units, probes and

accessories are medical devices “CE” marked, built to comply with

93/42/EEC European directive and EN ISO 9170-1 and NF S 90-

116 / FD S 90-119 standards.

Before using the device, please read this handbook and ensure it is

read by authorized operators.

1.2 Destination of use

Pres Block terminal units, probes and accessories have been

designed to connect in a safe way medical equipment to the

medical gases distribution system.

1.3 Classification and information under 93/42/EEC directive

The medical device:

•is identified with class of risk IIb, according to rule 11 of Annex IX

of directive 93/42/EEC;

•is neither for single use, nor sterile;

•does not intentionally contain latex;

•does not incorporate neither medicinal substances, nor biological

or animal tissues, nor human blood;

•does not contain phthalates classified as carcinogenic, mutagenic

or toxic to reproduction.

1.4 Marking

Marks on every device are:

“ ” or “Pres Block”

Identifies Pres Block as the manufacturer

“0476”

Identifies the Notified Body that approved

the CE certification for the device

Symbol of the gas distributed

according to EN ISO 9170-1 standard

Batch Numbers and other markings per component:

Sockets

Referenced standards

Batch number: either as a data stamp [XXYY], followed by one or two letters

identifying the gas [ZZ] or as “LOT XXYYZZ”. In both cases “XX” stands for

the year of manufacture

Name of the Customer

(optional)

Base Blocks: Please refer to handbook FTGTD05Ze and

FTGTI05e

Probes and Adaptors

“LOT XXYYZZ”

Batch number, where XX identifies the year of

manufacture

Referenced standard

(optional)

2. Technical information

2.1 Components

Available components are:

Name

Code

(initial part)

Descriptions

BASE

BLOCK

ZARMOR

ZARM

Part connected to the distribution system.

Please refer to handbook FTGTD05Ze for

ZARMOR and to handbook FTGTI05e for ZARM.

SOCKET

VGTF…-OR

Part integrated in or connected to the OR-base

block by a gas-specific interface.

Contains the gas-specific connection point with

the probe.

VGTF

Part connected to the base block by a gas-specific

thread.

Contains the gas-specific connection point with

the probe.

PROBE

IGTF /

IGTGF

Male component which is connected into and

retained by the socket.

ADAPTOR

/ SET

AGTF

Component for special applications /

Set made up of several components intended as a

single device

2.2 Technical and Operating characteristics

In compliance with the

following standards:

NF S 90-116 / FD S90-119 and EN ISO 9170-1

Transport, storage and

working temperatures

range:

-20 ÷ +60° C

Transport, storage and

working humidity range:

10 ÷ 90 %

Atmospheric pressure

limits:

700 ÷ 1060 hPa

Materials used:

Brass (type CW614N or CW617N) with and

without plating (chrome or nickel), Zamak (Zinc

alloy), AISI (302/304/420), ABS, PA66, PE,

POM, EPDM

Lubricants:

Compatible with distributed gases (especially for

O2)

Distributed gases and

relative working pressures:

O2; N2O; CO2; Air,

mixtures

from 320 kPa to 600 kPa

Vacuum

from -10 kPa to -60 kPa

N2; Air-800

from 560 kPa to 1200 kPa

2.3 Transport and storage

The original packaging is designed to guarantee the proper

transport and storage of the product, in compliance with the

requests of EN ISO 15001 standard.

The device must be transported and stored in its

original packaging; any damage to the packaging may

be detrimental to the functioning or safety of the

product.

The device must be protected from atmospheric agents

(rain, snow, etc.): water may cause malfunctioning.

3. Installation

The medical device must be installed only by expert

and authorized operators. The installation must strictly

follow these instructions and the requests of EN ISO

7396-1 standard.

The medical device must be installed at an easily accessible

height, reducing as much as possible the risk of damages, due to

furniture or other medical devices, and granting a distance ≥100

mm between 2 consecutive terminal units.

All the materials used during installation must be compatible with

the gases supplied and the materials of the device.

Every precaution must be taken to guarantee and maintain the

cleanliness of the device according to EN ISO 15001 standard.

Before installation, verify that the device is compatible with the

devices it must be connected with, especially if supplied by

different manufacturers.

Before use, connect the device to equipotential earth.

