2AWT420 | UNIVERSAL 4-WIRE, DUAL-INPUT TRANSMITTER | CI/AWT420-EN REV. B

Contents

1 Health & Safety ............................. 4

................................ 4

Safety precautions ................................ 4

Potential safety hazards ........................... 4

...............4

Safety standards .................................. 4

Product symbols .................................. 4

Product recycling and disposal

(Europe only).......................................5

End-of-life battery disposal ...................5

2011/65/EU (RoHS II) ...............................5

Cleaning ...........................................5

2 Cyber security...............................5

Communication protocol specific..............5

3 Overview....................................6

4 Mechanical installation.......................6

Transmitter installation............................ 6

Optional accessories..........................6

Location .....................................6

Sensor installation ................................ 6

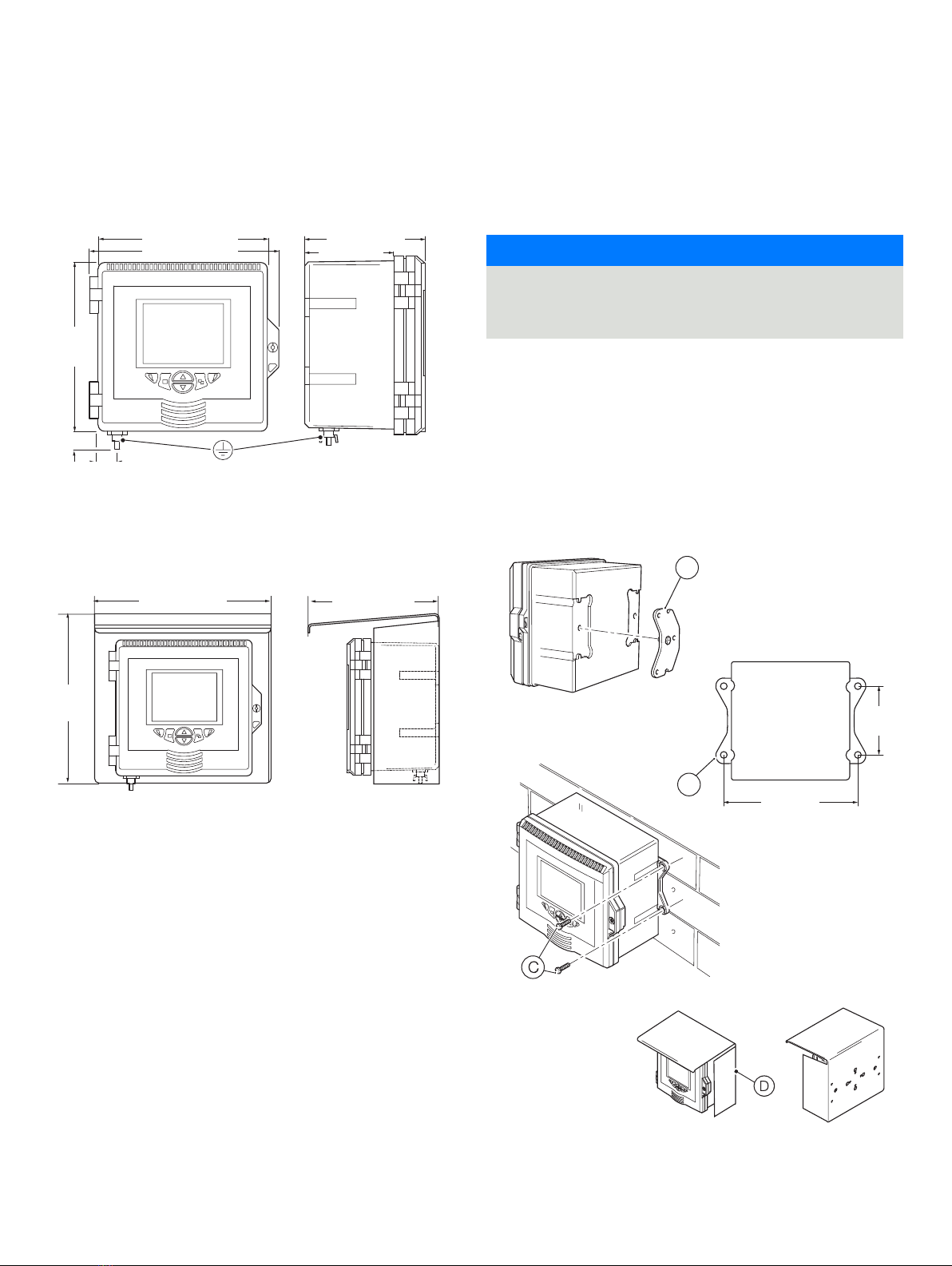

Transmitter dimensions.......................7

Optional weathershield dimensions............7

Sensor modules ..............................7

Communication module.......................7

Wall-mounting................................7

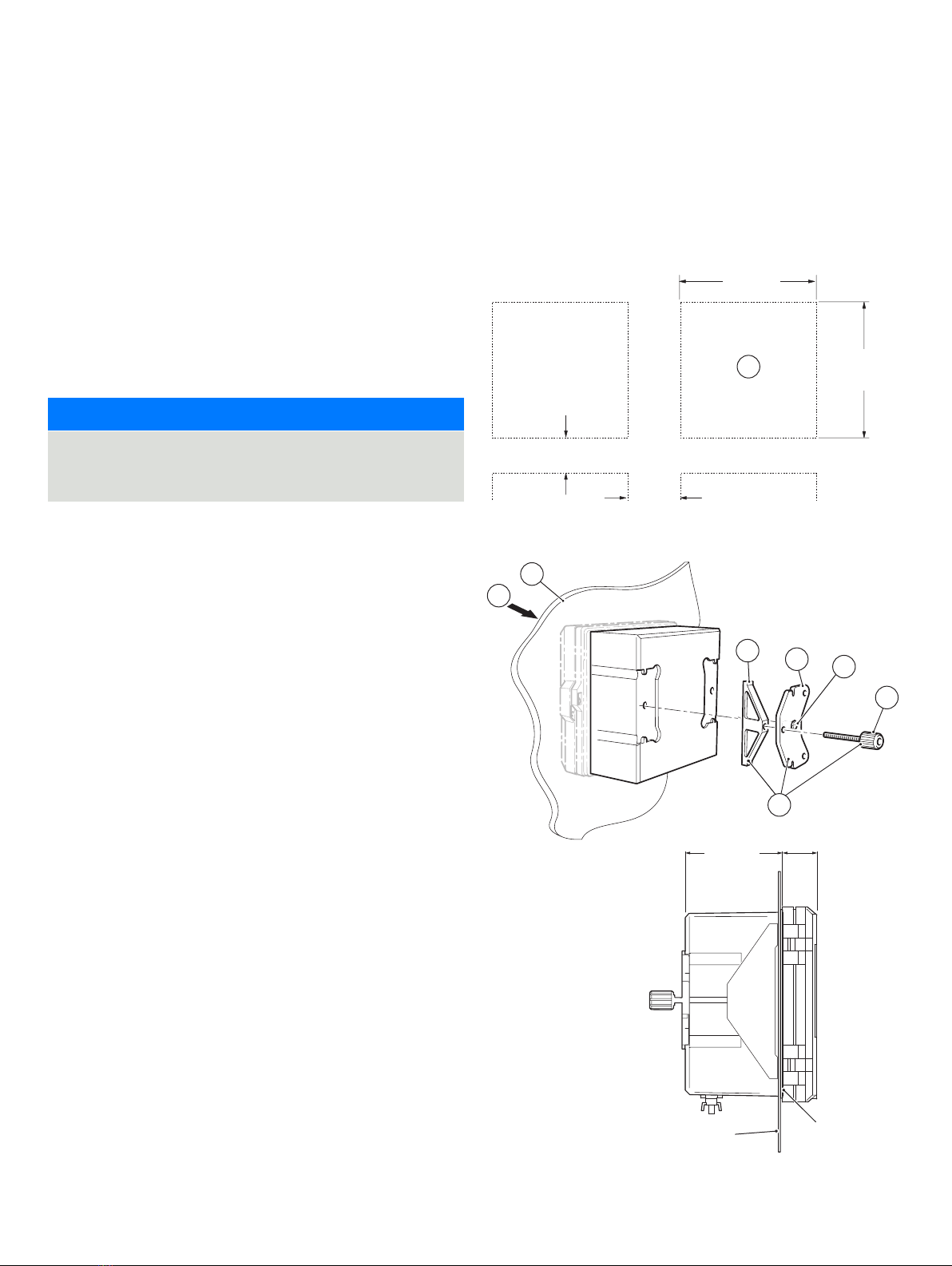

Panel-mounting (optional) ....................8

Pipe-mounting (optional) .....................9

5 Electrical installation ...................... 10

Earth bonding.....................................10

Cable entries......................................10

Terminal connections..............................11

...12

Conductivity sensor module connections ...........12

2-electrode sensors..........................12

4-electrode sensors .........................12

pH and conductivity connections ..................13

pH/ORP/pIon sensor module connections.....13

Power supply connection ..........................14

Fitting the EZLink modules ........................16

Connecting EZLink sensors ........................18

Long cables .................................18

6 Easy Setup .................................18

