Interdent AQUAMAT User manual

Polimerizator AQUAMAT GB 2

TABLE OF CONTENTS

1. INTRODUCTION...............................................................................................................................3

2. SAFETY INSTRUCTIONS.................................................................................................................... 4

3. DESCRIPTION OF THE UNIT .............................................................................................................5

4. INSTALATION AND INITIAL START-UP.............................................................................................6

5. PRACTICAL USE................................................................................................................................ 6

6. TECHNICAL DATA ............................................................................................................................8

7. MAINTENANCE................................................................................................................................9

8. DELIVERY SCOPE..............................................................................................................................9

WARRANTY FOR PRODUCT REF.: 0689 ................................................................................................10

Polimerizator AQUAMAT GB 3

1. INTRODUCTION

Thank you for having purchased the polymerizer for acrylic plastics AQUAMAT furnace

which, we are sure will meet all your needs and will satisfy your highest demands.

This device has been designed according to the requirements of latest industrial

standards and we guarantee that you will use it for many years as your closest assistant.

However, inappropriate use may damage the equipment and be harmful to personnel.

Please observe the relevant safety instructions and read the instructions for use

carefully.

We wish you a pleasant working experience with the polymerizer for acrylic plastics

AQUAMAT.

SIMBOLS:

This symbol indicates that there is high dangerous tension under the bonnet

which it is put on.

This symbol indicates that the unit complies with the requirements of the

Directives for Low Tension and Electromagnetic Compatibility as well as for the

Standards harmonized with them.

Polimerizator AQUAMAT GB 4

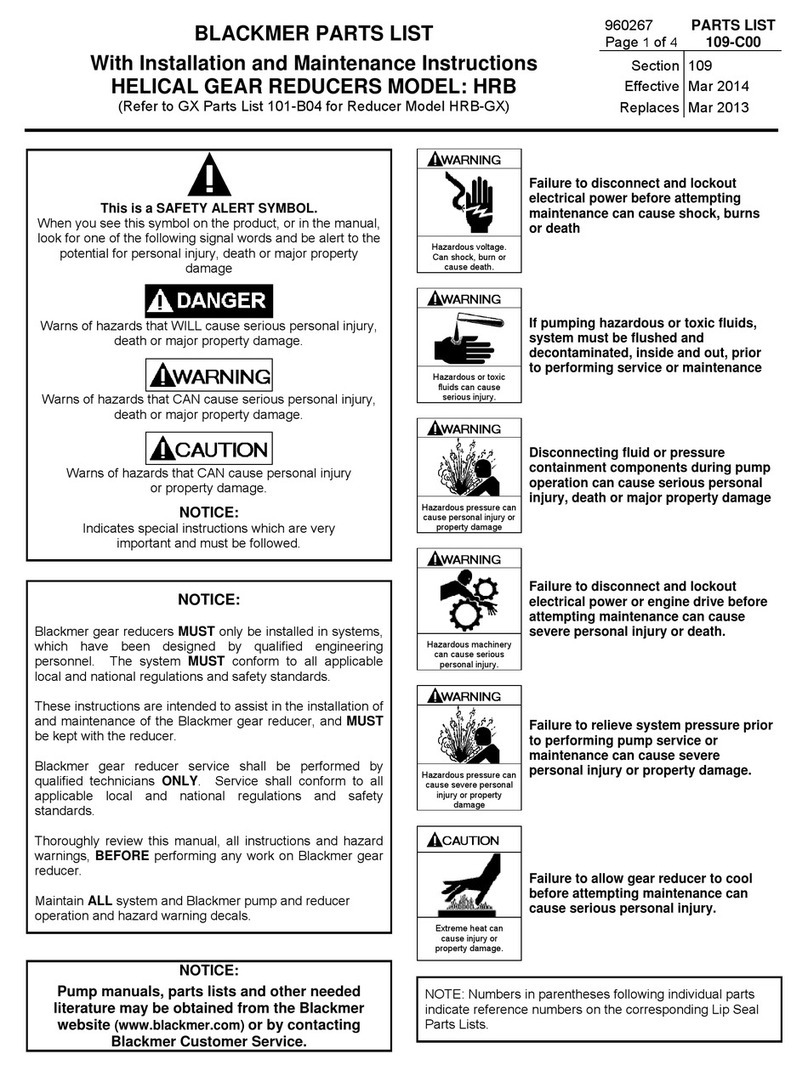

2. SAFETY INSTRUCTIONS

The following instructions must be observed in order to avoid personnel injury or

equipment failure.