33.1 Base blocks

Please refer to handbook FTGTD05Ze for ZARMOR base blocks

and to handbook FTGTI05e for ZARM base blocks.

3.2 Sockets

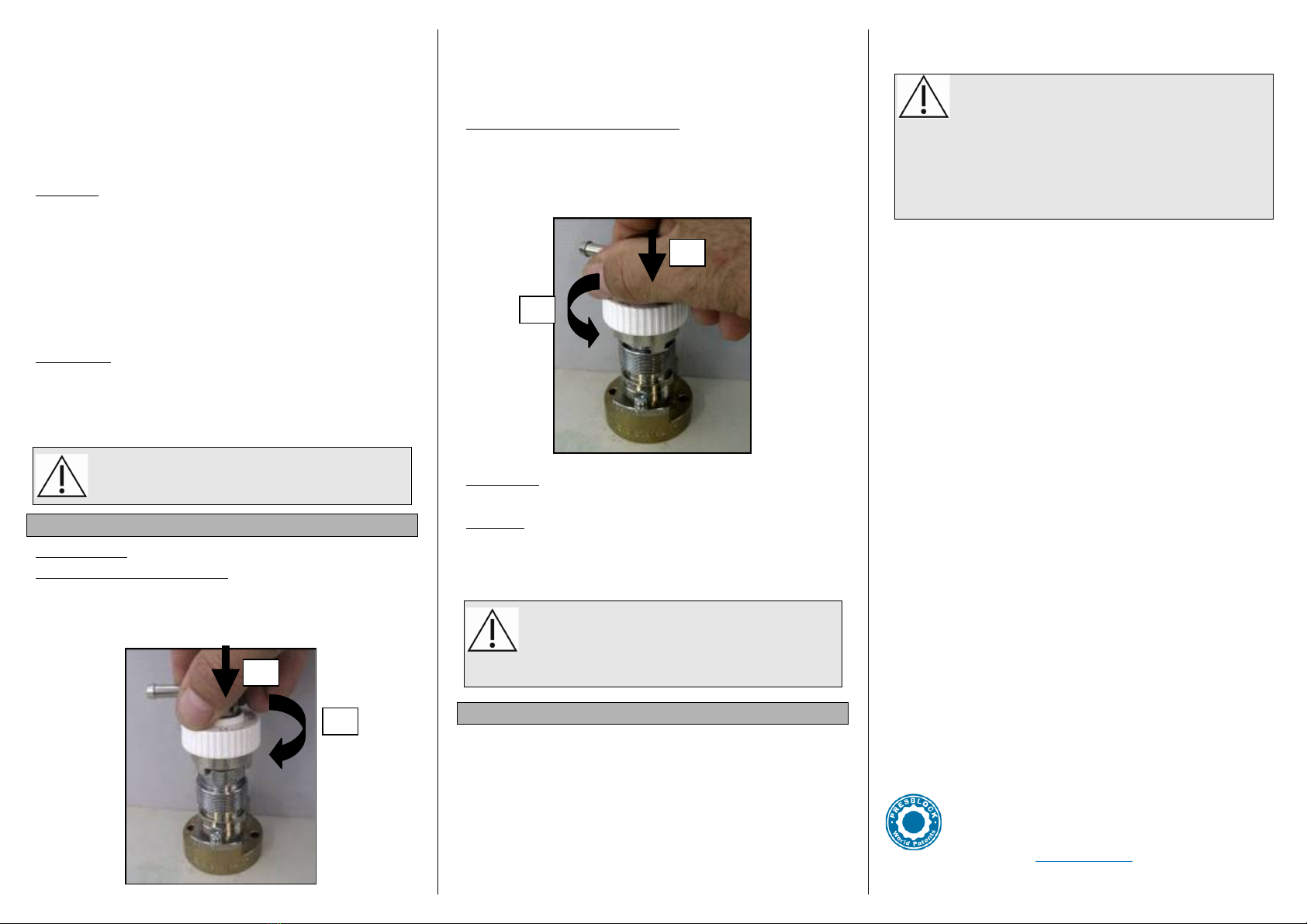

Socket model VGTF…-OR…

Perform the following operations in succession:

•align the 2 fixing holes I/D 4,5 mm. with the 2 females M4

threaded of the OR base block;

•fix the socket onto the ZARMOR base block tightening at the

same time the 2 M4 screws (supplied with the base block) with an

Allen wrench;

•fix the terminal unit into the box with the metal nuts, if supplied;

•place the gas identification disc (2) on the cassette, securing it by

means of a special plastic nut (1) that is screwed on the socket

body (3).

