Priefert RC22M User manual

www.priefert.com 800-527-8616

Roping Chute

MODEL RC22M & RC22AI

Operator’s Manual

Safety related warnings and instructions follow this Alert Symbol and are used to get your attention so

you may avoid serious injury or death to you and others. Read the Operator’s Manual in it’s entirety!

OPMAN-RC22AI_v1a-0523

OPMAN-RC22AI_v1a-0523ii

Congratulations on choosing “Priefert’s RC22

or RC22AI Remote Controlled Roping Chute.”

Priefert Roping Chutes simply dominate the market. Their smooth action,

durability, and proven performance has made them the obvious choice

for competition and practice arenas across the country.

Priefert Roping Chutes are the ocial chute of the PRCA, USTRC,

NTRL, WTRC, PTR, the World Series of Roping and many other major

roping organizations.

Priefert’s roping chutes are the most widely used roping chutes in the

country. The RC22 is the quietest, most advanced chute in the Priefert

line. It’s ingenious design will provide years of dependable service with

virtually no maintenance, at an aordable price.

Priefert products are used and tested in our manufacturing facility and on

the Priefert Ranch. The Priefert family personally tests and uses every

product they build before sharing it with their friends around the world

REMEMBER SAFETY FIRST!

Be Alert - Eliminate unsafe habits and risky behavior,

recognize hazards as they exist and read and follow these

Operational Instructions to successfully operate the

Priefert Steer Roping Chute.

READ AND UNDERSTAND THESE INSTRUCTIONS

BEFORE OPERATING.

Follow all safety warnings and recommendations.

FCC Compliance Statement:

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:2

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference

that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment o and

on, the user is encouraged to try to correct the interference by one or more of

the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit dierent from that to which

the receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

Using this manual:

These Operating Instructions are a compilation of engineering data

and eld experience, and are designed to help you with proper safety,

operation and adjustments. Read these instructions completely prior to

using this roping chute, and follow the recommendations to help ensure

safe and ecient operation.

The information contained herein was current at the time of printing.

Your model may vary in design and conguration from those shown in

this manual. There is a possibility that some illustrations in our manuals

were of prototype models. Design of production models may vary in

detail from those shown in our manuals.

Priefert Manufacturing maintains an ongoing program of continuous

product improvement. Therefore, Priefert reserves the right to make

improvements or modications in design, or specication changes without

incurring any obligation to replace said items on units previously sold.

Your RC22M, or RC22AI Remote Controlled Roping Chute, has this

manual available online in PDF format, as well as multiple online

videos designed to assist you in achieving optimal results with your

Roping Chute.

Terminology

“Right” or “Left” as used in this manual is determined by facing forward

in the direction the equipment will operate while in use unless otherwise

stated.

“NOTE:” provides the operator a brief summary of information that will

assist in operating the equipment.

“IMPORTANT:” denotes that the following content has signicance in the

operation or maintenance of the equipment.

“REMINDER:” provides information previously addressed, but important

enough to address again for equipment or assembly familiarization.

Owner Assistance

If customer service or repair parts are required, contact Priefert

Manufacturing to reach our trained personnel who will assist you with

repair parts and equipment needed to service your Roping Chute.

The parts on your Roping Chute have been specically designed and

should only be replaced with genuine Priefert parts. Therefore, should

your Priefert Roping Chute require replacement parts, contact our

Support Center.

Customer Service

Priefert Manufacturing wants you to be satised with your new RC22

Roping Chute. If for any reason you are not satised with the equipment,

the following actions are suggested:

Contact your Priefert Ranch Equipment dealer and discuss any

problems that you may be experiencing. Allow them the opportunity to

assist in correcting any problems that you may be experiencing.

For further assistance contact:

Priefert Manufacturing

Attention: Customer Service

2630 South Jeerson

P.O. Box 1540

Mount Pleasant, Texas 75456-1540

1-800-527-8616

Web-site address:

www.priefert.com

sales.priefert.com

OPMAN-RC22AI_v1a-0523 iii

Safety Alert Symbols

The SAFETY ALERT SYMBOL indicates there is a potential

hazard to personal safety involved and extra safety precaution must be

taken. When you see this symbol, be alert and carefully read the message

that follows it. In addition to design and conguration of equipment, hazard

control and accident prevention are dependent upon the awareness,

concern, prudence and proper training of personnel involved in the

operation, transport, maintenance and storage of equipment.

Owner/operator can prevent, and may be responsible for, accidents

or injuries occurring to other people, themselves, and/or property and

equipment.

Thoroughly read and understand the operation, references and other

material supplied with the Roping Chute. If the installer or operator

cannot read English, it is the owner’s responsibility to explain this

material to them.

We strongly recommend that children are not allowed to operate or

play on this equipment. Do not allow untrained people to operate

or service equipment.

Caution

Be familiar with equine activities and handling livestock prior to

use of this equipment. Working with livestock carries inherent risk of

injury or death.

Roping Chute and Equine Safety

Due to the inherent dangers associated with equestrian activities,

many states have adopted statutes pertaining to the liabilities of horse

owners, handlers, and individuals involved in equestrian activities.

Some states also require that you post signs at your facility with the

specic “Warning Law” on them, for personal and/or professional

equine activities. Posting these warning signs may help protect you

and/or your organization in the event an accident or injury does occur.

Please check the legal statute information in your state2.

Horses can be easily spooked and this is when injuries may occur.

One in three horse-related injuries happen when the rider/handler is

dismounted. These injuries typically involve the handler being kicked or

stepped on by the horse. Making sure all equine handlers are aware

of the dangers posed by frightened horses and what actions can scare

them can help prevent injuries. Some examples of things that can spook

a horse include, sudden or unexpected movements; loud or sudden

noises such as mobile phones or horns; other animals (i.e. unleashed

and/or barking dogs) and biting or stinging insects.

Priefert advises that individuals using this roping chute

have knowledge of equine activities, horse riding skills,

and, prior experience and training with cattle roping.

Installation / Operation Safety

• Read and understand the operation instructions completely before

using this equipment. Locate equipment in a dry, level area.

• Make sure any individuals operating this equipment understand the

instructions as well.

• Priefert also recommends wearing personal protective clothing while

setting-up this roping chute, including gloves and safety glasses, as

well as, arm, leg, head and foot protection.

• Allow only trained, qualied individuals to operate forklifts, tractors,

loaders or other vehicles used during installations; and that those

individuals are familiar with the operation of the specic vehicle used

during installations.

• Operate equipment only during fair weather conditions.

• Disconnect electric and/or pneumatic connections before performing

any service or repairs to the equipment. Remove all tools used during

installation from equipment before operation.

Safe Operation Guidelines

• Use caution introducing livestock into the steer chute due to the

inherent danger associated with livestock.

• Do not let children play in or on roping chute or its components.

• Do not allow children to operate roping chute or its components.

• Do not stick arms or legs through the chute rails anytime, especially

when a steer is loaded.

• Make sure all guests or observers are clear of moving components

prior to chute operation.

• Be cautious to prevent being conned between alleys while livestock

is present. Be cautious to prevent being caught between calves and

chute gates.

• Be sure that horses used in roping activities are accustomed to the

actions of the roping chute, and handlers are familiar with equine

behavior.

• Wearing proper clothing can help prevent injuries.

• Always take into consideration the age, physical condition and

specic characteristics of calves used to prevent exceeding their

limitations and causing injury.

DANGER: Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury. This signal word is limited

to the most extreme situations, typically for machine components that,

for functional purposes cannot be guarded.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury, and includes hazards

that are exposed when guards are removed. It may also be used to alert

against unsafe practices.

CAUTION: Indicates an imminently hazardous situation, which, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

NOTICE: Indicates failure to observe may cause property or equipment

damage.

NOTE: Provides helpful information to the operator.

BE AWARE OF SIGNAL WORDS: A signal word designates a degree of level of hazard seriousness.

OPMAN-RC22AI_v1a-0523iv

Precautionary Measures

The following are precautionary measures that are recommended to

anyone when working with livestock.

Be alert. It is impossible to fully know or predict an animals actions. Always

be aware of what is happening around you. This is particularly important

when handling livestock at sunrise and sunset when livestock are most

active.

Keep animals together. Livestock will be more calm and cooperative

when in groups. When alone, they quickly become agitated and frightened

making them dangerous and dicult to handle.

Carefully approach animals. Because of the placement of their eyes,

cattle have approximately a 270 degree range of vision. Despite their

range of vision, cattle have poor depth perception, and are unable to see

behind them. To reduce risk, always announce yourself when approaching

an animal.

Leave yourself an out. Never enter small enclosed areas with livestock.

If unavoidable, always be sure there is always a fast and easy method of

escape.

