Prevac MG14 User manual

PREVAC Sp z o.o., Raciborska 61 str. PL44362 Rogów

Tel.: +48 32 45 92 000, Fax: +48 32 45 92 001, e-mail: prevac@prevac.eu, http://www.prevac.eu

CONTENTS

1. INTRODUCTION............................................................................................................................................4

1.1 INTENDED USE ...........................................................................................................................................4

1.2 LIABILITY AND WARRANTY......................................................................................................................4

1.3 COMPATYBILITY ........................................................................................................................................4

1.4 SAFETY........................................................................................................................................................4

1.4.1 PERSONNEL QUALIFICATIONS ......................................................................................................................4

1.4.2 ILLUSTRATION OF RESIDUAL DANGERS.........................................................................................................5

1.4.3 GENERAL SAFETY INSTRUCTIONS.................................................................................................................5

2 TECHNICAL DATA.........................................................................................................................................7

2.1 GENERAL DATA..............................................................................................................................................7

2.1.1 MECHANICAL DATA .....................................................................................................................................7

2.1.2 AMBIENCE...................................................................................................................................................7

2.1.3 OPERATION .................................................................................................................................................7

2.2 MAINS CONNECTION .......................................................................................................................................8

2.3 CHANNELS .....................................................................................................................................................8

2.3.1 SENSOR CONNECTIONS ...............................................................................................................................8

2.3.2 SENSOR SUPPLY .........................................................................................................................................9

2.3.3 MEASURING RANGES...................................................................................................................................9

2.3.4 MEASURING TECHNIQUE ............................................................................................................................10

2.4 INTERFACES .................................................................................................................................................10

2.4.1 RELAY OUTPUTS .......................................................................................................................................10

2.4.2 I/O OUTPUTS .............................................................................................................................................10

2.4.3 COMMUNICATION INTERFACES....................................................................................................................11

3 INSTALLATION ............................................................................................................................................12

3.1 UNPACKING..................................................................................................................................................12

3.2 MECHANICAL INSTALLATION..........................................................................................................................12

3.2.1 DESK-TOP DEVICE.....................................................................................................................................12

3.2.3 RACK INSTALLATION..................................................................................................................................13

3.2.4 INTERFACE MODULE MOUNTING ..................................................................................................................14

3.3 CONNECTING................................................................................................................................................16

3.3.1 BACK SIDE OF THE DEVICE ........................................................................................................................16

3.3.2 MAINS CONNECTION ..................................................................................................................................16

3.3.3 GROUND....................................................................................................................................................17

3.3.4 CHANNEL 1 ...............................................................................................................................................17

3.3.5 CHANNEL 2 ...............................................................................................................................................18

3.3.6 RELAYS ..................................................................................................................................................19

3.3.8 ANYBUS MODULE.......................................................................................................................................20

3.3.9 I/O INTERFACE...........................................................................................................................................20

4 OPERATION .................................................................................................................................................23

4.1 FRONT PANEL ..............................................................................................................................................23

4.1.1 DISPLAY....................................................................................................................................................23

4.1.3 CONTROL BUTTONS...................................................................................................................................24

4.2.1 MENUS......................................................................................................................................................24

MG14 operating manual Rev 1.4

3

4.2.1.4 TRIGGER’S MENU -TRIGGERS ACTIVE ....................................................................................................28

4.2.11.1 INTERFACE MENU –INTERFACE .............................................................................................................38

4.2.11.3 BLUETOOTH PARAMETERS ....................................................................................................................38

4.2.11.4 RS232/485/USB PARAMETERS............................................................................................................39

4.2.12.1 CUSTOMER MENU -CUSTOMER..............................................................................................................39

4.2.13.1 SERVICE MENU –SERVICE.....................................................................................................................39

4.2.14.1 INFORMATION MENU –INFORMATION......................................................................................................39

5.MAINTENANCE AND SERVICE ..................................................................................................................39

5.1 MAINTENANCE..............................................................................................................................................39

5.1.1 CLEANING .................................................................................................................................................39

6 STORAGE AND DISPOSAL.........................................................................................................................41

6.1 PACKAGING..................................................................................................................................................41

6.2 STORAGE .....................................................................................................................................................41