•point out that the socket cannot be used, because final tests on

the system must be run before its use.

1

2

3

Socket model VGTF…

Perform the following operations in succession:

•screw the socket on the ZARM base block (always threaded right,

apart from air and nitrogen outlets with left thread);

•fix the terminal unit into the box with the metal nuts, if supplied;

•place the gas identification disc (2) on the cassette, securing it by

means of a special plastic nut (1) that is screwed on the socket

body (3).

•point out that the socket cannot be used, because final tests on

the system must be run before its use.

3.3 Probes

Probe with barb end terminal IGTF…PG…and IGTGF...PG...

Perform the following operations in succession:

•fix the barb end to the flexible hose (I/D 6 or 8 mm.) with a

suitable single-use clip or crimped ferrule, according to EN ISO

5359 standard.

Probe with threaded terminal IGTF…F…and IGTF…M…

Perform the following operations in succession:

•fix the threaded terminal granting the tightness with a suitable O-

ring or PTFE tape.

3.4 Adaptors

Perform the following operations in succession:

•fix the adaptor to the panel using suitable screws;

•fix the barb end to the flexible hose (I/D 6 mm.) with a suitable

single-use clip or crimped ferrule, according to EN ISO 5359

standard.

Once installation is completed, verify the tightness: no

leakages are allowed.

Afterwards testing required by EN ISO 7396-1 standard

must be run.

4. Use

4.1 Functioning

SOCKET / PROBE CONNECTION

1. Verify that the socket and the probe are designed for the same

gas and that they refer to the same standard;

2. Grasp the probe and turn it aligning its profile with the

corresponding profile of the socket;

3. Insert the probe into the socket with enough force to oppose the

upstream pressure;

4. Rotate clockwise the probe;

5. Release the probe verifying that it remains anchored into the

socket.

SOCKET / PROBE DISCONNECTION

1. Keep the probe, in order to prevent its quick projection;

2. Push the probe towards the base block with enough force to

oppose the upstream pressure;

3. Rotate anticlockwise the probe;

4. Pull out the probe from the socket.

4.2 Cleaning

For cleaning use only distilled water or diluted ethyl alcohol.

4.3 Safety

Before use, personnel must familiarize with the control devices and

their operations.

If the medical device is out of order or in maintenance, disconnect

the gas supply and place a visible sign stating “NOT IN SERVICE.

DO NOT USE”.

Do not use the medical device for gases or pressures

different from those for which it is designed.

Do not crash the probe, in order not to spoil its

functionality.

Do not try to insert probes designed for a different gas and/or

different standard into the sockets. This may damage both devices.

5. Maintenance

The maintenance program must envisage a minimum of biannual

inspections with particular reference to:

•easy coupling and disconnection;

•wear or damage;

•contamination;

•marking – labelling;

•tightness;

•flow rate according to EN ISO 7396-1.

These operations must be recorded.

The following maintenance kits are available for the sockets:

•VGTF-RIC (for all gases except VAC and AIR-800);

•VGTF-A8-RIC (only for AIR-800);

•VGTF-V-RIC (only for VAC).

Every precaution must be taken to maintain the

cleanliness according to the requests of EN ISO 15001

standard.

During maintenance and repair only original parts must be used.

Do not use lubricants that aren’t compatible with the distributed

gases at their operating pressures. Especially in the case of contact

with oxygen there might be safety issues relating to fire or

explosion, if an incompatible lubricant is used.

Once maintenance is completed, testing required by EN ISO 7396-

1 standard must be run again

PRES BLOCK S.p.A.

via Alpignano 151-155 – I-10040 Caselette (TO) - Italy

Ph: 0039-011-9688055 - Fax : 0039-011-9688668

www.presblock.com

FTGTF05e Rev.6 dated 2017-05

3°

4°

2°

3°

This manual suits for next models

1