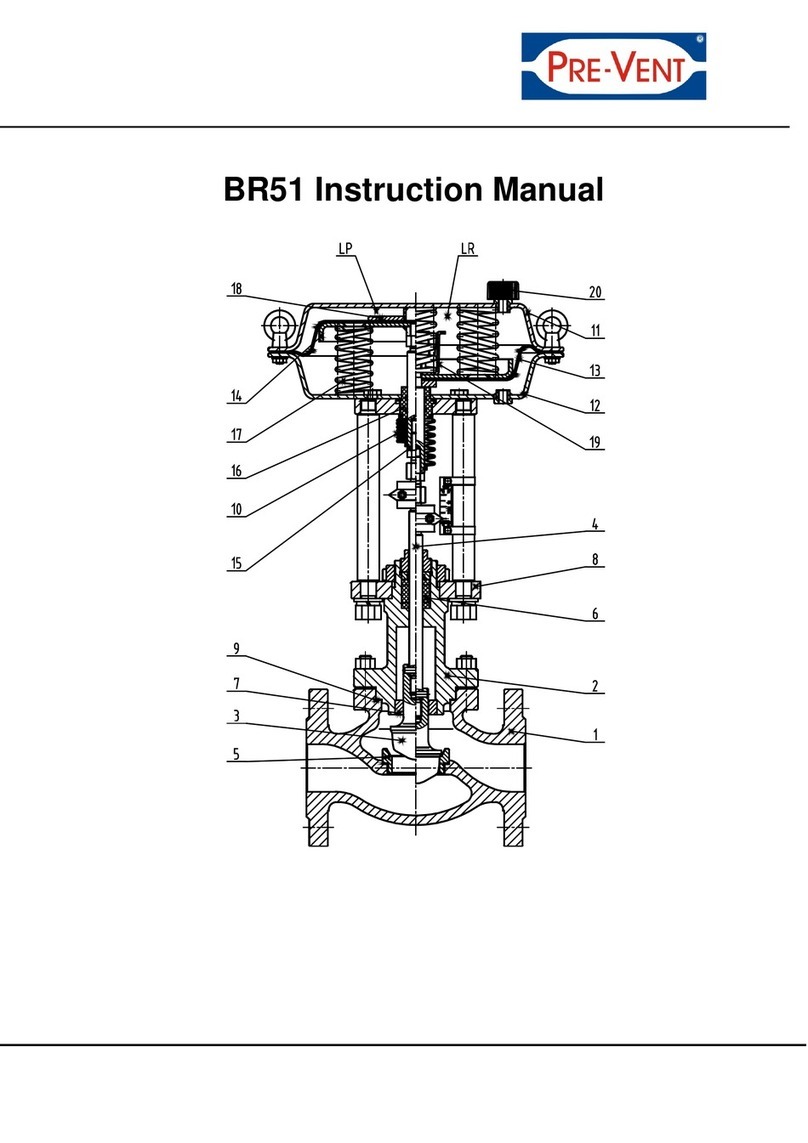

7

7. MAINTANANCE AND REPAIR

As long as the warranty is not expired it is admissible only to adjust the springs' tension and eliminate diaphragm leakages

(29) by tightening actuator's (02) housing bolts.

Repair and maintenance service include:

- replacing the soft seat (2b)

- replacing the plug gasket (7)

- replacing the actuator's diaphragm (29) and stem sealing (33, 35).

7.1 REPLACING THE SOFT SEAT.

If the soft seat occurs to be leaky, proceed as follows:

a) shut off the fluid flow

b) close the shut off valve (24) and remove the connection pipe from the actuator unit

c) remove nuts (11) that fasten the pressing plate (3) and valve body (1)

d) Remove the actuator with the adjuster, the pressing plate (3) and the plug (5)

e) Remove the guiding sleeve (4) from the valve body (1)

f) Unscrew the seat using special seat wrench. Clean thoroughly the thread and areas where valve body contacts the seat.

g) Sealing/antiseizing compound (e.g. LOCTITE 767) should be applied to the threads prior to screwing the seat.

To reassemble, proceed in the reverse order. It is necessary to replace the bodygasket (9).

7.2 REPLACING THE BALANCED PLUG GASKET (7)

If it is necessary to replace the gasket of balanced plug, proceed as follows:

a) Follow the 7.1 a,b,c,d,e

b) Lift the connector (6) with plug until perpendicularly to the stem (37). Split stem and connector.

c) Unscrew the plug (5) form the connector (6).

d) Remove plug gasket (7) and put a new one.

To reassemble, proceed in the reverse order. Keep the same connection length for connector (6) and plug (5) as it was

before disassembling. Replace the body gasket (9).

7.3 REPLACING ACTUATOR'S DIAPHRAGM AND STEM SEALING.

If it is necessary to replace actuator's diaphragm (29) or/and stem sealing (33,35)of the actuator's stem (37), proceed as

follows:

a) Shut off the fluid flow remove the connection pipe.

b) Unfasten the adjuster's (03) screw, spring tension should be set at minimal level.

c) Unscrew both spring unit (60, 61, 62) and the screw (68) simultaneously to remove adjuster unit (03).

d) To separate actuator's stem (37) and screw (68) move sleeve (59) towards actuator and disconnect connector (58) and

ring (63).

e) Unscrew nut (31)

f) Unscrew nuts (11) and remove actuator unit (02) with all housing and plug (5) from the valve (01)

g) Lift the connector (6) with plug until perpendicularly to the stem (37). Split stem and connector.

h) Unscrew nuts (39) and disassemble bottom (18) and top actuator's housing.

i) Unscrew nut (26) and remove diaphragm plate (28) and used diaphragm (29).

j) Unbolt screw plug (32) and renew stem sealing (33, 35).

To reassemble, proceed in the reverse order. Renew gasket (9). Apply threadlocker (e.g. LOCTITE 243) to threaded

connection between adjuster and actuator units. Apply silicon based sealing compound UNISILIKON L50/ 2 to actuator's

stem, plug and guiding face of regulating screw. Apply antiseize LOCTITE 767 compound to thread of regulating screw.