Presys TY-2090 User manual

Universal

Smart Transmitter

TY-2090

EM0319-00

TECHNICAL MANUAL

R

Energy

presys

presys

presys

Universal

presys

Universal

Smart Transmitter

presys

Smart Transmitter

presys

CAUTION!

In case of failure, the instrument can provide AC voltage levels in its metal box,

which for safety reasons must always be connected to an effective ground point. To

this end a suitable terminal is provided on the back of the box identified as GND. Never

connect this terminal to the neutral terminal of power supply.

It is recommended the use of an external fuse (2 A) on the power input of the

instrument. There is an internal fuse.

Operation of relays - Important Note!

When the instrument has relay module for alarm or control, you must follow the

instructions in this manual in the maintenance section on the snubber use.

The snubber is a protection against noise coming from the opening / closing of

the relay contacts, but depending on the application may be necessary to remove this

snubber!

CAUTION!

The instrument described in this manual is a device for use in specialized

technical area. The user is responsible for configuration and selection of values of the

instrument parameters. The manufacturer warns of the risks of occurrences with

damage to both the person and the property resulting from the incorrect use of the

instrument. The information and specifications in this manual are subject to change

without previous notice.

presys

In case of failure, the instrument can provide AC voltage levels in its metal box,

presys

In case of failure, the instrument can provide AC voltage levels in its metal box,

which for safety reasons must always be connected to an effective ground point. To

presys

which for safety reasons must always be connected to an effective ground point. To

this end a suitable terminal is provided on the back of the box identified as GND. Never

presys

this end a suitable terminal is provided on the back of the box identified as GND. Never

It is recommended the use of an external fuse (2 A) on the power input of the

presys

It is recommended the use of an external fuse (2 A) on the power input of the

Operation of relays - Important Note!

presys

Operation of relays - Important Note!

When the instrument has relay module for alarm or control, you must follow the

presys

When the instrument has relay module for alarm or control, you must follow the

instructions in this manual in the maintenance section on the snubber use.

presys

instructions in this manual in the maintenance section on the snubber use.

The snubber is a protection against noise coming from the opening / closing of

presys

The snubber is a protection against noise coming from the opening / closing of

the relay contacts, but depending on the application may be necessary to remove this

presys

the relay contacts, but depending on the application may be necessary to remove this

CAUTION!

presys

CAUTION!

The instrument described in this manual is a device for use in specialized

presys

The instrument described in this manual is a device for use in specialized

technical area. The user is responsible for configuration and selection of values of the

presys

technical area. The user is responsible for configuration and selection of values of the

instrument parameters. The manufacturer warns of the risks of occurrences with

presys

instrument parameters. The manufacturer warns of the risks of occurrences with

damage to both the person and the property resulting from the incorrect use of the

presys

damage to both the person and the property resulting from the incorrect use of the

instrument. The information and specifications in this manual are subject to change

presys

instrument. The information and specifications in this manual are subject to change

without previous notice.

presys

without previous notice.

PRESYS Instruments TY-2090-Energy

EM0319-00

Table of Contents

1.0 - Introduction ............................................................................................................1

1.1 - Description............................................................................................................1

1.2 - Order Code...........................................................................................................2

1.3 - Technical Specifications........................................................................................3

2.0 - Installation ..............................................................................................................5

2.1 - Mechanical Installation..........................................................................................5

2.2 - Electrical Installation .............................................................................................5

2.3 - Process Input Signal Connections ........................................................................6

2.3.1 - RTD Connections...........................................................................................7

2.3.2 - Current Input ..................................................................................................8

2.3.3 - Voltage Inputs ................................................................................................9

2.4 - Output Connections ............................................................................................10

2.5 - Connection Diagram ...........................................................................................12

2.6 - Communication...................................................................................................13

2.7 - Engineering Units................................................................................................13

3.0 - Operation ..............................................................................................................14

3.1 - Normal Operation................................................................................................14

3.2 - Configuration.......................................................................................................17

4.0 - Maintenance..........................................................................................................30

4.1 - Hardware ............................................................................................................30

4.2 - Hardware Configuration ......................................................................................32

4.3 - Using Snubber with relays...................................................................................33

4.4 - Optional Modules Installation..............................................................................34

4.5 - Calibration...........................................................................................................37

4.6 - Hardware Maintenance Instructions....................................................................42

4.7 - List of Components.............................................................................................44

4.8 - List of Recommended Spare Components .........................................................47

5.0 - MODBUS Communication....................................................................................48

5.1 - List of MODBUS Communication Registers........................................................48

5.2 - List of Communication Coils ...............................................................................52

presys

................................

presys

................................

............

presys

............

................................

presys

................................

............

presys

............

1

presys

1

................................

presys

................................

................................

presys

................................

...........

presys

...........

2

presys

2

................................

presys

................................

........................

presys

........................

3

presys

3

................................

presys

................................

................................

presys

................................

..............

presys

..............

5

presys

5

................................

presys

................................

..........................

presys

..........................

5

presys

5

................................

presys

................................

.............................

presys

.............................

................................

presys

................................

................................

presys

................................

........

presys

........

................................

presys

................................

................................

presys

................................

...........................

presys

...........................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

............................

presys

............................

................................

presys

................................

................................

presys

................................

...........................

presys

...........................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

3.1 - Normal Operation

presys

3.1 - Normal Operation

................................

presys

................................

................................

presys

................................

................................

presys

................................

................................

presys

................................

4.0 - Maintenance

presys

4.0 - Maintenance

................................

presys

................................

................................

presys

................................

4.1 - Hardware

presys

4.1 - Hardware

................................

presys

................................

................................

presys

................................

4.2 - Hardware Configuration

presys

4.2 - Hardware Configuration

................................

presys

................................

4.3 - Using Snubber with relays

presys

4.3 - Using Snubber with relays

................................

presys

................................

4.4 - Optional Modules Installation

presys

4.4 - Optional Modules Installation

................................

presys

................................

4.5 - Calibration

presys

4.5 - Calibration

................................

presys

................................

................................

presys

................................

4.6 - Hardware Maintenance I

presys

4.6 - Hardware Maintenance I

nstructions

presys

nstructions

4.7 -

presys

4.7 -

List of Components

presys

List of Components

................................

presys

................................

4.8 -

presys

4.8 -

List of Recommended Spare Components

presys

List of Recommended Spare Components

5.0 - MODBUS Communication

presys

5.0 - MODBUS Communication

................................

presys

................................

5.1 - List of MODBUS Communication Registers

presys

5.1 - List of MODBUS Communication Registers

5.2 - List of Communication Coils

presys

5.2 - List of Communication Coils

PRESYS Instruments TY-2090-Energy

Introduction

Page 1

1.0 - Introduction

1.1 - Description

The TY-2090-Energy transmitter is ideal for security applications in turbines,

hydroelectric plants and thermoelectric generators. It is a microprocessor-based

instrument which receives any process variable found in industrial plants such as:

temperature, pressure, flow, level etc. Ithas a non-volatile internal memory (E2PROM)

for storing calibration values.

It can communicate with acomputer through an optional RS-232 or RS-422/485

Communication Module. The Transmitter is capable of monitoring two

universal standard inputs, accepting direct connection

of thermocouples, RTDs, current (mAdc) and voltage

(mVdc, Vdc). The RTD inputs are automatically

linearized by means of tables stored in the EPROM. A

24 Vdc power supply,isolated from the output and

with short circuit protection, is provided to power up

standard field two-wire instruments.

The type of input selected by the user is

enabled by jumpers and by configuration via software.

All configuration data can be protected by a password

system and are stored in the non-volatile memory in

case of power failure.

Designed within the concept of modularity, the

transmitter accepts up to 4 output cards. The possible

output types are analog, SPDT relay, SPST relay,

solid-state relay and open collection voltage.

In case of input sensor breaking, the trip alarms

are not triggered (configurable for 4-20 mA and RTD

inputs) and the analog outputs assume preconfigured

safety values. The alarm outputs can be

independently configured to work in latch mode,

demanding the acknowledgement by the operator

through the MCY-20 configurator keys or via

communication in order to be disabled after the

return of the process variable to the normal

condition. The outputs are electrically isolated from

the inputs. In addition to the high and low alarms, the

transmitter can be set for failure alarms (watchdog) triggered by the detectionof broken

sensors connected to the current or RTD inputs.

It allows the use of a universal power supply from 75 to 264 Vac 50/60Hz or 100

to 360 Vdc (any polarity).

The instrument has an extruded aluminum case which makes it highly immune to

electrical noise, electromagnetic interference and resistant to the most severe conditions

of industrial usage.

