4

Manual Version 1.1 07.11.2019

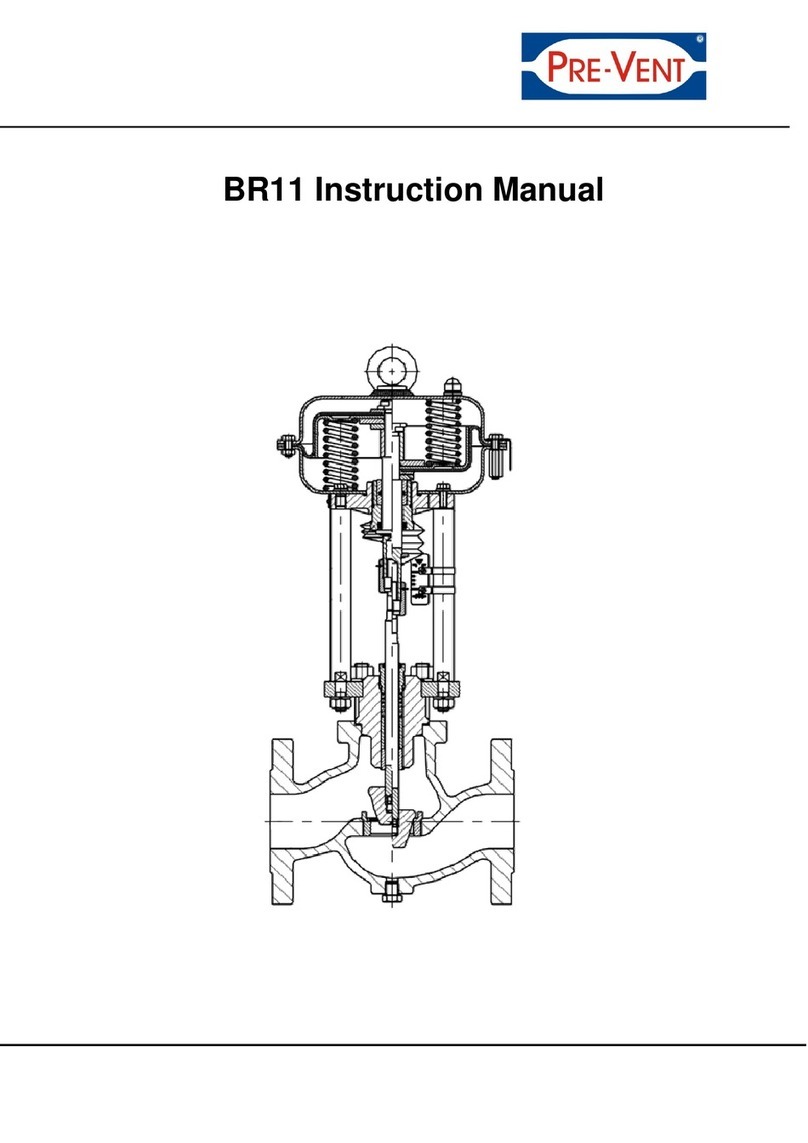

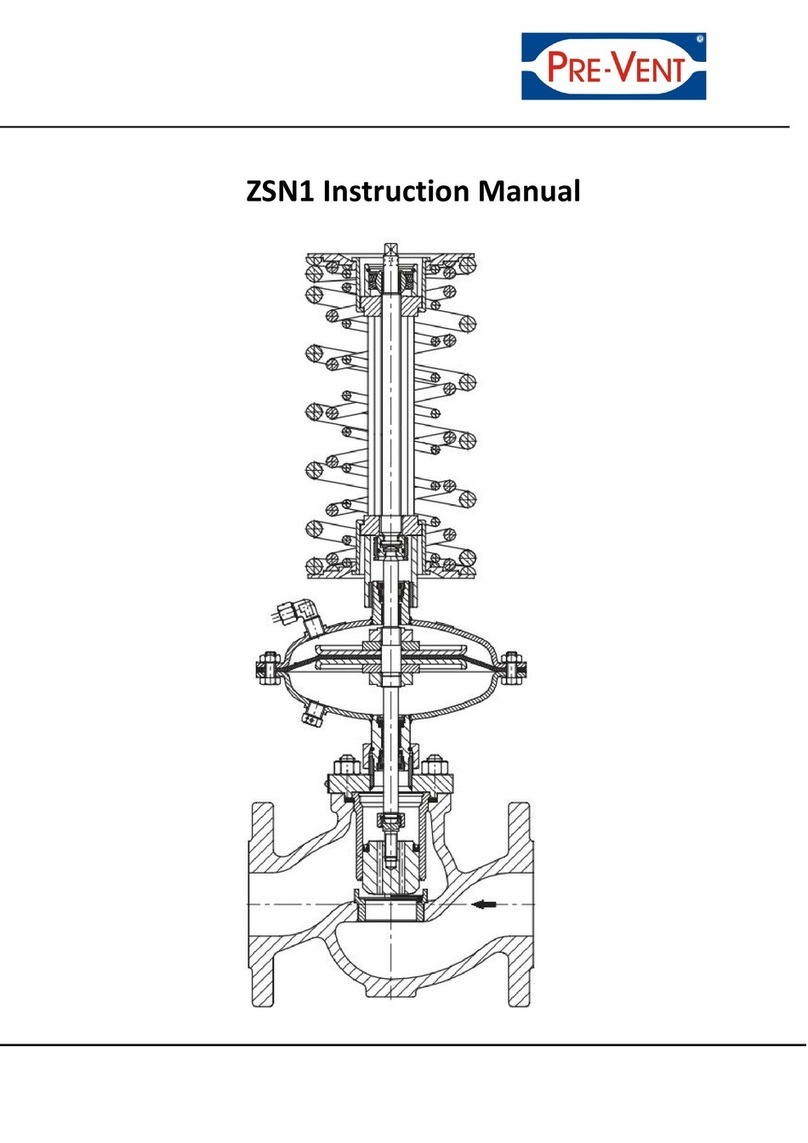

4. OPERABILITY, MAINTENANCE AND REPAIR

The operability of the regulator valve during use is based on maintaining an appropriate flow characteristic and not

exceeding the permitted leakage level for the valve

To ensure long-term correct and safe operation of the valve, it is essential to carry out regular recorded inspections. Valves

that operate continuously should be checked at least every 6 months. Valves that operate discontinuously should be

checked at least every 12 months.

If it is necessary to carry out maintenance or repair work on the regulator valve, it should be carried out as follows:

A key criterion for operability is external seal-tightness, which is provided by the gland packing.

The gland packing to be used is normally pre-specified based on the operating conditions.

With normal gland packing, the tightness of the seal is achieved by tightening the sealing nut.

WARNING:

When the valve is supplied, the sealing nut is only hand-tightened. Before putting the valve into service, it is

essential to tighten the sealing sufficiently to achieve an adequate contact pressure, thus ensuring a secure

external seal, but without blocking the valve spindle.

If self-adjusting sealing glands are used, the constant contact pressure is provided by a stainless steel spring. For this

reason, the sealing nut should be screwed in up to the stop.

4.1 Valve dismantling

For dismantling and cleaning the valve during periodical inspection carry out every time the following operations:

a) disconnect the conduit with actuator input signal and if it is necessary dismount the valve from the pipe. In case of

pneumatic actuator with positioner disconnect signal and supply

b)

Disconnect the plug stem from the stem of the actuator or driver in the following mode:

- In valves with pneumatic actuators or manual drives by unscrewing the union nut (27), having the low counter nut (28)

loosen first

- In valves with electric actuators by screwing out the valve stem from the connector by stem-plug unit rotating. Prior to

dismantling the actuator from the bellow bonnet, loosen up the screw plug (19) and nuts (62). While disconneting the stems,

pay special attention as not to overtighten the bellow

c) Unscrew nut (12) which fasten the actuator or manual driver and than disconnect it from the connecting plate

d) Unscrew nuts (9) and dismount bonnet with steam and plug

e) Clean the valve seat and valve plug sealing faces and clean inside the valve body

f) make sure that the valve seat sealing face (2) and valve plug face (4) ,the valve plug guide face and Stem guide face and

body gasket (6) are in satisfactory condition