•the device must not be run by an operator who is not familiar with these instructions;

•before you plug in the device check if the voltage in the electrical network corresponds

to the working tension. In case of discrepancy, consult a specialist;

•on no account should the device be altered;

•the notices and stickers must be kept in good condition so that they are easily readable;

they should not be removed!

•the unit must not function in case of being damaged and in position to injure the staff or

a third person;

•keep the power cable out of heat, oil and coarse objects; while moving the cable do not

make contact with the device.

•switch off the device and pull out the feeder cable plug from the power socket before

each cleaning or upkeep.

•spare parts which are not specified by the manufacturer must not be used!

•keep from falling and hitting;

•to accomplish its functions the device must be heated so bear in mind the possible

dangers of explosion or emissions of toxic or combustible gas as a result of the heating of

materials in the device itself. Therefore, the unit is recommended to be placed in a

suitable ventilated spot in the premises.

If the unit is used by means not indicated by the manufacturer, the provided protection can worsen!

WARRNING!

Polimerizator AQUAMAT GB 5

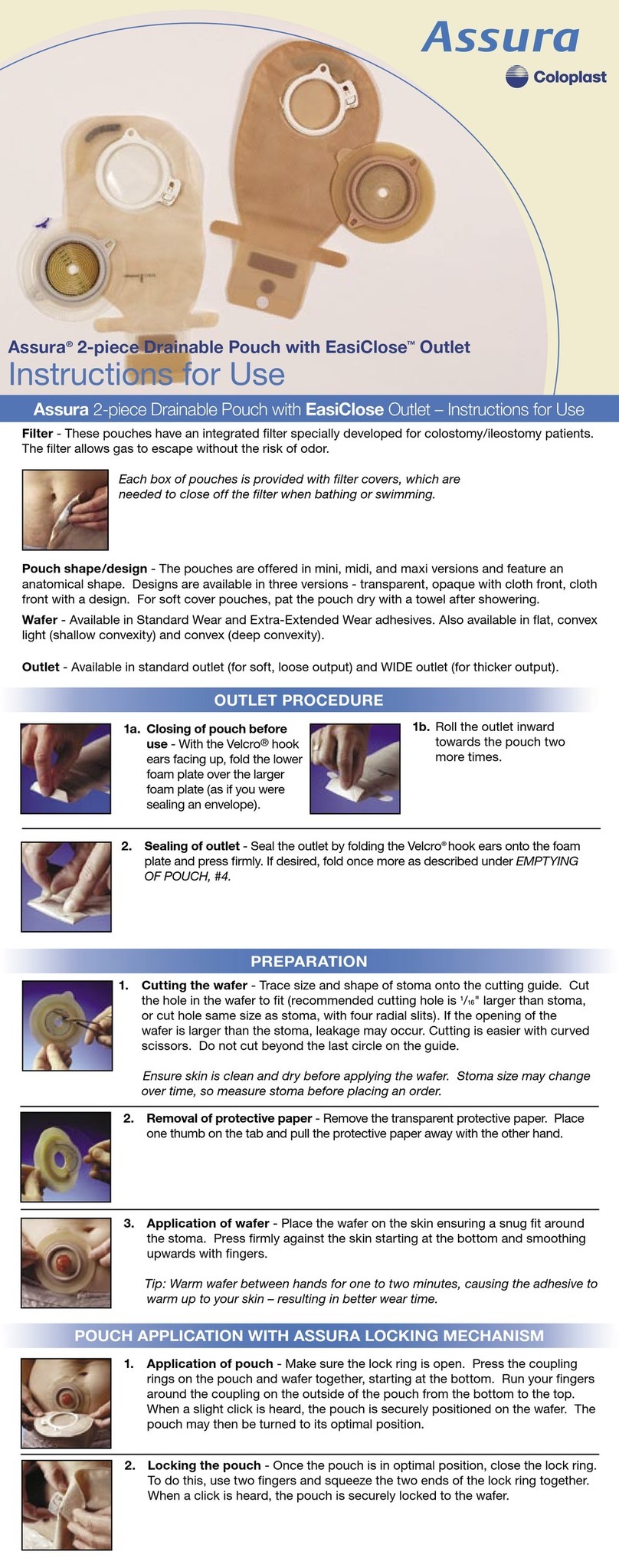

3. DESCRIPTION OF THE UNIT

This device is used for polymerization of acrylic plastics and can also be used as a pressure chamber.

