Rev. Descrizione Redatto/Gestito Approvato Cod.Ident. Pagine Data Em.

03 Manuale Istruzioni Ufficio Tecnico Resp.Tecnico C314.M01.EN.03 5/18 03/2009

5

•The further installations

The machine is usually packed shipped in a wooden case that allows an easy moving and transport.

The case must be moved by means of a forklift with enough capacity to lift the weight given in this manual for the

appliance.

ATTENTION Pay attention to avoid impacts and turnovers

ATTENTION Protect the machine from the atmospheric agents. Water and humidity could oxidise it, damaging it

seriously.

3.2 UNPACKING

After removing the package, check that any parts of the machine are not damaged. In case of doubt, DO NOT USE THE

MACHINE and ask the manufacturer.

DANGER The materials used for the package (plastic, polystyrene, screws, nails, wood etc.) have to be kept far

from children. They must be thrown away in a proper collection centre.

ATTENTION Before throwing away the package, pay attention that any accessories, manuals, documents, spare

parts are not inside.

3.3 POSITIONING

•The appliance must be placed in a position and a site suitable for the use it has been conceived (use in a laboratory

safe from atmospheric agents); qualified staff must arrange the installation.

Admitted temperature: from 5° C. up to 40° C. (for a proper working of the climatic chamber we do

recommend placing it in a dusty free environment, properly aired and with a room

temperature between 14° C. and 26° C.)

Allowed humidity: from 30% to 95%

O.S.L max. height: 1000 meters.

The machine must be installed so that it is free from each side in order to be able to carry out easily the maintenance

operations (free space around the appliance: at least 50 cm. on each side).

•No authorised people and no dangerous objects must be near the machine.

•Check that the appliance is perfectly levelled in order to be able to close the door perfectly.

•The main working position for the operator is in front of the appliance.

No authorised people and no dangerous objects are allowed to stay in the area around the machine.

•Clean carefully inside the chamber using a cloth with some alcohol on it in order to clean out the protective oils, wash

with cold or tepid water and dry with care. (The manufacturer recommends not to use any detergent or chemical).

•Position the selves/trays on the relative supports (4 for each tray).