6.3 DISPOSAL.....................................................................................................................................................41

7. APPENDINX.................................................................................................................................................42

7.1 TROUBLE SHUTTINGS –ERROR MASSAGES.....................................................................................................42

7.2 INDEX...........................................................................................................................................................44

8. WARRANTY CONDITIONS.........................................................................................................................46

8. WARRANTY CONDITIONS.........................................................................................................................46

DECLARATION OF CONFORMITY................................................................................................................47

MG14 operating manual Rev 1.4

4

1. INTRODUCTION

Please read this manual carefully to ensure optimum operating conditions right from the start. This user

manual handbook contains important information about functionality, installation, start-up and operation of

the Vacuum Gauge controller MG14

1.1 INTENDED USE

The Ionization Multi Gauge controller MG14 is a versatile microprocessor controlled ionization gauge

controller for pressure measurements in the range 2x10-12 through 1x103mbar. The concept and design of

the controller allow for a reliable and complete integration in complex process control systems. The Multi

Gauge MG14 can handle two measuring systems simultaneously. An optional different interface may be

used for complete remote control of the device.

In the following, the Ionization Multi Gauge MG14 will be referred to as «MG 14».

1.2 LIABILITY AND WARRANTY

PREVAC Sp. z o.o. assumes no liability and the warranty becomes null and void if the end user or third

parties

- Disregard the information in this document

- Use the product in a non-conforming manner

- Make any kind of alterations (modifications, repair work, etc.) to the product

- Use the product with accessories not listed in the corresponding product documentation

We reserve the right to make technical changes without prior notice. The figures are non-committal.

1.3 COMPATYBILITY

The MG 14 is partially compatible with its predecessor MG13. In order to operate the MG 14 in one of the

MG14 modes, you have to change the configuration settings accordingly. See Chapter 4.2.4.8 - Transmitter

selection for channel 2,

1.4 SAFETY

1.4.1 Personnel Qualifications

All work described in this document may only be carried out by persons who have suitable technical training

and the necessary experience or who have been instructed by the end user of the product.

MG14 operating manual Rev 1.4

5

1.4.2 Illustration of Residual Dangers

This Operating Manual illustrates safety notes concerning residual dangers as follows:

DANGER

!

Information on preventing any kind of physical injury.

WARNING

!

Information on preventing extensive equipment and environmental damage.

CAUTION

!

Information on correct handling or use. Disregard can lead to malfunctions or equipment damage.

NOTE:

Indicates particularly important, but not safety-relevant information.

1.4.3 General Safety Instructions

For all work you are going to do, adhere to the applicable safety regulations.

Also observe all safety notes given in this document and forward the information to all other users of the

product. In particular, pay attention to the following safety notes:

DANGER

!

Mains voltage.

Contact with live parts is extremely hazardous when any objects are introduced or any

liquids penetrate into the device.

Make sure that no objects enter through the louvers of the device. Keep the device dry.

MG14 operating manual Rev 1.4

6

Fig. 1-2 Do not insert objects through louvers and keep device dry

WARNING

!

Improper use.

Improper use can damage the MG14.

Use the MG14 only as intended by the manufacturer.

WARNING

!

Improper installation and operation data.

Improper installation and operation data may damage the MG14.

Strictly adhere to the stipulated installation and operation data.