It is designed for work in dental laboratories.

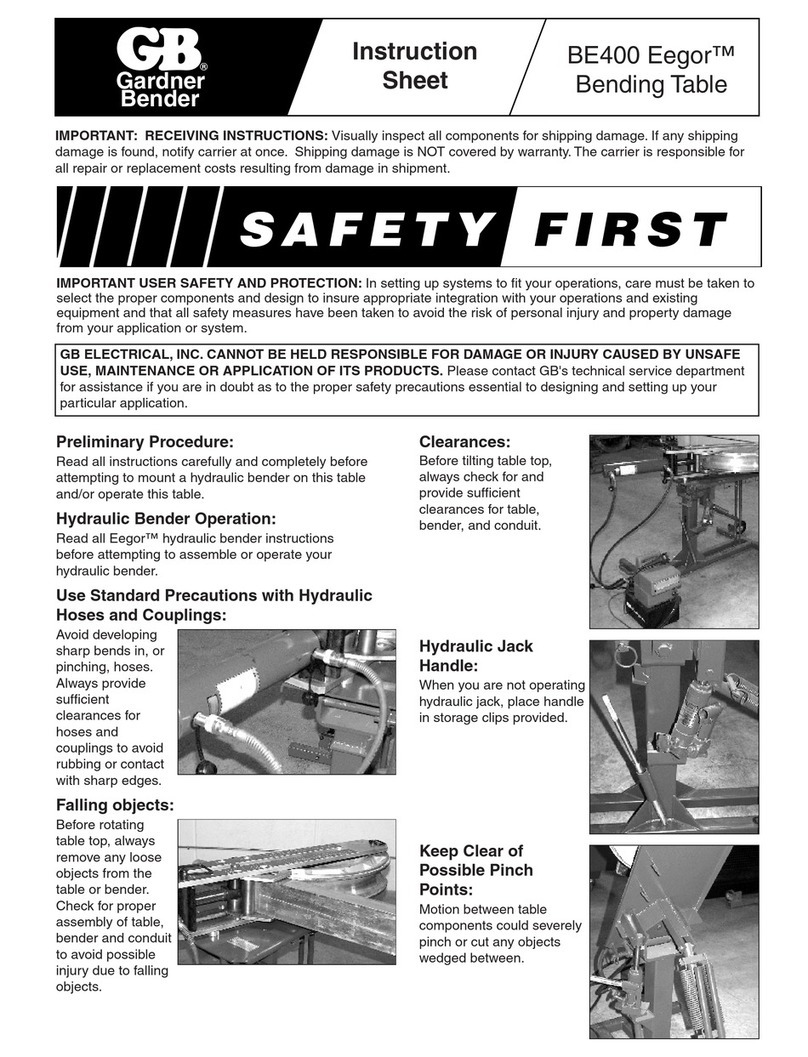

1. Front panel;

2. Power switch;

3. Manometer;

4. Cover;

5. Handle for opening / closing

6. Nozzle for exit water;

7. Nozzle for air;

8. Filter for power cord;

9. Power cord;

10. Fuses;

11. Pressure reducing valve;

12. Lock;

13. Filter.

1

3

4

5

6

9

1

1

7

10

8

2

12

13

Polimerizator AQUAMAT GB 6

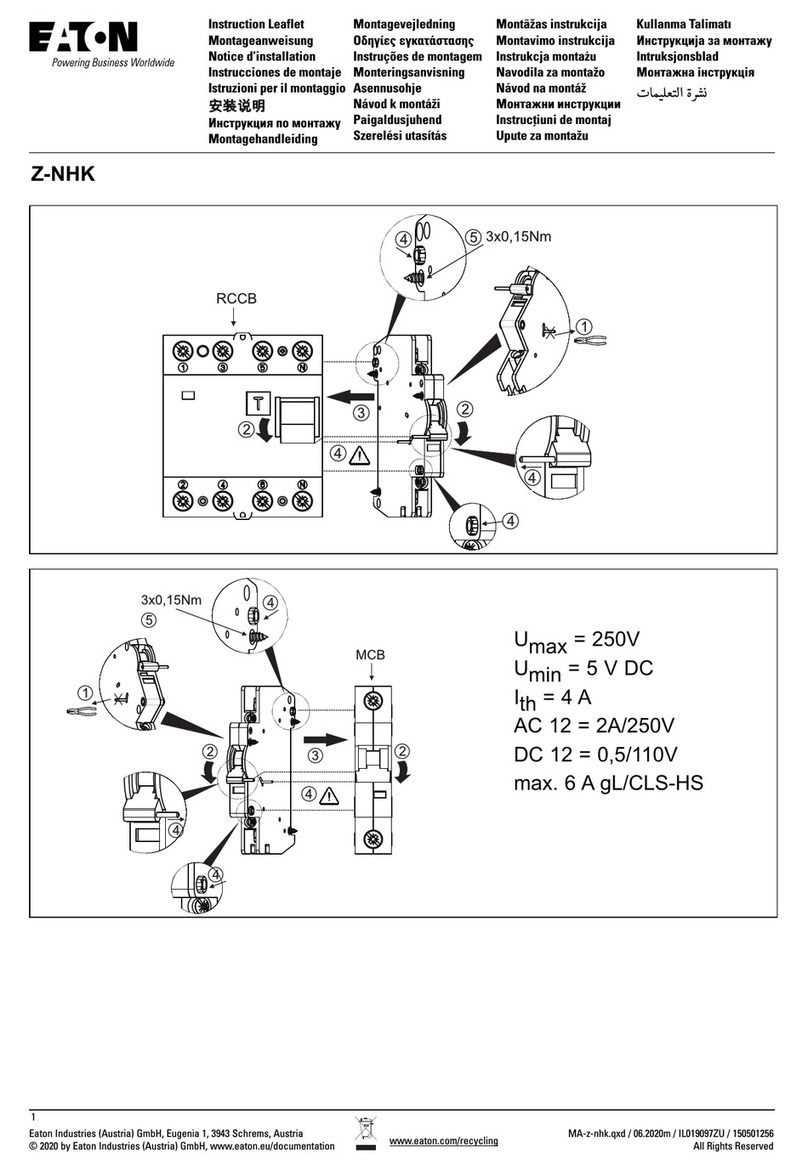

4. INSTALATION AND INITIAL START-UP

UNPACKING

•Carefully remove modules from packages;

•Make sure that the rated voltage is ~230V and the contact is reliably grounded;

•Place the device near the power socket, so it is accessible.

CONNECTIONS

•Connect the main air supply on the rear panel to the nozzle for air (7.). The connecting orifice

is ø6 sized. The maximum pressure in the mains should not be higher than 6 Bar.

•Connect hose ø8 to the nozzle for exit water (6.) and lead it to the sewage system or to an

outside container for collection of the resting liquid. This orifice is placed on the right-side of

the device.

ATTENTION: Do not sink this hose in any liquid, because it might destroy the unit!

•The safety valve is on the rear panel. The unit should be put in a proper place so that if this

valve is activated you are able to avoid the damage of another part. Do not put it on

combustibles.

5. PRACTICAL USE

PRESETTINGS

The preparation for the work consists in setting of the needed time and temperature. The adjustments

are done using the selection buttons - button and button .

After pressing one of these buttons you will see the current value blinking on the display. When the

indication is blinking, you can change it with the help of the arrow buttons until you reach the desired

value.

To save this value you must press the relevant selection button ( or ) again. This way you

exit the mode for adjustment of the parameters and the unit is ready for work.

The polymerization unit has two working temperature zones which means that the device can heat at

two stages. For adjustment of the middle stage the same buttons as described above are used but

they should be kept pressed for more than 2 seconds.

The setting of the middle stage is made in the same way as the final stage. The middle stage cannot

be achieved either if the adjusted temperature is 39°C or if the adjusted time is 0 minutes.