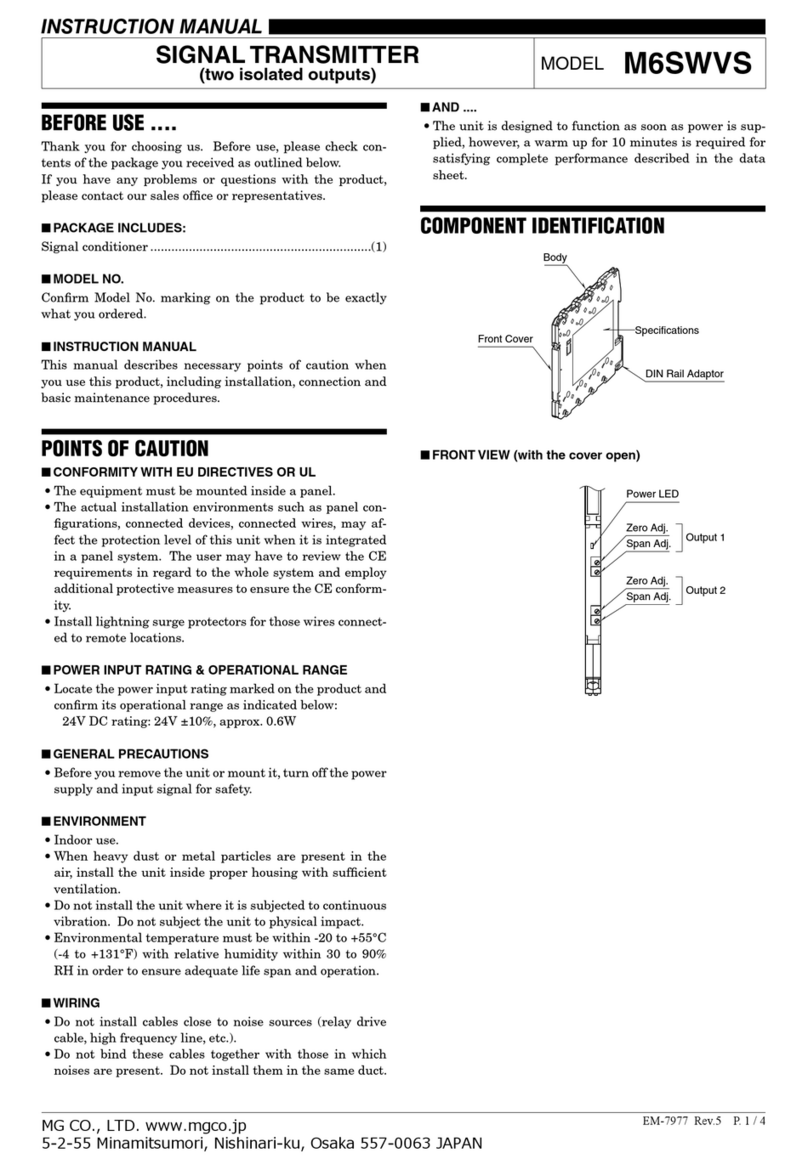

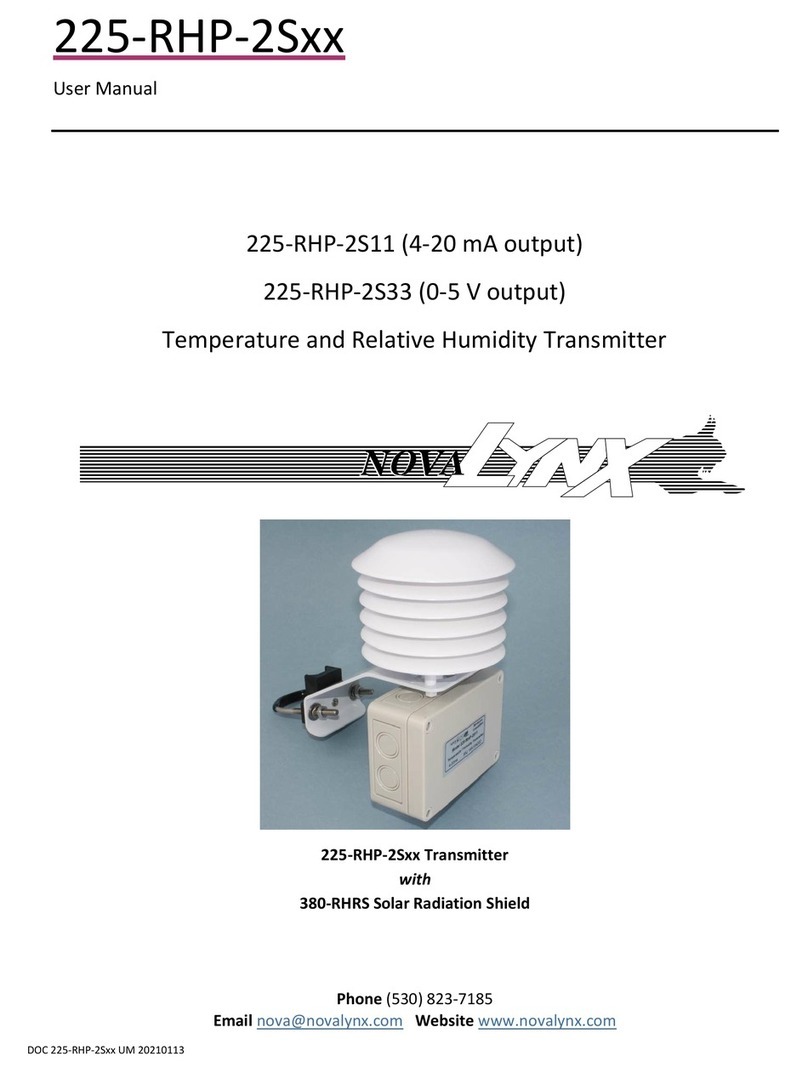

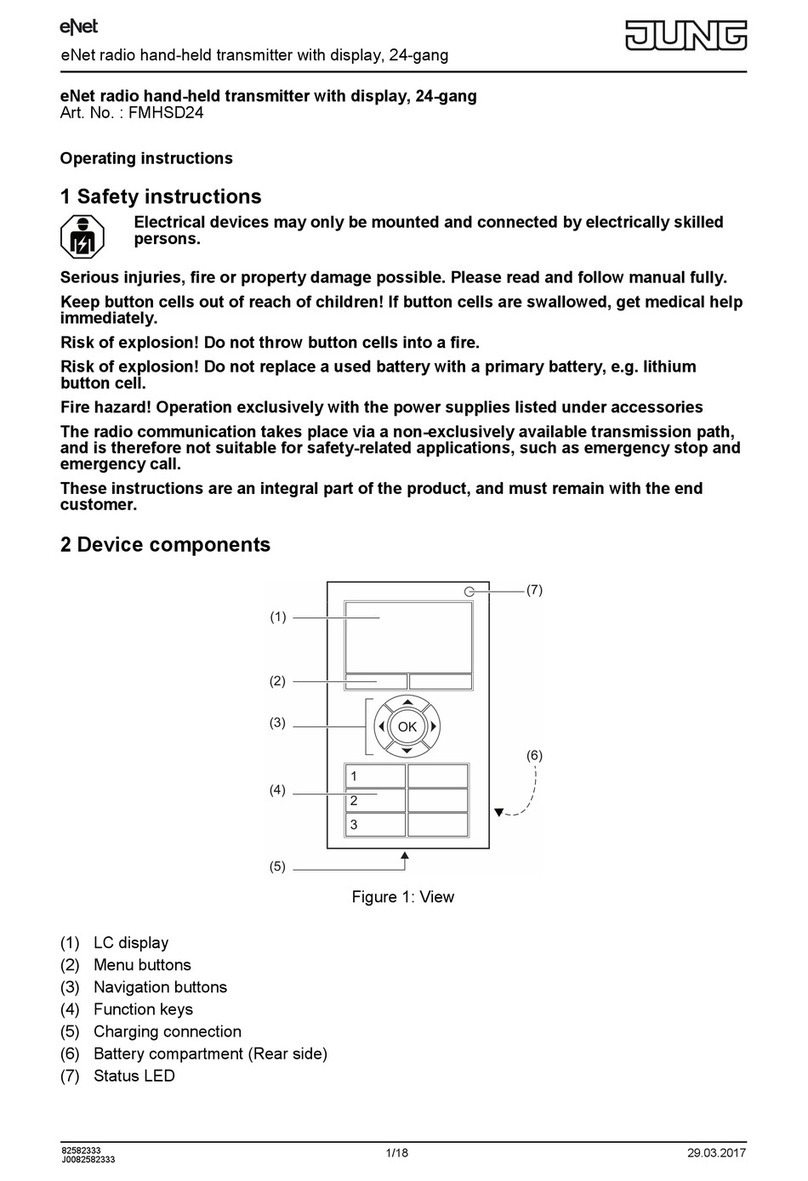

Fig. 1 -Front view of the

TY-2090-Energy Transmitter

presys

-Energy transmitter is ideal for security applications in turbines,

presys

-Energy transmitter is ideal for security applications in turbines,

is a microprocessor-based

presys

is a microprocessor-based

instrument which receives any process variable found in industrial plants such as:

presys

instrument which receives any process variable found in industrial plants such as:

-volatile internal memory (E2PROM)

presys

-volatile internal memory (E2PROM)

an

presys

an

optional

presys

optional

RS

presys

RS

-232 or RS-422/485

presys

-232 or RS-422/485

The Transmitter is capable of monitoring two

presys

The Transmitter is capable of monitoring two

universal standard inputs, accepting direct connection

presys

universal standard inputs, accepting direct connection

of thermocouples, RTDs, current (mAdc) and voltage

presys

of thermocouples, RTDs, current (mAdc) and voltage

(mVdc, Vdc). The RTD inputs are automatically

presys

(mVdc, Vdc). The RTD inputs are automatically

rized by means of tables stored in the EPROM. A

presys

rized by means of tables stored in the EPROM. A

Vdc power supply

presys

Vdc power supply

,

presys

,

isolated from the output and

presys

isolated from the output and

with short circuit protection, is provided to power

presys

with short circuit protection, is provided to power

standard field two-wire instruments.

presys

standard field two-wire instruments.

The type of input selected by the user is

presys

The type of input selected by the user is

enabled

presys

enabled

by jumpers and by configuration via software.

presys

by jumpers and by configuration via software.

All configuration data can be protected by a password

presys

All configuration data can be protected by a password

system and are stored in the non-volatile memory in

presys

system and are stored in the non-volatile memory in

case of power failure.

presys

case of power failure.

Designed with

presys

Designed with

in

presys

in

the concept of modularity, t

presys

the concept of modularity, t

transmitter accepts up to 4 output cards. The poss

presys

transmitter accepts up to 4 output cards. The poss

output types are analog, SPDT relay, SPST relay,

presys

output types are analog, SPDT relay, SPST relay,

solid-state relay and open collection voltage.

presys

solid-state relay and open collection voltage.

In case of input sensor break

presys

In case of input sensor break

are not triggered (configurable for 4-

presys

are not triggered (configurable for 4-

inputs) and the analog outputs assume preconfigured

presys

inputs) and the analog outputs assume preconfigured

s

presys

s

afety values. The alarm outputs can be

presys

afety values. The alarm outputs can be

independently

presys

independently

demanding the acknowledgement by the operator

presys

demanding the acknowledgement by the operator

through the MCY-

presys

through the MCY-

communication in order to be disabled after the

presys

communication in order to be disabled after the

transmitter can

presys

transmitter can

be

presys

be

set for failure alarms (watchdog) triggered by the detectio

presys

set for failure alarms (watchdog) triggered by the detectio

sensors connected to the current or RTD

presys

sensors connected to the current or RTD

It allows the use of a universal power supply from

presys

It allows the use of a universal power supply from

to

presys

to

360 Vdc (any polarity

presys

360 Vdc (any polarity

The instrument

presys

The instrument

electrical noise, electromagnetic interference and resistant to the most severe conditions

presys

electrical noise, electromagnetic interference and resistant to the most severe conditions

of industrial usage.

presys

of industrial usage.

presys

Fig

presys

Fig

. 1

presys

. 1

-

presys

-

Front view of

presys

Front view of

the

presys

the

TY

presys

TY

-

presys

-

2090

presys

2090

-

presys

-

Energy

presys

Energy

Transmitter

presys

Transmitter

PRESYS Instruments TY-2090-Energy

Introduction

Page 2

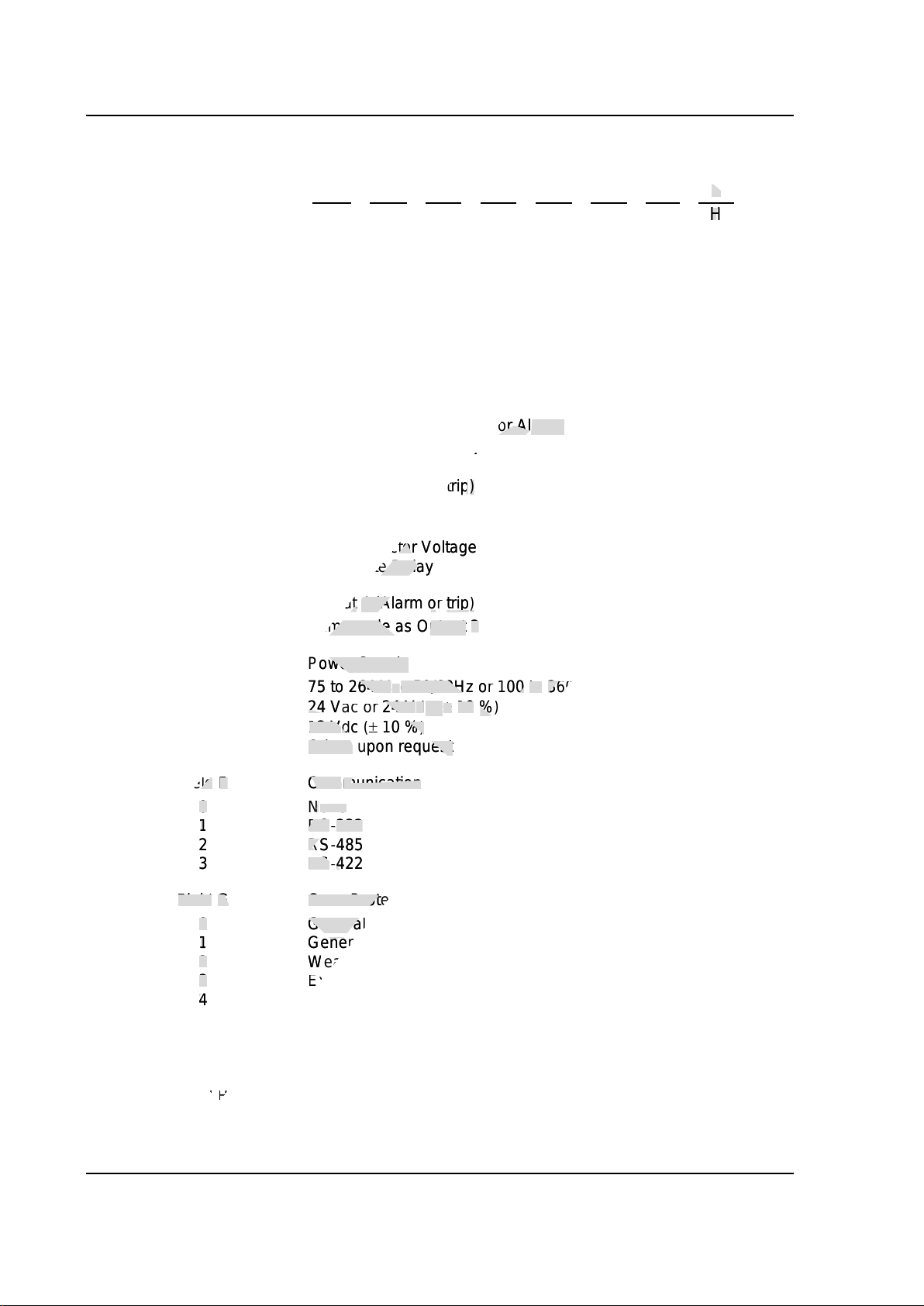

1.2 - Order Code

TY -2090

-

A

-

B

-

C

-

D

-

E

-

F

-

G

-

E

H

Field A Output 1 (Retransmission or Alarm)

0

None

1

4to 20 mAdc

2

1to 5 Vdc

3

0 to 10 Vdc

4

SPST Relay

5

Open Collector Voltage

6

Solid State Relay

Field B

Output 2 (Retransmission or Alarm)

Same code as Output 1

Field C

Output 3 (Alarm ortrip)

0

None

1

SPDT Relay

2

Open Collector Voltage

3

Solid State Relay

Field D Output 4 (Alarm ortrip)

Same code as Output 3

Field E

Power Supply

1

75 to 264 Vac 50/60Hz or100 to 360 Vdc (any polarity)

2

24 Vac or 24 Vdc (

10 %)

3

12 Vdc (

10 %)

4

Other, upon request

Field F

Communication

0

None

1

RS-232

2

RS-485

3

RS-422

Field G

Case Protection Grade

0

General usage, sheltered place, surface mounting

1

General usage, sheltered place, DIN rail mounting

2

Weather-proof

3

Explosion-proof (BR-Ex d IIB T6 IP 65), without display (*)

4

Dust proof

(*) Explosion proof box:

Dimensions: 310x310x200 mm (HxWxD)

Weight: 11kg nominal

Field H

Application

E

Energy

presys

-

presys

-

E

presys

E

presys

H

presys

H

(Retransmission or Alarm)

presys

(Retransmission or Alarm)

1

presys

1

r

presys

r

trip

presys

trip

)

presys

)

ollector

presys

ollector

V

presys

V

oltage

presys

oltage

tate Relay

presys

tate Relay

Output

presys

Output

4 (Alarm o

presys

4 (Alarm o

r

presys

r

trip

presys

trip

)

presys

)

Same code as Output

presys

Same code as Output

3

presys

3

Power Supply

presys

Power Supply

75

presys

75

to

presys

to

264 V

presys

264 V

a

presys

a

c 50/60Hz o

presys

c 50/60Hz o

r

presys

r

100

presys

100

to

presys

to

360 V

presys

360 V

24 V

presys

24 V

a

presys

a

c

presys

c

or

presys

or

24 V

presys

24 V

d

presys

d

c (

presys

c (

presys

10

presys

10

%)

presys

%)

12 V

presys

12 V

d

presys

d

c (

presys

c (

presys

10

presys

10

%)

presys

%)

Other,

presys

Other,

upon request

presys

upon request

Field

presys

Field

F

presys

F

Com

presys

Com

munication

presys

munication

0

presys

0

N

presys

N

one

presys

one

1

presys

1

RS

presys

RS

-

presys

-

232

presys

232

2

presys

2

RS

presys

RS

-

presys

-

485

presys

485

3

presys

3

RS

presys

RS

-

presys

-

422

presys

422

Field

presys

Field

G

presys

G

Case Protection Grade

presys

Case Protection Grade

0

presys

0

General usag

presys

General usag

1

presys

1

General usage, sheltered place,

presys

General usage, sheltered place,

2

presys

2

Weather

presys

Weather

3

presys

3

Explosion

presys

Explosion

4

presys

4

Field

presys

Field

H

presys

H

PRESYS Instruments TY-2090-Energy

Introduction

Page 3

Note - Ranges and input types, the use of relays as alarms and alarm setpoints

are, among others, items that the user can program through the MCY-20 Configuration

Module (if desired, specify such information so that all programming may be previously

done by PRESYS).

Note: Any other desired software or hardware feature may be available upon request.

Code Example:

1) TY - 2090 - 1 - 0 - 1- 0 - 1 - 0 - 0 - E

This code defines a TY-2090-Energy transmitter with output 1for 4-20 mA,

output 2not used, SPDT relay for use as alarm with configurable trip function, power

supply for the range 75-264 Vac 50/60Hz or 100-360 Vdc, without serial communication,

for use in a sheltered place and surface mounting.

