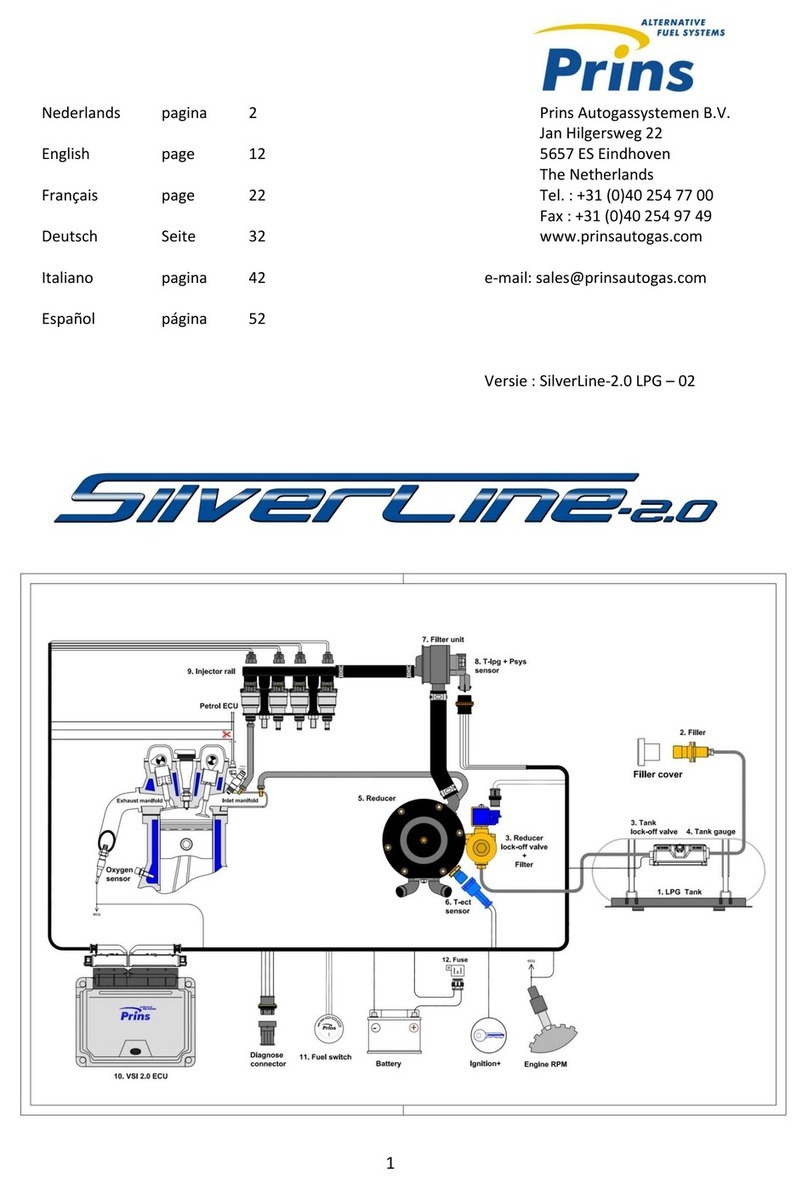

Prins VSI LPG User manual

DATE :

2013-09-04

Copyright © Prins Autogassystemen B.V. 2013 VERSION NR :

C

Table of contents

Required equipment / tools / materials for installing a complete system _______________________ 3

Vehicle check ________________________________________________________________________ 3

General instructions __________________________________________________________________ 4

Introduction _________________________________________________________________________ 5

Approval numbers VSI LPG / CNG components ___________________________________________ 6

The Prins LPG reducer ________________________________________________________________ 7

The Keihin CNG regulator______________________________________________________________ 8

The injector rail ______________________________________________________________________ 9

The Prins filter unit __________________________________________________________________ 10

The Keihin filter unit _________________________________________________________________ 10

The VSI computer____________________________________________________________________ 11

VSI-I _______________________________________________________________________________ 11

VSI-2.0 computer ____________________________________________________________________ 12

Instructions rotating the Prins VSI injector rail ___________________________________________ 13

The wiring loom._____________________________________________________________________ 14

VSI-I _______________________________________________________________________________ 14

VSI-2.0_____________________________________________________________________________ 14

Hose connections ___________________________________________________________________ 15

