Prevac MG15 User manual

USER MANUAL

MG15

MULTI GAUGE CONTROLLER

1

2

OPERATING MANUAL

English translation

MG15

MULTI GAUGE CONTROLLER

Document no. 1068251

Rev. 03

June 2020

Firmware version 1.4

Precision and Vacuum Technology

MULTI GAUGE CONTROLLER Contents

Contents

1 INTRODUCTION 11

1.1 INFORMATION ABOUT VERSION - RELEASE NOTE . . . . . . . . . . . . . . . . . . . . 11

1.2 INTENDEDUSE......................................... 11

1.3 SAFETY ............................................. 11

1.3.1 PERSONNEL QUALIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.2 ILLUSTRATION OF RESIDUAL DANGERS . . . . . . . . . . . . . . . . . . . . . 11

1.3.3 GENERAL SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.4 GROUNDING...................................... 14

1.3.5 INTERNAL CIRCUITS OF DEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3.6 SPARE PARTS AND MODIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3.7 VENTILATION..................................... 14

1.3.8 OPERATION IN EXPLOSIVE ATMOSPHERES . . . . . . . . . . . . . . . . . . . 14

1.3.9 CLEANING ....................................... 14

1.4 TECHNICALDATA ....................................... 15

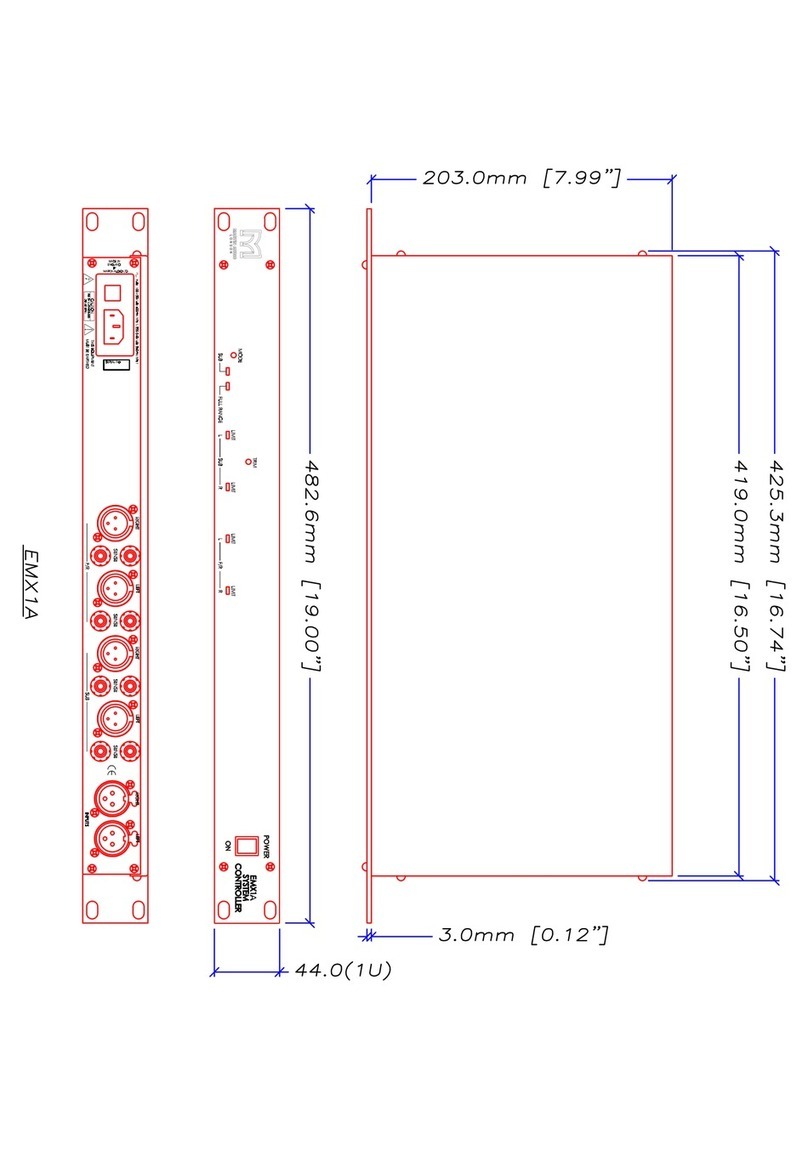

1.4.1 MECHANICALDATA ................................. 15

1.5 SPECIFICATION......................................... 16

1.5.1 TECHNICALDATA................................... 16

1.5.2 OPERATION ...................................... 18

1.5.3 STANDARDS ...................................... 18

2 INSTALLATION 19

2.1 UNPACKING........................................... 19

2.2 MECHANICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3 COOLING ............................................ 20

