Prins VALVECARE-DI User guide

VALVECARE-DI SYSTEM MANUAL

SYSTEM VERSION

ValveCare-DI

DATE

23-11-2020

Revision version

v 1.2

Copyright © Prins Autogassystemen 2020

PAGE 1

General manual ValveCare-DI

Copyright © Prins Autogassystemen B.V.

2020

Copyright © Prins Autogassystemen B.V.

TABLE OF CONTENTS1

TABLE OF CONTENTS.............................................................................................................. 11

MANUAL UPDATES / REVISION .............................................................................................. 22

ABOUT THIS MANUAL............................................................................................................ 23

SAFETY INSTRUCTIONS........................................................................................................... 24

GENERAL INSTRUCTIONS........................................................................................................ 35

TOOL REQUIREMENTS............................................................................................................ 46

ABBREVIATIONS AND TERMS................................................................................................. 47Abbreviations ........................................................................................................................... 47.1 Terms........................................................................................................................................ 47.2

INTRODUCTION...................................................................................................................... 58Highlights.................................................................................................................................. 58.1

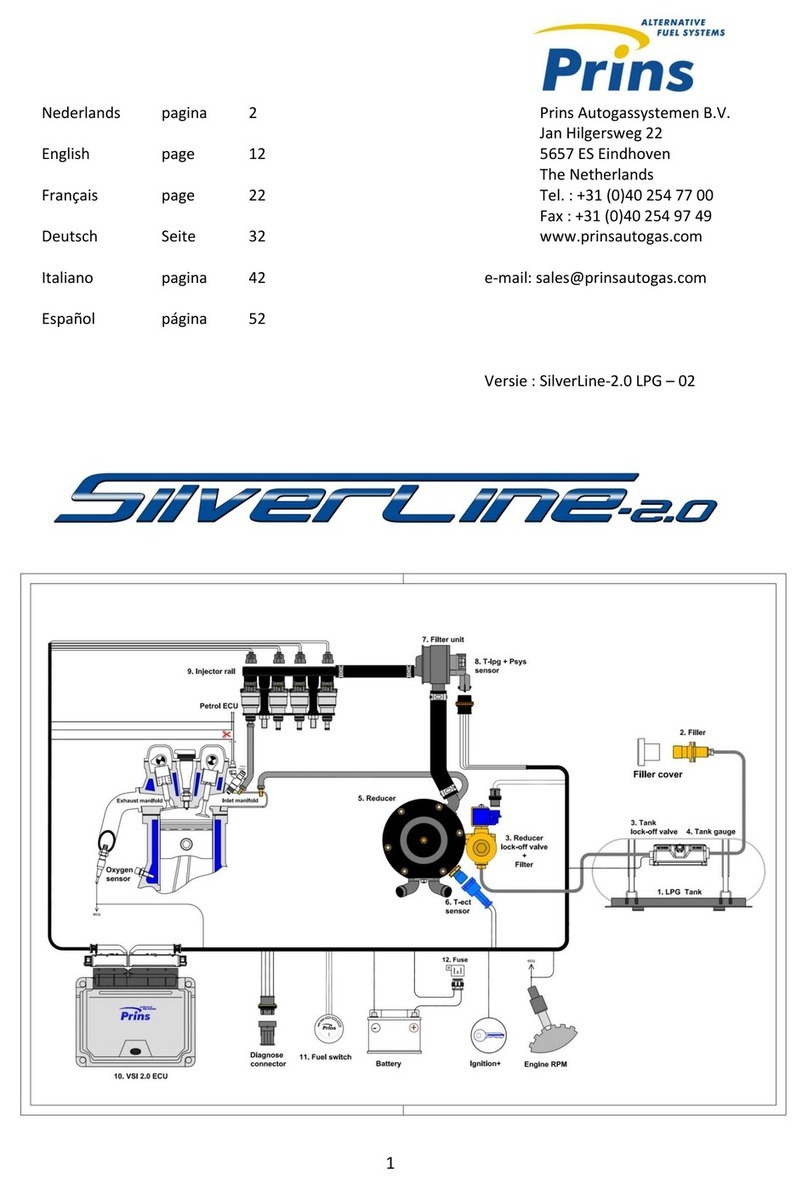

SYSTEM OVERVIEW................................................................................................................ 59