Polimerizator AQUAMAT GB 7

WAY OF USE

Put an object in the device. Pour as much liquid as needed to fill the chamber up to 2 cm below the

upper edge. Close the lid till it reaches the stopper. Start the process by pressing the button .

The process can be discontinued at any time by pressing the button again.

After starting the program, you must press the button for draining of the liquid, the relevant LED

flashes and the liquid will be drained automatically in the end of the process.

In case you need to drain the liquid manually this can be done when the device is not in mode for

program execution. For this purpose, the button should be pressed. Having emptied the device

you must press the same button again so that the electromagnet valve will close.

To start a working cycle while the difference between set temperature and temperature in the bowl

is less than 10°С, you must press and hold the button for several seconds. The unit will start after

issuing a beep.

This unit can work without heating. You can start the different working mode by pressing the two

arrow buttons and simultaneously.

This way pressured air will enter into the chamber and will stay there for preliminary adjusted time.

This mode is useful for preliminary dry pressing of some objects.

WARRNING!

Do not open the lid of the device before the temperature drops under 100°C because then

the water will boil and there will be risk of burns.

Take care of the red silicone sealing ring that is under the hood. If it is dry, wet it with water

before closing the lid to protect it from accidental damage.

THERMAL PROTECTION

This device is equipped with thermal protection. If the temperature in the chamber exceeds 150°С a

special component will stop the heating.

To restore normal function, you need to:

•unplug the device from the socket;

•remove the left side cover;

•resume normal work by pressing the red button which is on the thermal protection component;

Polimerizator AQUAMAT GB 8

6. TECHNICAL DATA

Electrical supply

~230 V, ±10%, 50Hz

Power consumption

1220 W

Category of over tension

ІІ

Effective volume of the chamber

1,5L

Interior dimensions

Ф140 mm; h=145 mm

Maximum operating pressure

6 Bar

Limits set for the working temperature

40°С - 125°С

Operating temperature zones

2

Limits set for the time

1min – 99min

Overall dimensions:

- Width

- Length

- Height

300 mm

330 mm

240 mm

Model Weight

9,3 кg

Working temperature

5°С - 40°С

Level of environment pollution

2

The device is designed for usage in normal dental laboratories up to 2000 m altitude above sea

level.

The maximum relative humidity of the air must be 80% for temperatures up to 31°С, decreasing

lineally to 50% relative humidity for temperature of 40°С.

Polimerizator AQUAMAT GB 9

7. MAINTENANCE

•Avoid positioning the unit in the immediate vicinity of heat sources (radiators);

•Do not leave objects on the body of the unit;

•Clean with a slightly moist cloth.

•Change the safety locks with the announced values only, namely:

6,3А/250V; slow (class T)

•No repair activity by a service technician who is not authorized by the manufacturer is

allowed!

•The lifting and carrying should be made only with both hands from below as the furnace is

standing upright.

•No carrying and transportation in another state except for vertical position is allowed!

8. DELIVERY SCOPE

- Polymerization Unit Aquamat 1 pc.

- Drain hose-pipe 1 pc.

- Spare fuses:

Т 6,3А/250V 2 pcs.

- User manual 1 pc.

MANUFACTURER: Interdent d.o.o.

Opekarniška cesta 26

SI-3000 Celje

Slovenija

T: +386 (0)3 425 62 00

E: info@interdent.cc

Polimerizator AQUAMAT GB 10

WARRANTY FOR PRODUCT REF.: 0689

Product: AQUAMAT

Serial number: ………………………………………

Date of sale: ………………………………………….

Signature of the seller: ………………………….

Warranty declaration:

•The product will work flawless during the warranty period if being

administered in accordance with its purpose and the instructions

provided;

•Warranty period expires after 12 months from purchase day. At

your request, we will repair failure or defects on the product, if you

will report it within the warranty period. Failure will be resolved

free of charge within 45 days from the date of failure report. The

product, which will not be repaired within this deadline, will be, at

your request, replaced with a new one. We will extend the

warranty period for the time the product was being repaired.

•Validity of the warranty should be proofed by certified warranty

card and original invoice.

The warranty is voided:

•If an unauthorized person interferes into the device

•If provided instructions for use are not being considered

•If the device is being mechanically injured

•If the unoriginal spare parts are being built in

Table of contents

Other Interdent Industrial Equipment manuals