2.4 ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4.1 POWERSUPPLY.................................... 20

2.4.2 MAINSSWITCH .................................... 21

2.4.3 GROUNDINGTERMINAL............................... 21

2.5 DEVICEREARPANEL ..................................... 22

2.5.1 ACTIVECHANNELS.................................. 24

2.5.2 PASSIVECHANNELS ................................. 25

2.5.3 REMOTECONTROL ................................. 26

2.5.4 I/OINTERFACE .................................... 27

2.5.5 RELAY OUTPUTS CONNECTION (SETPOINTS) . . . . . . . . . . . . . . . . . . 28

2.5.6 ADDRESSDIPSWITCH................................ 29

3 OPERATION 31

3.1 SWITCHINGONTHEDEVICE................................. 31

3.2 FRONTPANEL-STANDARD ................................. 31

3.2.1 DISPLAY WITH TOUCH PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.2.2 USBPORTCONNECTOR ............................... 32

3.3 FRONTPANEL-BLACKBOX ................................. 33

3.4 USERINTERFACE ....................................... 34

3.4.1 MAINWINDOW.................................... 35

3.4.2 CHARTWINDOW ................................... 39

3.4.3 TIMERWINDOW ................................... 43

3.4.4 NUMERICKEYPAD .................................. 44

User manual rev. 03 Page 5

Contents MULTI GAUGE CONTROLLER

3.4.5 ALPHANUMERICKEYPAD.............................. 46

3.4.6 SETUPMENU ..................................... 47

3.4.7 SETUPSHORTCUTS.................................. 48

3.4.8 MESSAGES....................................... 49

3.4.9 VIDEOPLAYER .................................... 50

3.5 SETUPMENU.......................................... 54

3.6 MENUTREE........................................... 54

3.6.1 GAUGE CONFIGURATION - SENSOR MENU . . . . . . . . . . . . . . . . . . . . 60

3.6.2 DEGASSING ...................................... 65

3.6.3 EMISSION CONTROL - EMISSION CONTROL MENU . . . . . . . . . . . . . . . 65

3.6.4 READINGS CORRECTION OF GAS TYPE - GAS TYPE MENU . . . . . . . . . . . 66

3.6.5 FILTER ......................................... 68

3.6.6 FLUXMONITOR.................................... 68

3.6.7 CHANGING NUMBER OF DISPLAYED CHANNELS - DISPLAYED CHANNELS

MENU.......................................... 68

3.6.8 CHANGING CHANNEL NAMES - CHANNEL NAMES MENU . . . . . . . . . . . 68

3.6.9 OUTPUTSSETTINGS ................................. 68

3.6.10TREND ......................................... 70

3.6.11DEVICESETTINGS .................................. 70

3.6.12 SAVING/LOADING SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.6.13INFORMATIONMENU ................................ 73

3.6.14LOGSMENU ...................................... 73

3.6.15REBOOT ........................................ 73

4 STEP BY STEP 74

4.1 QUICKSTART.......................................... 74

4.2 COMMUNICATION INTERFACE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . 74

4.3 LANGUAGESELECTION.................................... 75

5 TROUBLESHOOTING 76

5.1 NOTIFICATIONS IN PRESSURE VALUE/INBFORMATION BOX . . . . . . . . . . . . . . 76

5.2 MESSAGEBARNOTIFICATIONS ............................... 78

5.2.1 ERRORS......................................... 78

5.2.2 5.2.2WARNINGS ................................... 78

5.3 5.3 NOTIFICATIONS IN MESSAGE BOX . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6 COMMUNICATION 81

6.1 INTRODUCTION ........................................ 81

6.1.1 CABLESELECTION .................................. 81

6.1.2 PRECAUTIONS..................................... 82

6.1.3 GROUNDING...................................... 83

6.2 REMOTEENABLEMODE ................................... 83

6.3 COMMUNICATIONINTERFACES............................... 84

6.3.1 RS232/RS485 CONNECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.3.2 ETHERNETCONNECTOR .............................. 85

6.3.3 PROFINET CONNECTOR (OPTION) . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.4 MODBUSPROTOCOL ..................................... 87

6.4.1 INTRODUCTION.................................... 87

6.4.2 INTERFACE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.4.3 MODBUSRTU ..................................... 89

6.4.4 MODBUSTCP ..................................... 93

6.4.5 FUNCTIONCODES .................................. 95

Page 6 User manual rev. 03

MULTI GAUGE CONTROLLER Contents

6.4.6 RESPONSE IN CASE OF ERROR . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.4.7 TYPE OF DATA USED IN COMMUNICATION . . . . . . . . . . . . . . . . . . . . 98

6.4.8 TABLE OF MODBUS VARIABLES - MAP OF REGISTERS . . . . . . . . . . . . . 100

7 MAINTENANCE AND SERVICE 110

7.1 MAINTENANCE......................................... 110

7.2 CLEANING............................................ 110

7.3 FIRMWAREUPGRADE..................................... 110

7.3.1 AUTOUPDATE..................................... 115

7.4 PREBOOTENVIRONMENT .................................. 116

7.4.1 BOOTMENU...................................... 117

7.4.2 TOOLSMENU ..................................... 118

7.4.3 NETWORKTAB .................................... 119

7.4.4 TESTTAB........................................ 119

8 STORAGE AND DISPOSAL 120

8.1 PACKING............................................. 120

8.2 STORAGE ............................................ 120

8.3 DISPOSAL............................................ 120

9 APPENDIX 121

9.1 DIPSWITCHADDRESSING .................................. 121

User manual rev. 03 Page 7

List of Tables MULTI GAUGE CONTROLLER

List of Tables

1.1 Devicespeciication ...................................... 17

2.1 Description of pins of active channel socket. . . . . . . . . . . . . . . . . . . . . . . . . 24

2.2 Description of pins of passive channel socket . . . . . . . . . . . . . . . . . . . . . . . 25

2.3 Description of pins of I/O connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.4 Description of Setpoints connector pins . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.5 Weight of individual switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.6 DIPswitchesfunctions .................................... 29

2.7 Interfaceselection....................................... 30

2.8 DIPswitchesfunctions .................................... 30

2.9 Interfaceselection....................................... 30

3.1 Identifying resistances for supported gauges . . . . . . . . . . . . . . . . . . . . . . . 63

3.2 Correction factors for Bayard Alpert gaugest . . . . . . . . . . . . . . . . . . . . . . . 66

3.3 Correction factors for Bayard Alpert gauges not implemented in the device . . . . . 67

5.1 Notiications in pressure value/information box. . . . . . . . . . . . . . . . . . . . . . 78

6.1 Pins description of ”RS232/RS485” connector . . . . . . . . . . . . . . . . . . . . . . 84

6.2 Pins description of ”ETH” connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.3 Pins description of ”PROFINET” connector . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.4 EIAStandard .......................................... 89

6.5 Connectionparameters.................................... 90

6.6 ModbusRTUframeformat .................................. 90

6.7 ModbusTCPframeformat .................................. 94

6.8 Modbus protocol function codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.9 Erroscodes........................................... 98

6.10 Float IEEE-754 format in Modbus table . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.11 Example loat IEEE-754 value in Modbus table . . . . . . . . . . . . . . . . . . . . . . 99

6.12 Basic registers table ..................................... 104

6.13 Communication registers map ............................... 104

6.14 Digital outputs registers map ............................... 105

6.15 Analogue outputs register map .............................. 105

6.16 Additional registers map .................................. 106

6.17 Vacuum gauge types ..................................... 106

6.18 Vacuum gauges possible statuses ............................. 107

6.19 Emission control options .................................. 107

6.20 Gas types ............................................ 108

6.21 Setpoints source assignment options .......................... 108

6.22 Digital outputs assignment options ........................... 108

6.23 Analogue outputs assignment options .......................... 109

6.24 Analogue outputs modes options ............................. 109

6.25 Analogue outputs scales options ............................. 109

8.1 Storageparameters ...................................... 120

9.1 DIPSwitchAddressing .................................... 122

Page 8 User manual rev. 03

MULTI GAUGE CONTROLLER List of Figures

List of Figures

1.1 Make sure that no objects enter through the vent holes of the device. Keep the device

dry................................................. 13

1.2 Dimensions........................................... 15

2.1 Three-conductor cable with protective ground and mains connection . . . . . . . . . 20

2.2 View of the rear panel of the standard MG15 . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3 View of the rear panel of the MG15 with optional PROFINET interface. . . . . . . . . 23