1.3 - Technical Specifications

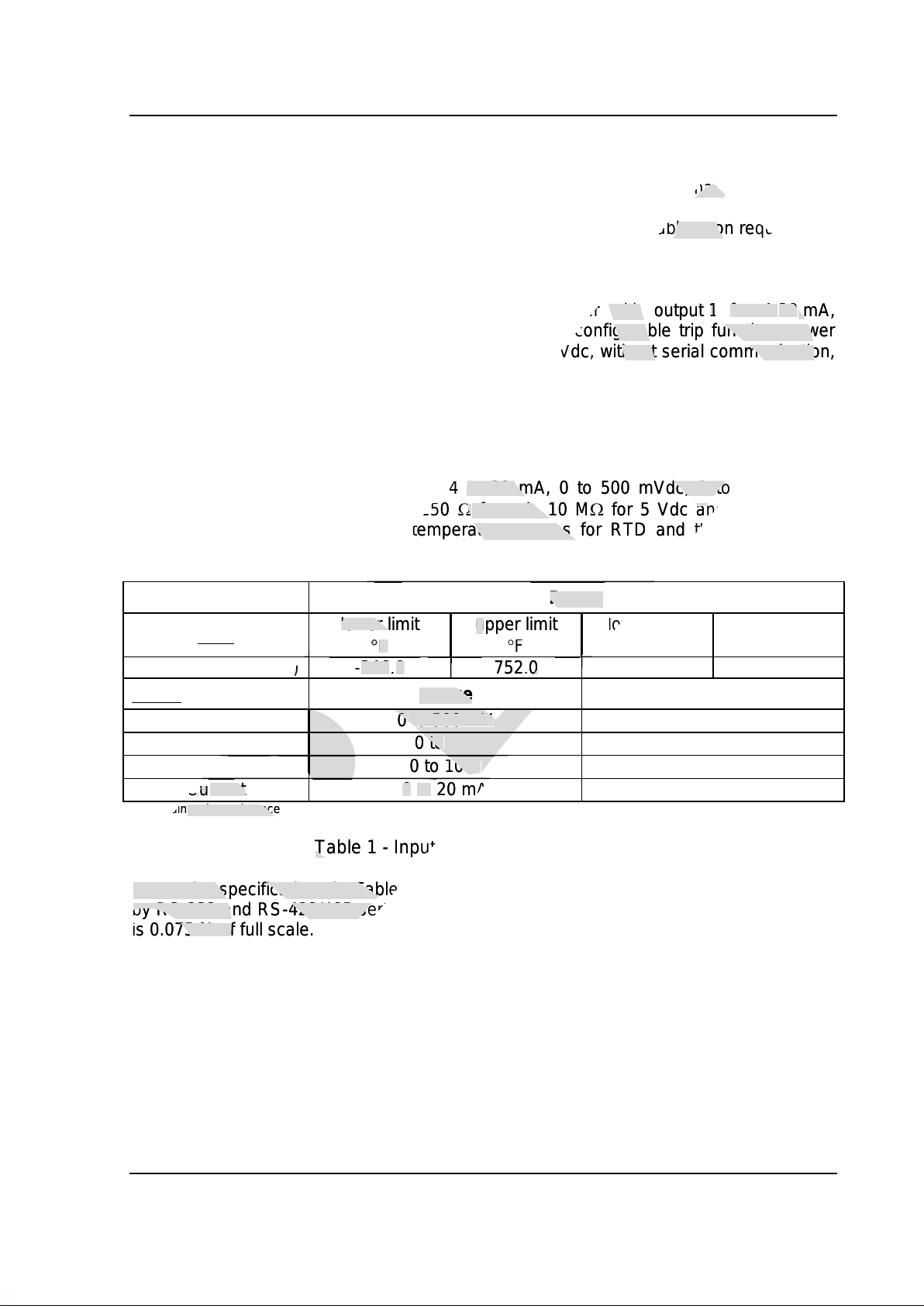

Inputs:

Pt-100 RTD under DIN 43760, 4 to 20 mA, 0 to 500 mVdc, 1 to 5 Vdc, 0 to

10 Vdc. Input impedance of 250 for mA, 10 Mfor 5 Vdc and 2 Mabove

5 Vdc. Table 1 shows the temperature ranges for RTD and the resolution for

linear input sensors.

Input sensor Range

RTD

lower limit

F

upper limit

F

lower limit

C

upper limit

C

Pt-100 (2 or 3wires)

-346.0

752.0

-210.0

400.0*

Linear Range Resolution

Voltage

0to 500 mV

25

V

0to 5 V

250

V

0to 10 V

500

V

Current

0to 20 mA

1

A

(*)including wire resistance

Table 1 - Input Sensor Measuring Range

Note: The specifications in Table 1 refer to analog/digital conversion and are accessed

by RS-232 and RS-422/485 serial communication. For the analog outputs, the resolution

is 0.075 % of full scale.

presys

Module (if desired, specify such information so that all programming may be previously

presys

Module (if desired, specify such information so that all programming may be previously

Note: Any other desired software or hardware feature may be available upon request.

presys

Note: Any other desired software or hardware feature may be available upon request.

-Energy transmitter with output

presys

-Energy transmitter with output

1

presys

1

for 4-

presys

for 4-

20

presys

20

mA,

presys

mA,

not used, SPDT relay for use as alarm with configurable trip function, power

presys

not used, SPDT relay for use as alarm with configurable trip function, power

50/60Hz or 100-360 V

presys

50/60Hz or 100-360 V

dc

presys

dc

, without serial communication,

presys

, without serial communication,

RTD under DIN 43760, 4 to 20 mA, 0 to 500 mVdc, 1 to 5 Vdc, 0 to

presys

RTD under DIN 43760, 4 to 20 mA, 0 to 500 mVdc, 1 to 5 Vdc, 0 to

Vdc. Input impedance of 250

presys

Vdc. Input impedance of 250

presys

for mA, 10 M

presys

for mA, 10 M

presys

for 5 Vdc and 2 M

presys

for 5 Vdc and 2 M

5 Vdc. Table 1 shows the temperature ranges for RTD and the resolution for

presys

5 Vdc. Table 1 shows the temperature ranges for RTD and the resolution for

Range

presys

Range

presys

lower limit

presys

lower limit

presys

F

presys

F

upper limit

presys

upper limit

presys

F

presys

F

lower limit

presys

lower limit

presys

presys

presys

presys

presys

presys

presys

presys

s

presys

s

)

presys

)

-

presys

-

346

presys

346

.

presys

.

0

presys

0

752

presys

752

.

presys

.

0

presys

0

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

Range

presys

Range

presys

presys

presys

presys

presys

presys

Voltage

presys

Voltage

presys

0

presys

0

to 500 mV

presys

to 500 mV

presys

presys

presys

presys

presys

0

presys

0

to

presys

to

5 V

presys

5 V

presys

presys

presys

presys

0

presys

0

to

presys

to

10 V

presys

10 V

presys

presys

presys

presys

C

presys

C

u

presys

u

rrent

presys

rrent

0

presys

0

to

presys

to

20 mA

presys

20 mA

presys

presys

presys

presys

including wire resistance

presys

including wire resistance

presys

presys

presys

Table 1 - Input Sensor Measuring Range

presys

Table 1 - Input Sensor Measuring Range

Note: The specifications in Table 1 refer to analog/digital conversion and are accessed

presys

Note: The specifications in Table 1 refer to analog/digital conversion and are accessed

by RS-232 and RS-422/485 serial communication. For the analog outputs, the resolution

presys

by RS-232 and RS-422/485 serial communication. For the analog outputs, the resolution

is 0.075 % of full scale.

presys

is 0.075 % of full scale.

PRESYS Instruments TY-2090-Energy

Introduction

Page 4

Outputs:

Analog retransmitter output for 4-20 mA, 1 to 5 Vdc, 0 to 10 Vdc, use of

optional cards, with installation of up to two modules, galvanically isolated

(300 Vac)from inputs and power supply.

Alarm outputs for up to two SPDT relays and two SPST relays rated

3 A/220 Vac.

Logic Level, open collector transistor, 24 Vdc, 40 mA maximum with isolation.

Solid-state relay, rated 2A/250 Vac with isolation.

Serial Communication:

RS-232 or RS-422/485 with 50 Vdc isolation, as an optional module installed on

the CPU board. MODBUS®- RTU Communication Protocol.

Configuration:

Via RS-232,RS-422/485 serial communication or the MCY-20 Configuration

Module.

Scanning Time:

120 ms, standard.

Accuracy:

0.1 % of full scale for RTD, mA, mV and Vinputswith acquisition via RS-232

and RS-422/485 serial communication.

0.2 % of full scale for analog outputs and 750 maximum load.

Linearization:

0.1 Cfor RTD.

Square Root Extraction:

0.5 % of reading for input above 10 % of span.

0 to 5 % programmable cut-off.

Stability at ambient temperature:

0.005 % / ºC of span referred to 25 ºC ambient temperature for acquisition via

RS-232 and RS-422/485.

0.015 % /ºC of span referred to 25 ºC ambient temperature for analog outputs.

Power Supply:

75 to 264 Vac 50/60Hz or 100 to 360 Vdc (any polarity), 10 W nominal; 24 Vac/dc

(10 %); 12 Vdc (10 %).

2-Wire Transmitter Power Supply:

24 Vdc voltage and 50 mA maximum, isolated from outputs, with short-circuit

protection.

Operating ambient:

0 to 50ºC temperature and 90% maximum relative humidity.

Dimensions:

140 mm x 53 mm x 175 mm (HxWxD).

Weight:

0.5 kg nominal.

Warranty:

One year.

presys

Analog retransmitter output for 4-20 mA, 1 to 5 Vdc, 0 to 10 Vdc, use of

presys

Analog retransmitter output for 4-20 mA, 1 to 5 Vdc, 0 to 10 Vdc, use of

optional cards, with installation of up to two modules, galvanically isolated

presys

optional cards, with installation of up to two modules, galvanically isolated

two SPST relays rated

presys

two SPST relays rated

Logic Level, open collector transistor, 24 Vdc, 40 mA maximum with isolation.

presys

Logic Level, open collector transistor, 24 Vdc, 40 mA maximum with isolation.

Vdc isolation, as an optional module installed

presys

Vdc isolation, as an optional module installed

on

presys

on

- RTU Communication Protocol.

presys

- RTU Communication Protocol.

-422/485 serial communication or the MCY-20 Configurati

presys

-422/485 serial communication or the MCY-20 Configurati

on

presys

on

0.1 % of full scale for RTD, mA, mV

presys

0.1 % of full scale for RTD, mA, mV

and

presys

and

V

presys

V

input

presys

input

s

presys

s

with acquisition via

presys

with acquisition via

and RS-422/485 serial communication.

presys

and RS-422/485 serial communication.

0.2 % of full scale for analog outputs and 750

presys

0.2 % of full scale for analog outputs and 750

presys

maximum load.

presys

maximum load.

0.5 % of reading for input above 10 % of span.

presys

0.5 % of reading for input above 10 % of span.

0 to 5 % programmable cut-off.

presys

0 to 5 % programmable cut-off.

Stability at ambient temperature:

presys

Stability at ambient temperature:

0.005 % / ºC of span referred to

presys

0.005 % / ºC of span referred to

25

presys

25

ºC ambient temperature for acquisition via

presys

ºC ambient temperature for acquisition via

-232 and RS-422/485.

presys

-232 and RS-422/485.

0.015 %

presys

0.015 %

/

presys

/

ºC of span referred to 25 ºC ambient temperature for analog outputs.

presys

ºC of span referred to 25 ºC ambient temperature for analog outputs.

Power Supply:

presys

Power Supply:

75

presys

75

to

presys

to

264 Vac 50/60Hz or

presys

264 Vac 50/60Hz or

100

presys

100

to

presys

to

360 Vdc (any polarity), 10 W nominal; 24 Vac/dc

presys

360 Vdc (any polarity), 10 W nominal; 24 Vac/dc

(

presys

(

presys

10

presys

10

%); 12 Vdc (

presys

%); 12 Vdc (

presys

10

presys

10

%).

presys

%).

2-Wire Transmitter Power Supply:

presys

2-Wire Transmitter Power Supply:

24 Vdc voltage and 50 mA maximum, isolated from outputs, with short-circuit

presys

24 Vdc voltage and 50 mA maximum, isolated from outputs, with short-circuit

protection.

presys

protection.

Operating ambient:

presys

Operating ambient:

0 to 50ºC temperature and 90% maximum relative humidity.

presys

0 to 50ºC temperature and 90% maximum relative humidity.

Dimens

presys

Dimens

ion

presys

ion

s:

presys

s:

140 mm x 53 mm x 175 mm (HxWxD

presys

140 mm x 53 mm x 175 mm (HxWxD

Weight:

presys

Weight:

presys

0.5 kg nominal.

presys

0.5 kg nominal.

One year.

presys

One year.

PRESYS Instruments TY-2090-Energy

Installation

Page 5

2.0 - Installation

2.1 - Mechanical Installation

The TY-2090-Energy Transmitter can be mounted on a surface or on all types of

existing DIN rails,by means of an optional adapter, as illustrated in the figure below.

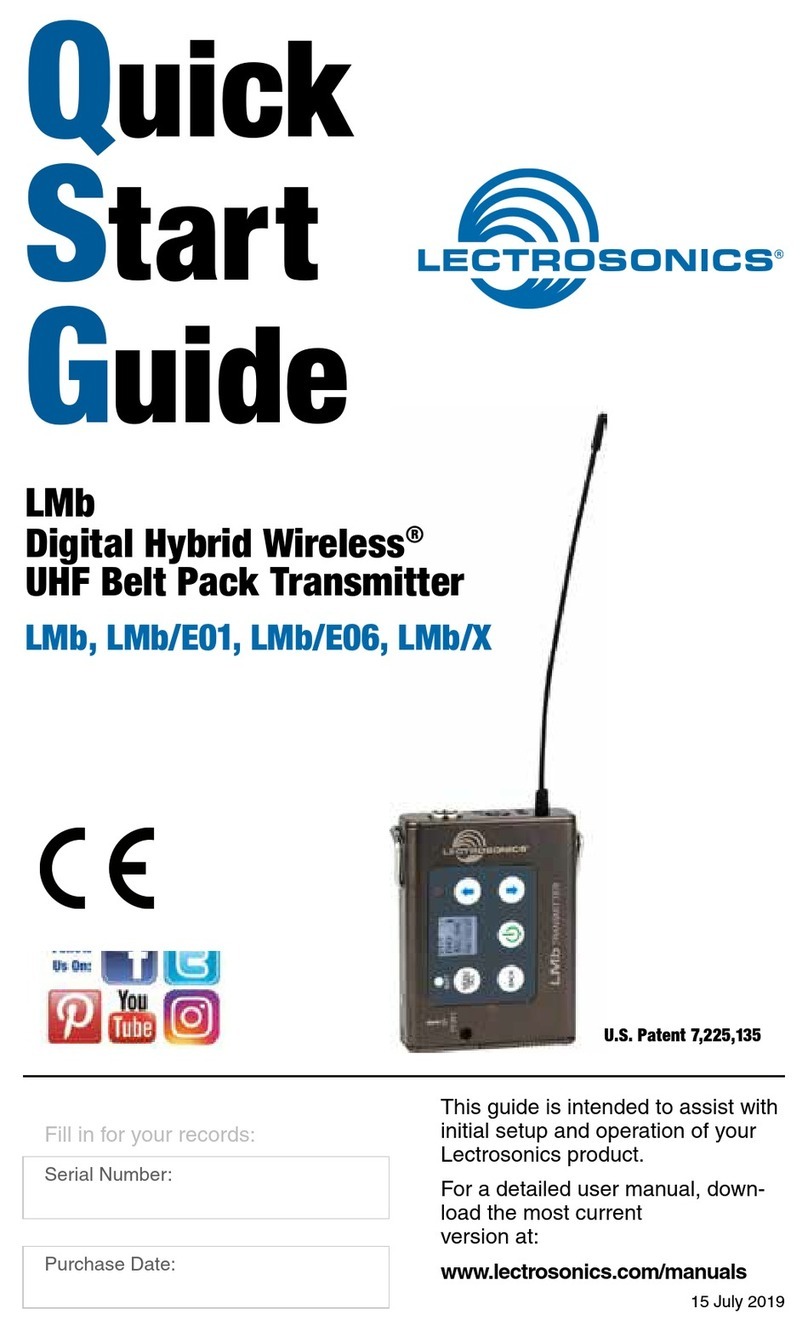

Fig. 2 - Dimensional drawing and detail of the adapter for DIN rail

2.2 - Electrical Installation

The TY-2090-Energy Transmitter may be powered up by voltage between 75 and

264 Vac or 100 to 360 Vdc, any polarity. Remember that the internal circuit is powered

whenever the instrument is connected to the external power supply.

Connections of process input and output signals should only be done with the

instrument turned off.

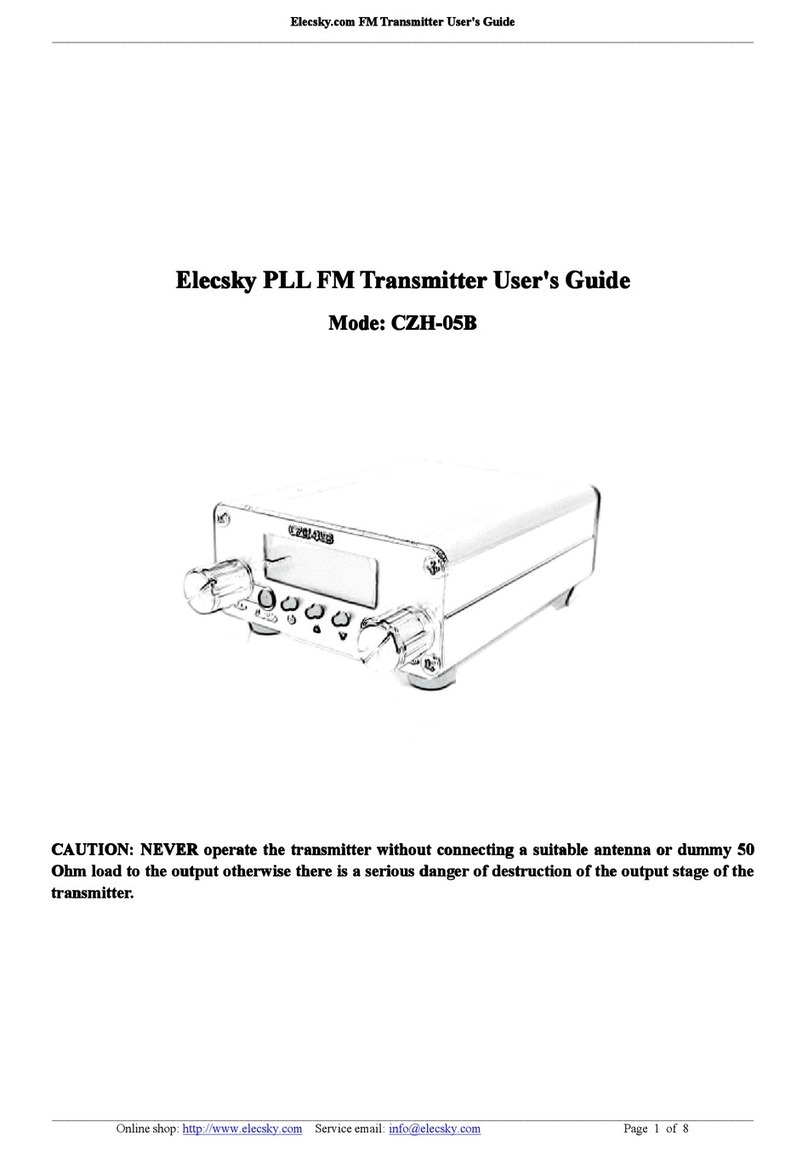

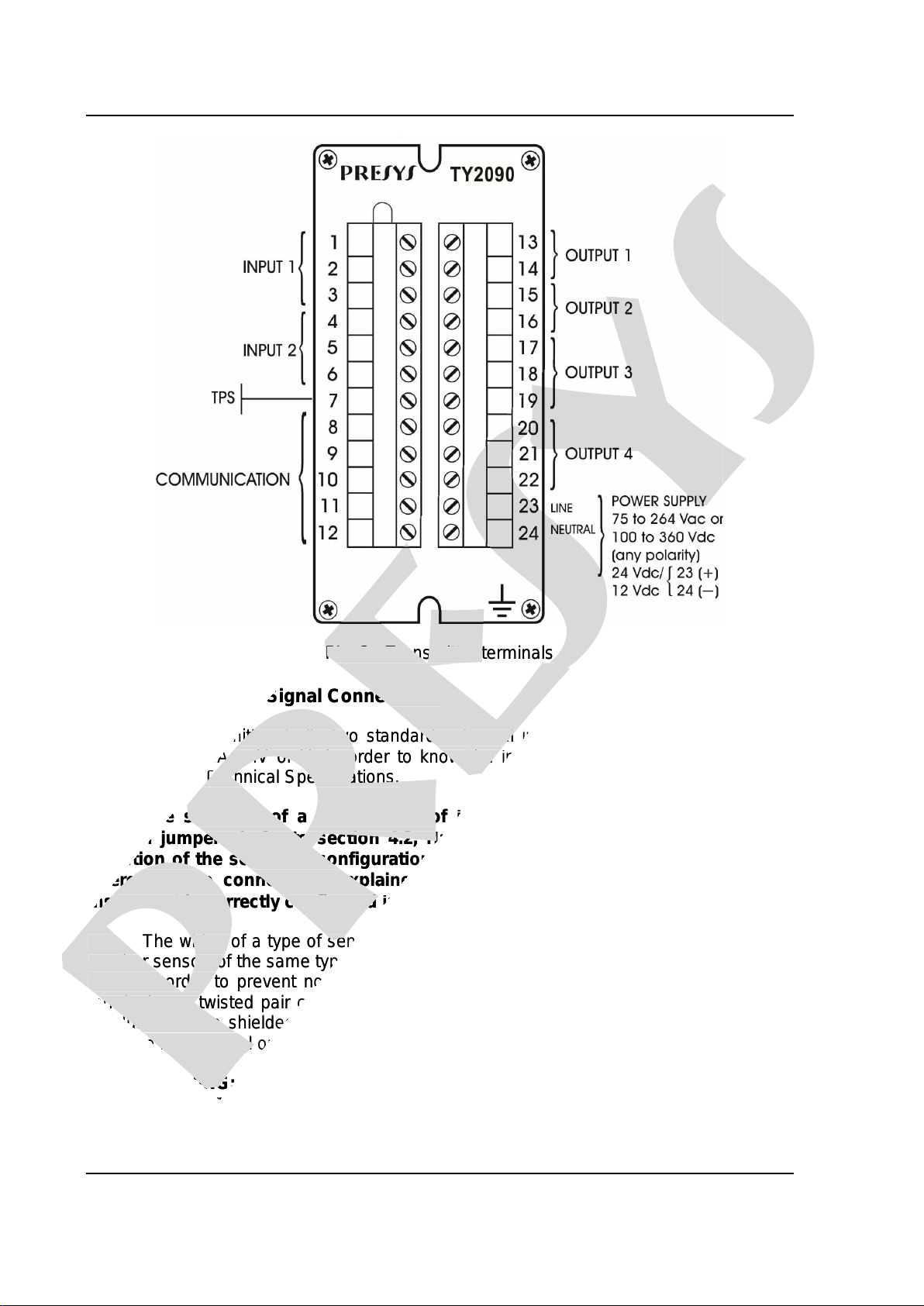

Figure 3 shows the instrument I/O terminal scheme with all designations for power

supply, grounding, communication and process input and output signals.

Signal wires must be kept far away from power supply wires.

Due to its metal case the instrument ground should be connected to earth

ground. Never connect the ground to the neutral terminal.

presys

-Energy Transmitter can be mounted on a surface or on all types of

presys

-Energy Transmitter can be mounted on a surface or on all types of

by means of an optional adapter, as illustrated in the figure below.

presys

by means of an optional adapter, as illustrated in the figure below.

presys

Fig. 2 - Dimensional drawing and detail of the adapter for DIN rail

presys

Fig. 2 - Dimensional drawing and detail of the adapter for DIN rail

2.2 - Electrical Installation

presys

2.2 - Electrical Installation

The TY-

presys

The TY-

2090

presys

2090

-Energy Transmitter may be powered

presys

-Energy Transmitter may be powered

264

presys

264

Vac or 100 to 360 Vdc, any polarity. Remember that the internal circuit is powered

presys

Vac or 100 to 360 Vdc, any polarity. Remember that the internal circuit is powered

whenever the instrument is connected to the external power supply.

presys

whenever the instrument is connected to the external power supply.

Connections of process input and output signals should only be

presys

Connections of process input and output signals should only be

instrument turned off.

presys

instrument turned off.

Figure 3 shows the instrument I/O terminal scheme with all designations for power

presys

Figure 3 shows the instrument I/O terminal scheme with all designations for power

supply, grounding, communication and process input and output signals.

presys

supply, grounding, communication and process input and output signals.

Signal wires must be kept far away from power supply wires.

presys

Signal wires must be kept far away from power supply wires.

Due to its metal case the instrument ground should be connected to earth

presys

Due to its metal case the instrument ground should be connected to earth

ground.

presys

ground.

Never

presys

Never

connect the ground to the neutral terminal.

presys

connect the ground to the neutral terminal.

PRESYS Instruments TY-2090-Energy

Installation

Page 6

Fig. 3 - Transmitter terminals

2.3 - Process Input Signal Connections

The Transmitter, in its two standard universal inputs, can be connected to 2 or

3-wire RTDs, mA, mV or V. In order to know the input sensor types refer to Table 1,

section 1.3 on Technical Specifications.

The selection of a certain type of input sensor is enabled by means of

internal jumpers (refer to section 4.2, Hardware Configuration) and by aproper

selection of the sensor in configuration time (refer to section 3.2, Configuration).

Therefore, the connections explained below will only become effective if the

instrument is correctly configured in terms of hardware and software.

The wiring of a type of sensor to input 1 does not restrict the simultaneous use of

another sensor, of the same type or different type, for input 2.

In order to prevent noise induction in the wire connecting the sensor to the I/O

terminal, use twisted pair cable and run the sensor connection wires through a metallic

conduit or use a shielded cable. Be sure to connect only one shielded wire end to the

negative I/O terminal or to the sensor ground, as outlined in the following items.

WARNING: GROUNDING TWO SHIELD WIRE ENDS MAY CAUSE NOISE IN

THE TRANSMITTER.

presys

presys

Fig. 3 - Transmitter terminals

presys

Fig. 3 - Transmitter terminals

Process Input Signal Connections

presys

Process Input Signal Connections

The Transmitter, in its two standard universal inputs, can be connected to 2 or

presys

The Transmitter, in its two standard universal inputs, can be connected to 2 or

3-wire RTDs, mA, mV or V. In order to know the input sensor types refer to Table 1,

presys

3-wire RTDs, mA, mV or V. In order to know the input sensor types refer to Table 1,

section 1.3 on Technical Specifications.

presys

section 1.3 on Technical Specifications.

The selection of a certain type of input sensor is enabled by means of

presys

The selection of a certain type of input sensor is enabled by means of

internal jumpers (refer to section 4.2, Hardware Configuration) and by

presys

internal jumpers (refer to section 4.2, Hardware Configuration) and by

selection of the sensor in configuration time (refer to section 3.2, Configuration).

presys

selection of the sensor in configuration time (refer to section 3.2, Configuration).

Therefore, the connections explained below will only become effective if the

presys

Therefore, the connections explained below will only become effective if the

instrument is correctly configured in terms of hardware and software.

presys

instrument is correctly configured in terms of hardware and software.

The wiring of a type of sensor to input 1 does not restrict the simultaneous use of

presys

The wiring of a type of sensor to input 1 does not restrict the simultaneous use of

another sensor, of the same type or different type, for input 2.

presys

another sensor, of the same type or different type, for input 2.

In order to prevent noise induction in the wire connecting the sensor to the I/O

presys

In order to prevent noise induction in the wire connecting the sensor to the I/O

terminal, use twisted pair cable and run the sensor connection wires through a metallic

presys

terminal, use twisted pair cable and run the sensor connection wires through a metallic

presys

conduit or use a shielded cable. Be sure to connect only one shielded wire end to the

presys

conduit or use a shielded cable. Be sure to connect only one shielded wire end to the

negative I/O terminal or to the sensor ground, as outlined in the following items.

presys

negative I/O terminal or to the sensor ground, as outlined in the following items.

WARNING: GROUNDING TWO SHIELD WIRE ENDS MAY CAUSE NOISE IN

presys

WARNING: GROUNDING TWO SHIELD WIRE ENDS MAY CAUSE NOISE IN

THE TRANSMITTER.

presys

THE TRANSMITTER.