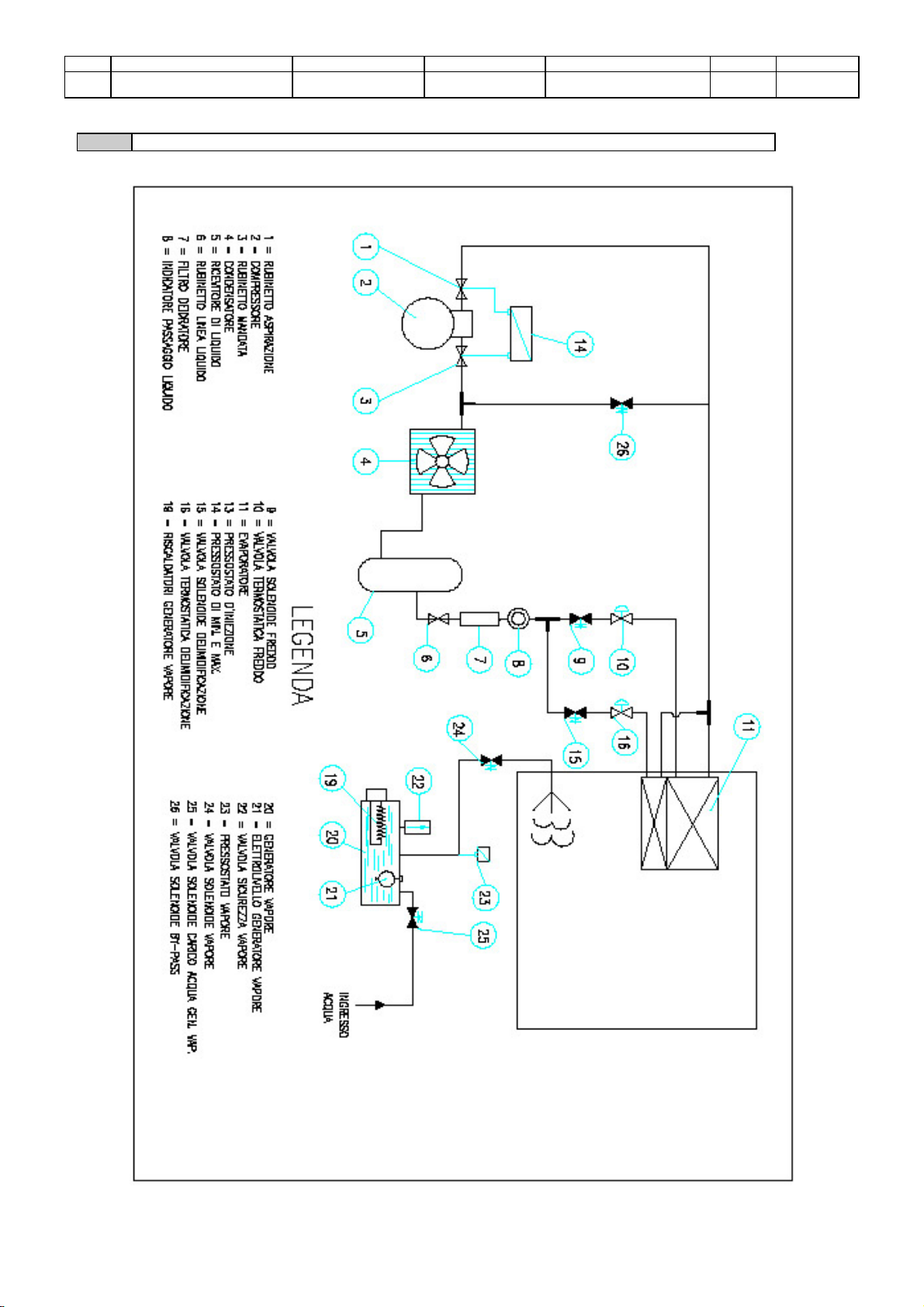

•Connect the Climatic Chamber to a water network in order to supply water sufficiently cold. If the water temperature is

not cold enough, a refrigerator is required.

The climatic chamber have to be connected to the water net by means of the relevant coupling device dia. 10 mm

placed on the left top of the climatic chamber back side.

•Connect the emergency drain (cupper pipe on lower back side on the right) to a water drain paying attention to use a

pipe as much as short and large as possible in order not to create any obstacle to the water flow.

DANGER Temperature of the water on the water drain can be 120º C.

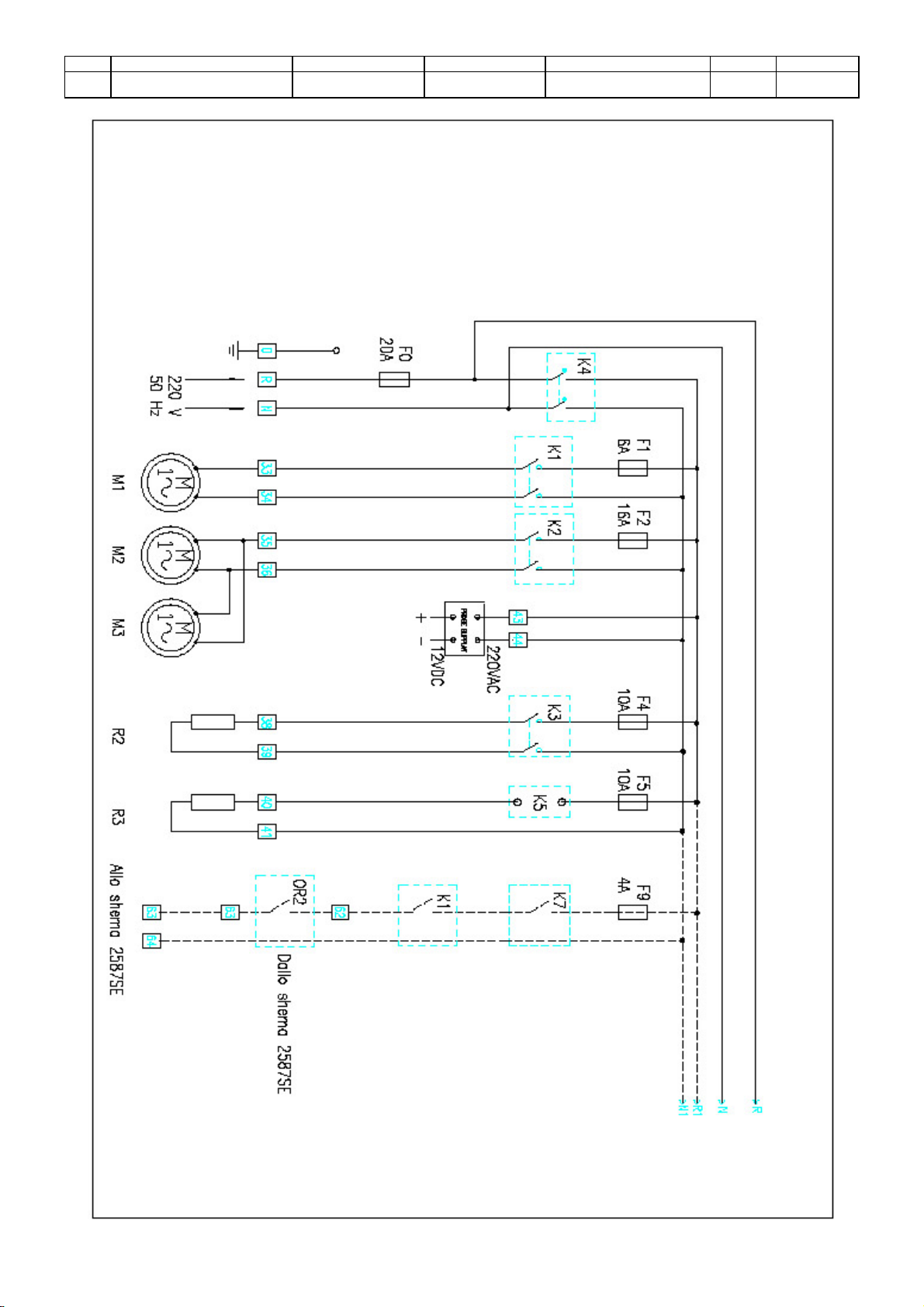

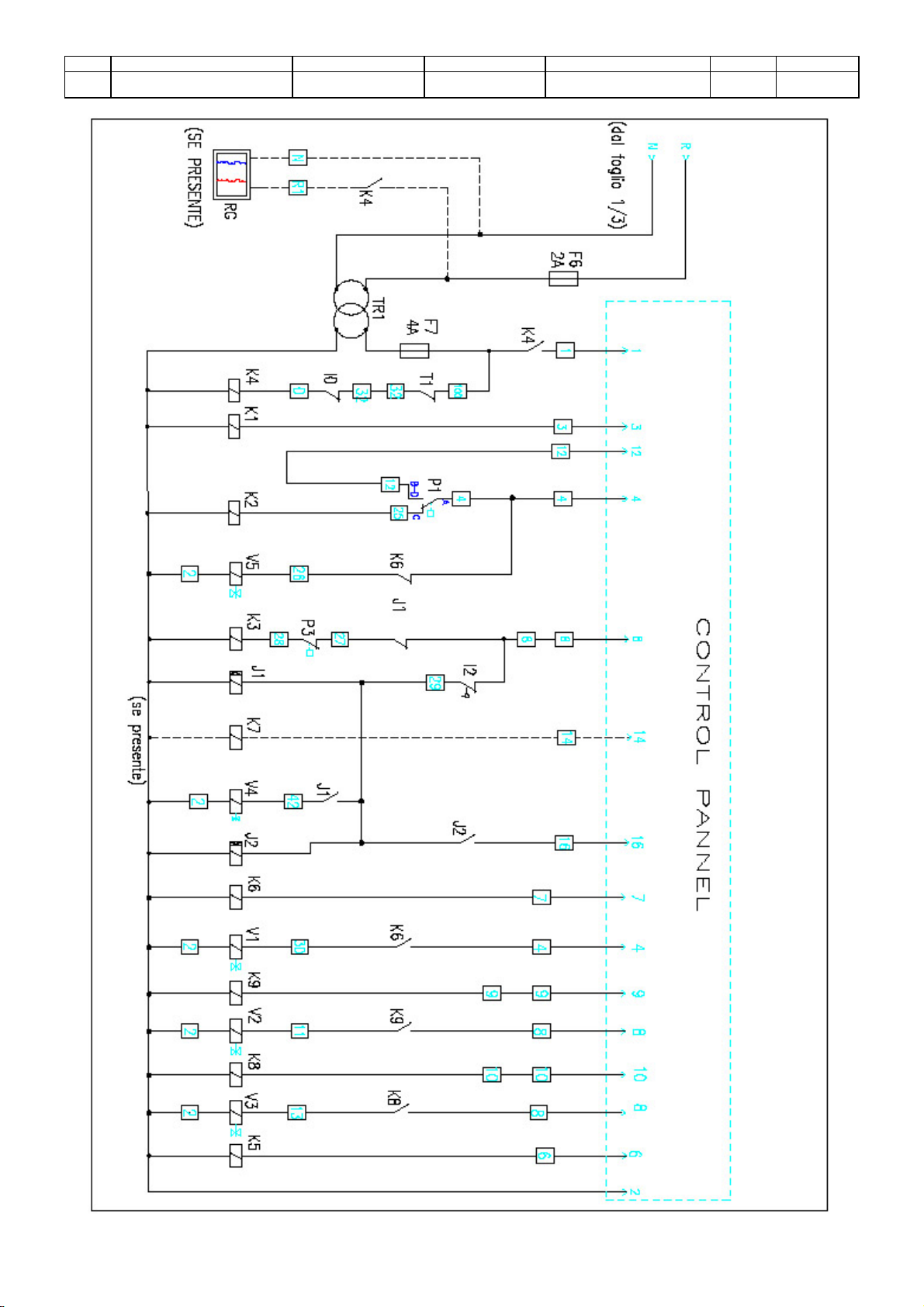

3.4 ELECTRIC CONNECTIONS

DANGER Skilled operators must arrange the electric connections.