Avoid quick movements and loud noises. Livestock can startle and

frighten easily. Move slowly and deliberately around livestock. Be careful

not to create excess noise.

Be patient. When working with livestock in a crowding pen, chute, or

squeeze, prodding an animal when it has no place to go is dangerous.

Animals can react quickly and violently.

Respect livestock. Do not fear them. Underestimating an animal’s size,

strength, and speed can result in serious injury. Always consider mature

males to be dangerous. Be aware of animals who are sick, injured, or

otherwise frightened.

Livestock Safety2

One of the most important issues for consideration when handling

livestock is safety. Although considered domesticated animals, working

with livestock carries with it an inherent risk of danger. It is important

to understand that livestock have both instincts and habits, known as

behavior patterns, that are based on actions that make them the most

comfortable. These instincts and habits allow them to react to changes in

their environment.

Many instincts and habits are strong and potentially dangerous. Using

common sense, practicing caution, and understanding livestock behavior

can greatly reduce a handlers risk and enable him or her to work safely

with livestock. The following information details some important livestock

behaviors as well as cautionary tips to practice when handling livestock.

Livestock Behaviors2

• Animals who are used to being around other livestock can become

frightened and agitated when separated, becoming dangerous and

dicult to handle.

• The maternal instinct is also very powerful. Many times these instincts

are not evident in an animal’s behavior until shortly after giving birth. It

is important to recognize these behavior patterns and use appropriate

caution.

• Another behavior pattern that livestock may exhibit is a territorial instinct.

Feed time is when this instinct is most readily observable.

• A valuable behavior is the instinct to follow the leader. Often times, all

that is required is to begin one animal moving and the rest will follow.

• Livestock exhibit the most activity at sunrise and sunset. In contrast,

livestock are the most inactive during night and at midday.

• The ight zone is one of the most important principles regarding

livestock behavior and safe handling. It is an animal’s personal space.

Livestock will react in a variety of ways according to a handlers activities

relative to their ight zone. For example, livestock will face a handler

and maintain a safe distance, when the handler is outside their ight

zone. In contrast, livestock will turn away from a handler who enters

their ight zone. Individual animals will have ight zones of varying size.

Working from the edge of the ight zone will generally keep livestock

calm and manageable.

• The point of balance is another important behavioral principle to

understand. An animal’s point of balance is located at their shoulders.

An animal will move depending on a handlers position relative to

their point of balance. This principle can be used to calmly and easily

encourage livestock through crowding pens, chutes, and squeezes. For

example, when a handler stands behind the animal’s point of balance,

the animal will move forward. When the handler stands in front of an

animals point of balance, the animal will stop or back up. To encourage

an animal forward, simply walk towards the animal, crossing the point of

balance, and it will move forward.

Remember that livestock draw upon past experiences and treatment

when reacting to a situation.

Additional information is provided in the Appendix at the

end of this manual.

NOTICE

BEFORE OPERATION

LUBRICATE ALL MOVING

PARTS WITH WD-40

D964

Safety Labels

Your implement comes equipped with all safety labels in place. They were

designed to help you safely operate your Roping Chute.1

1. Read and follow their directions.

2. Keep all safety labels clean and legible.

3. Replace all damaged or missing labels. To order new labels go to your

nearest Priefert Dealer.

4. Some new equipment installed during repair requires safety labels to

be axed to the replaced component as specied by Priefert. When

ordering new components make sure the correct safety labels are

included in the request.

5. Refer to this section for proper label placement.

Applying new labels:

1. Clean the area the label is to be placed.

2. Wipe the surface dry.

3. Peel backing from label.

4. Press rmly onto the surface.

Use a small straight edge plastic (credit card) to squeeze out air bubbles

working from the center out towards the sides.

OPMAN-RC22AI_v1a-0523 v

Congratulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Using this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

FCC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Customer Service Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Alert Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Roping Chute and Equine Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safe Operation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Precautionary Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Livestock Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Manual Roping Chute. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Roping Chute Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Roping Chute Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Upgrade Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Automatic Roping Chute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Roping Chute Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Remote Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Automatic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Delay Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Suggested References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table Of Contents

NOTICE

USE OF LUBRICANTS ON COMPRESSED AIR SYSTEMS

OF THIS CHUTE CAN CAUSE COMPONENT FAILURE!

DO NOT Lubricate Air Cylinder Rods Externally.

DO NOT Lubricate Air System Internally.

DO NOT Clean Components with Solvents.

Read and follow additional notices within this manual

OPMAN-RC22AI_v1a-052302

Manual Roping Chute

Operating Instructions (RC22M)

Roping Chute Hook-Up

The RC22M Roping Chute can attach to almost any steer alley or panel conguration with standard

chain connections. Lubricate all working parts including tailgate before operating the RC.

Use WD-40 or other light lubricant. Heavier oil collects dust and restricts proper operation.

Frequent lubrication will be necessary until excess paint is worn o working parts.

Note: Be aware of specic locations that should not be lubricated.

These locations are noted with decals stating DO NOT OIL. (Noted on Previous Page)

Roping Chute Operation

All of the RC22M controls are accessible from Header or Healer side.

Familiarize yourself with their operation using the illustrations provided below.

Now Available with the RC22AI, RC22Q39, &

RC22SCORE

The RC22 Chutes now work, not only Automatically, but, Manually as

well. This means if an RC22M Manual Chute was initially purchased,

it can be upgraded to a Q39 or an Automatic chute. An RC22AI or

Q39 can be operated manually if power is not available.

In addition, the RC22SCORE can also be operated manually if

power is not available.

Contact Customer Service at 1-800-527-8616 for any questions

about upgrading.

Front Gate Close Handles

Pull Handle back to close spring-

loaded front gate and reset for

next release.

Front Gate Release Handles

Push Handle down to open spring-

loaded front gate and release steer.

Resets automatically.

Tailgate Handles

Pull Handle to open Tailgate and

allow steer to enter chute.

Push Handle to close Tailgate.

Front Gate Brake

The urethane brake system on top front of chute

& springs on each side of the chute are pre-

adjusted at the factory and should not need to be

adjusted until chute has considerable use on it.

RC22AI

OPMAN-RC22AI_v1a-0523 03

Automatic Mode

Using the button on the right rear of the Control Box, the chute can be switched into the “Automatic” mode, where the chute uses an

electronic eye to detect the presence or absence of a steer. A red light will appear. To release the steer, push the “Front / Open” (1) button

on the upper left of the remote control. The headgate opens and a few seconds after detecting that the steer has left, the headgate closes;

the tailgate then opens and upon detection of the next steer having entered the chute, the tailgate closes. One push of a single button

has completed the entire cycle and ropers have the next steer loaded and ready to go upon return to the roping box. To take the chute out

of auto mode, simply push the button again on the back right side of the Control Box.

This chute also oers the operator the option to override the Automatic mode and “score” his horse by opening and closing the tailgate

with the push of buttons (3 & 4). This will not take the chute out of Automatic mode and continues to be a great training tool to keep your

horse from leaving the box at the sound of the chute rather than from a cue from the rider.

Automatic Roping Chute

Operating Instructions (RC22AI)