MG14 operating manual Rev 1.4

7

2 Technical Data

2.1 General Data

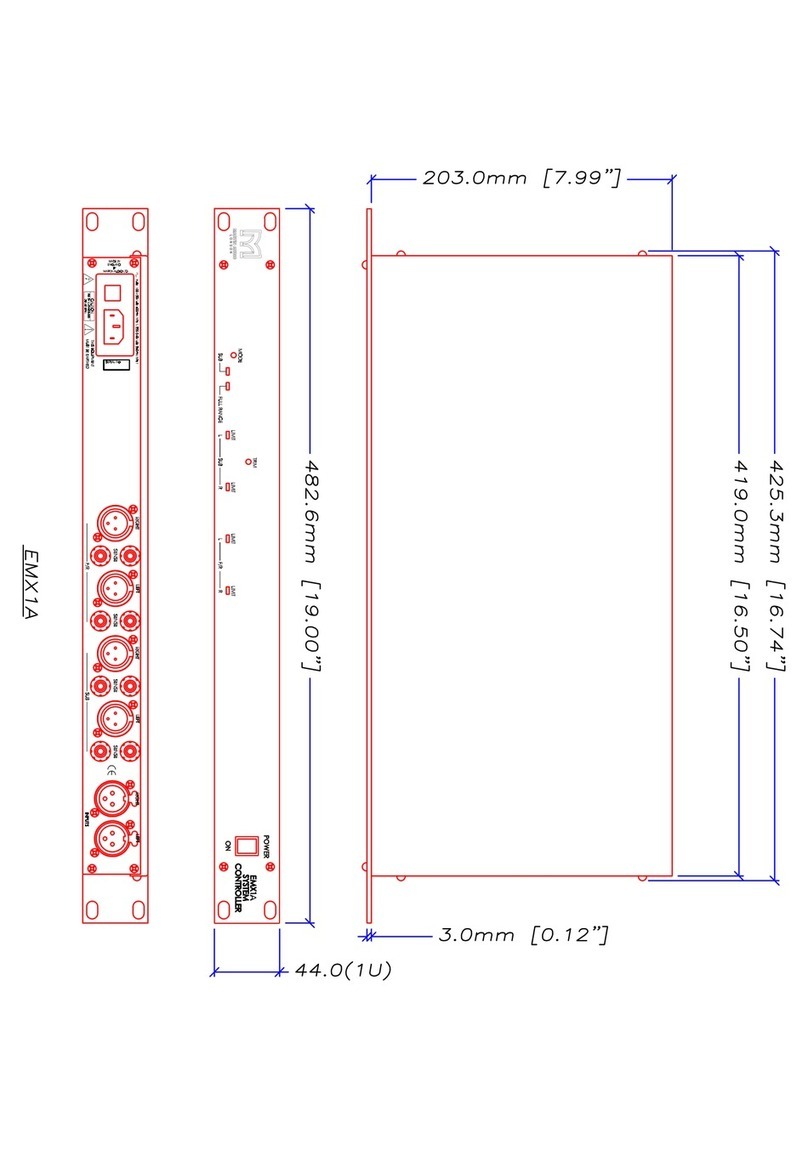

2.1.1 Mechanical Data

Dimensions Width: 241,3 mm

Height: 44 mm (1 HU)

Depth: 337 mm

See Fig. 2-1,

Weight 3.0 kg

Use Desktop device

Control panel mounted

Rack mounted

Fig. 2-1 Dimensions (in mm)

2.1.2 Ambience

Temperature Storage: -40…+70 °C

Operation: +5…+50 °C

Relative humidity Max. 75 % (up to 32 °C), decreasing to max. 50 % (above 45 °C)

Use Indoors only

Altitude max. 2000 m NN

Pollution degree II

Protection type IP20

2.1.3 Operation

Manually Via 5 control buttons on the front panel

Remote control Via RS232; RS485;USB;CAN-BUS, PROFI-BUS, EthernetIP –this has to be

chosen with order or can be implemented any time by user –see chapter 2.4.3.

MG14 operating manual Rev 1.4

8

2.1.4 Standards

Conformity with the Directive relating to electrical equipment designed for use within certain voltage

limits 73/23/EWG

Conformity with the Directive relating to electromagnetic compatibility 89/336/EWG

Harmonized and international/national standards and specifications:

EN 61010-1 (Safety requirements for electrical equipment for measurement, control and

laboratory use)

EN 61000-6-2 (Electromagnetic compatibility generic emission standard)

EN 61000-6-3 (Electromagnetic compatibility generic immunity standard)

2.2 Mains Connection

Voltage 90 - 250 VAC

Frequency 50 - 60 Hz

Current consumption Max. 3,5 A at 115 V

Max. 1,75 A at 230 V

Power consumption Max. 250 W

Overvoltage category II

Protection class 1

Connection European appliance connector IEC 320 C14

Fuse 3,5 A (in power supply)

2.3 Channels

2.3.1 Sensor Connections

Channel 1:

Sensor connections: UTG0187SVDEU + BNC

Compatible IONIVAC sensors: EXTRACTOR gauge IE514, IE414 B-A gauge, and any

Bayard-Alpert sensor

Channel 2:

Sensor connection: J45

Compatible sensors:

- THERMOVAC transmitters:

TTR 90, TTR 90S, TTR 91,TTR91S

- CERAVAC transmitters:

(CTR): Preferably CTR 90,CTR 91

- Ioni transmitters: ITR 90, ITR100

MG14 operating manual Rev 1.4

9

2.3.2 Sensor Supply

2.3.2.1 IONIVAC Sensors

Measuring operation:

Universal

Bayard-Alpert

gauge

IE 414

Bayard-Alpert

gauge

IE 515

Extractor

gauge

Tol

Anode potential:

Reflector potential:

Cathode potential:

Emission current:

(selectable)

180V

------

30V

0,1 mA

1 mA

4 mA

10 mA

220V

------

80V

0,1 mA

1 mA

4 mA

10 mA

220V

205V

100V

1,6 mA

± 1%

± 1%

± 1%

± 5%

± 1%

± 1%

± 1%

Degassing:

Universal

Bayard-Alpert

gauge

IE 414

Bayard-Alpert

gauge

IE 515

Extractor

gauge

Tol

Anode potential:

Reflector potential:

Cathode potential:

Emission current:

Power:

Degas timer:

500V

------

90V

max 80 mA

adjustable

max 40W

adjustable

1-20 min

480V

------

20V

max 80 mA

adjustable

max 40W

adjustable

1-20 min

480V

205V

10V

max 80 mA

adjustable

max 40W

adjustable

1-20 min

± 1%

± 1%

± 1%

± 5%

± 1%

± 1%

2.3.2.2 THERMOVAC, CERAVAC and IONIVAC Transmitters

Voltage +24 VDC ±5%

Current 0.1 A Thermovac, Ceravac; 1,2A IONIVAC ITR90, ITR100

2.3.3 Measuring Ranges

Total measuring range: 2x10-12 to 1000 mbar

IONIVAC sensors: Bayard-Alpert: 2x10-11….1x10-3 mbar

Extractor: 2x10-12….1x10-4 mbar

CERAVAC transmitters CTR 90 and CTR 91: 0.1 Torr: (CTR 91 only) 1x10-5….1x10-1 Torr

1 Torr: 1x10-4…..1 Torr

MG14 operating manual Rev 1.4

10

10 Torr: 1x10-3…..1x101Torr

100 Torr: 1x10-2…..1x102Torr

1000 Torr: 1x10-1…..1x103Torr

THERMOVAC transmitters: 5x10-4….1x103mbar

IONIVAC transmitters ITR90: 5x10-10 …. 5x10-4 mbar

2.3.4 Measuring Technique

Accuracy of measurement

Current: (channel 1) - Relative to current reading: ±1%

- Absolute: ±0.6 fA

Voltage:(channel 2) - Relative to voltage reading: ±0.3%

- Absolute: ±2 mV

Measuring rate

Channel 1 ( B-A gauge): 2 mA.10 pA 25 s-1

10 pA.100 fA 1.25 s-1

< 100 fA 2.5 s-1

Channels 2 (transmitters): Entire range 20 s-1

Display rate, temperature drift, unit of measurement

Display rate 4 s-1

Temperature drift < 0.1 % per °C

Unit of measurement mbar, Pa, Torr, Micron

Resolution of the A/D converter

THERMOVAC, CERAVAC and IONIVAC: bit

Extractor, B-A Gauge bit

2.4 Interfaces

2.4.1 Relay Outputs

Name Relay

Connection: D-Sub, 9 pins, female.

See Fig. 3-8,

Number of relays: 4 NO, include one NO,NC

Response time Max. 70 ms,

Synchronous to channels: adjustable to 1,2,3 or 4; above, bellow and hysteresis option

Load (ohmic): Max. 50 VDC, 0.5 A

2.4.2 I/O outputs

For detailed description please refer to chapter 3.3.9

MG14 operating manual Rev 1.4

11

2.4.3 Communication interfaces

For network connectivity requirements Anybus CompactCom ( Anybus-CC ) modules has been

implemented.