PRESYS Instruments TY-2090-Energy

Installation

Page 7

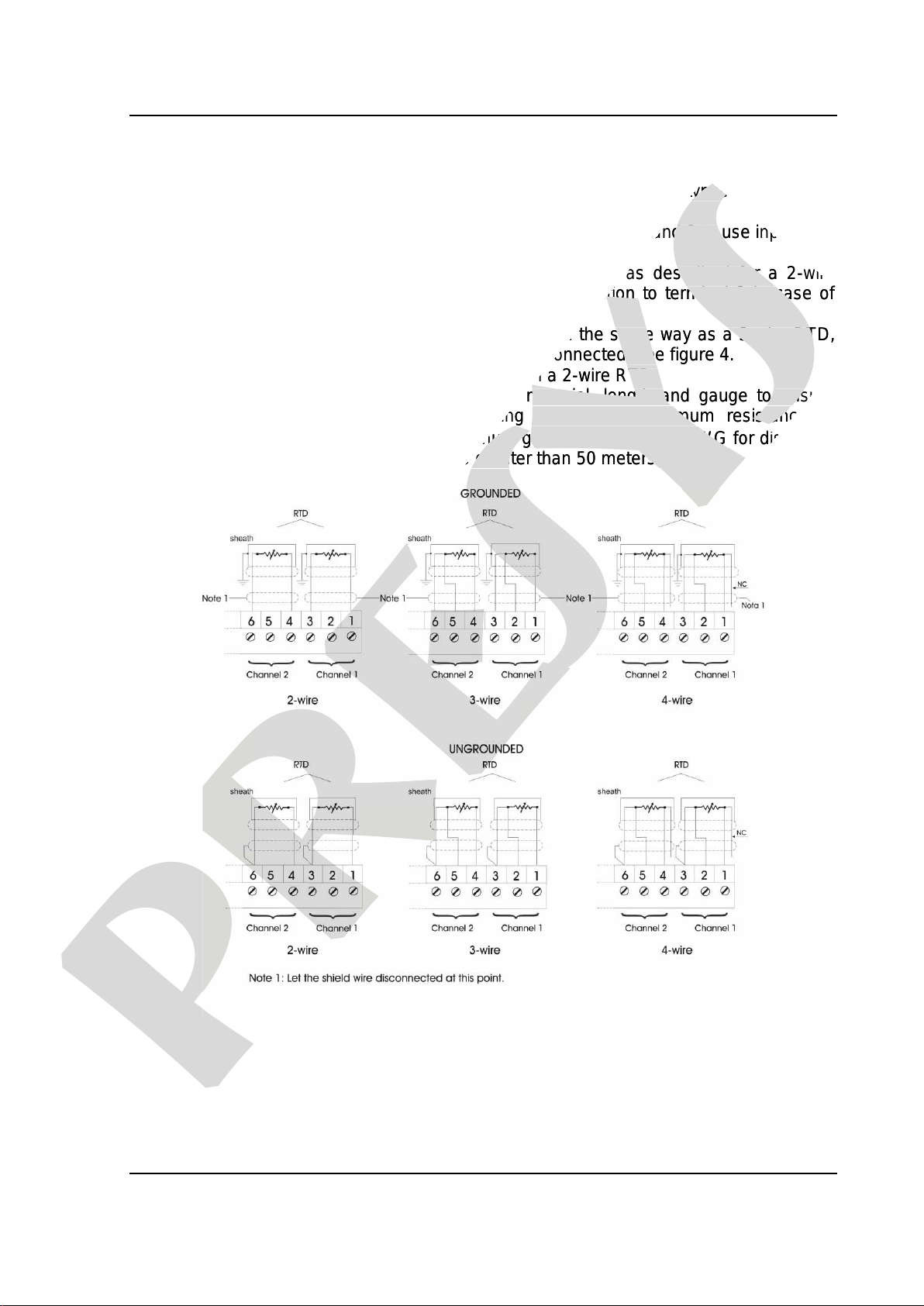

2.3.1 - RTD Connections

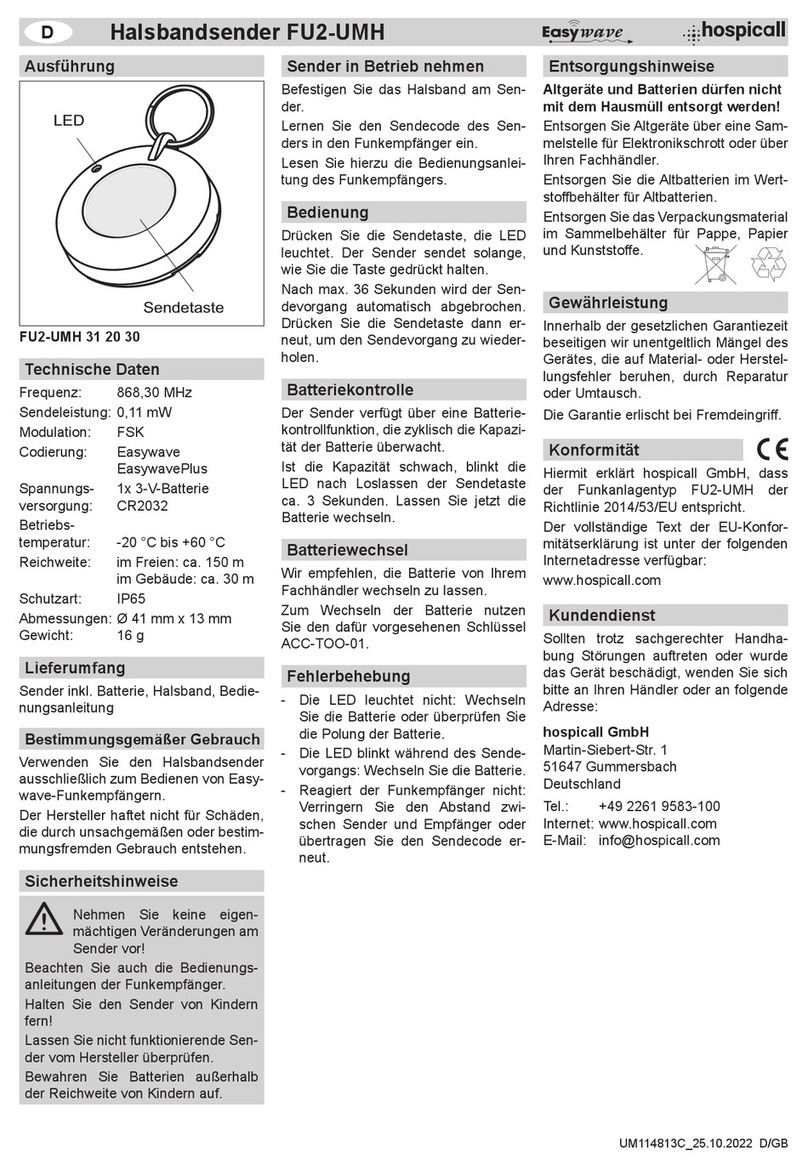

The RTD can be connected with 2, 3 or 4 wires. All connection types are shown in

figure 4.

For 2-wire RTD, connect the RTD between I/O terminals 1 and 3 to use input 1, or

to terminals 4 and 6 to use input 2, as illustrated in figure 4.

For 3-wire RTD, connect the RTD in the same way as described for a 2-wire

connection, and connect the third wire for RTD compensation to terminal 2 in case of

input 1, and to terminal 5 in case of input 2, see figure 4.

A 4-wire RTD is connected to the Transmitter in the same way as a 3-wire RTD,

except that the fourth wire is disregarded and left disconnected, see figure 4.

A 3-wire RTD provides greater accuracy than a 2-wire RTD.

The RTD wiring should be of the same material, length and gauge to ensure

proper resistance compensation of connecting wires. The maximum resistance of

connecting wires is 10 per wire. The minimum gauge should be 18 AWG for distances

up to 50 meters and 16 AWG for distances greater than 50 meters.

Fig. 4 - RTD Connection

presys

The RTD can be connected with 2, 3 or 4 wires. All connection types are shown in

presys

The RTD can be connected with 2, 3 or 4 wires. All connection types are shown in

For 2-wire RTD, connect the RTD between I/O terminals 1 and 3 to use input 1, or

presys

For 2-wire RTD, connect the RTD between I/O terminals 1 and 3 to use input 1, or

For 3-wire RTD, connect the RTD in the same way as described for a 2-wire

presys

For 3-wire RTD, connect the RTD in the same way as described for a 2-wire

connection, and connect the third wire for RTD compensation to terminal 2 in case of

presys

connection, and connect the third wire for RTD compensation to terminal 2 in case of

A 4-wire RTD is connected to the Transmitter in the same way as a 3-wire RTD,

presys

A 4-wire RTD is connected to the Transmitter in the same way as a 3-wire RTD,

except that the fourth wire is disregarded and left disconnected, see figure 4.

presys

except that the fourth wire is disregarded and left disconnected, see figure 4.

A 3-wire RTD provides greater accuracy than a 2-wire RTD.

presys

A 3-wire RTD provides greater accuracy than a 2-wire RTD.

presys

The RTD wiring should be of the same material, length and gauge to ensur

presys

The RTD wiring should be of the same material, length and gauge to ensur

proper resistance compensation of connecting wires. The maximum resistance of

presys

proper resistance compensation of connecting wires. The maximum resistance of

per wire. The minimum gauge should be 18 AWG for distances

presys

per wire. The minimum gauge should be 18 AWG for distances

up to 50 meters and 16 AWG for distances greater than 50 meters.

presys

up to 50 meters and 16 AWG for distances greater than 50 meters.

presys

presys

PRESYS Instruments TY-2090-Energy

Installation

Page 8

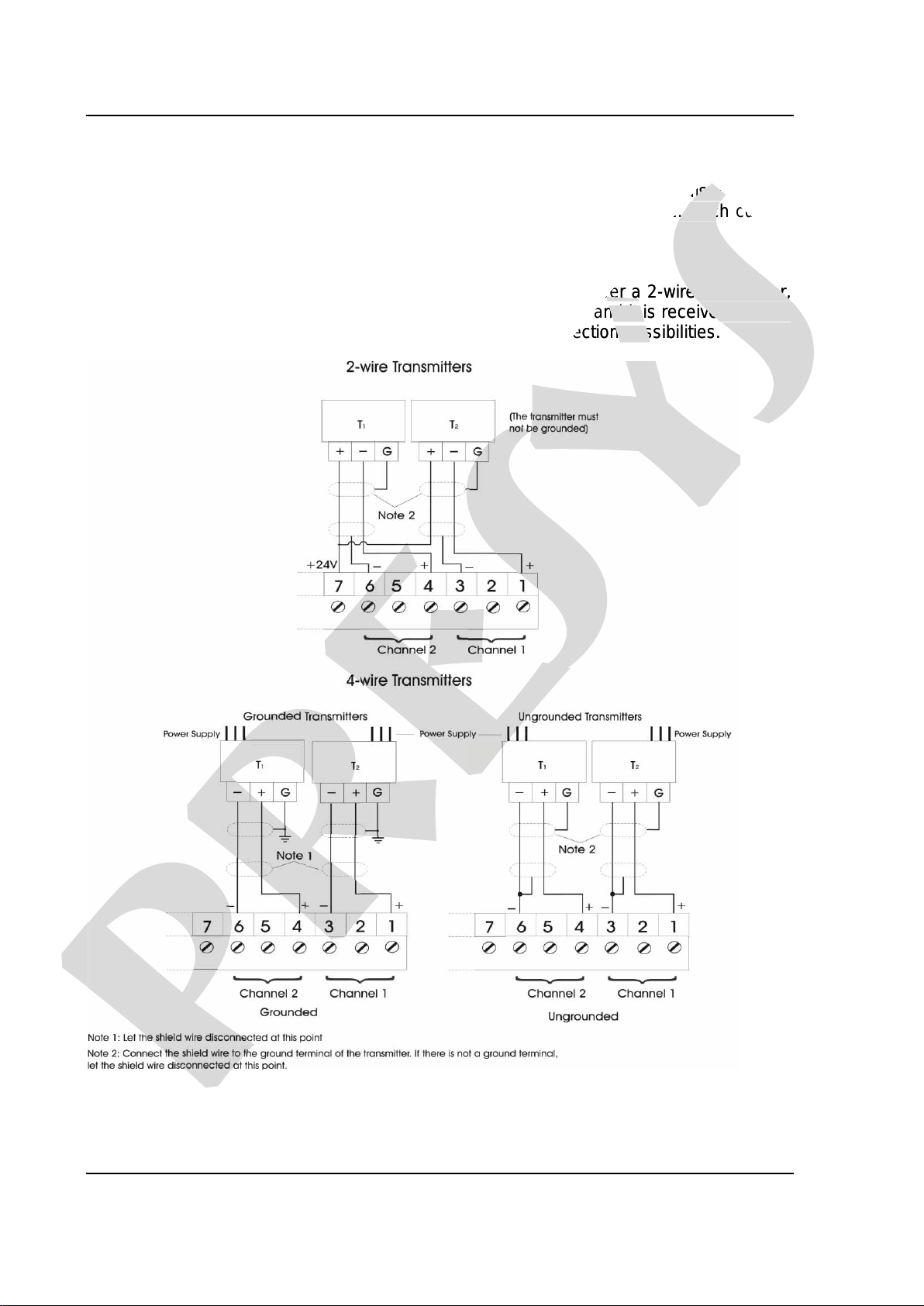

2.3.2 - Current Input

A standard current source of 4 to 20 mA can be applied to terminals 1 (+) and

3 (-) in case of input 1, and to terminals 4 (+) and 6 (-) in case of input 2. Such current

can be generated by a transmitter with external power supply.

When using the intrument’s internal 24 Vdc source to power a 2-wire transmitter,

the current is received only by terminal 1 (+) in case of input 1, and it is received only by

terminal 4 (+) in case of input 2. Figure 5 illustrates both connection possibilities.

Fig. 5 - Current Source Connection

presys

terminals 1 (+) and

presys

terminals 1 (+) and

terminals 4 (+) and 6 (-) in case of input 2. Such current

presys

terminals 4 (+) and 6 (-) in case of input 2. Such current

internal 24 Vdc source to power a 2-wire transmitter,

presys

internal 24 Vdc source to power a 2-wire transmitter,

the current is received only by terminal 1 (+) in case of input 1, and it is received only by

presys

the current is received only by terminal 1 (+) in case of input 1, and it is received only by

terminal 4 (+) in case of input 2. Figure 5 illustrates both connection possibilities.

presys

terminal 4 (+) in case of input 2. Figure 5 illustrates both connection possibilities.

presys

presys

PRESYS Instruments TY-2090-Energy

Installation

Page 9

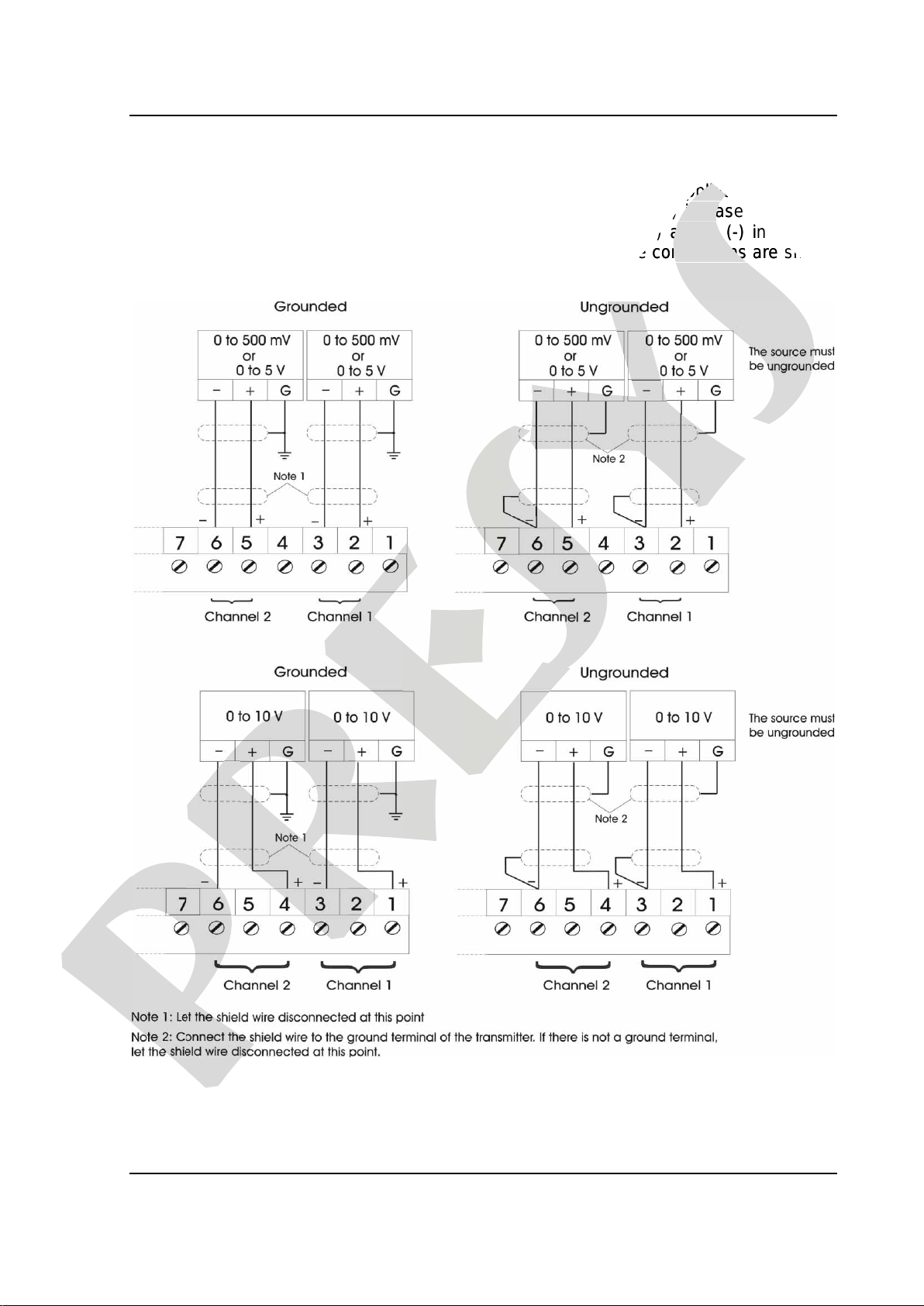

2.3.3 - Voltage Inputs

Voltages from 0 to 500 mVdc or from 0 to 5 Vdc must be applied to terminals

2 (+) and 3 (-) in case of input 1, and to terminals 5 (+) and 6 (-) in case of input 2.