The Upper buttons of the Remote operate

the Front Gate of the Roping Chute

The Lower buttons of the Remote operate

the Rear Gate of the Roping Chute

Pressing this button will OPEN the

FRONT GATE of the Roping Chute

Pressing this button will CLOSE the

FRONT GATE of the Roping Chute

Pressing this button will OPEN the

REAR GATE of the Roping Chute

Pressing this button will CLOSE the

REAR GATE of the Roping Chute

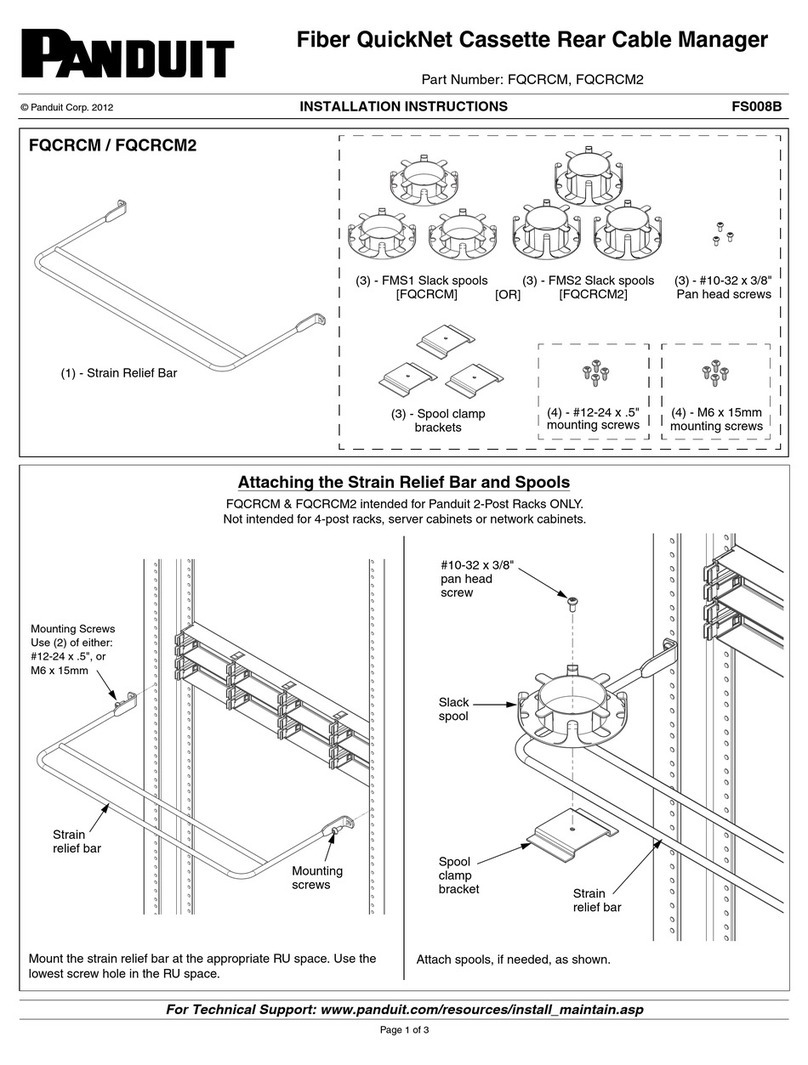

Roping Chute Connections

Step 1: On the back panel of the Automatic Control Box (ACB), is a

standard 1/4” NPT, male, quick-connect air tting marked

“Compressed Air In”. Be sure that this tting is the correct size

for the air line you intend to use. (See Diagram 1)

Step 2: Connect air supply line from compressor to the tting at the back

of ACB. Set regulator on air compressor at 90 psi.

Proper performance requires a minimum of 2hp air compressor

that will produce 3.1 cfm at 90 psi, with a 4 gallon tank.

Step 3: Connect electrical cord to standard 110/125 volt, grounded outlet.

DIAGRAM 1

- Connect Air Supply

(Male, 1/4” NPT Quick-Connect Shown)

NOTICE: Priefert Manufacturing Recommends using a dedicated

Air Compressor to prevent damage of contamination to the

ACB Compressed Air System.

Use Clean & Dry Compressed Air Supply. Drain Compressor &

Air Tanks Daily. Do Not Use Lubricants on Compress Air System

1

2

3

Remote Functions

Delay Setting

Another control feature located on the back left of the Control Box is a “Delay” setting. Just to the right of

the green “on” indicator light is a silver knob used to activate and set the delay timing (See Diagram 4).

Each click clockwise gradually delays the activation of the opening of the headgate from 2-30 seconds.

When no one else is around, this great feature oers ropers improved practice opportunities by allowing

the roper/operator to be fully prepared before the steer is released.

DIAGRAM 4

- Delay Setting

Caution

Be aware of air hose and electric cord layout and arrangement to prevent

trip hazards or entanglement of persons or livestock.

OPMAN-RC22AI_v1a-052304

References

1. American Equestrian Alliance; State Equestrian Liability Limitation Laws; © Copyright, American Recreation & Entertainment Alliance

<https://www.americanequestrian.com/equinelaws/>

2. Jill Webster Ph.D., & Mark Gonzalez; Livestock Safety; Agricultural Systems Technology and Education, Utah State University Extension; Utah

State University , <http://extension.usu.edu/les/publications/factsheet/AHS-11.pdf>

3. SafetySign.com; ANSI_SafetyHeaders, © 1988–2022 Brimar Industries, LLC., < https://www.safetysign.com/docs/ANSI_SafetyHeaders.pdf>

Suggested References

Priefert assumes no liability for the use, claims, or accuracy of information provided in the following references:

Rodeo 101: Team Roping - PRCA

https://www.prorodeo.com/prorodeo/rodeo/rodeo101/team-roping

The Team Roping Journal; © 2020 Cruz Bay Publishing, Inc.

https://teamropingjournal.com

Compressed Air Regulators; © Copyright 2019 - Understanding-Air-Compressors.com

https://understanding-air-compressors.com/compressed-air-regulators/

TEAGASC, Agriculture and Food Development Authority,

https://www.teagasc.ie/rural-economy/farm-management/farm-health--safety/

NASD, National AG Safety Database, Federal Laws and Regulations Aecting Farm Safety,

http://nasdonline.org/document/1842/d001777/federal-laws-and-regulations-aecting-farm-safety.html