One of the following Anybus-CC modules can be mounted:

EtherNet/IP

- Active module with serial and parallel application interface

- Complete EtherNet/IP adapter

- CIP Parameter Object Support

- Explicit and implicit messaging

- Transformer isolated Ethernet interface 10/100 Mbit/s full

duplex

- TCP/IP socket interface

- FTP server, E-mail and dynamic web server with SSI

support

- Generic EDS-file provided

Bluetooth

- Passive module with serial application interface

- Physical layer converter for Bluetooth communication

standard

- Completely transparent interface

- Bluetooth class 2 SPP compatible

- Wireless range up to 30 meters

RS-232

- Passive module with serial application interface

- Physical layer converter for the RS-232 communication

standard

- Supports baud rates up to 250 kbit/s

- No configuration necessary, since the module acts only

on the physical layer

RS-485

- Passive module with serial application interface

- Physical layer converter for the RS-485/422

communication standard

- Supports baud rates up to 10 Mbit/s

- No configuration necessary, since the module acts only

on the physical layer

- Galvanically isolated RS-485/422 interface

USB

- Passive module with serial application interface

- Physical layer converter for

- USB communication standard (USB 1.1 & USB 2.0 full

speed)

- Supports 1 and 2 Mbit/s USB communication speed

- The baud rate is set from the host computer side

- Software drivers available

- Galvanically isolated USB interface

MG14 operating manual Rev 1.4

12

3 Installation

3.1 Unpacking

1 Visually inspect the transport packaging for signs of external damage

2 Unpack the MG14 and put the packaging material aside

NOTE:

Keep the packaging material for later use. The MG14 must be stored and transported in the

original packaging material only.

3 Examine the MG14 for completeness

4 Visually inspect the MG14 for signs of damage

DANGER

!

Damaged product.

Putting a damaged product into operation can be extremely dangerous.

Never attempt to put a damaged product into operation. Secure the damaged product

from unintended operation. Send a damage report to the haulage company or the

insurer.

3.2 Mechanical Installation

The MG14 can be used as follows: As a desk-top device, mounted in a control panel, or mounted in

a 19" rack. In each of these cases you must pay attention to the following safety note:

WARNING

!

Ambient temperature.

Exceeding the maximum permitted ambient temperature may damage the device.

Make sure that the maximum permitted ambient temperature is not exceeded and that

the air can flow freely through the louvers. Do not expose the device to direct sunlight.

3.2.1 Desk-Top Device

MG14 is delivered with four stuck gummy legs –no other protection is needed. The device can be

use as a desk-top like it is.

MG14 operating manual Rev 1.4

13

3.2.3 Rack Installation

The MG14 is designed for installation into a rack according to DIN 41 494 (19", 1 HU).

DANGER

!

Protection class of the rack.

If the product is installed in a rack, it is likely to lower the protection class of the rack

(protection from foreign bodies and water) e.g. according to the EN 60204-1

regulations for switching cabinets.

Take appropriate measures to restore the required protection class of the rack.

In order to use MG14 in the rack there is necessary to remove four stuck gummy legs. For this purpose

proceed as follows:

1. Switch off the MG14 and disconnect it from mains power

2. Turn the MG14 upside down as shown in Fig. 3-1,

3. Remove ( unstuck ) the four stuck gummy legs

4. Turn the MG14 back to normal orientation and place it on the required location

Fig. 3-1 Unstuck gummy legs from the device

NOTE:

In order to reduce the strain on the front panel it is recommended to equip the rack chassis

adapter with a guide rail.

1. Insert the MG14 into the rack chassis adapter

2. Fasten the MG14 with the supplied collar screws and plastic sleeves to the rack chassis adapter

MG14 operating manual Rev 1.4

14

3.2.4 Interface module mounting

The Anybus interfaces modules ( ref. to chapter 2.4.3 ) can exchange any time on request For the

proper installation please follow the instruction.

CAUTION

!

Turn the unit off

Before proceed with any modules, ensure that the main power is off. This prevents

any electric damages in the unit

CAUTION

!

Screws fully loose

Before inserting the module, ensure that the affixing screws have been fully loosened.

MG14 operating manual Rev 1.4

15

NOTE:

Please carefully insert the module in –parallel to the PCB board –please refer to the Fig.3.2.