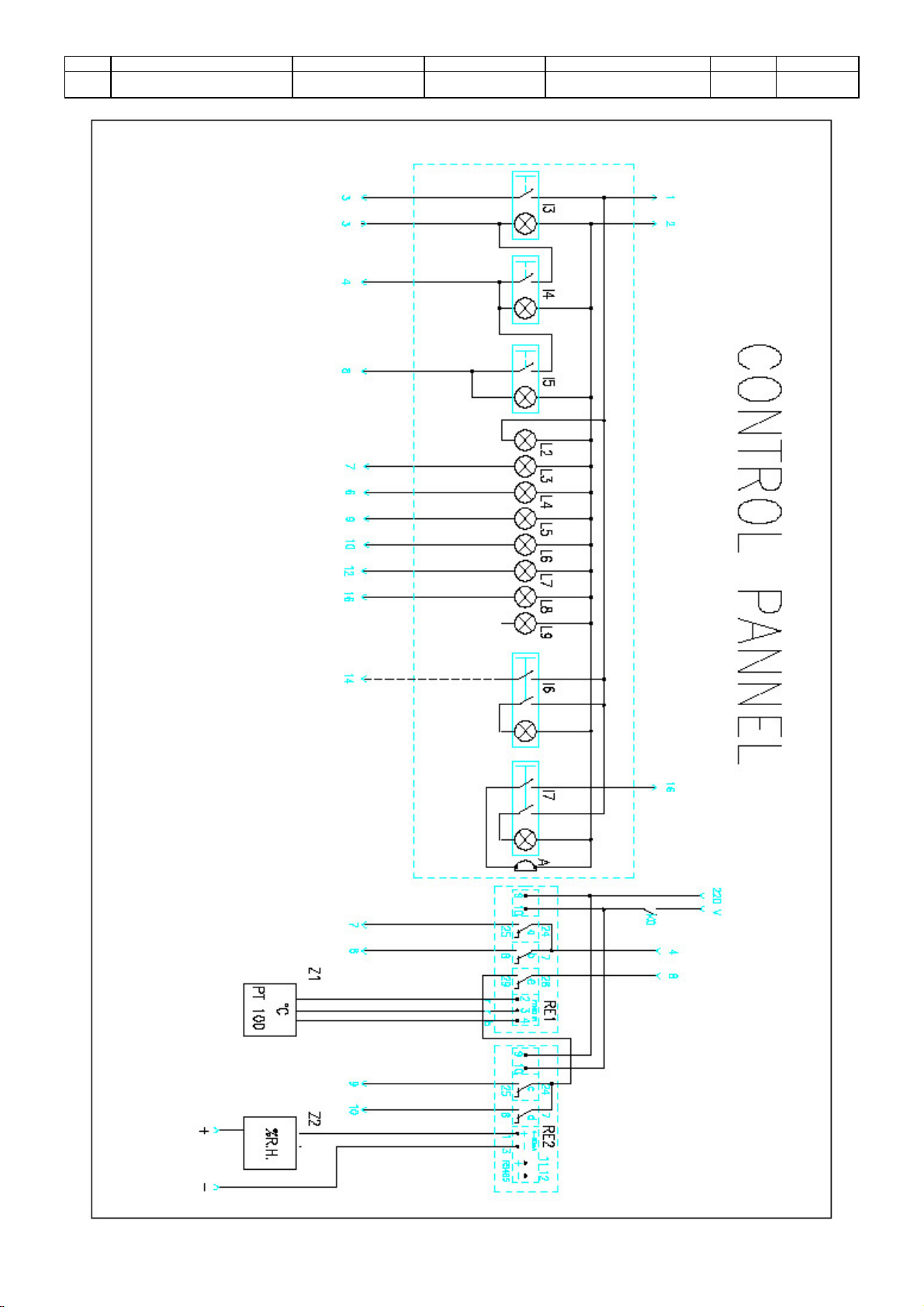

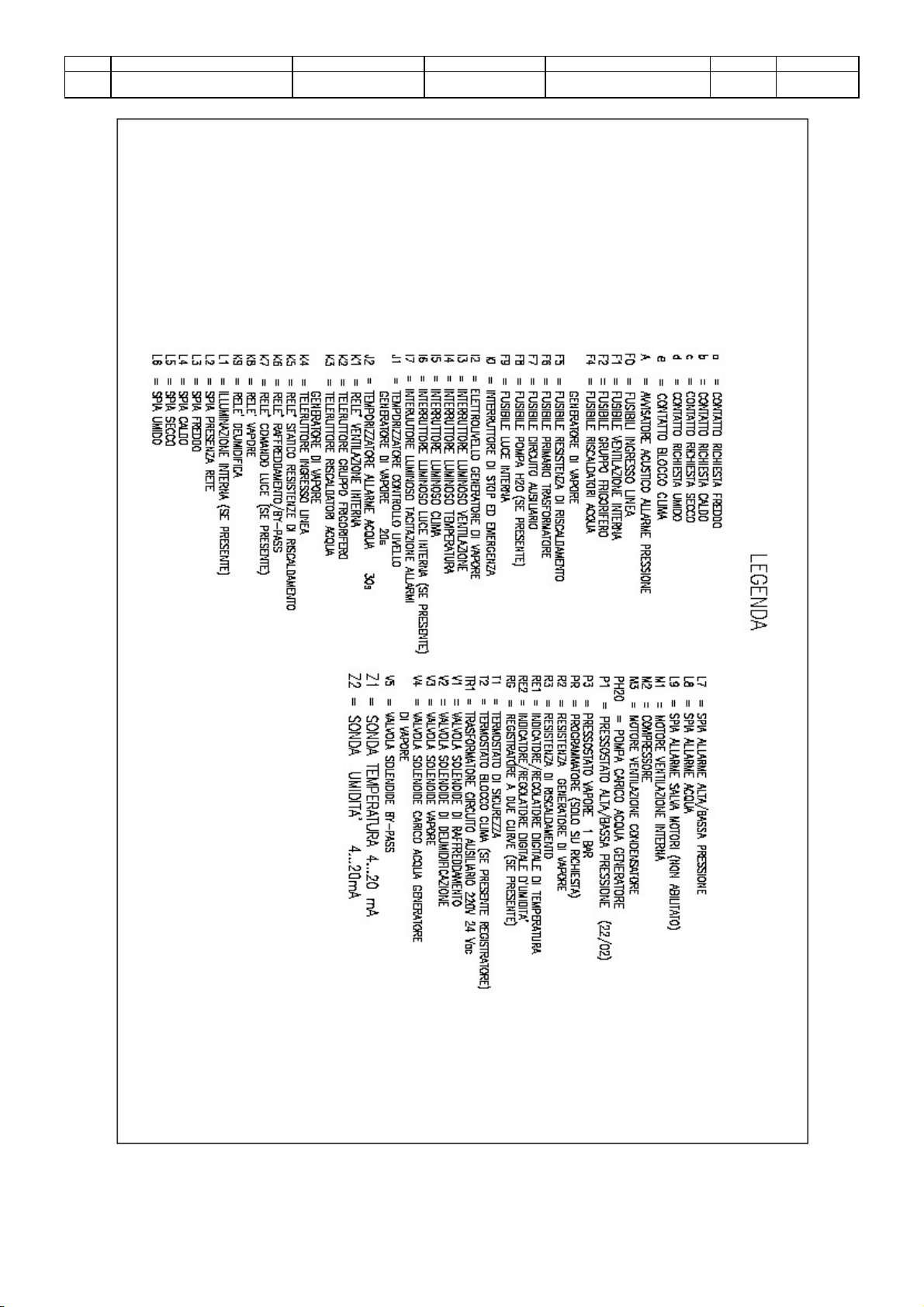

DANGER Before connecting, see the attached electric diagram and the plate on the machine for the information

about the voltage, the frequency, etc.

It is advisable to use demineralized water for a better functioning of the chamber and a better

maintenance of the moisturizing system.

It is advisable to use a decalcificator, model CULLIGAN Refill line soft 10 litres.

If the climatic chamber has been connected to the water network, check that the water hardness is not

higher than 12º f and not lower than 7ºf.

Check the pressure feed. If the pressure is higher than 3 bar, use a pressure reducer in order to keep it at 3bar.

It is also advisable to use a mechanical filter of 50 match.