2.4 Active channel socket (RJ45) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5 Passive channel socket (UTG-type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.6 Modbus RTU and TCP remote control module . . . . . . . . . . . . . . . . . . . . . . . 26

2.7 ProiNet remote control module (option) . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.8 I/O socket (D-sub HD 15-pin female) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.9 Setpoints socket (D-Sub 25 female) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.10AddressDIPSwitch ...................................... 29

3.1 Frontpanel ........................................... 31

3.2 Front panel in BlackBox version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3 Three main device windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4 Description of main window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5 Description of main window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.6 Description of single vacuum channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.7 Setpointsbehaviour...................................... 36

3.8 Setpointssettings ....................................... 37

3.9 Gaugechange.......................................... 37

3.10Pressureunitchange ..................................... 38

3.11 Enlargement of pressure value window . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.12Chartmodule.......................................... 39

3.13 Adding data series and editing chart parameters . . . . . . . . . . . . . . . . . . . . . 39

3.14 View of selected fragment of chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.15Changeofchartunits ..................................... 41

3.16 Notiication about detecting USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.17 USB menu - chart data saving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.18Chartactivationmenu..................................... 42

3.19 Correct activation of chart module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.20Enteringsystemdate ..................................... 43

3.21Timersetting.......................................... 43

3.22Numerickeypad ........................................ 44

3.23 Increasing/Decreasing value via numeric keypad . . . . . . . . . . . . . . . . . . . . . 45

3.24 Number in exponential form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.25Alphanumerickeypad..................................... 46

3.26Devicesetup .......................................... 47

3.27 Set up shortcut in the setup menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.28Exampleuseofshortcut.................................... 48

3.29 Example warning and error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.30Warningmessage ....................................... 49

3.31Errormessage ......................................... 50

3.32Multiplemessages....................................... 50

User manual rev. 03 Page 9

List of Figures MULTI GAUGE CONTROLLER

3.33Menubar-videoplayer.................................... 51

3.34Videoplayer-menu...................................... 51

3.35Deletingavideoile ...................................... 52

3.36Videoplayer........................................... 52

3.37 Notiication about detecting USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.38 USB menu - list of videos on USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

3.39Copy*.avitodevice ...................................... 53

3.40BayardAlpertGauge...................................... 62

4.1 Communication interface coniguration . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.2 Languageselection....................................... 75

6.1 Example of 3-conductor (+ screen) EIA485 connection . . . . . . . . . . . . . . . . . 82

6.2 Maintaining communication - sequence diagram . . . . . . . . . . . . . . . . . . . . . 83

6.3 Female socket of RS232/RS485 (Modbus RTU) interface . . . . . . . . . . . . . . . . 84

6.4 Female socket of Ethernet 10baseT (Modbus TCP) interface . . . . . . . . . . . . . . 85

6.5 Female socket of ProiNet (Modbus RTU) interface . . . . . . . . . . . . . . . . . . . . 86

6.6 Modbus RTU network structures model . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6.7 Checksum calculation algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.1 USBdetectedhint ....................................... 111

7.2 USBmenu............................................ 112

7.3 Firmwarelist.......................................... 112

7.4 Restartmessage ........................................ 113

7.5 Updatingirmware....................................... 113

7.6 Updatesummaryexample .................................. 114

7.7 Autoupdate1.......................................... 115

7.8 Autoupdate2.......................................... 115

7.9 Enter into preboot environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.10Bootmenu ........................................... 117

7.11Switchsoftwareversion.................................... 117

7.12 Message box conirming the changed settings . . . . . . . . . . . . . . . . . . . . . . . 117

7.13Toolsmenu ........................................... 118

7.14Selectingadditionaltool.................................... 118

7.15Networktab........................................... 119

7.16Numericpanel ......................................... 119

7.17Testtab ............................................. 119

Page 10 User manual rev. 03

MULTI GAUGE CONTROLLER INTRODUCTION

1 INTRODUCTION

Please read this manual carefully to ensure the optimum operating conditions and safety of the

user. This user manual handbook contains important information about functionality, installation,

start-up and operation of the MG15 device.