Diagram 1 VSI inlet manifold coupling_________________________________________________ 16

Diagram 2 VSI inlet manifold coupling with nylon hose __________________________________ 17

Diagram 3 Parallel water connection __________________________________________________ 18

Diagram 4 Serial water connection____________________________________________________ 19

Diagram 5 Serial water connection CNG regulator_______________________________________ 20

The VSI-I fuel switch _________________________________________________________________ 21

The VSI-2.0 fuel switch _______________________________________________________________ 22

Electrical connections on the LPG reservoir _____________________________________________ 23

Electrical connections VSI-I wiring harness ______________________________________________ 24

Electrical connections VSI-I wiring harness ______________________________________________ 25

Electrical connections VSI-2.0 wiring harness____________________________________________ 26

Electrical connections VSI-2.0 wiring harness____________________________________________ 27

Insulate all not used wires. ____________________________________________________________ 27

Electrical connections VSI-2.0 wiring harness____________________________________________ 28

Electrical connections VSI-2.0 wiring harness____________________________________________ 29

Electrical connections RPM module 091/0236 ____________________________________________ 30

Electrical connections Petrol Pressure Simulator 091/0252 _________________________________ 31

Electrical connections Dual Sensor Interface (DSI)________________________________________ 32

Electrical connections CNG Prins Timing Optimizer (PTO) _________________________________ 33

Diagram CNG PTO wiring Prins Turbo / MAP sensor ______________________________________ 33

Prins Turbo / MAP sensor_____________________________________________________________ 34

Diagram 5 LPG Base layout VSI 4 cylinder connector____________________________________ 35

Copyright © Prins Autogassystemen B.V. 2013 Page 2

Diagram 6 LPG Base layout VSI 4 cylinder solder _______________________________________ 36

Diagram 7 LPG Base layout VSI 5 cylinder _____________________________________________ 37

Diagram 8 LPG Base layout VSI 6 cylinder connector____________________________________ 38

Diagram 9 LPG Base layout VSI 6 cylinder solder _______________________________________ 39

Diagram 10 LPG Base layout VSI 8 cylinder connector___________________________________ 40

Diagram 11 LPG Base layout VSI 8 cylinder solder ______________________________________ 41

Diagram 12 CNG Base layout ________________________________________________________ 42

Diagram 13 VSI-2.0 LPG Base layout __________________________________________________ 43

Diagram 14 VSI-2.0 MAP LPG Base layout_____________________________________________ 44

Diagram 13 Injection module 4-cylinder ( 180/70024 connector )___________________________ 46

Diagram 14 Injection module 4-cylinder ( 180/ 70024 solder )______________________________ 47

Diagram 15 Injection module 6-cylinder ( 180/70026 connector )___________________________ 48

Diagram 16 Injection module 6-cylinder ( 180/70026 solder ) ______________________________ 49

Diagram 17 Injection module 8-cylinder ( 180/ 70024 connector)___________________________ 50

Diagram 18 Injection module 8-cylinder ( 180/70024 solder)_______________________________ 51

Diagram 19 Repair module 180/30024 (4-8 cylinder) _____________________________________ 52

Diagram 20 connector injection module 091/71004 ______________________________________ 53

Diagram 21 injection module 091/71006 _______________________________________________ 54

Diagram 22 Replacing the injection module 180/70024 → 091/0145_________________________ 55

Diagram 23 Replacing the injection module 180/70024 → 091/71004 (4 cylinder) _____________ 56

Diagram 24 Replacing the injection module 180/70026 → 091/71006 (6 cylinder) _____________ 57

Diagram 25 Replacing the injection module 180/70024 → 091/71004 (8 cylinder) _____________ 58

Diagram 26 LPG wiring 180/70014 ____________________________________________________ 59

Diagram 27 LPG wiring 180/70004 ____________________________________________________ 60

Diagram 28 LPG wiring 180/70016 ____________________________________________________ 61

Diagram 29 LPG wiring 180/70006 ____________________________________________________ 62

Diagram 30 LPG wiring 180/70018 ____________________________________________________ 63

Diagram 31 LPG wiring 180/70008 ____________________________________________________ 64

Diagram 32 LPG wiring 080/72040 ____________________________________________________ 65

Diagram 33 LPG wiring 080/72045 ____________________________________________________ 66

Diagram 34 LPG wiring 080/72050 ____________________________________________________ 67

Diagram 35 LPG wiring 080/72055 ____________________________________________________ 68

Diagram 36 LPG wiring 080/72060 ____________________________________________________ 69

Diagram 37 LPG wiring 080/72065 ____________________________________________________ 70

Diagram 38 CNG wiring 095/72045 ____________________________________________________ 71

Diagram 39 VSI-2.0 wiring 191/040002 _________________________________________________ 72

Trouble code chart LPG ______________________________________________________________ 73

Maintenance instructions _____________________________________________________________ 74

Checklist after installation ____________________________________________________________ 76

Copyright © Prins Autogassystemen B.V. 2013 Page 3

Required equipment / tools / materials for installing a complete system

-Complete workshop toolbox ( wrenches, screwdrivers, cutters, pliers, ratchet, sockets )

-Car lift

-Portable computer : operating on Windows 98,W2000 or XP.

Internal memory : 16 Mb or more

Memory HD space : 5MB

Screen : 256 colours, advise colours 16 bits or more

Com port : 1 free COM port 1 or COM port 2 with a 9 or 25 pins connector

or USB

-Vehicle fuel system scan tool or OBD scan tool Prins ( part nr. 099/99928 )

-Exhaust gas analyser

-Multimeter

-Oscilloscope

-Prins VSI diagnostic software

-Prins VSI serial interface

-Prins VSI break out box ( part nr. 080/70090 )

-Torque wrench ( 10Nm )

-Portable light

-Assortment drill bits 4 to 12 mm

-Assortment cutters ( ø 20, 30, 50, 70 mm )

-Punching tool ø 70 mm

-Round file

-Portable drill or pneumatic drill

-Threading device ( male M6x1, M8x1, M10x1 )

-Pipe-flaring tool ( for 6 and 8 mm copper pipe )

-Air gun

-Vacuum cleaner

-Hot air gun

-Allan spanner for inlet couplings 3,5mm ( part nr. 099//9970 )

-Reducer adjustment tool ( part nr. 099/9960 )

-Molex extraction tool for VSI switch connector ( part nr. 090/9929 )

-Soldering iron, soldering tin

-Wire-stripping pliers

-Adhesive tape

-Adhesive sealant

-Thread locking compound

-Anti-corrosion agent / black body coating

-Gas leak detection device or foam leak spray

-Shrink sleeves

-Engine coolant

Vehicle check

-Check the vehicle drivability on petrol

-Check the fuel system for error codes ( scan tool )

-Check if the catalytic converter is in good condition ( exhaust gas analyzer )

-Check the condition of the ignition system ( spark plugs, cables, coil )

Copyright © Prins Autogassystemen B.V. 2013 Page 4

General instructions

The installation of the system shall be done in accordance with the installation manual provided by Prins

Autogassystemen.

Always disconnect the battery when installing the LPG/CNG system.

Do not place the main fuse into the fuse holder before having completed the installation of the VSI system.

The VSI computer has to be activated by means of the diagnosis software.

In the unlikely event the VSI computer fails, it will automatically switch over to petrol.

Never disconnect the VSI computer connector, unless you have removed the main fuse.

When installing the VSI wiring harness, ensure that it does not run near any of the ignition components.

Solder and insulate all electrical connections.

The wires in the loom are provided with numbers and text. The text on the wire explains the function of the wire.

The wire loom is not model specific, therefore is it may be necessary to adjust the length of the wires.

Ensure maximum care is taken when connecting wiring.

Make professional joints using solder and shrink sleeve. Do not stretch the wiring harness.

No component of the LPG/CNG-system shall be located within 100 mm of the exhaust or similar heat source,

unless such components are adequately shielded against heat.

Remove any internal burrs, after having shortened the LPG/CNG hose. (This guarantees the maximum flow

through the hose without pollution.)

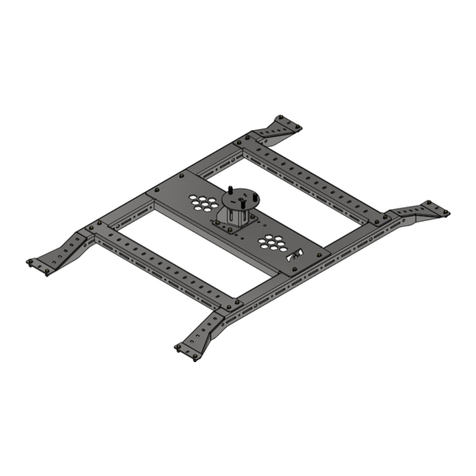

If holes have to be drilled (wear safety glasses) in order to facilitate mounting the device frame, the reservoir

frame, the LPG/CNG cut-off valve, etc., the drilled holes must always be treated with an anti-corrosive, after the

burrs have been removed ( especially when mounting a exterior filler ).

After having completed the installation, check the whole system for gas leakage; use a gas leak detection device.

Fitting and maintenance is only allowed by Prins Autogassystemen selected LPG/CNG engineers.

Prins Autogassystemen is not responsible for any damages to people or objects as a result of changes to Prins

products.

Check our website regularly for updates, info-bulletins and product information. ( www.prinsautogassytemen.com )

For installing a dedicated VSI-system download DEDICATED MANUAL ( part 2/2 )

Please fill in the warranty card completely and return it within 8 days after installation.

Copyright © Prins Autogassystemen B.V. 2013 Page 5

Introduction

VSI stands for “vapour sequential injection”, it points directly to the most important properties of the system.

This second-generation gas injection system is based on a vapour LPG/CNG injection that is injected

sequentially in the engine. Sequential means that the gas injectors will inject the LPG/CNG in the sequence

equal to the injection sequence of the petrol injectors,

This sequence in most applications is equal to the firing order of the ignition sequence of the engine, for

example with a 4-cylinder engine this is normally 1-3-4-2. Sequential injection means that the amount of

injected fuel per cylinder the can be metered and timed individually.

This achieves a much higher level of performance emission and drivability. The VSI system was designed

and developed in-house by Prins Autogassystemen B.V.

VSI characterizes itself with a high level of integration into to the petrol management system. The two

systems integrate as “master-slave” system.

This means that the original petrol management ECM controls the amount of LPG/CNG injected via the gas

injectors into the engine. The VSI ECM only translates the relevant signals coming from the engine

management system necessary for MASTER /SLAVE strategy.

Following this strategy the petrol management system is the “MASTER” and the VSI ECM the “SLAVE”.

The advantage of this strategy: while driving on LPG/CNG the lambda control and OBD functions keep

within the OE parameters, functioning correctly and controlled by the petrol management system. So when

operating on LPG/CNG it is not necessary to generate simulated signals.

There is one exception made for the petrol injector signals, while driving on LPG/CNG the petrol injector’s

are switched off to discontinue the petrol supply. To maintain the injection control signals it is necessary to

simulate the petrol injectors to ensure the original ECM does not detect a fault code. Secondly when

operating on LPG/CNG it is necessary to maintain a petrol injector control signal to measure the required

fuel demand.

The second generation injection system VSI has the ability to inject sequentially making it quicker and more

accurate, large benefits can be gained in engine and emission performance.

Copyright © Prins Autogassystemen B.V. 2013 Page 6

Approval numbers VSI LPG / CNG components

Mark

Component

LPG

CNG

Prins

VSI Reducer

E4-67R-010054

Valtec

6 / 8mm lock-off valve

E4-67R-010041

Keihin

Regulator

E4-110R-000092

OMB

lock-off valve

E4-110R-000095

Wika

CNG Pressure indicator

E4-110R-000190

Prins

VSI Injector rail

E4-67R-010093

E4-110R-000021

Keihin

VSI Injector

E4-67R-010092

E4-110R-000020

Prins

Filter unit

E4-67R-010096

E4-110R-000028

Keihin

Filter unit

E4-67R-010177

E4-110R-000091

Prins

ECU

E4-67R-010098

E4-110R-000083

Electrical VSI components

EMC : E4-10R-020507

VSI-I LPG VSI-2.0 LPG / VSI-2.0 DI LPG

VSI-1 CNG VSI-2-0 CNG / VSI-2-0 DI CNG

Copyright © Prins Autogassystemen B.V. 2013 Page 7

The Prins LPG reducer

Mount the reducer to the body of the vehicle in the engine compartment, never on the engine!

Mount the reducer so that it is easy to adjust the pressure.

Install the supplied 8 mm threaded end in the back cover of the reducer.

Mount the reducer as shown in the drawing.

Mount the reducer on a bracket and bolt on with a M8x1 nut.

The LPG lock-off valve can be installed in different positions. Do not damage the O-rings when

rotating the lock-off valve. See picture for torque moment.

The reducer is connected to the heating system circuit by couplings between the coolant fluid

hoses: dependant on the converted vehicle the reducer is placed in series or in parallel with the

heating system.

Overpressure 5mm relief hose : connect to the intake manifold.

No component of the LPG-system shall be located within 100 mm of the exhaust or similar heat

source, unless such components are adequately shielded against heat.

The pressure can be adjusted with the adjusting screw (Allan screw) in the front cover.

Seal the adjusting screw, with the sticker, in the front cover of the reducer after adjusting the

pressure.

mounting positions

Standard reducer, 6 mm LPG pipe, used for engines with a HP up to 135 kW ( 180 HP ).

High Output reducer, 8 mm LPG pipe, used for engines with a HP over 135 kW ( 180 HP ).

Use a High Output MAP reducer on blown engines ( turbo / compressor )

NO threat locking compound allowed !!

Copyright © Prins Autogassystemen B.V. 2013 Page 8

The Keihin CNG regulator

Mount the Keihin regulator to the body of the vehicle in the engine compartment, never on the

engine!

Mount the regulator so that it is easy to replace the inlet filter.

Mount the regulator as shown in the drawing with the water connections downwards.

Mount the regulator on a bracket and bolt on with 3 M6x1 nuts.

The regulator is connected to the heating system circuit by couplings between the coolant fluid

hoses.

Optional MAP connection: connect to the intake manifold if needed.

No component of the CNG-system shall be located within 100 mm of the exhaust or similar heat

source, unless such components are adequately shielded against heat.

The pressure may not be adjusted and is fixed on 3.3 bar

Copyright © Prins Autogassystemen B.V. 2013 Page 9

The injector rail

VSI 4-cylinder injector rail [KN8/KN9]

The Prins injector rail is available in 2 - 3 - 4 - 5 rail versions.

Guideline VSI injector choice : divide total engine power in kW up into the amount of cylinders.

LPG:

CNG:

Color ID

(KN-8)

Injector size

Minimum power per

cylinder [LPG]

Maximum power per

cylinder [LPG]

kW

HP

kW

HP

Green

32cc /stroke

13,0

17,4

white

42cc/stroke

9,0

12,1

15,0

20,1

Blue

52cc/stroke

13,0

17,4

20,0

26,8

Orange

63cc/stroke

18,0

24,1

27,0

36,2

Yellow

73cc/stroke

25,0

33,5

35,0

46,9

82cc/stroke

28.0

37,6

39,0

52,3

Brown

100cc/stroke

31,0

41,6

45,0

60,3

Color ID

(KN-8)

(KN-8)

Injector size

Minimum power per

cylinder [CNG]

Maximum power per

cylinder [CNG]

kW

HP

kW

HP

Green

9,0

12,1

White

42cc/stroke

7,0

9,4

12,0

16,1

Blue

52cc/stroke

10,0

13,4

16,0

21,5

Orange

63cc/stroke

14,0

18,8

22,0

29,5

Yellow

73cc/stroke

20,0

26,8

28,0

37,5

82cc/stroke

23,0

30,8

33,0

44,2

Brown

100cc/stroke

25

33,5

36,0

48,3

Copyright © Prins Autogassystemen B.V. 2013 Page 10

The Prins filter unit

The filter unit filters the LPG/CNG and is also used to measure the gas temperature (T_gas) and gas

pressure (Psys) in the VSI system, by means of a combination sensor.

The filter unit has a single or a double outlet of 11mm.

Single outlet : on converted vehicle with 3-4 or 5 cylinder engines with one VSI injector rail.

Double outlet : on converted vehicle with 6 or 8 cylinder engines with two VSI injector rails.

Single outlet Double outlet

3-4-5 cylinder engine 6-8 cylinder engine

The Keihin filter unit

Copyright © Prins Autogassystemen B.V. 2013 Page 11

The VSI computer

The VSI computer can be mounted into the engine room as well as inside the car, depending on the

converted vehicle.

Never mount the computer near a heat source.

Never mount the computer upside down.

Never clean engine room with a high pressure cleaner.

VSI-I

Copyright © Prins Autogassystemen B.V. 2013 Page 12

VSI-2.0 computer

The Prins VSI-2.0 computer is the second generation master-slave management system. This new design

has distinctive features and will be used as a new platform for current and future Prins injection systems.

Copyright © Prins Autogassystemen B.V. 2013 Page 13

Instructions rotating the Prins VSI injector rail

This is an instruction how to convert a “right” rail into a “left” injector rail

Tools : Ring spanner size 13 mm

Torque spanner ( 0-3 Nm )

Disassembly / assembly:

1. Unscrew both M8 (4) nuts.

2. Remove the strip (2).

3. Remove the injectors (10) with a rotating movement out of the fuel rail (1).

4. Rotate the rail (1) 180 degrees.

5. Mount the injectors (10) with a rotating movement into the fuel rail (1).

6. Mount the strip (2) on the injectors (10).

7. Tighten the strip (2) with two M8 nuts (4). Tightening moment 2.5 Nm.

Copyright © Prins Autogassystemen B.V. 2013 Page 14

The wiring loom.

The cables in the loom are provided with numbers and text. The text on the cable explains the function of

the wire. The wire loom is not model specific, therefore is it may be necessary to adjust the length of the

wires.

The watertight ECM housing is made from aluminium; this material is chosen for its excellent heat

dissipation qualities, necessary for cool the injector drivers.

Always fix the computer in the coolest place in the engine compartment.

Ensure maximum care is taken when connecting wiring.

Make professional solder joints and insulate the joints.

Do not stretch the wiring harness.

VSI-I

The wiring harness is equipped with a 56 position interlocking connector which slots into the VSI computer.

Pull the purple interlocking clip and push the connector into the VSI computer, push the clip back into its

original position, the connector is now locked into the VSI computer.

VSI-2.0

The wiring harness connects to the computer via two Bosch a 81+40 pins connector which is locked to the

VSI-2.0 computer by means of connector clamping mechanism.

All cable numbers correspond with a position numbered on the connector.

Example wire number 4 is mounted on connector position 4.

Copyright © Prins Autogassystemen B.V. 2013 Page 15

Hose connections

Try to keep the inlet manifold hoses as short as possible.

Use a hose clamp on all the LPG/CNG hose connections.

Please observe that there is no damage or fouling to the hoses.

16

Diagram 1 VSI inlet manifold coupling

Lambda sensor

exhaust manifold

VSI inlet manifold coupling

inlet manifold

petrol injector

VSI injector

Hose clamp

LPG hose

Hose clamp

Coupling

Copyright © Prins Autogassystemen B.V. 2013 Page 17

Diagram 2 VSI inlet manifold coupling with nylon hose

petrol injector

Coupling

Barrel

Hose clamp

Nylon hose

LPG hose

Nut

VSI injector

Hose clamp

inlet manifold

VSI inlet manifold coupling with nylon hose

exhaust manifold

oxygen sensor

Copyright © Prins Autogassystemen B.V. 2013 Page 18

Diagram 3 Parallel water connection

injector rail

filter unit

+

lock-off valve

reducer

oxygen sensor

heater

valve

petrol injector

cylinder 1

VSI injector 1 2 3 4

exhaust

T-piece

interior heater with valve

LPG fuel line Tank

overpressure hose

Psys + Tlpg

sensor

engine coolant

in

out

inlet manifold

vsi coupling

throttle body

Copyright © Prins Autogassystemen B.V. 2013 Page 19

Diagram 4 Serial water connection

injector rail

filter unit

+

lock-off valve

reducer

overpressure hose

oxygen sensor

interior heater without valve

engine coolant

LPG fuel line Tank

petrol injector

cylinder 1

VSI injector 1 2 3 4

inlet manifold

exhaust

vsi coupling

in

out

throttle body

Psys + Tlpg

sensor

in

This manual suits for next models

1

Table of contents

Other Prins Automobile Accessories manuals