7 Operation ..................................19

Front panel keys...................................19

Modes of operation .............................. 20

Operator menus.................................. 20

Operating modes .................................21

View mode....................................... 23

............................23

Signals View.................................23

Chart View ..................................23

Alarms View .................................23

Outputs View................................23

Log mode........................................ 24

Log entries ...................................... 24

8 Data logging .............................. 25

Removable SD card ..............................25

Removable media ................................ 25

.................... 25

9 Password security and Access Level......... 26

Setting passwords ............................... 26

Access Level ..................................... 26

10 Sensor setup ...............................27

2-electrode conductivity...........................27

dual input calculated values setup ................. 28

4-electrode conductivity ......................... 29

pH/Redox/ORP .................................. 30

..............................................31

Turbidity/Suspended solids .......................31

11 Specification ...............................32

Operation........................................ 32

Mechanical data .................................. 32

Security ......................................... 32

Electrical ........................................ 32

Analog outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Relay outputs .................................... 32

.............................. 32

Connectivity/Communications (optional).......... 33

..................................... 33

Environmental data .............................. 33

2-electrode conductivity.......................... 33

4-electrode conductivity ......................... 34

pH/ORP (Redox) ................................. 34

EZLink ........................................... 35

EMC ............................................. 35

Approvals, certification and safety ................ 35