GENERAL OPERATION ............................................................................................................ 610

HARDWARE............................................................................................................................ 711 Dosing module ......................................................................................................................... 711.1 Wiring loom.............................................................................................................................. 711.2 Resistor..................................................................................................................................... 811.3 Additional white wiring module (DLM Gen3)........................................................................... 811.4 Additive reservoir..................................................................................................................... 811.5 Mirror leaflet............................................................................................................................ 811.6 ValveCare-DI Additive Fluid...................................................................................................... 811.7 Nipples and hose connections ................................................................................................. 911.8 3 & 4 Cylinder sets.................................................................................................................. 1111.9 5 & 6 Cylinder sets.................................................................................................................. 1111.10

PRINS LPG SYSTEM INTEGRATION........................................................................................ 1212 Installation flow...................................................................................................................... 1212.1 Supported software ............................................................................................................... 1212.2 Advanced Calibration parameters.......................................................................................... 1312.3 Add 1K8 resistor (MPI engines).............................................................................................. 1312.4 VSI-2.0 MPI –AFC Compact.................................................................................................... 1412.5 VSI-2.0 MPI –AFC V2.x ........................................................................................................... 1512.6 VSI-2.0 DI –AFC V2.x.............................................................................................................. 1612.7 VSI-3 DI –AFC 3.0 DI............................................................................................................... 1712.8 Direct LiquiMax Gen3............................................................................................................. 1812.9 Direct LiquiMax Gen3 [Without additional wire]................................................................... 1912.10

VALVECARE-DI SOFTWARE AND SETTINGS........................................................................... 2013 ValveCare-DI Software download .......................................................................................... 2013.1 Connection to laptop ............................................................................................................. 2113.2 Check ValveCare-DI software version .................................................................................... 2113.3 Set ValveCare-DI parameters [Configuration]........................................................................ 2213.4 Ventilate lines......................................................................................................................... 2313.5 ValveCare-DI system check [Live]........................................................................................... 2413.6 Tools....................................................................................................................................... 2413.7 Flash Module ValveCare-DI module....................................................................................... 2413.8

SERVICE AND MAINTENANCE............................................................................................... 2514 Check...................................................................................................................................... 2514.1 Refill the reservoir.................................................................................................................. 2514.2

TROUBLE SHOOTING............................................................................................................ 2615 ValveCare-DI module ............................................................................................................. 2615.1 Prins AFC Software V2............................................................................................................ 2615.2

PAGE 2

General manual ValveCare-DI

Copyright © Prins Autogassystemen B.V.

2020

Copyright © Prins Autogassystemen B.V.

Manual updates / revision2

Rev. nr

Rev. Date

Subject update

1.0

02-06-2020

First official release

1.1

10-09-2020

More detailed information; added DLM

1.2

06-10-2020

Added ValveCare-DI settings for 2 tank strategy [separate]

About this manual3

This manual describes:

Operation of the ValveCare-DI system

System and components description

General installation instructions

Prins system integration

Calibration setting (for Firmware 1055 ->)

Service and maintenance

General diagnostics

Safety instructions4

Always avoid direct contact between additive and skin, eyes or mouth. Always wear

protective clothing and safety goggles during work or maintenance on the ValveCare-DI

dosing system.

If the additive comes in contact with the eyes, this may cause irritation. In this case rinse

the eyes 10 to 15 minutes with water and seek medical attention.

If the additive comes in contact with the skin, this may cause irritation. In this case wash

the skin thoroughly with soap and rinse with plenty of water. Seek medical attention if the

irritation persists.

If the additive is swallowed, do not provoke vomiting. Rinse the mouth with water and

drink 2 to 4 glasses of water. Then immediately seek medical attention.