Fig. 3.2 Installation of an interface module

To be sure if the module is mounted correctly please have a look into the unit via the holes as shown

on the photo Fig. 3.3

Fig. 3.3 Anybus Module mounting

1. When inserting the module into the slot, press it with its plain side onto the MG14 board.

2. Tighten the affixing screws until they make contact with the panel –ref..

3. The affixing screws lock the module in place in the slot.

MG14 operating manual Rev 1.4

16

3.3 Connecting

3.3.1 Back Side of the Device

Fig. 3-4, shows the back side of the MG14.

Fig. 3-4 Back side of the MG14

A Connection for IONIVAC measuring signal, channel 1

B Ground screw

C Connection for transmitter, channel 1

D Connection for transmitter, channel 2

E RELAY connection

F AnybusCC connection module

G Mains connection

H I/O interface

DANGER

!

Screw for internal protective conductor.

The internal protective conductor is connected to the casing with a screw.

Do not turn or loosen this screw.

The configuration of the available connections is described in the following sections.

3.3.2 Mains Connection

The mains connection (Fig. 3-4, item G) is designed for a mains cable which contains a European

appliance connector on the device side. A mains cable is supplied with the device. If the plug is not

compatible with your wall socket, you have to get a suitable mains cable:

Three-conductor cable with protective ground

Conductor cross-section 3x1.5 mm2or larger

MG14 operating manual Rev 1.4

17

Fig. 3-5 Three-conductor cable with protective ground (example)

DANGER

!

Mains power.

Improperly grounded devices can be extremely dangerous in the event of a fault.

Use three-wire mains or extension cables with protective ground only.

Plug the mains cable into wall sockets with protective ground only.

1. Connect the European appliance connector of the mains cord with the mains connection of the

device

2. Connect the plug of the mains cable with the wall socket

NOTE:

If the device is installed in a switching cabinet, the mains power can be supplied via a

switchable central power distributor.

3.3.3 Ground

The ground screw (Fig. 3-4, item B) can be used to connect the MG14 with the protective ground of

the pumping station.

If required: Connect the protective ground of the pumping station with the ground screw. Use a

protective conductor.

The metal flanges of the B-A gauge sensors are connected to the ground via the measuring lines

inside of the MG14.

3.3.4 Channel 1

MG14 operating manual Rev 1.4

18

The Channel 1 connection is used to connect B-A sensors and EXTRACTOR gauge as well.

Control signals

A 7-pin appliance socket (type Metalock Bantam) is available for channel 1. See Fig. 3-4, item C

Pin assignment:

Fig. 3-6 Channel 1 appliance socket (type Metalock Bantam)

1 Filament 1

2 Filament COM

3 Anode

4 Reflector (Extractor)

5 Not used

6 Filament 2

7 Ground(PE)

DANGER

!

Hazardous voltage.

As soon as the emission is switched on, both appliance plugs carry hazardous levels

of voltage, even if only one measuring system is connected.

The device must be switched off before any work is performed to the sensor or the

measuring line. After switching off, wait approx.15 seconds before starting the work.

Measuring signals

The measuring signals, i.e. the ion currents, of each sensor are transferred via a coaxial cable. See

Fig. 3-4, item A

Pin assignment:

Inner conductor Ion current

Outer conductor Shielding

3.3.5 Channel 2

The Channel 2 connection is used to connect the transmitters.

MG14 operating manual Rev 1.4

19

An 8-pin J-45 female appliance socket is available for each sensor. See Fig. 3-4, item D

Pin assignment

Fig. 3-7 Channel 2 appliance socket (RJ45 )

1 +24VDC supply

2 Supply GND

3 Analog Input

4 n.c.

5 Analog GND

6 ITR emission OK

7 ITR Degas

8 ITR emission ON/OFF

n.c. - not connected

CAUTION

!

Improper transmitter.

Transmitters which are not designed for use with the MG14 may damage the device.

Operate the MG14 with proper transmitters only. See Chapter 2.3.1 Sensor

Connections.

CAUTION

!

Multiple connection.

Only one transmitter may be connected to each of the channels. Otherwise the

connected transmitters will be damaged.

Never connect more than one transmitter per channel.

3.3.6 RELAYS

MG14 operating manual Rev 1.4

20

The switching functions and the error monitoring system influence the states of several relays inside

of the MG14. The RELAY connection (Fig. 3-4, item E) allows to utilize the relay contacts for

switching purposes. The relay contacts are potential-free (floating).

Fig. 3-8 RELAY appliance socket (D-Sub, 9-pin)

1 Trigger 1 common (COM)

2 Trigger 1 (NC)

3 Trigger 1 (NO)

4 Trigger 2 common (COM)

5 Trigger 2 (NO)

6 Trigger 3 common (COM)

7 Trigger 3 (NO)

8 Trigger 4 common (COM)

9 Trigger 4 (NO)

COM common

NC normally closed

NO normally open

3.3.8 Anybus module

User has possibilities to operate the unit via one of the “Anybus”module –for exact type please refer

to the chapter: 2.4.2. For exact module description and the pin assignment please refer to the extra

datasheet which is delivered together with the unit

3.3.9 I/O interface

The I/O connections contains the following signal pins:

•Digital outputs,

•Analogue outputs

This manual suits for next models

1

Table of contents

Other Prevac Controllers manuals

Popular Controllers manuals by other brands

Keating Of Chicago

Keating Of Chicago Silver Edition 8 manual

aerl

aerl CoolMax SRX-R Series Installation and operation manual

gefran

gefran ADV20 series Quick start-up

elsner elektronik

elsner elektronik KNX K4 Technical specifications and installation instructions

Eaton

Eaton CDAE-01/05-I manual

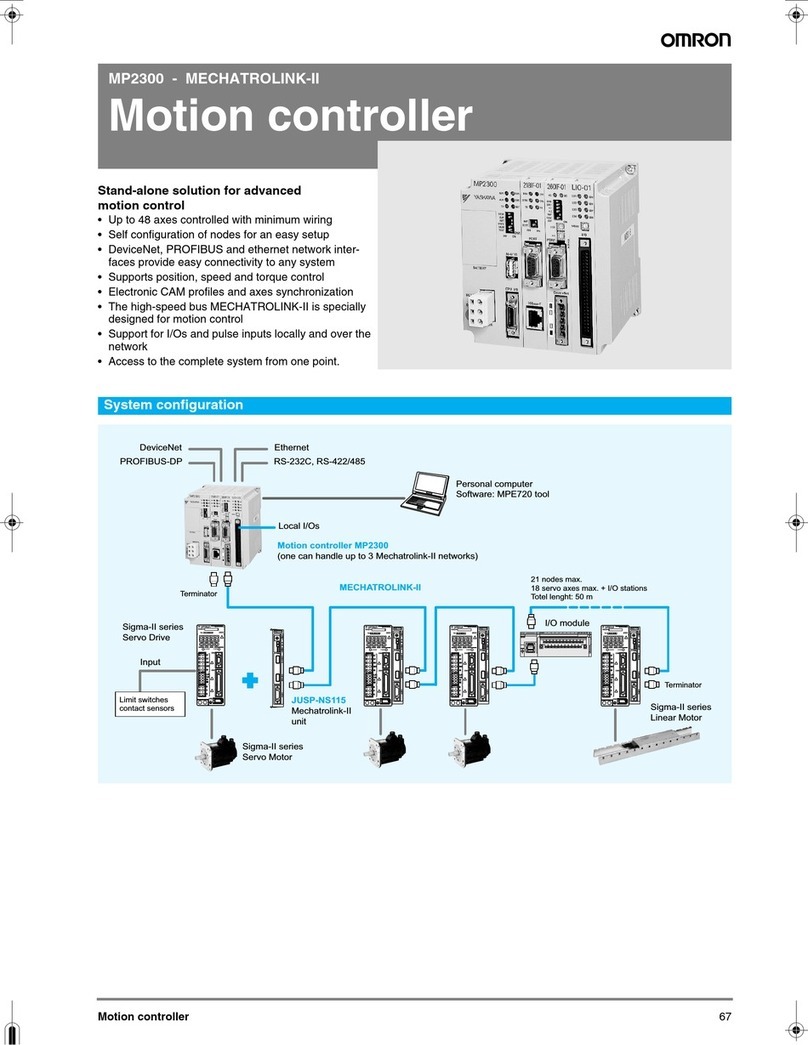

Omron

Omron F3SX-N-L1D1RR2 instruction sheet