What are the Rules of the Road for Farm Vehicles?; Foster Swift Agricultural Law News, 2018,

https://www.fosterswift.com/communications-Rules-of-the-Road-Farm-Vehicles.html

Appendix

RC22SCOREAIRC22Q36

RC22CALFA

Limited Warranties:

Priefert Manufacturing Company, Inc., (“Priefert”) 2630 South Jeerson, P.O. Box 1540, Mount Pleasant, TX 75456-1540, warrants

for one (1) year from the purchase date to the original non-commercial, governmental, or municipal purchaser (“Purchaser”)

and warrants for six (6) months to the original commercial or industrial purchaser (“Purchaser”) that the product purchased are

free from defects in material or workmanship. Priefert will replace or repair, free of charge to the original purchaser any part(s)

found, upon examination at our factory, to be defective under normal use and service due to defects in material or workmanship,

provided that the original purchaser:

a. Noties Priefert in writing of any defect in material or workmanship within the above specied warranty period.

b. Returns must be routed through an authorized Priefert dealer or distributor from whom the purchase was made.

c. Purchaser is responsible for cost of shipping.

In no event will Priefert be held liable under this warranty unless written notice is received and failure must have occurred within

the warranty period. Genuine Priefert replacement parts and components will be warranted for 90 days from date of purchase, or

the remainder of the original equipment warranty period, whichever is longer.

is limited warranty does not apply to any part of the product which has been subjected to improper or misintended use,

negligence, alteration, modication, or accident, damaged due to lack of maintenance or use of wrong oil or lubricants, or repairs

that have been made with parts other than those obtainable through Priefert, or which has served its usual life. is limited

warranty does not apply to any expendable item such as blades, shields, guards, or pneumatic tires, or other trade accessories

since these items are warranted separately by their respective manufacturers, except as specically noted in your Operator’s

Manual.

Except as provided herein, no employee, agent, Dealer, or other person is authorized to give any warranties of any nature on behalf

of Priefert. Only Priefert is authorized to make any representation to the purchaser concerning “normal” use and service for its

product as described in the Operator’s Manual, or in authorized printed materials or stickers axed to the product.

If aer examination of the product and/or part(s) in question; Priefert nds them to be defective under normal use and service

due to defects in material or workmanship,

Priefert will:

1. Repair or replace the defective product or part(s); if Priefert has made several reasonable number of attempts in repairing the

product and/or part(s) to conform to the warranty; then

2. Priefert will replace part(s) or product.

3. Purchaser is responsible for any labor charges exceeding a reasonable amount as determined by Priefert and for returning

product and/or part(s) to the Dealer, whether or not the claim is approved. Purchaser is responsible for the transportation

cost for the product or part(s) from the Dealer to the factory.

e choice of remedy shall belong to Priefert. Repair or replacement are the only remedies against Priefert under this limited

warranty.

Limitation of Liability:

1. Priefert disclaims any express (except as set forth herein) and implied warranties with respect to the product including, but

not limited to, merchantability and tness for a particular purpose.

2. Priefert makes no warranty as to the design, capability, capacity, or suitability for use of the product.

3. is warranty shall not be interpreted to render us liable for injury or damages of any kind or nature to person or property.

Priefert will not be liable for any special, incidental or consequential damages based upon breach of warranty, breach of

contract, negligence, strict tort liability, or any other legal theory. Such damages include but are not limited to loss of crops,

loss of savings or revenue, cost of capital, loss of use of equipment, facilities or services, down time, expense or loss incurred

for labor, supplies, substitute machinery, rental, and claims of third parties including customers, and injury to property.

Supplementary:

1. Proper venue for any lawsuits arising from or related to this limited warranty shall be only in Titus County, Texas.

2. Priefert may waive compliance with any of the terms of this limited warranty, but no waiver of any terms shall be deemed to

be a waiver of any other term.

3. If any provision of this limited warranty violates any applicable law and is held unenforceable, then the invalidity of such

provision shall not invalidate any other provisions.

4. Applicable law may provide rights and benets to purchaser in addition to those herein.

2630 South Jeerson P.O. Box 1540 Mount Pleasant, Texas 75456-1540

This manual suits for next models

1

Table of contents