1.1 INFORMATION ABOUT VERSION - RELEASE NOTE

Information about MG15 device version can be found at www.prevac.eu, in the DOWNLOAD tab.

There is information about any possible changes in subsequent versions of the device or software.

1.2 INTENDED USE

The MG15 multi gauge controller is a universal devices controlled by a microprocessor, able to sup-

port several types of pressure gauges in a range of 2 ⋅ 10mbar to 2 ⋅ 10mbar (depending on the

gauge used). The concept and design of the controller enable stable and reliable integration of the

comprehensive process control systems. The MG15 is able to support up to seven gauges, includ-

ing up to three passive and four active gauges. Optionally, the user may on placing an order choose

the number of supported passive (with hot cathode) and an additional communication interface

(ProiNet). In further part of the manual the device will be referred to as the ”MG15”.

1.3 SAFETY

The owner of the device must ensure that all the users have been informed about the safety require-

ments contained in this manual. In the event of sale or transfer of the device to another owner this

manual should be attached.

1.3.1 PERSONNEL QUALIFICATIONS

All work described in this document may only be carried out by persons who have suitable technical

training and the necessary experience or who have been instructed by the inal user of the device.

1.3.2 ILLUSTRATION OF RESIDUAL DANGERS

This user manual illustrates safety notes concerning dangers as follows:

1. Information on potential serious accident or personal injury.

User manual rev. 03 Page 11

INTRODUCTION MULTI GAUGE CONTROLLER

2. Information on possible damage to the device.

3. Information on correct handling or use. Disregarding safety notes can lead to malfunctions

or device damage.

4. Note. Indicates particularly important, but not safety-relevant information.

1.3.3 GENERAL SAFETY INSTRUCTIONS

The MG15 has been designed to maximally protect the user and his environment against burns or

electric shocks, mechanical hazards, high temperature and ire spreading out of the device. The

environmental conditions different from those speciied below may pose a threat to the user and

his environment:

• Use inside buildings.

• Elevation above sea level of up to 2000 metres.

• Temperature range of safe operation: 5°C do 40°C.

• Maximum relative humidity: 80% (to 31°C), decreased linearly down to max. 50% at 40°C.

• Fluctuations of supply voltage cannot exceed ±10% of the rated value.

• Protection class 1.

During all the operations carried out with the use of the device described in this manual, observe

the applicable safety regulations. Observe all the safety notes given in this document and forward

the information to all other users of the device. Pay particular attention to the following safety

notes:

Supply voltage.

Contact with live parts is extremely hazardous when any objects are introduced

or any liquids penetrate into the device.

Make sure that no objects enter through the vent holes of the device. Keep the

device dry.

Page 12 User manual rev. 03

MULTI GAUGE CONTROLLER INTRODUCTION

Fire of device.

If smoke or lames coming from the device are sighted, disconnect power sup-

ply immediately (by unplugging the power cord, or if it is not possible by dis-

connecting a relevant circuit in the switchboard powering the device). Remove

lammable materials at a safe distance. Start extinguishing the ire. If the power

supply could not be disconnected use only E-type extinguishers or dry-powder

extinguishers designed to extinguish equipment under voltage.

Improper installation, operation or use.

Improper installation, operation or use may damage the MG15 . Strictly adhere

to the stipulated installation and operation data.

Self-coniguration of the device.

Self-coniguration of the MG15 by the user through the service application re-

sults in waiver of the PREVAC’s liability for proper functioning of the device.

Figure 1.1: Make sure that no objects enter through the vent holes of the device. Keep the device

dry.

Failure to observe the general safety instructions may result in potentially dangerous situa-

tions.

User manual rev. 03 Page 13

INTRODUCTION MULTI GAUGE CONTROLLER

1.3.4 GROUNDING

The MG15 is the class 1 device. To minimize a risk of electric shock connect the device to the mains

with a 3-conductor mains cable. Conductor cross-section should be min. 1 mm2 (17AWG). Plug the

mains cable into wall sockets with protective ground only.

1.3.5 INTERNAL CIRCUITS OF DEVICE

The operating personnel cannot remove the device covers. The device does not contain any inter-

nal control systems and replaceable elements, which could be operated by unauthorized persons.

Replace any attached components only after disconnecting the mains cable. To avoid electric shock

always disconnect the mains cable, any external voltage sources and discharge the output circuits.

1.3.6 SPARE PARTS AND MODIFICATIONS

Replacement of spare parts, modiications and repairs may be carried out only by the PREVAC’s

authorized personnel. Therefore, the device must be delivered to the PREVAC’s service.

1.3.7 VENTILATION

The device has vent holes located on the side panels of the enclosure. Do not cover the vent holes

during the operation of the device.

1.3.8 OPERATION IN EXPLOSIVE ATMOSPHERES

Operation in explosive atmospheres.

The device cannot be used in the presence of lammable gases or vapours. The

device cannot be used in potentially explosive atmospheres.

1.3.9 CLEANING

Keep the device dry. For cleaning device’s enclosure, use only moistened cloth. Do not use any

aggressive or abrasive cleaning agents.

Page 14 User manual rev. 03

INTRODUCTION MULTI GAUGE CONTROLLER

1.5 SPECIFICATION

1.5.1 TECHNICAL DATA

PARAMETER DESCRIPTION

ELECTRICAL PARAMETERS

Power supply 100-240 VAC

Frequency 50 - 60 Hz

Current consumption 1.8A (110V)

0.85A (230V)

Maximum power consumption 200 W

Protection class I

Overvoltage category II

Power supply connection socket European connection socket IEC 60 320 C13

Fuse 3.15A (250V)

6.3A (125V)

MEASUREMENT CHANNELS

Measurement channels 4 active channels

up to 3* passive channels

Supported active gauges** CTR90, TTR91, TTR211, PTR225,

PKR251/360/361, PCR280, TPR280/281, PTR90,

ITR90, ITR100, Baratron, ANALOG IN, PG105,

ATMION, IKR360/361

Supported passive gauges** IE414, IE514, UHV-24, UHV-24p, MKS Series 274,

NUDE-UHV-8A, NR-F-UHV, G8130, BARION basic II

MEASUREMENT RANGE

Active gauges 5x10mbar (depending on type)

Passive gauges 2x12mbar (depending on type)

VOLTAGE MEASUREMENT SPECIFICATION

Resolution of converter 0.6𝜇V

Accuracy of measurement 2𝜇V

Sampling frequency 12 sps

CURRENT MEASUREMENT SPECIFICATION

continued on next page

Page 16 User manual rev. 03

MULTI GAUGE CONTROLLER INTRODUCTION

continued from previous page

PARAMETER DESCRIPTION

Resolution of converter 0.1fA

Accuracy of measurement 3fA***

Sampling frequency 10sps

Screen refreshment 10 sps

Temperature drift Automatically adjusted by internal temperature

control

GAUGE CONNECTION

Active gauge RJ45

Passive gauge UTG0187SVDEU + BNC

COMMUNICATION

Communication interfaces RS232/485, Ethernet, PROFINET*

I/O

Digital inputs 4

Digital outputs 4

Analogue outputs 4 (0-10V)

AMBIENCE

Operating temperature range +5 ºC - +40 ºC

Storage temperature range 0 ºC - +70 ºC

Relative humidity Max. 80% (to 31°C), decreased linearly down to max.

50% (at 40°C)

MECHANICAL PARAMETERS

Dimensions Width: 212.6 mm

Height: 128.4 mm

Depth: 260.3 mm

Weight 4.2 kg

Installation Rack mounted or Desktop device

(*) - optional

(**) - additional gauges can be deined, see section 3.6.1.3 or 3.6.1.5.

(***) - at lowest range (highest vacuum).

Table 1.1: Device speciication

User manual rev. 03 Page 17

INTRODUCTION MULTI GAUGE CONTROLLER

1.5.2 OPERATION

The device can be controlled in two ways:

• Manually on the display with touch panel.

• Remotely via RS232, RS485 or Ethernet, see chapter 6.

1.5.3 STANDARDS

• The MG15 conforms to the following standards and harmonised standards:

–PN-EN 61326-1:2013-06 (EN 61326-1:2013) - Electrical equipment for measurement,

control and laboratory use - EMC requirements - Part 1: General requirements.

–PN-EN 61000-6-4:2008/A1:2012 (EN 61000-6-4:2007/A1:2011) - Electromagnetic com-

patibility (EMC) – Part 6-4: General standards – Emission standard for industrial envi-

ronments.

–PN-EN 61010-1:2011 (EN 61010-1:2010) - Safety requirements for electrical equip-

ment for measurement, control and laboratory use - Part 1: General requirements.

–PN-EN 50581:2012 EN 50581:2012 - Technical documentation for the assessment of

electrical and electronic products with respect to the restriction of hazardous substances.

• Conforms to the essential requirements of the following directives

–EMC 2014/30/EU - Directive 2014/30/EU of the European Parliament and of the Coun-

cil of 26 February 2014 on the harmonisation of the laws of the Member States relating

to electromagnetic compatibility.

–LVD 2014/35/EU - Directive 2014/35/EU of the European Parliament and of the Council

of 26 February 2014 on the harmonisation of the laws of the Member States relating

to the making available on the market of electrical equipment designed for use within

certain voltage limits.

–RoHS 2011/65/UE - Directive 2011/65/EU of the European Parliament and of the Coun-

cil of 8 June 2011 on the restriction of the use of certain hazardous substances in elec-

trical and electronic equipment Text with EEA relevance.

–WEEE 2012/19/UE - Directive 2012/19/EU of the European Parliament and of the Coun-

cil of 4 July 2012 on waste electrical and electronic equipment (WEEE) Text with EEA

relevance.

Page 18 User manual rev. 03

MULTI GAUGE CONTROLLER INSTALLATION

2 INSTALLATION

This chapter describes the procedures for unpacking, mechanical installation and electrical instal-

lation. Take care when lifting the unit that the weight and position do not exceed comfortable limits.

2.1 UNPACKING

1. Visually inspect the transport packaging for signs of external damage.

2. Unpack the MG15 .

Note: Retain the packaging materials for later use. The MG15 must be stored and trans-

ported in the original packaging material only.

3. Examine the MG15 for completeness.

4. Visually inspect the MG15 for signs of damage.

Damaged product.

Using the destroyed or damaged device or connection cables can result in elec-

tric shock. Never attempt to put a damaged product into operation. Secure

the damaged product from unintended operation. Send a damage report to the

courier company or the insurer.

2.2 MECHANICAL INSTALLATION

The MG15 device can be mounted in a DIN 41 494 (19”, 3 HU) cabinet/rack, occupying half of its

width. In each of these cases you must pay attention to the following safety note.

Ambient temperature.

Exceeding the maximum permitted ambient temperature may damage the de-

vice.

Before switching on the device, make sure that the maximum permitted ambi-

ent temperature is not exceeded and that the air can low freely through the

vent holes.

Do not expose the device to direct sun.

User manual rev. 03 Page 19

INSTALLATION MULTI GAUGE CONTROLLER

Protection class of the rack.

If the product is installed in a rack, the protection class of the rack (protection

from foreign bodies and water) is likely to be lowered, e.g. according to the EN

60204-1 regulations for switching cabinets.

Take appropriate measures to restore the required protection class of the rack.

2.3 COOLING

The MG15 is equipped with a cooling system. The power unit is equipped with a suction fan. Air is

supplied from the panels located by the power unit enclosure. Hot air outlet is located on the rear

panel. At least 15mm should be ensured to let air get inside from the side panels. The MG15 should

not be operated at temperatures exceeding 40°C.

2.4 ELECTRICAL INSTALLATION

2.4.1 POWER SUPPLY

The main mains connection is an IEC 320 socket on the rear wall of the device. The MG15 enclosure

is grounded to protect the user against electric shock. Always connect the device to a socket with

protective ground. If necessary, contact an electrician before connecting the device. A suitable

mains cable is supplied with the device. If the plug is not compatible with the socket, use a suitable

mains cable:

• Three-conductor cable with protective ground.

• Conductor cross-section should be min. 1mm(17AWG).

Figure 2.1: Three-conductor cable with protective ground and mains connection

Page 20 User manual rev. 03

Other manuals for MG15

1

Table of contents

Other Prevac Controllers manuals

Popular Controllers manuals by other brands

Keating Of Chicago

Keating Of Chicago Silver Edition 8 manual

aerl

aerl CoolMax SRX-R Series Installation and operation manual

gefran

gefran ADV20 series Quick start-up

elsner elektronik

elsner elektronik KNX K4 Technical specifications and installation instructions

Eaton

Eaton CDAE-01/05-I manual

Omron

Omron F3SX-N-L1D1RR2 instruction sheet