Voltages from 0 to 10 Vdc should be applied to terminals 1 (+) and 3 (-) in case of

input 1, and to terminals 4 (+) and 6 (-) in case of input 2. These connections are shown

in figure 6.

Fig. 6 - Voltage Source Connection

presys

Voltages from 0 to 500 mVdc or from 0 to 5 Vdc must be applied to terminals

presys

Voltages from 0 to 500 mVdc or from 0 to 5 Vdc must be applied to terminals

terminals 5 (+) and 6 (-) in case of input 2.

presys

terminals 5 (+) and 6 (-) in case of input 2.

terminals 1 (+) and 3 (-) in case of

presys

terminals 1 (+) and 3 (-) in case of

presys

terminals 4 (+) and 6 (-) in case of input 2. These connections are shown

presys

terminals 4 (+) and 6 (-) in case of input 2. These connections are shown

presys

PRESYS Instruments TY-2090-Energy

Installation

Page 10

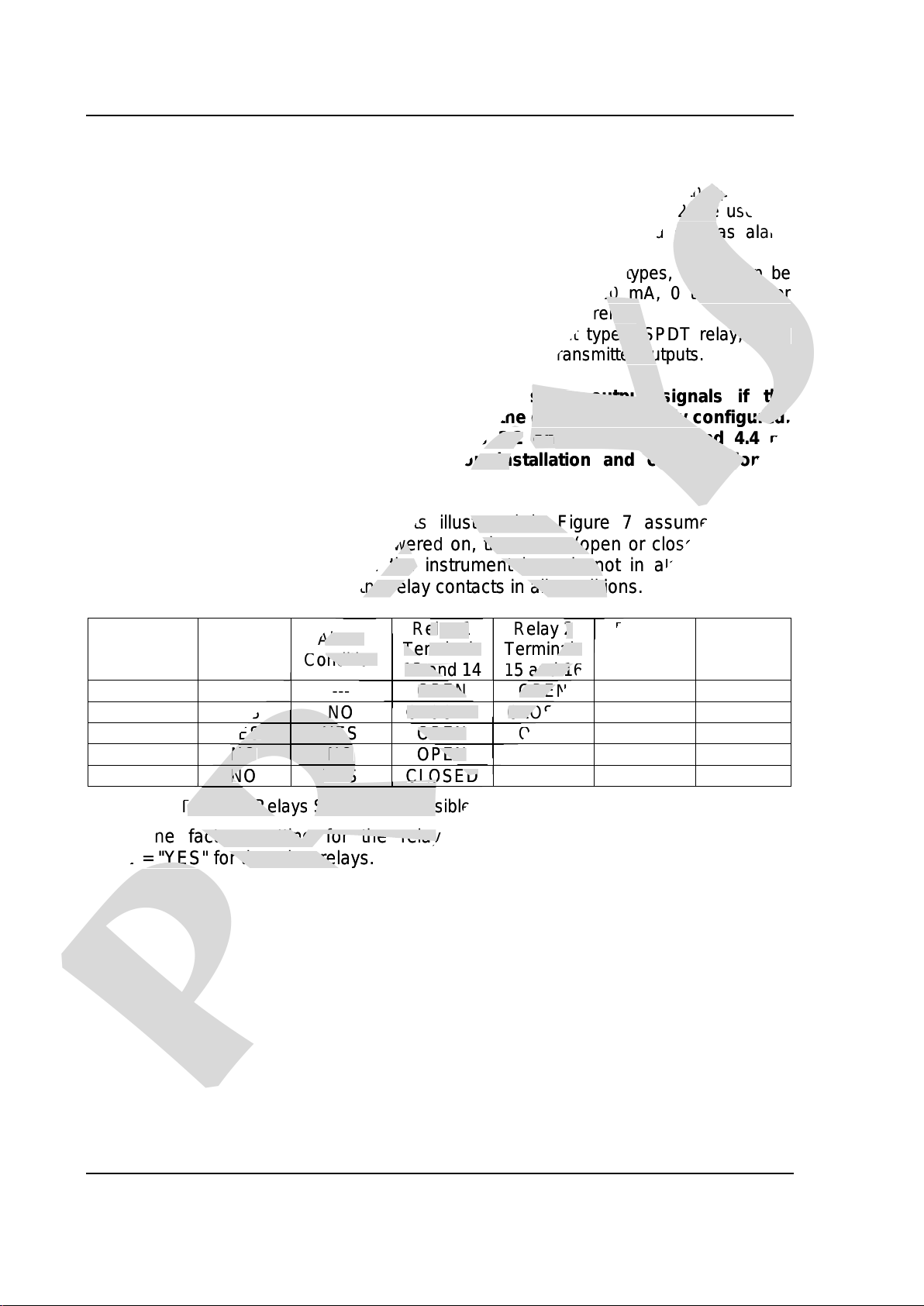

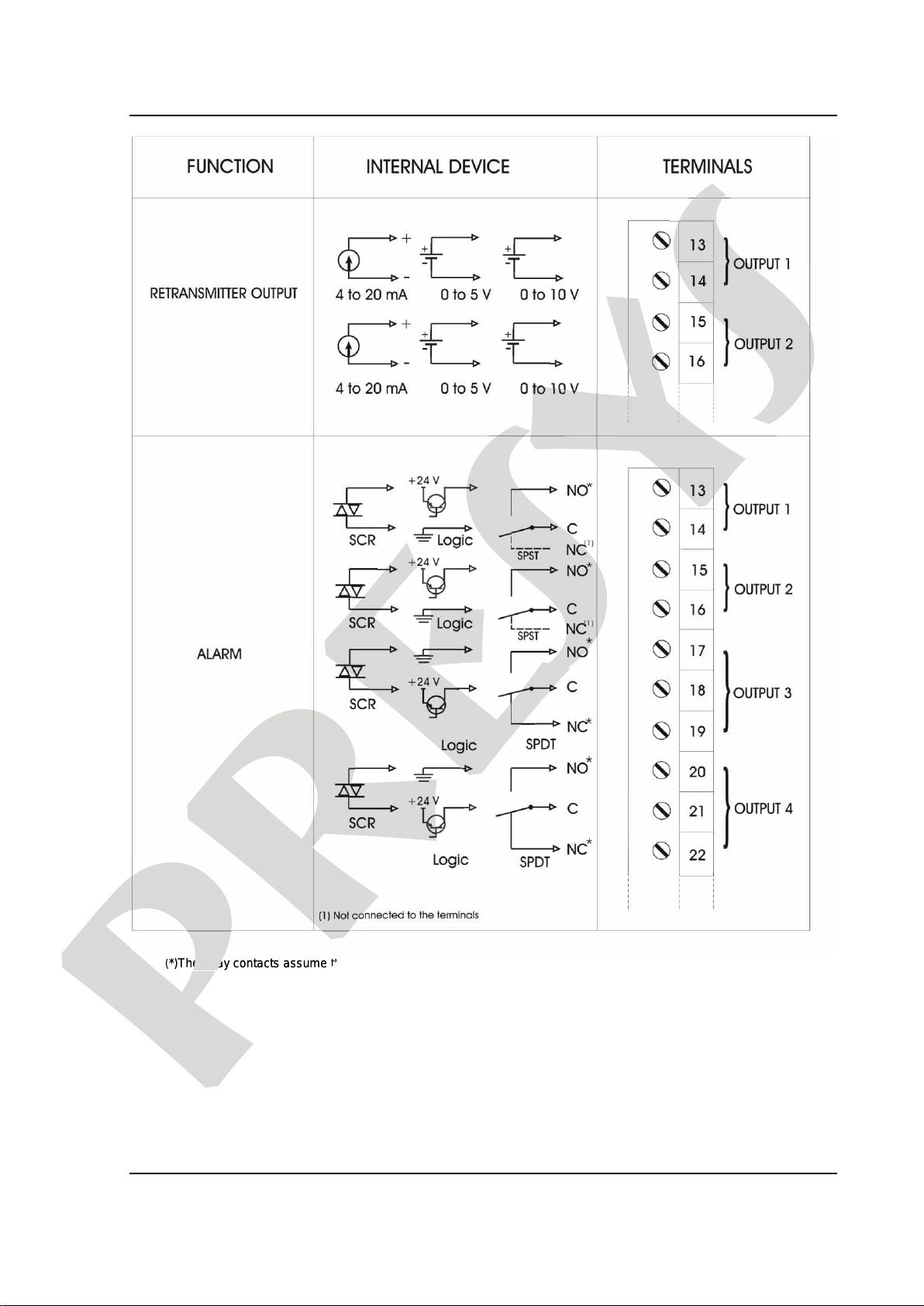

2.4 - Output Connections

The Transmitter, in its most complete version, can be provided with up to four

output signals: output 1, output 2, output 3 and output 4. Outputs 1 and 2 are used as

retransmission outputs or alarm outputs. Outputs 3 and 4 are used only as alarm

outputs.

In case of outputs 1 and 2, there are six different output types, which can be

obtained between I/O terminals: retransmission output (4 to 20 mA, 0 to 5 Vdc or

0 to 10 Vdc), SPST relay, open collector voltage and solid-state relay.

For outputs 3 and 4 there are three different output types: SPDT relay, open

collector voltage and solid-state relay. Figure 7 shows the Transmitter outputs.

Notice that the I/O terminals will only show output signals if the

corresponding optional module is installed and the output is correctly configured.

In case of analog outputs, refer to sections 3.2 on Configuration and 4.4 on

Optional Module Connection for details on installation and configuration of

optional modules.

The state of the relay contacts illustrated in Figure 7 assume that the

instrument is powered off. When powered on, the status (open or closed) depends

on the SAFE configuration and if the instrument is or is not in alarm condition.

Table 2 summarizes the state of the relay contacts in all conditions.

Power

Supply SAFE Alarm

Condition

Relay 1

Terminals

13 and 14

Relay 2

Terminals

15 and 16

Relay 3

Terminals

17 and 18

Relay 4

Terminals

20 and 21

OFF

---

---

OPEN

OPEN

OPEN

OPEN

ON

YES

NO

CLOSED

CLOSED

CLOSED

CLOSED

ON

YES

YES

OPEN

OPEN

OPEN

OPEN

ON

NO

NO

OPEN

OPEN

OPEN

OPEN

ON

NO

YES

CLOSED

CLOSED

CLOSED

CLOSED

Table 2 - Relays State in All Possible Conditions of the Instrument

The factory setting for the relay is SAFE = "NO" for trip relays and

SAFE = "YES" for the other relays.

presys

The Transmitter, in its most complete version, can be provided with up to four

presys

The Transmitter, in its most complete version, can be provided with up to four

output signals: output 1, output 2, output 3 and output 4. Outputs 1 and 2 are used as

presys

output signals: output 1, output 2, output 3 and output 4. Outputs 1 and 2 are used as

retransmission outputs or alarm outputs. Outputs 3 and 4 are used only as alarm

presys

retransmission outputs or alarm outputs. Outputs 3 and 4 are used only as alarm

In case of outputs 1 and 2, there are six different output types, which can be

presys

In case of outputs 1 and 2, there are six different output types, which can be

obtained between I/O terminals: retransmission output (4 to 20 mA, 0 to 5 Vdc or

presys

obtained between I/O terminals: retransmission output (4 to 20 mA, 0 to 5 Vdc or

Vdc), SPST relay, open collector voltage and solid-state relay.

presys

Vdc), SPST relay, open collector voltage and solid-state relay.

For outputs 3 and 4 there are three different output types: SPDT relay, open

presys

For outputs 3 and 4 there are three different output types: SPDT relay, open

collector voltage and solid-state relay. Figure 7 shows the Transmitter outputs.

presys

collector voltage and solid-state relay. Figure 7 shows the Transmitter outputs.

Notice that the I/O terminals will only show output signals if the

presys

Notice that the I/O terminals will only show output signals if the

corresponding optional module is installed and the output is correctly configured.

presys

corresponding optional module is installed and the output is correctly configured.

In case of analog outputs, refer to sections 3.2

presys

In case of analog outputs, refer to sections 3.2

on

presys

on

Configuration and 4.4

presys

Configuration and 4.4

on

presys

on

Optional Module Connection for details on installation and configuration of

presys

Optional Module Connection for details on installation and configuration of

The state of the relay contacts illustrated in Figure 7 assume that the

presys

The state of the relay contacts illustrated in Figure 7 assume that the

powered off. When power

presys

powered off. When power

ed

presys

ed

on, the status (open or closed) depends

presys

on, the status (open or closed) depends

on the SAFE configuration and if the instrument is or is not in alarm condition.

presys

on the SAFE configuration and if the instrument is or is not in alarm condition.

Table 2 summarizes the state of the relay contacts in all conditions.

presys

Table 2 summarizes the state of the relay contacts in all conditions.

Alarm

presys

Alarm

Condition

presys

Condition

Rel

presys

Rel

ay 1

presys

ay 1

Terminals

presys

Terminals

13 and 14

presys

13 and 14

Relay 2

presys

Relay 2

Terminals

presys

Terminals

15 and 16

presys

15 and 16

Relay 3

presys

Relay 3

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

---

presys

---

OPEN

presys

OPEN

OPEN

presys

OPEN

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

YES

presys

YES

NO

presys

NO

CLOSED

presys

CLOSED

CLOSED

presys

CLOSED

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

YES

presys

YES

YES

presys

YES

OPEN

presys

OPEN

OPEN

presys

OPEN

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

NO

presys

NO

NO

presys

NO

OPEN

presys

OPEN

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

NO

presys

NO

YES

presys

YES

CL

presys

CL

OSED

presys

OSED

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

Table 2 - Relays State in All Possible Conditions of the Instrument

presys

Table 2 - Relays State in All Possible Conditions of the Instrument

The factory setting for the relay is SAFE = "NO" for trip relays and

presys

The factory setting for the relay is SAFE = "NO" for trip relays and

SAFE = "YES" for the other relays.

presys

SAFE = "YES" for the other relays.

PRESYS Instruments TY-2090-Energy

Installation

Page 11

(*)The relay contacts assume that the instrument is powered off.