Observe the statutory national regulations when installing the device.

Only competent and qualified persons are allowed to install, maintain and repair the

dosing unit and peripheral equipment.

When connecting or disconnecting electrical wiring, always switch off the power supply by

disconnecting the vehicle's battery.

Assembly of ValveCare-DI device with non-original parts, which have not been checked and

recommended by Prins, is not allowed and may cause material damages for which Prins

cannot be held liable.

This manual was developed by Prins Autogassystemen B.V.

© All rights reserved. No part of this publication may be

reproduced or published without the permission of Prins

Autogassystemen BV

For more information:

Prins Autogassystemen B.V.

Jan Hilgersweg 22

5657 ES Eindhoven, the Netherlands

Tel: (+31) 040-2547700

www.prinsautogas.com

PAGE 3

General manual ValveCare-DI

Copyright © Prins Autogassystemen B.V.

2020

Copyright © Prins Autogassystemen B.V.

General instructions5

The installation of the system shall be done in accordance with the installation manual provided by

Prins Autogassystemen.

This manual is based on Dutch regulations; always install the system in accordance with

local regulations.

Fitting and maintenance is only allowed by LPG engineers.

Failure to follow the instructions in this manual can result in a poor or non-working LPG-

installation or a dangerous situation.

For maintenance instructions and filter registration also see the Driver’s Guide.

Prins Autogassystemen is not responsible for any damages to people or objects as a result

of changes to Prins products.

Power and fuses:

Make sure the ignition key is outside the car / windows open.

Be aware of central door locking, radio / telephone memory code and

alarm system.

Always disconnect the battery when installing the ValveCare-DI system.

Do not place the fuse before having completed the installation of the

system.

ValveCare-DI dosing module

ValveCare-DI dosing module has to be configured with the Valve-Protector software.

Never disconnect the connectors, unless you have removed the main fuse.

Prins AFC Software v2

Set the advanced calibration parameters like described in this document

For a MPI system run the import file from the Members Area.

Harness and wiring:

The text on the wire explains the function of the wire.

The wire harnesses are mainly not model specific. Therefore it may be necessary to

adjust the wire length.

Ensure maximum care is taken when connecting the wiring.

Ensure that it does not run near any of the ignition components.

Make sure there is no stretch on the wire harness.

Solder and insulate all electrical connections.

Make professional joints using solder and shrink sleeve.

Hardware installation:

Always use this manual for installation instructions.

Thread all drilled holes with an anti-corrosion agent, after removing the chips.

Check components for gas leakage with a gas leak detection device after the

installation. Also check for air and fluid leakage.

Contact your local distributer for:

Homologation information.

Technical information

Sales information

Warranty:

Register the components for warranty period after installation.

Work safe:

WEAR SAFETY GOGGLES

PAGE 4

General manual ValveCare-DI

Copyright © Prins Autogassystemen B.V.

2020

Copyright © Prins Autogassystemen B.V.