Fig. 7 - Output Connections

presys

presys

(*)The relay contacts assume that the instrument is

presys

(*)The relay contacts assume that the instrument is

PRESYS Instruments TY-2090-Energy

Installation

Page 12

2.5 - Connection Diagram

presys

presys

PRESYS Instruments TY-2090-Energy

Installation

Page 13

2.6 - Communication

The TY-2090-Energy Transmitter can communicate with computers via RS-232 or

RS-422/485 provided the optional communication module is installed and the proper

communication parameters are configured via software.

Specific information about communication and signal connection can be found in

the Communication Manual and on section 5.0 - MODBUS Communication.

2.7 - Engineering Units

A label with several Engineering Units is supplied with each transmitter. Choose

the one corresponding to the variable shown in the configurator MCY-20 of the

transmitter.

presys

-Energy Transmitter can communicate with computers via RS-232 or

presys

-Energy Transmitter can communicate with computers via RS-232 or

-422/485 provided the optional communication module is installed and the proper

presys

-422/485 provided the optional communication module is installed and the proper

Specific information about communication and signal connection can be found in

presys

Specific information about communication and signal connection can be found in

presys

the Communication Manual and on section 5.0 - MODBUS Communication.

presys

the Communication Manual and on section 5.0 - MODBUS Communication.

A label with several Engineering Units is supplied with each transmitter. Choose

presys

A label with several Engineering Units is supplied with each transmitter. Choose

presys

the one corresponding to the variable shown in the configurator MCY-20 of the

presys

the one corresponding to the variable shown in the configurator MCY-20 of the

PRESYS Instruments TY-2090-Energy

Operation

Page 14

3.0 - Operation

3.1 - Normal Operation

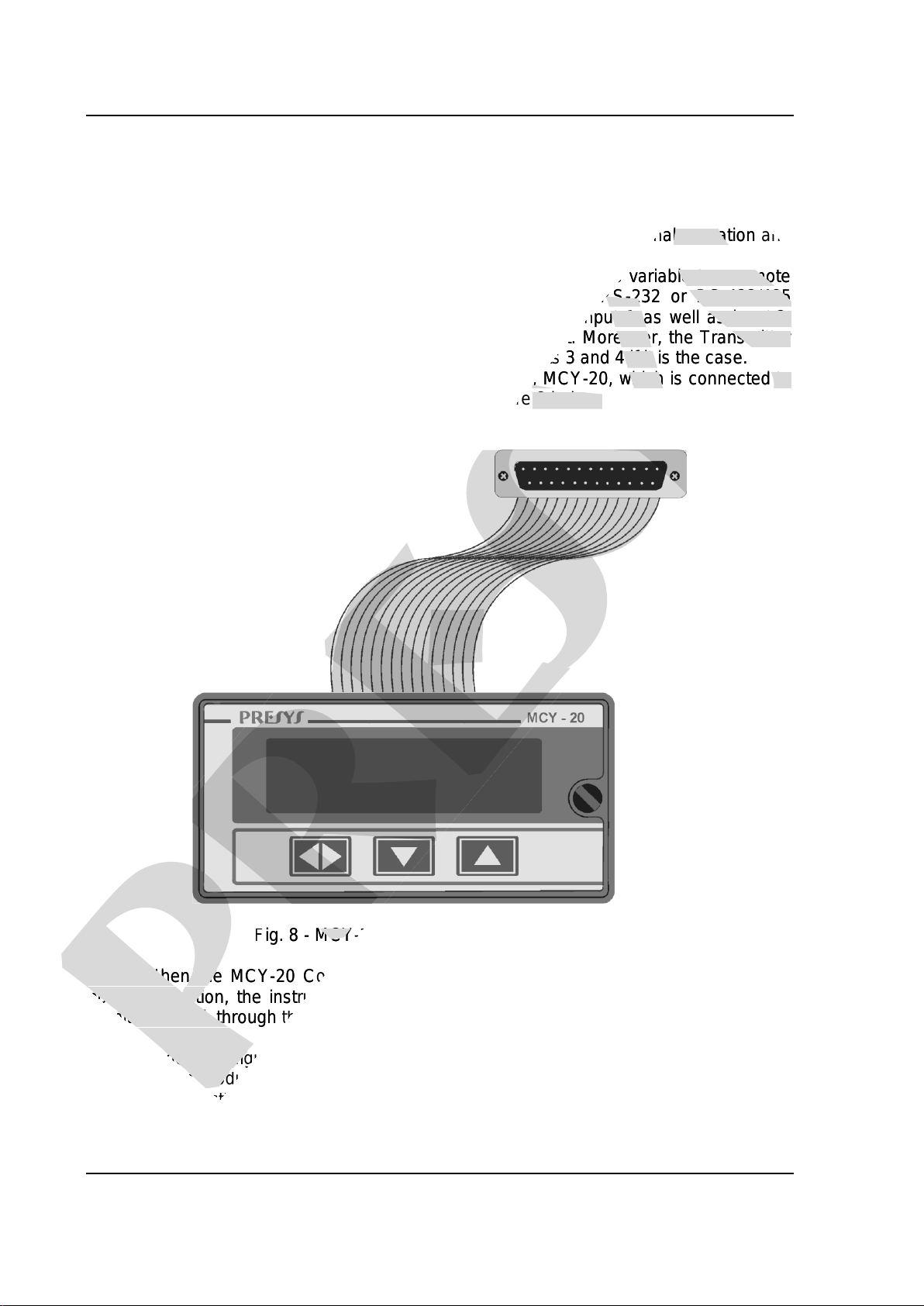

The TY-2090-Energy Transmitter has two operation modes: normal operation and

operation in configuration time.

In normal operation the Transmitter retransmits the process variable to a remote

point either through its two analog outputs 1 and 2, or via RS-232 or RS-422/485

communication. The analog outputs 1 and 2 can retransmit input 1 as well as input 2.

The two analog outputs can even retransmit the same input. Moreover, the Transmitter

checks the alarm conditions and activates the alarm outputs 3 and 4 if it is the case.

The Transmitter has a portable configuration unit, MCY-20, which is connected to

it by means of a DB-25 connector, as illustrated in figure 8 below.

Fig. 8 - MCY-20 Portable Configuration Module

When the MCY-20 Configuration Module is connected to the Transmitter under

normal operation, the instrument begins to function as a transmitter and as a process

monitor as well, through the Module display.

Under configuration time operation mode the user, through the MCY-20

Configuration Module, selects and assigns values to the parameters which regulate the

Transmitter functioning, when in normal operation. Such parameters are, among others,

alarm setpoint values, retransmission output range, etc.

presys

-Energy Transmitter has two operation modes: normal operation and

presys

-Energy Transmitter has two operation modes: normal operation and

In normal operation the Transmitter retransmits the process variable to a remote

presys

In normal operation the Transmitter retransmits the process variable to a remote

point either through its two analog outputs 1 and 2, or via RS-232 or RS-422/485

presys

point either through its two analog outputs 1 and 2, or via RS-232 or RS-422/485

communication. The analog outputs 1 and 2 can retransmit input 1 as well as input 2.

presys

communication. The analog outputs 1 and 2 can retransmit input 1 as well as input 2.

The two analog outputs can even retransmit the same input. Moreover, the Transmitter

presys

The two analog outputs can even retransmit the same input. Moreover, the Transmitter

checks the alarm conditions and activates the alarm outputs 3 and 4 if it is the case.

presys

checks the alarm conditions and activates the alarm outputs 3 and 4 if it is the case.

The Transmitter has a portable configuration unit, MCY-20, which is connected to

presys

The Transmitter has a portable configuration unit, MCY-20, which is connected to

it by means of a DB-25 connector, as illustrated in figure 8 below.

presys

it by means of a DB-25 connector, as illustrated in figure 8 below.

presys

Fig. 8 - MCY-20 Portable Configuration Module

presys

Fig. 8 - MCY-20 Portable Configuration Module

When the MCY-20 Configuration Module is connected to the Transmitter under

presys

When the MCY-20 Configuration Module is connected to the Transmitter under

normal operation, the instrument begins to function as a transmitter and as a process

presys

normal operation, the instrument begins to function as a transmitter and as a process

monitor as well, through the Module display.

presys

monitor as well, through the Module display.

Under configuration time operation mode the user, through the MCY-

presys

Under configuration time operation mode the user, through the MCY-

Configuration Module, selects and assigns values to the parameters which regulate the

presys

Configuration Module, selects and assigns values to the parameters which regulate the

Transmitter functioning, when in normal operation. Such parameters are, among others,

presys

Transmitter functioning, when in normal operation. Such parameters are, among others,

PRESYS Instruments TY-2090-Energy

Operation

Page 15

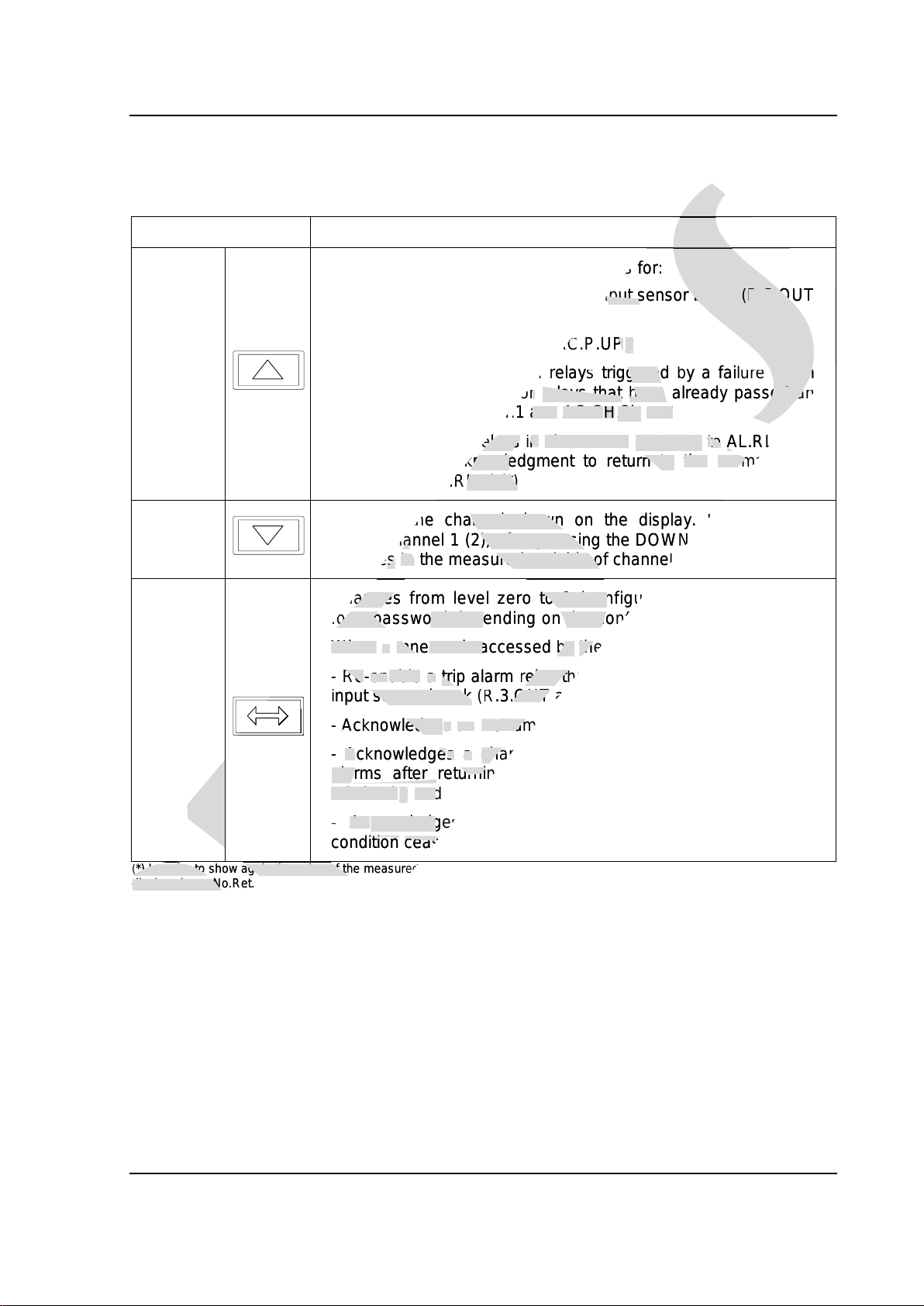

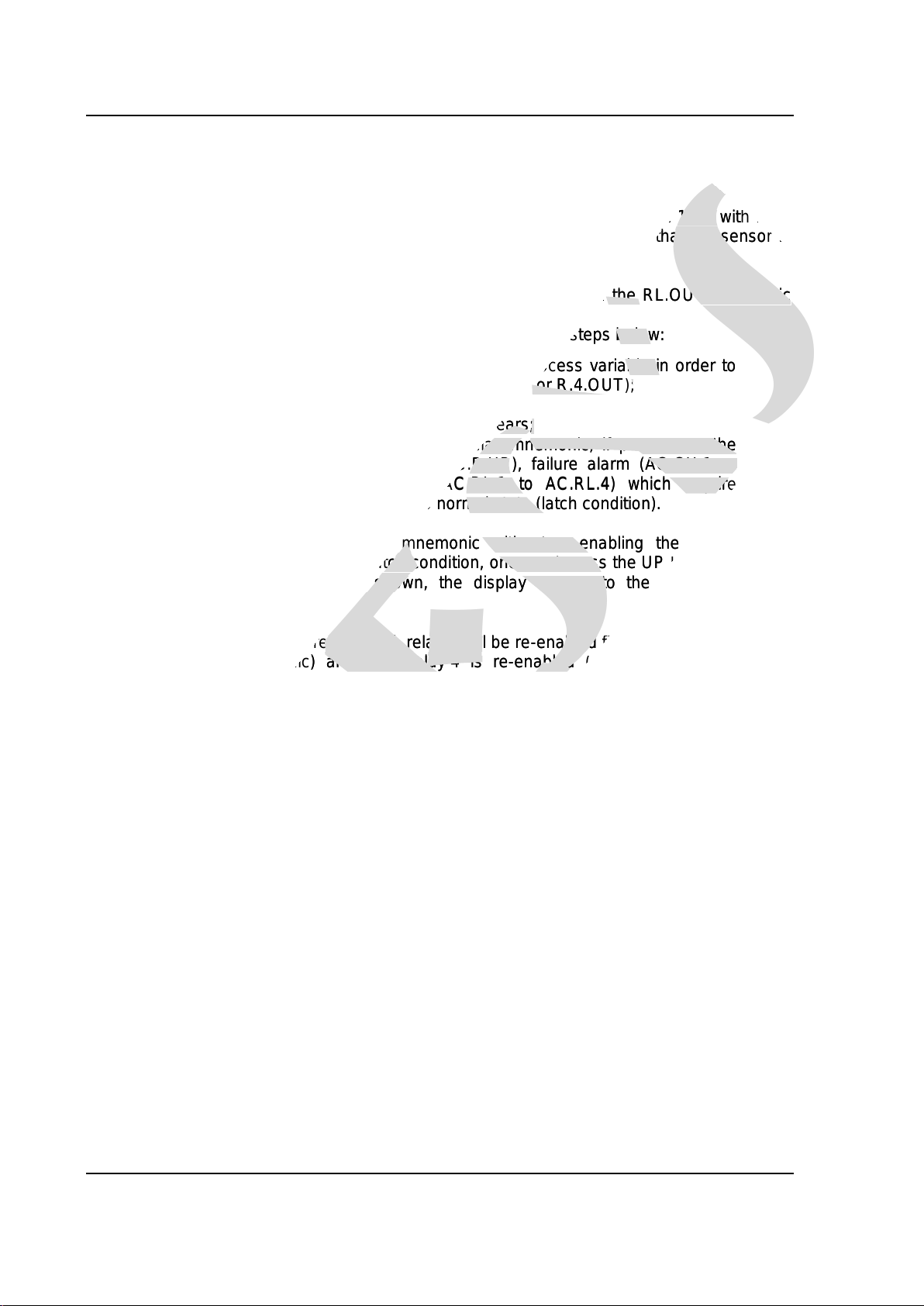

The normal operation mode, in which the Transmitter operates most of the time,

will be called level zero. At this level, the keys on the panel of the MCY-20 Configuration

Module have the following functions:

Key Function

UP

Presents the corresponding mnemonics for:

- Trip alarm relays disabled due to input sensor break (R.3.OUT

and R.4.OUT);

- Instrument power-up event (AC.P.UP);

-Channels associated with relays triggered by a failure alarm

(AL.CH.1 and AL.CH.2) or relays that have already passed an

alarm condition (AC.CH.1 and AC.CH.2); and

- Latch configured relays in alarm state (AL.RL.1 to AL.RL.4) or

which require acknowledgment to return to the normal state

(AC.RL.1 to AC.RL.4) (*)

DOWN Changes the channel shown on the display. If the display

shows channel 1 (2), after pressing the DOWN key, the display

changes to the measured variable of channel 2 (1).

ENTER

Changes from level zero to 1 (configuration mode) or asks

for a password depending on the configuration.

When a mnemonic accessed by the UP key is presented:

-Re-enable atrip alarm relay that has been disabled due to an

input sensor break (R.3.OUT and R.4.OUT);

-Acknowledgesan instrument power-up event (AC.P.UP);

-Acknowledges a channel associated with relays with failure

alarms after returning to the normal condition (AC.CH.1 or

AC.CH.2); and

-Acknowledgesa latch configured relay after the alarm

condition ceased (AC.RL.1 to AC.RL.4).

(*) In order to show again the value of the measured variable, continue to press the UP key. If there is no latched relay, the

display shows No.Ret.

presys

presys

corresponding mnemonics

presys

corresponding mnemonics

for

presys

for

:

presys

:

due to input sensor break

presys

due to input sensor break

(

presys

(

R.3.OUT

presys

R.3.OUT

(AC.

presys

(AC.

P.UP

presys

P.UP

);

presys

);

with

presys

with

relay

presys

relay

s

presys

s

triggered

presys

triggered

by a

presys

by a

fail

presys

fail

ure

presys

ure

alarm

presys

alarm

or

presys

or

relays that

presys

relays that

have already passed

presys

have already passed

an

presys

an

H

presys

H

.1

presys

.1

and

presys

and

AC.C

presys

AC.C

H

presys

H

.2);

presys

.2);

and

presys

and

r

presys

r

elays

presys

elays

in

presys

in

alarm state

presys

alarm state

(AL.RL.1

presys

(AL.RL.1

t

presys

t

o

presys

o

AL.RL.4) o

presys

AL.RL.4) o

acknowledgment to return to

presys

acknowledgment to return to

the

presys

the

normal state

presys

normal state

AC.RL.4) (*)

presys

AC.RL.4) (*)

presys

presys

Changes the channel shown on

presys

Changes the channel shown on

the

presys

the

display. If the display

presys

display. If the display

channel 1 (2), after pressing the DOWN key, the display

presys

channel 1 (2), after pressing the DOWN key, the display

changes

presys

changes

to

presys

to

the measured variable of channel 2 (1).

presys

the measured variable of channel 2 (1).

presys

presys

presys

presys

presys

Changes from level zero to 1 (configuration mode) or asks

presys

Changes from level zero to 1 (configuration mode) or asks

for a password depending on the configuration

presys

for a password depending on the configuration

When

presys

When

a

presys

a

mnemonic accessed

presys

mnemonic accessed

by

presys

by

the UP key

presys

the UP key

-

presys

-

Re

presys

Re

-

presys

-

en

presys

en

able

presys

able

a

presys

a

trip alarm

presys

trip alarm

relay that has been disabled due to

presys

relay that has been disabled due to

input sensor break

presys

input sensor break

(

presys

(

R.3.OUT and R.4.OUT

presys

R.3.OUT and R.4.OUT

-

presys

-

Ac

presys

Ac

knowledge

presys

knowledge

s

presys

s

an

presys

an

instrument

presys

instrument

-

presys

-

Ac

presys

Ac

knowledge

presys

knowledge

s

presys

s

a

presys

a

channel associated with relays with failure

presys

channel associated with relays with failure

alarms after returning to the normal cond

presys

alarms after returning to the normal cond

AC.CH.2

presys

AC.CH.2

);

presys

);

and

presys

and

-

presys

-

Ac

presys

Ac

knowledge

presys

knowledge

s

presys

s

condition

presys

condition

ceased

presys

ceased

presys

presys

presys

presys

presys

presys

presys

presys

presys

presys

(*) In order to show again the value of the measured variable, continue to press the UP key. If there is

presys

(*) In order to show again the value of the measured variable, continue to press the UP key. If there is

display shows No.Ret.

presys

display shows No.Ret.

PRESYS Instruments TY-2090-Energy

Operation

Page 16

In the operation mode it is possible to re-enable the trip alarms configured with failure

manual reset (see section 3.2 - Configuration: Level 3- Alarms) by following the procedure

below:

(i) The display shows a blinking B.OUT.1 / 2 mnemonic (for channel 1 / 2 with RTD

input) or the BRK.1 /2 mnemonic (for 4-20 mA current input), indicating that the sensor is

broken and the TRIP alarms are disabled;

(ii) Reconnect the sensor to the instrument terminals;

(iii) The display shows alternatively the indication value and the RL.OUT mnemonic

(relays 3 and/or 4 disabled);

(iv) Enable the relays with TRIP alarms according to the steps below:

1. Press the UP key during the exhibition of the process variable in order to

show the mnemonic of the disabled relay (R.3.OUT or R.4.OUT);

2. Press ENTER;

3. The R.3.OUT or R.4.OUT mnemonic disappears;

4. The display shows the next disabled relay mnemonic, if present, or the

mnemonics for the power up event (AC.P.UP), failure alarm (AC.CH.1 or

AC.CH.2) or for the relay alarms (AC.RL.1 to AC.RL.4) which require

acknowledgement in order to return to normal state (latch condition).

In order to pass to the next mnemonic without re-enabling the trip relay or

acknowledging an alarm relay under latch condition, one must press the UP key once again.

After all available mnemonics are shown, the display returns to the process variable

indication.

Note: If both relays 3 and 4 are disabled, relay 3 will be re-enabled first (by pressing ENTER

for the R.3.OUT mnemonic) and then relay 4 is re-enabled (ENTER for the R.4.OUT

mnemonic).

presys

(i) The display shows a blinking B.OUT.1 / 2 mnemonic (for channel 1 / 2 with RTD

presys

(i) The display shows a blinking B.OUT.1 / 2 mnemonic (for channel 1 / 2 with RTD

mA current input), indicating that the sensor is

presys

mA current input), indicating that the sensor is

(iii) The display shows alternatively the indication value and the RL.OUT mnemonic

presys

(iii) The display shows alternatively the indication value and the RL.OUT mnemonic

(iv) Enable the relays with TRIP alarms according to the steps below:

presys

(iv) Enable the relays with TRIP alarms according to the steps below:

Press the UP key during the exhibition of the process variable in order to

presys

Press the UP key during the exhibition of the process variable in order to

show the mnemonic of the disabled relay (R.3.OUT or R.4.OUT

presys

show the mnemonic of the disabled relay (R.3.OUT or R.4.OUT

);

presys

);

The R.3.OUT or R.4.OUT mnemonic disappears;

presys

The R.3.OUT or R.4.OUT mnemonic disappears;

The display shows the next disabled relay mnemonic, if present, or the

presys

The display shows the next disabled relay mnemonic, if present, or the

mnemonics for the power up event (AC.P.UP), failure alarm (AC.CH.1 or

presys

mnemonics for the power up event (AC.P.UP), failure alarm (AC.CH.1 or

AC.CH.2) or for the relay alarms (AC.RL.1 to AC.RL.4) which require

presys

AC.CH.2) or for the relay alarms (AC.RL.1 to AC.RL.4) which require

acknowledgement in order to return to normal state (latch condition).

presys

acknowledgement in order to return to normal state (latch condition).

In order to pass to the next mnemonic without re-enabling the trip relay or

presys

In order to pass to the next mnemonic without re-enabling the trip relay or

acknowledging an alarm relay under latch condition, one must press the UP key once again.

presys

acknowledging an alarm relay under latch condition, one must press the UP key once again.

presys

After all available mnemonics are shown, the display returns to the process variable

presys

After all available mnemonics are shown, the display returns to the process variable

If both relays 3 and 4 are disabled, relay 3 will be re-enabled first (by pressing ENTER

presys

If both relays 3 and 4 are disabled, relay 3 will be re-enabled first (by pressing ENTER

presys

for the R.3.OUT mnemonic) and then relay 4 is re-enabled (ENTER for the R.4.OUT

presys

for the R.3.OUT mnemonic) and then relay 4 is re-enabled (ENTER for the R.4.OUT

PRESYS Instruments TY-2090-Energy

Operation

Page 17

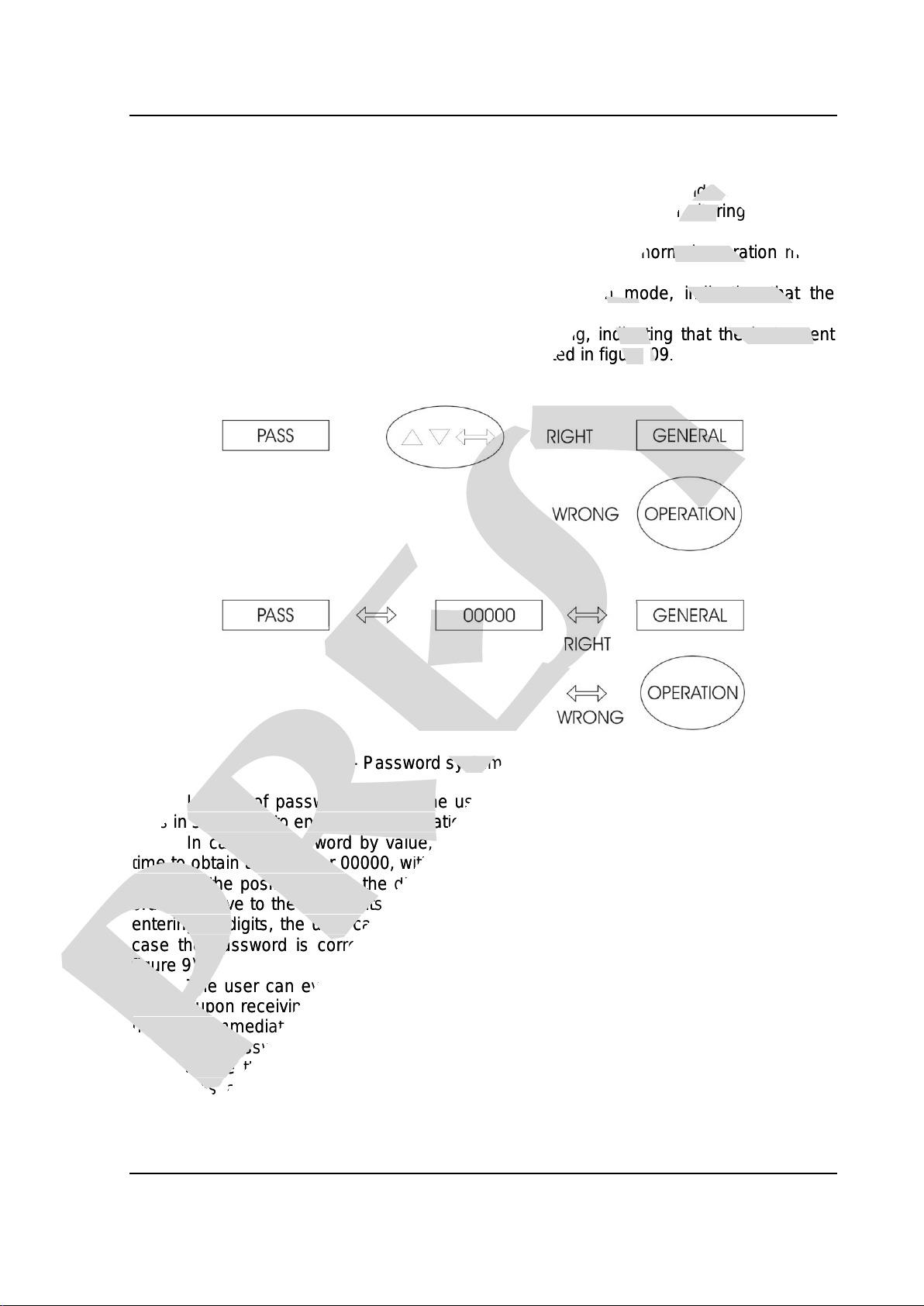

3.2 - Configuration

To have access to the configuration mode, one should provide the password

configured with the purpose of preventing unauthorized people from altering the critical

parameters of the process.

Therefore, whenever the ENTER key is pressed under normal operation mode,

one of the following cases might occur:

i) Enter directly into level 1 (GENERAL) of configuration mode, indicating that the

instrument was not configured with a password system.

ii) The Module display shows the PASSWORD warning, indicating that the instrument

has a password system by key or by value, as illustrated in figure 09.

Fig. 9 - Password system by key and by value

In case of password by key, the user should press the UP, DOWN and ENTER

keys in sequence to enter the configuration levels.

In case of password by value, the user should press the ENTER key a second

time to obtain the number 00000, with the last digit blinking on the right. The blinking digit

indicates the position where the digit of a 4-digit number will be entered by the user. In

order to move to the next digits on the left, the user should press the ENTER key. After

entering all digits, the user can press the ENTER key once more to switch to level 1 in

case the password is correct, otherwise the system reverts to normal operation (see

figure 9).

The user can even select both password systems, by key and by value. In such

case, if upon receiving a request for a password the user enters a wrong key sequence,

he will be immediately reverted to password by value.

The password can be a number chosen by the user (customized) or the number

2090. Notice that in case of password by value the number 2090 is always enabled,

serving as a help to the user in case he forgets his password. In order to enter a

password number or any other parameter value, the user can use the front Module keys,

which have the following functions:

presys