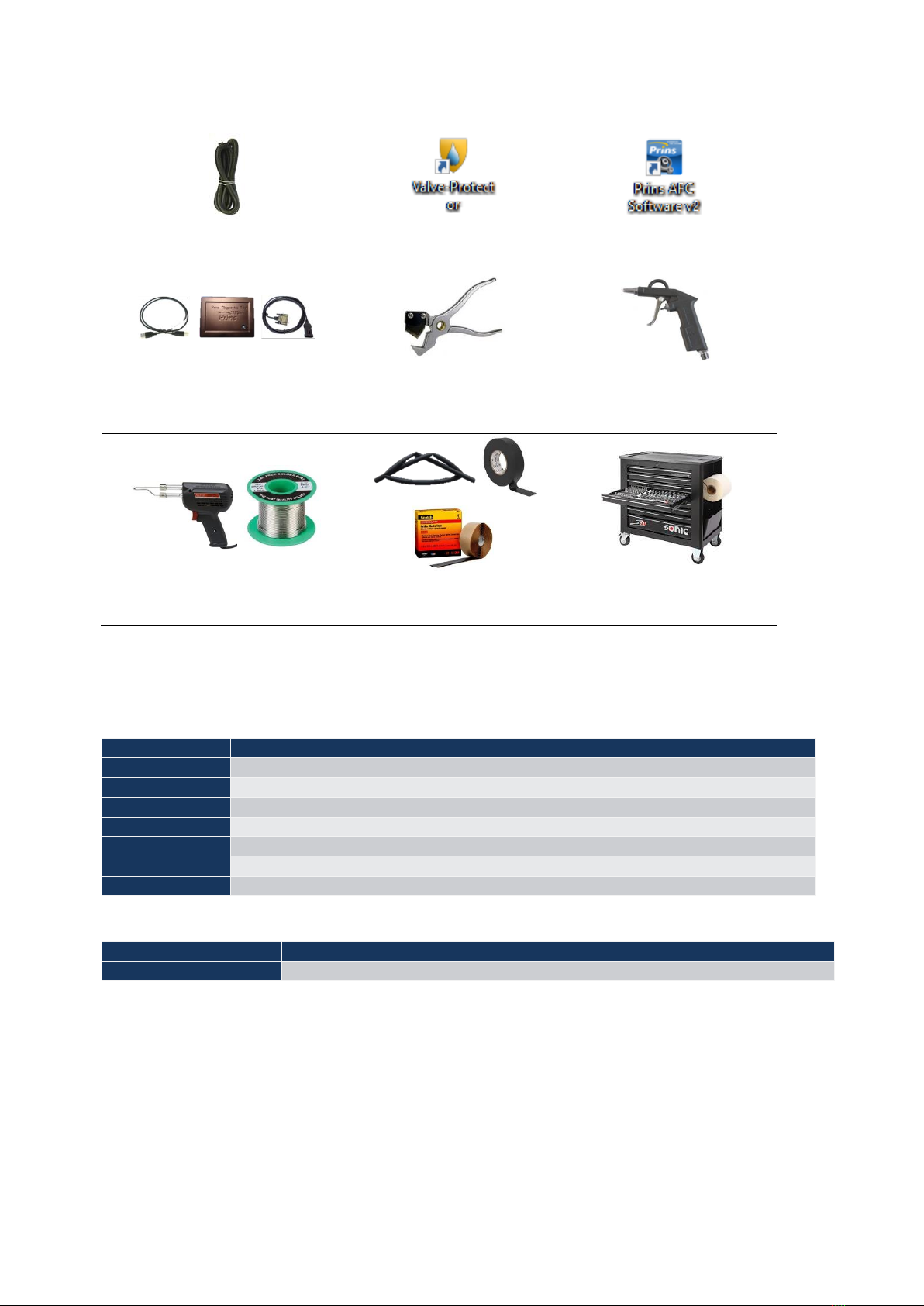

Tool requirements 6

Cable diagnostic ValveCare-DI

099/040003

ValveCare-DI software

Prins Diagnostic program V2.0

Tool kit PDT Diagnose

191/020001

Hose cutter

099/520024/A

Compressed air & air gun

Soldering iron & soldering tin

Insulating tape & adhesive

shrink sleeve

Basic workshop

equipment/tools

Abbreviations and terms7

Abbreviations7.1

Abbreviations

Out written

Explanation

AD

Analog digital

Sensor input

AFC

Alternative Fuel Controller

LPG computer

DI

Direct injection

Fuel injection in cilinder chamber

DIG IN

Digital Input

Input of on / off signal (high / low)

MPI

Multi Point Injection

Fuel injection in inlet manifold

VSI

Vapour Sequential Injection

Gas conversion systems for engines

DLM

Direct LiquiMax

Terms7.2

Terms

Explanation

Prins AFC Software V2

Name of the calibration, service and diagnostic program

Table of contents

Other Prins Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction