Prins Tiger User manual

User Manual Prins Tiger

Prins Maasdijk, October-2013

2

C

CO

ON

NT

TE

EN

NT

TS

S

1.

FOREWORD ............................................................................................... 3

2.

GENERAL SAFETY REGULATIONS..................................................................... 4

3.

SUMMARY OF COMPONENTS .......................................................................... 6

3.1

Main components ...................................................................................................... 6

3.2

Driving controls and instrument panel ............................................................................ 7

3.3

Switches and levers .................................................................................................. 12

3.4

Body components.................................................................................................... 20

3.5

LPG-version............................................................................................................ 24

4.

PRE-OPERATION CHECK .............................................................................. 29

5.

WEEKLY MAINTENANCE.............................................................................. 36

6.

SELF-SERVICING ........................................................................................ 39

7.

PERIODIC MAINTENANCE ............................................................................ 44

7.1

Periodic replacement table......................................................................................... 44

7.2

Periodic maintenance table ........................................................................................ 45

8.

SERVICE DATA.......................................................................................... 50

9.

ENGINE SPECIFICATIONS ............................................................................. 52

10.

WHEELS AND TIRES .................................................................................... 52

10.1

Tire air pressure ...................................................................................................... 52

10.2

Overview wheels and tires ......................................................................................... 52

User Manual Prins Tiger Foreword

3

Prins Maasdijk, October-2013

1

1.

.

F

FO

OR

RE

EW

WO

OR

RD

D

As manufacturer, we thank you for purchasing this Prins Tiger Forklift truck.

For your safety, please obey all safety guidelines as set out in this manual. To obtain a long and

trouble free operation from your forklift keep up regular servicing and read this manual thoroughly

before you start to work with it. Make sure other users of the truck read the manual as well.

Keep this manual, after poring it over, on a place where you can find it easily back, so that you always

have the information at one’s disposal concerning maintenance, defects and the like.

When you want to order some parts, or you have questions/remarks about your forklift truck, please

contact Prins Maasdijk. Please: always be sure you know your Service number and Serial number,

mentioned on the tag plates in the left and right upper corner of the steering column. Keep it always

nearby when you call us.

We wish you much success with your new forklift truck.

Prins Maasdijk

User Manual Prins Tiger General Safety Regulations

Prins Maasdijk, October-2013

4

2

2.

.

G

GE

EN

NE

ER

RA

AL

L

S

SA

AF

FE

ET

TY

Y

R

RE

EG

GU

UL

LA

AT

TI

IO

ON

NS

S

Accidents can occur if the safety regulations are disregarded, insufficient care is taken during

maintenance or when operating the machine. You must be aware of the risks entailed in certain

actions. This manual describes potentially hazardous situations and the measures to be taken during

operation and maintenance.

It is impossible for the manufacturer to foresee every potentially hazardous situation, which may lead

to injuries or damage. The user must ensure the safety of all actions, procedures or the use of any

tools that are not recommended by the manufacturer. Always use original spare parts.

For your and other people’s safety:

Never load the forklift truck above the maximum stipulated weight.

Always check the loading diagram on the bonnet.

The lifting capacity is halved when the load rests on only one fork. Avoid this as much as possible.

Keep the load as close to the ground as possible when driving with a loaded machine. Never drive

at top speed in this situation.

Keep the speed as low as possible when driving with an elevated load and keep track of the

maximum clearance height.

ALWAYS carry out the necessary preventive inspections and regular maintenance. Never start

working with the machine unless it has been thoroughly checked. Pay particular attention to the

tires, battery, brakes, steering gear, fuel system, and electrical components.

Do not refuel while the engine is running. No smoking is allowed during refueling or changing /

adding oil and fire and sparks must be prevented. Explosive gases are released during refueling.

Carefully remove any spilt liquids after refueling or changing / adding oil.

Before changing or adding oil, the machine must be checked for oil stains. Try to find out where

they come from. If they are caused by a technical failure, first repair the failure before continuing

working with the truck.

When leaving the machine, ensure that the handbrake is engaged and that the gears are in

neutral.

A wrong sitting position can cause accidents. Always adjust the chair so that you can properly

operate the levers and have a good sight.

Never work with a truck without a safety guard or safety bracket (which are standard supply).

Always wear you seat belts when operating the forklift truck.

Operate at a speed that gives you positive control of the truck. High speeds can be very

dangerous. Also sudden brakes, accelerations, or turns can cause dangerous situations.

If you have to drive at locations with little clearance height, take the following things into account:

oAlways check if there is enough clearance above and beside the truck.

oKeep all parts of the body inside the safety guard, keep your hands on the steering wheel and

keep your feet on the pedals.

oPay attention to where you drive

Gently operate the levers. This increases the life span of the truck and is much safer.

User Manual Prins Tiger General Safety Regulations

5

Prins Maasdijk, October-2013

Never walk under an elevated load. This is extremely dangerous.

Never carry a person on the forks or on the truck.

When lowering the forks, make sure the forks are horizontal or tilted a bit backwards. Never lower

the forks when they are tilted forwards.

The state of the machine can be checked by many factors. Any changes of sound, vibrations, or

reactions on the levers can indicate failures. If you suspect a failure, immediately pull over the

truck and stop the engine. Check for causes and take the necessary actions.

Table 2.1 | Safety symbols

Follow the instructions

for use and safety

Wear safety glasses

and protective clothing

Smoking and open

flames prohibited

Electrolyte is very

corrosive

Connectors are live,

avoid contact

Areas where batteries

are stored or charged

must be sufficiently

ventilated

Danger of explosions,

avoid short circuits

User Manual Prins Tiger Summary of components

Prins Maasdijk, October-2013

6

3

3.

.

S

SU

UM

MM

MA

AR

RY

Y

O

OF

F

C

CO

OM

MP

PO

ON

NE

EN

NT

TS

S

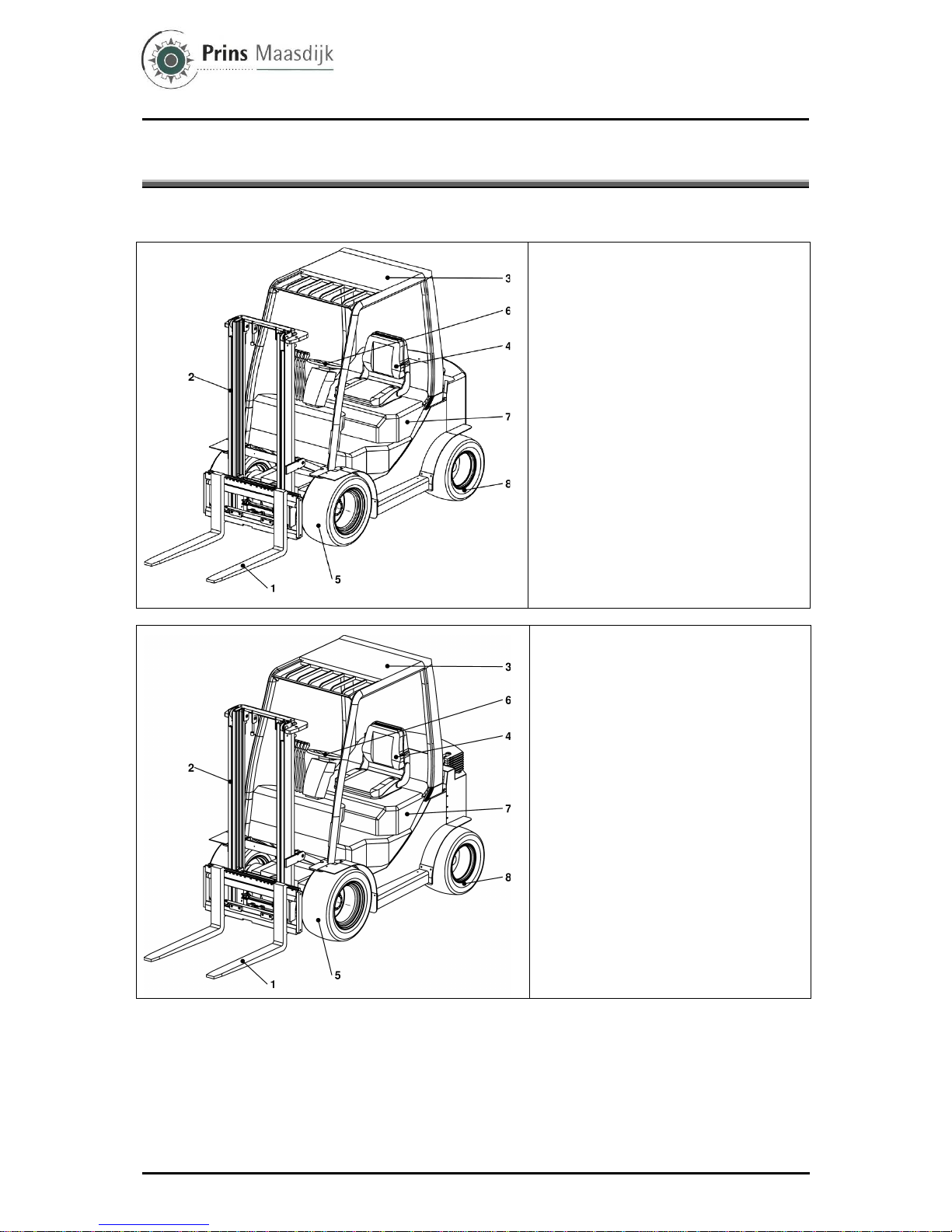

3.1

Main components

Tiger L

1 – Forks

2 – Mast

3 – Overhead guard

4 – Operator’s seat

5 – Front wheel

6 – Steering wheel

7 – Engine hood

8 – Rear (steering) wheel

Tiger XL

1 – Forks

2 – Mast

3 – Overhead guard

4 – Operator’s seat

5 – Front wheel

6 – Steering wheel

7 – Engine hood

8 – Rear (steering) wheel

User Manual Prins Tiger Summary of components

7

Prins Maasdijk, October-2013

Tiger XXL

1 – Forks

2 – Mast

3 – Overhead guard

4 – Operator’s seat

5 – Front wheel

6 – Steering wheel

7 – Engine hood

8 – Rear (steering) wheel

3.2

Driving controls and instrument panel

Driving controls

1 – Control lever

2 – Steering wheel

3 – Horn button

4 – Light control and turn signal switch

5 – Lift lever

6 – Tilt lever

7 – Side shifter lever

8 – Accumulator switch (option)

9 – Accelerator pedal

10 – Brake pedal

11 – Ignition switch

12 – Parking brake release lever

13 – Inching- en brake pedal

14 – Tilt steering adjust lever

15 – Parking brake pedal

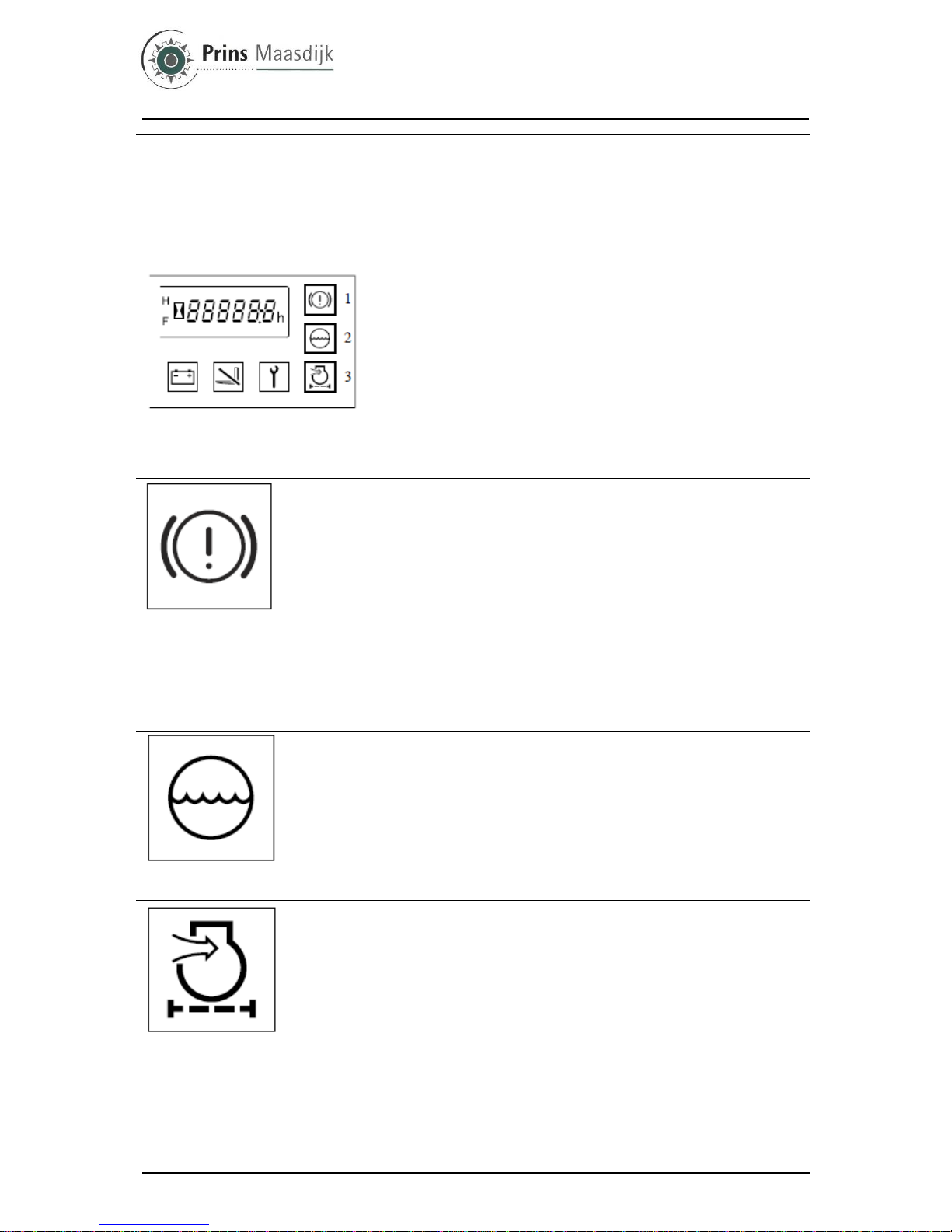

Diesel engine models

General screen

1 - Water temperature gauge

2 - Hour meter

3 - Brake warning lamp

(OK monitor: option)

4 - Fuel gauge (Diesel and Gasoline/LPG

engine models)

5 - Sedimenter warning lamp

(Diesel engine models)

User Manual Prins Tiger Summary of components

Prins Maasdijk, October-2013

8

LPG engine models

General screen (continuation)

6 - Glow indicator lamp

(Diesel engine models)

Engine check lamp (LPG and

Gasoline/LPG engine models)

7 - Engine oil pressure warning lamp

8 - Charge warning lamp

9 - OPS lamp

10 - Diagnosis lamp

11 - Air cleaner warning lamp

(OK monitor: option)

12 - Coolant level warning lamp

(OK monitor: option)

Gasoline/LPG engine models

Start

Warning lamp check method

Please check if all warning lamps come on when the ignition switch is turned

to ON.

Note:

Use the light control switch to check the meter-lighting lamp.

►Caution!

• The glow indicator lamp (Diesel engine models) is only on for 2 seconds

when the engine coolant temperature exceeds 50°C.

• If a lamp does not light up, contact Prins Maasdijk and request an

inspection.

Hour meter also serving as diagnosis indicator

The hour meter operates when the ignition switch is turned to ON. It indicates

the total number of vehicle operating hours. The unit of the right most digit is

1/10 hour.

Please use this meter for the timing of periodic maintenance and recording

the operation hours.

When an abnormality occurs to the vehicle (diagnosis lamp lights up or

blinks) the error code and hour meter will be alternately displayed.

►Caution!

• Should an error code be displayed, park the vehicle in a safe location and

contact your dealer to request an inspection.

User Manual Prins Tiger Summary of components

9

Prins Maasdijk, October-2013

Engine oil pressure warning lamp

Comes on to indicate low engine oil pressure while the engine is running.

1. If normal, the lamp comes on when the ignition switch is turned to ON and

goes off when the engine starts.

2. If the lamp comes on while the engine is running, either the engine oil is

low or the lubrication system is faulty. Stop the operation immediately and ask

Prins Maasdijk for inspection and repair.

Note:

The “engine oil pressure warning lamp” does not indicate the oil level. Check

the oil level using the oil level gauge before starting work.

Sedimenter warning lamp (Diesel engine models)

The sedimenter is a device for separating water from the fuel.

1. The warning lamp comes on to indicate water in the sedimenter exceeds

the predetermined level while the engine is running.

2. If normal, the lamp comes on when the ignition switch is turned to ON and

goes off when the engine starts.

3. If the lamp comes on while the engine is running, drain water immediately.

(See the self service section for the draining instructions.)

►Caution!

• Continued operation with the lamp on may cause seizure of the injection

pump and pump damage. If the warning lamp lights up, always make sure to

drain the water.

Glow indicator lamp (Diesel engine models)

Indicates heating of glow plugs.

When the ignition switch is turned to ON, the lamp comes on and glow plug

heating begins. The lamp goes off automatically when glow plug heating is

complete. The engine will start easily once the glow plugs are heated.

Note:

The glow indicator lamp is on for 2 seconds when the engine coolant

temperature exceeds 50°C.

Engine check lamp (LPG and Gasoline/LPG engine models)

When an error occurs to the engine controller, the display will light up to

inform the operator. When condition is normal, the lamp will light up when the

ignition switch is turned to the ON position. The lamp will turn off when the

engine is started.

►Caution!

• If the engine check lamp lights up during operation, stop operations and

park the vehicle in a safe location, ask your dealer to perform an inspection.

Charge warning lamp

1. This lamp comes on to indicate an abnormality in the charging system

while the engine is running.

2. If normal, the lamp comes on when the ignition switch is turned to ON and

goes off when the engine starts.

3. If the lamp comes on while the engine is running, stop immediately, park

the vehicle in a safe location, stop the engine and after the engine has cooled

down inspect the fan belt for cuts or looseness, adjust it, and restart the

engine.

If lamp does not go off, the electrical system may be faulty.

Please ask Prins Maasdijk immediately for inspection and repair.

User Manual Prins Tiger Summary of components

Prins Maasdijk, October-2013

10

OPS lamp

If the operator leaves the seat, the OPS lamp will light up, indicating that the

OPS System is operating. (If the operator returns to normal seating position

within 2 seconds, loading can be continued.) In such a situation, return the

control lever and lift lever to the neutral position, then sit on the seat again.

►Caution!

In the following cases, a malfunction may have occurred to the OPS System.

Park the vehicle in a safe location and contact Prins Maasdijk to request an

inspection.

• If the operator leaves the seat, the OPS lamp does not light up.

• Even when the operator re-seats, the OPS lamp does not turn off.

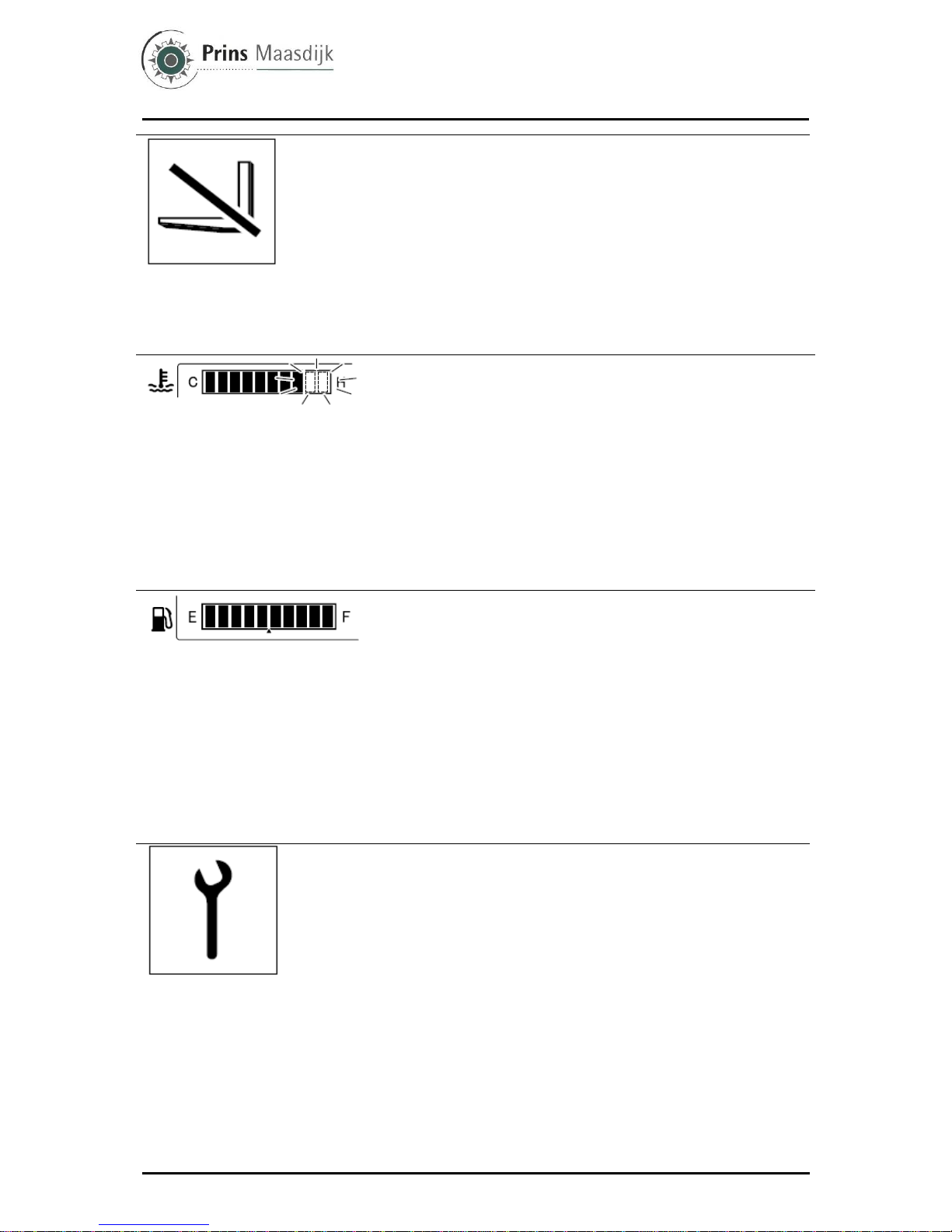

Water temperature gauge

Indicates the temperature of the engine coolant.

1. This gauge functions with the ignition switch ON, and displays

the coolant water temperature from left to right in a 10-stage

gradation scale.

2. The operator will be notified when the water temperature is

115ºC or over (above 8th stage), as the final two stages at far

right begin blinking. Again, when the engine protection function

activates (for vehicles with Multifunction display: OPT), the entire

gauge will start blinking to inform the operator.

3. Temporary overheating may be caused by coolant leakage, low

engine coolant level, loosened fan belt, or other problem in the

cooling system. Contact Prins Maasdijk to request an inspection.

Fuel gauge (Diesel and Gasoline/LPG engine models)

Indicates the amount of remaining fuel in the fuel tank in terms of

a 10-stage gradation scale. The operator will be notified that

remaining fuel level is low when the two stages at far left start

blinking. It takes some time for the indication to be stabilized after

refueling and the ignition switch is turned to ON.

Note:

• If the operating area is not level, attention must be paid because

the correct level may not be indicated.

• When the gauge begins blinking, refuel as soon as possible.

In case of diesel engine, be sure to refuel it before it runs out

because when this occurs it becomes necessary to bleed air from

the fuel supply system.

Diagnosis lamp

If an abnormality is registered by the OPS or mini lever, the

respective lamps will light up or blink to inform the operator and

the diagnosis error code will be displayed in the hour meter

display area. If the following conditions occur to the lamp, there

may be a system abnormality. Contact your dealer to request an

inspection.

• The lamp does not light up when the ignition switch is turned

ON.

• The lamp lights up when ignition switch is turned ON and stays

ON.

• The lamp blinks during ignition switch is turned ON.

►Caution!

• Continuing to use the vehicle while the diagnosis lamp is

lighted or blinking may lead to a breakdown. When the lamp

lights up or blinks, halt all operations and park the vehicle in a

safe location. Contact Prins Maasdijk to request an inspection.

User Manual Prins Tiger Summary of components

11

Prins Maasdijk, October-2013

(In the case of diesel engine vehicles, the diagnosis lamp may

light up during engine warm-up after a cold-start, but does not

indicate an abnormality.)

• If the operator remains seated for a long period with the ignition

switch turned to OFF, the next time the ignition switch is turned

to ON, the diagnosis lamp may start blinking. If this occurs, leave

the seat. The diagnosis lamp will then turn off.

1 - Brake warning lamp

2 - Coolant level warning lamp

3 - Air cleaner warning lamp

OK monitor (option)

Senses the engine coolant level, brake fluid level, clogged air

cleaner element and parking brake status. The lamp comes on to

indicate a problem. If the lamp comes on when the ignition switch

is on (irrespective of the engine speed), the corresponding part

may be abnormal. Contact Prins Maasdijk to request an

inspection.

►Caution!

• Always perform pre-operation checks. Do not rely on the OK

monitor, even if it is not lit.

Brake warning lamp

When the parking brake is engaged or brake liquid is low, the warning lamp

will light up to notify the operator.

1. The warning lamp will light up when the parking brake is engaged. After

disengaging the brake to operate the vehicle, check to make sure the warning

lamp has turned off.

2. The lamp will light up to notify the operator when the brake oil is low.

►Caution!

• If the warning lamp does not turn off when the parking brake is disengaged,

the brake fluid may be low. Inspect the brake fluid level and replenish it if

necessary.

• If the warning lamp remains a lighted even if the brake fluid level is

sufficient, contact Prins Maasdijk to request an inspection.

Coolant level warning lamp

1. When the coolant level of the radiator reserve tank becomes low, the

indicator lamp will light up to notify the operator.

2. If the lamp lights up while the engine is running, this may indicate a

deficiency in coolant. Stop the engine and inspect the coolant level in the

radiator reserve tank and the radiator. Before checking coolant level in the

radiator wait for it to cool as it maybe under pressure when hot.

3. Even if the coolant level warning lamp is not lighted, always inspect the

coolant level before starting operations.

Air cleaner warning lamp

1. This lamp comes on when the air cleaner element gets clogged while

engine is running.

2. If normal, the lamp comes on when the ignition switch is turned to ON and

goes off when the engine starts.

3. If the lamp comes on while the engine is running, stop operations and park

the vehicle in a safe location, stop the engine and clean the element and dust

cup. For the cleaning method, refer to the Weekly Inspection Section in this

manual.

User Manual Prins Tiger Summary of components

Prins Maasdijk, October-2013

12

3.3

Switches and levers

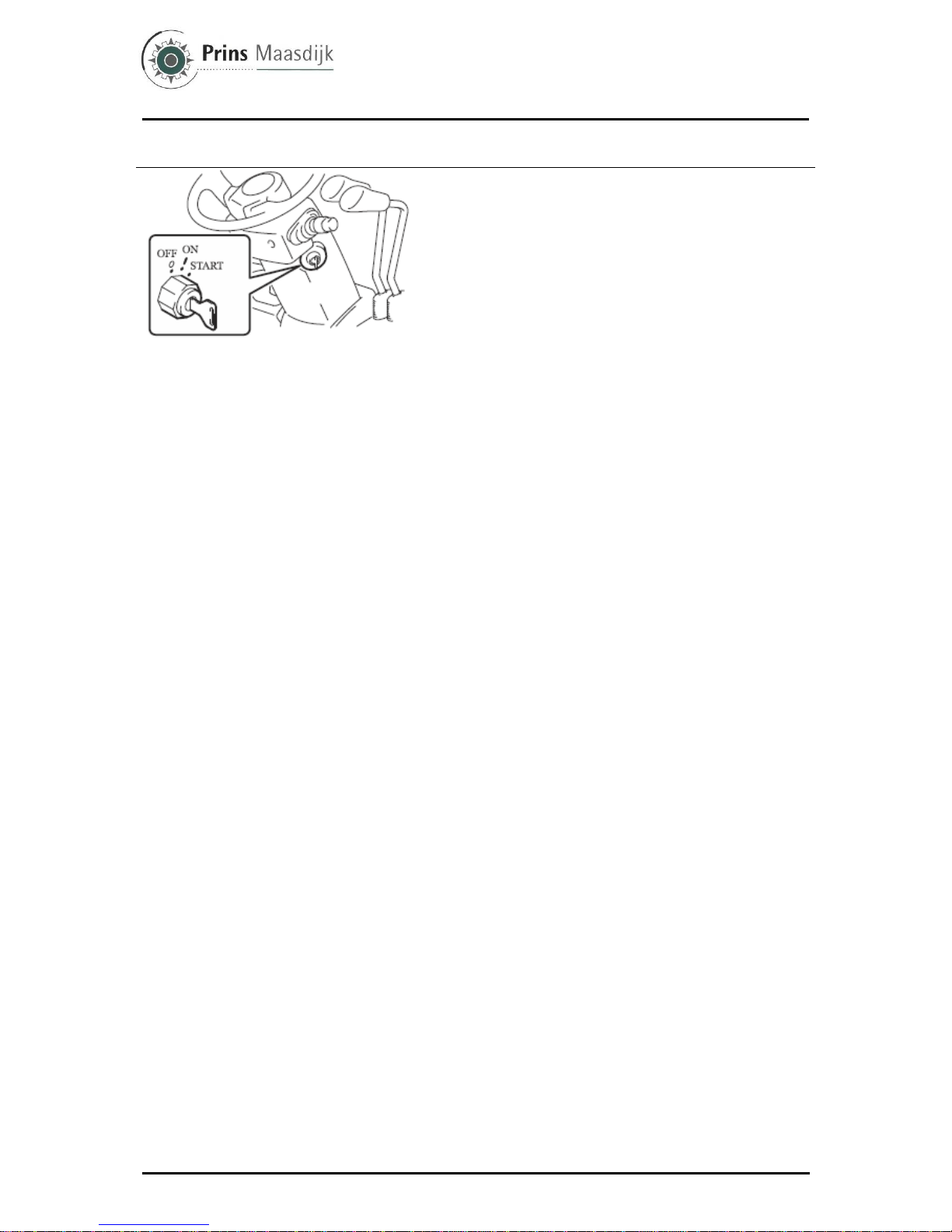

Ignition switch

O [OFF] – Engine stop position. Key insertion and

withdrawal are performed in this position.

I [ON] – Engine operation position. Located one position

clockwise from O [OFF] position.

The intake heater is preheated before starting in the

diesel models.

START – Engine, start position. Located one position

clockwise from the I [ON] position.

After the engine starts, release the key and it will return to

the I [ON] position automatically.

In the torque converter model, the engine does not start

unless the control lever is set in the neutral position.

►Caution!

• Never operate the ignition switch without First sitting on

the seat. Otherwise, the forklift could start to move

uncontrolled, causing an accident.

• When the OPS lamp is on, return each lever to the

neutral position and sit on the seat. Then confirm that the

lamp has gone off.

• Do not leave the switch in the [ON] position when the

engine is stopped. It may cause over discharge of the

battery.

• Do not turn the switch to the START position while the

engine is running.

• For the sake of safety it is recommended to always start

the engine of a vehicle with the transmission gear shift

lever shifted in the neutral position.

• Do not operate the starter motor for more than 30

seconds continuously. Return the switch to the [OFF]

position and wait at least 30 seconds prior to attempting

restart.

• In case of the anti-restart ignition switch (optionally

available), be sure to shift the switch to the [OFF] position

before attempting to start the engine again.

• With the ignition switch OFF (engine off), the forks will

not lower even if the lift lever is operated. However, if you

sit in the seat and turn on the ignition switch, you can

lower the forks. (Except mini lever models) Do not operate

the lift lever before getting on the vehicle and starting up

the engine. (key-off, lift locked)

• If the diagnosis lamp does not go off even when the

operator sits on the seat, the battery power may be low. In

such a case, do not drive the vehicle until the lamp goes

off, otherwise the vehicle may not operate correctly. If you

are obliged to drive the vehicle, do so with the utmost

care.

Also, stop driving and ask Prins Maasdijk for inspection if

the lamp does not go off 1-2 minutes after the engine

starts, or when you race the engine for a while. (For diesel

vehicles, the diagnosis lamp may be on for a while to

warm up the engine after cold starting. This is, however,

not an engine malfunction or failure.)

User Manual Prins Tiger Summary of components

13

Prins Maasdijk, October-2013

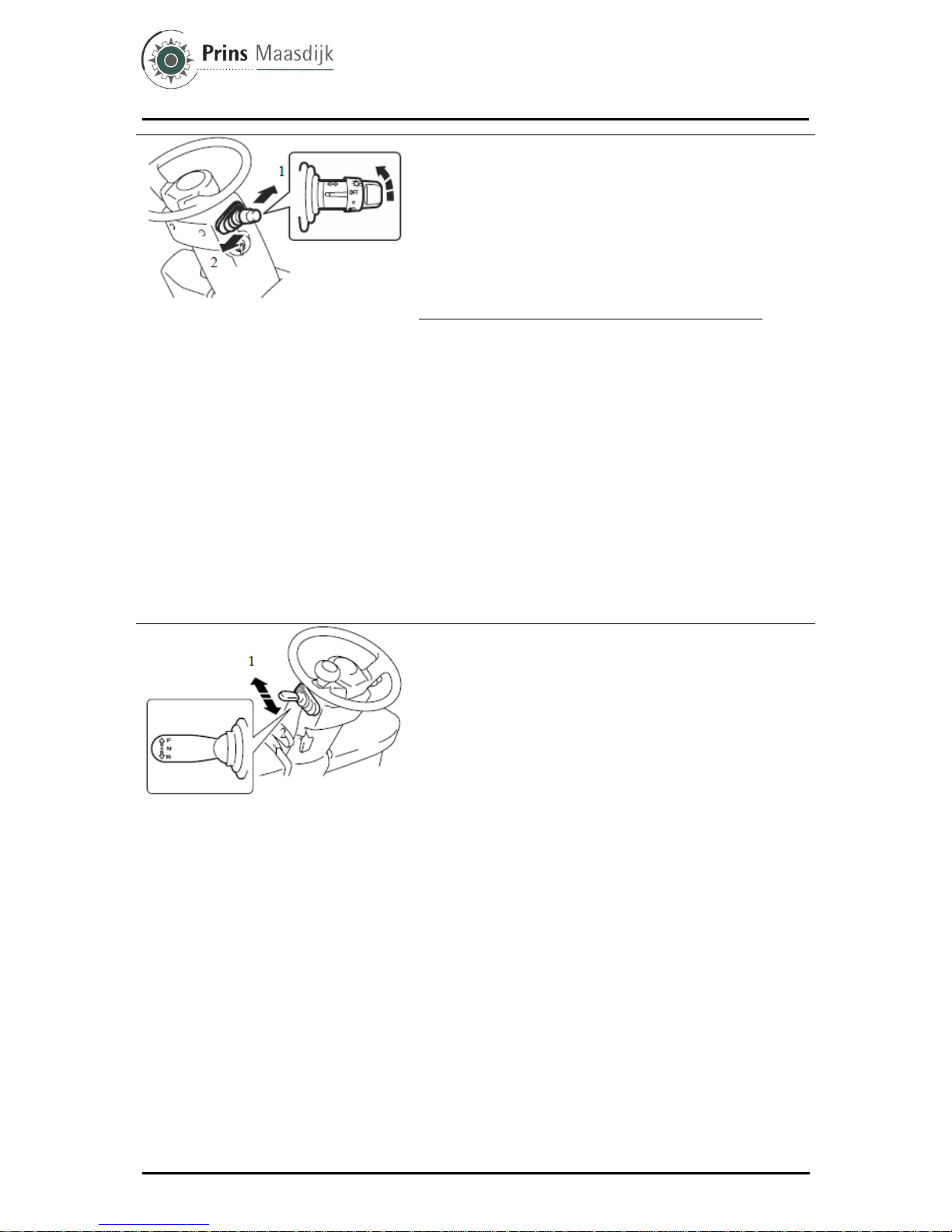

1 – Left turn

2 – Right turn

Integrated light and turn signal switch

This two-position switch serves as both a light switch and

turn signal switch.

Light control switch

Irrespective of an ignition switch position, this switch allows

you to turn on and off the lights.

This switch has two positions. With the switch at each

position, the light comes on as shown below.

Lamp name Step 1 Step 2

Head lamps − O

Side lamps, tail lamps (option) O O

Meter illumination lamp O O

►Caution!

• Do not keep lights such as head lights on for a long period

when the engine is stopped. It may cause over discharge of

the battery and make engine starting impossible.

Turn signal switch

Makes the turn signal lamps blink.

Left turn – Push forward

Right turn – Pull backward

The signal switch will operate when the ignition switch is

ON.

The turn signal lever returns automatically to the original

position after making a direction change.

1 – Forward

2 – Reverse

Control lever

Lever for shifting between forward and reverse

Forward – Push forward

Reverse – Pull backward

The neutral position is halfway between the forward and

reverse position.

Note:

After the OPS System operates, return the accelerator

pedal to its fully released position and set the control lever

to the neutral position, and sit on the seat to restart driving.

(Even though the operator sits on the seat, driving is

impossible unless the control lever is in the neutral

position.)

►Caution!

• The engine cannot be started unless the control lever is in

the neutral position.

• Stop the vehicle before shifting between forward and

reverse direction.

Torque convertor interlock function (OPT)

If you switch the control lever direction to something other

than the current travel direction while moving at high speed,

this function electrically disengages the drive and sets the

torque converter to neutral. Once the speed drops below

the set speed while running in neutral, the travel direction is

automatically switched.

To change travel direction, operate the control lever after

travel speed is reduced sufficiently. Ask Prins Maasdijk for

changing speed setting.

User Manual Prins Tiger Summary of components

Prins Maasdijk, October-2013

14

►Caution!

• When the interlock has engaged, release the accelerator

pedal and use the brake pedal to reduce speed. After the

vehicle has stopped moving, slowly press the accelerator

pedal down to start moving again. Disengaging the interlock

while the accelerator pedal is pressed down could result in

wheel spin.

• Do not perform Forward or Backward operation on slopes.

If control lever is operated on a down slope, torque

converter interlock function may not operate correctly.

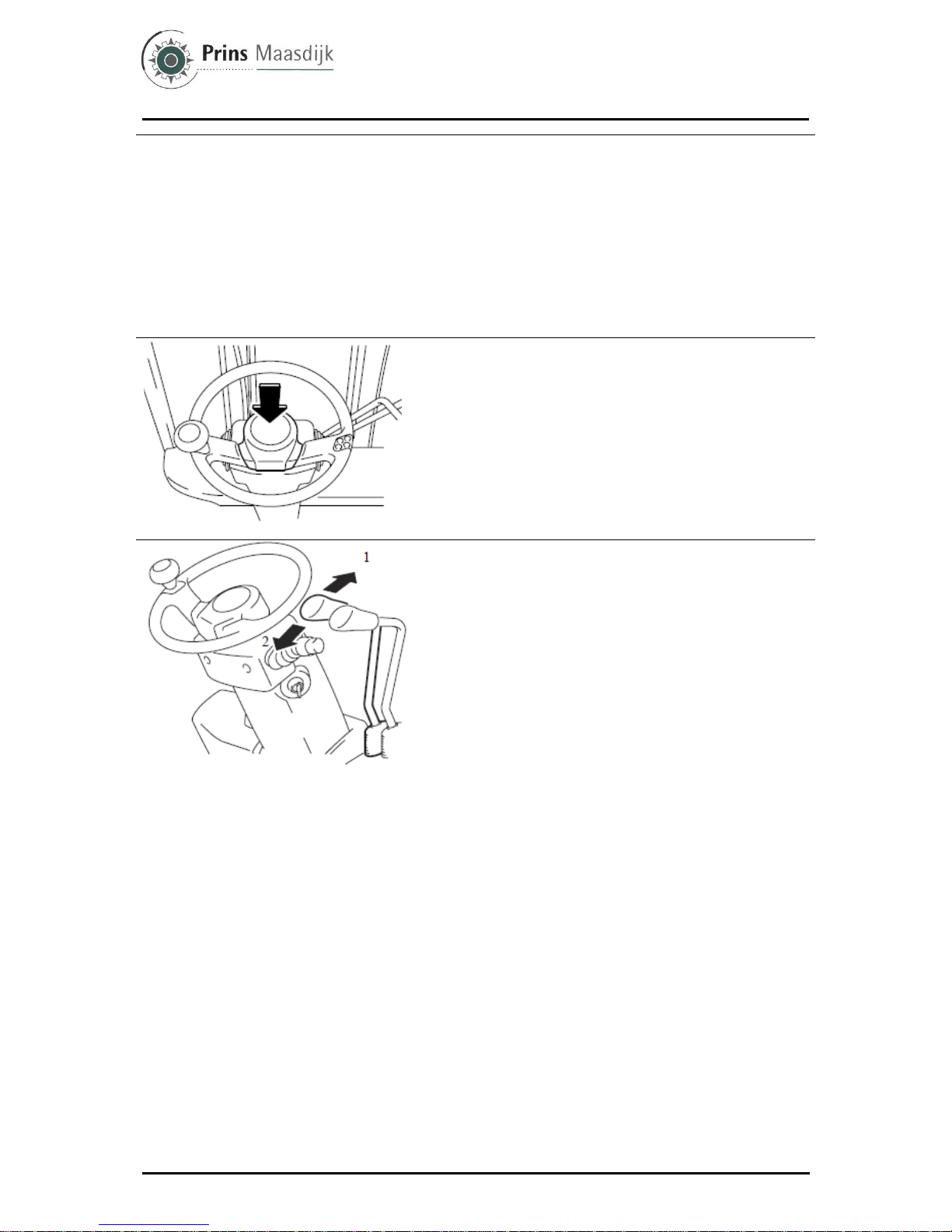

Horn button

Press the button in the center of the steering wheel to

sound the horn.

The horn will sound even when the ignition switch is OFF.

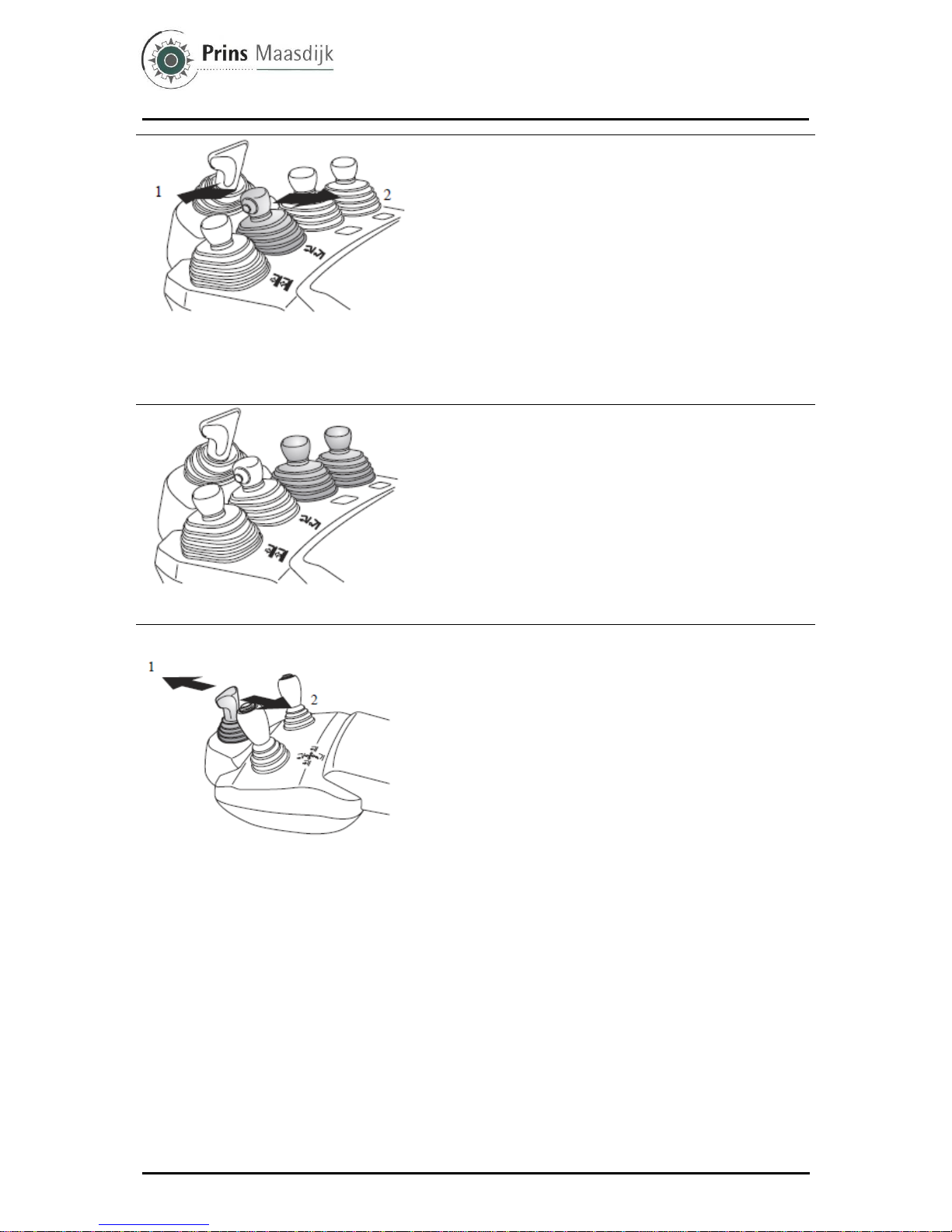

1 – Lower

2 – Raise

Lift lever

Raises and lowers the forks

Raise – Pull backward

Lower – Push forward

The lifting speed can be adjusted by how far the

accelerator pedal is depressed and how far the lever is

pull back.

The lowering speed can be adjusted only by how far the

lever is pushed forward.

►Caution!

• After the OPS System operates, return the accelerator

pedal to its fully released position and set the lift lever to

the neutral position, and sit on the seat to restart the

operation. (If you sit on the seat while raising the lift lever,

the forks will start to move 1 second later.)

• If you sit on the seat while lowering the lift lever, the

forks will not lower due to the return to neutral function.

• Always operate the lift lever while correctly seated.

• When the ignition switch is turned to OFF and lowering

the lift lever, the forks will not lower.

However, if the operator sits in the normal seated position

then the ignition switch is turned to ON, the forks will be

lower even if the engine is off. (Except mini-lever/joy stick

models)

User Manual Prins Tiger Summary of components

15

Prins Maasdijk, October-2013

1 – Lift lock release bolt

Key-lift interlock

When the ignition switch is OFF, the lift will not descend

even if the lift lever is lowered. However, if the operator

sits properly in the seat and turns the ignition switch

ON, the forks can be lowered even if the engine is off

(Except mini lever/joy stick models).

If the ignition switch cannot be turned ON for whatever

reason, loosen the manual lowering valve located on

the oil control valve beneath the toe board, and operate

the lift lever in the downward direction.

Once the forks have been lowered with the lift lock

release bolt, close and lock the valve.

1 – Forward tilting

2 – Backward tilting

Tilt lever

Tilts the mast forward and backward.

Forward – Push forward

Backward – Pull backward

The forward or backward tilting speed can be adjusted

by the degrees of accelerator pedal depression and

lever operation stroke.

►Caution!

• Insure the load-handling control levers are in their

neutral positions before returning to the operator's seat,

if not load-handling functions will start movement 1

second after operator returns to the seat.

• Always operate the tilt lever from a seated position.

• After the OPS System operates, return the accelerator

pedal to its fully released position and the tilt lever to the

neutral position, and sit on the seat to restart the

operation. (If the operator sits on the seat without

returning the load-handling control levers to their neutral

positions, load-handling functions will start movement 1

second after.)

1 – Shifting towards left

2 – Shifting towards right

Side shifter lever

Shifts the fork carriage on the left or on the right

Left – Push forward

Right – Pull backward

►Caution!

• Insure the load-handling control levers are in their

neutral positions before returning to the operator's seat,

if not load-handling functions will start movement 1

second after operator returns to the seat.

• Always operate the side shifter lever from a seated

position.

• After the OPS System operates, return the accelerator

pedal to its fully released position and the side shifter

lever to the neutral position, and sit on the seat to restart

the operation. (If the operator sits on the seat without

returning the load-handling control levers to their neutral

positions, load-handling functions will start movement 1

second after.)

User Manual Prins Tiger Summary of components

Prins Maasdijk, October-2013

16

1 – Forward

2 – Backward

Mini lever (option)

Control lever

Lever for shifting between forward and reverse

Forward – Push forward

Reverse – Pull backward

The speed of forward and backward traveling can be

adjusted by the extent of pressing the accelerator

pedal.

Note:

• Stop the vehicle before shifting between forward and

backward traveling.

• After the OPS System has been activated, return the

accelerator pedal and control lever to their neutral

positions and return to the seat before recommencing

operations.

• Always operate the control lever from a properly

seated position.

• Depending on the vehicle specifications, the position

of the control lever may vary.

1 – Lower

2 – Raise

1 – Lift lock release bolt

Lift lever

Raise and lower the forks for loading.

Raise – Pull backward

Lower – Push forward

Raising speed can be adjusted by the extent of

pressing the accelerator pedal and pulling the lift

lever.

Lowering speed can be adjusted by the extent of

pushing the lift lever.

Note:

• After the OPS System has been activated, return the

accelerator pedal and all of the levers to their neutral

positions and return to the seat before recommencing

operations.

• If you return to the seat while lowering the lift lever,

the forks will not descend due to the return to neutral

function.

• Always operate the lift lever from a properly seated

position.

• When the ignition switch is turned to OFF, the forks

will not descend even if the lift lever is lowered. (Key-

lift interlock)

• When the forks will not lower due to system

malfunction or other reasons, they can be lowered by

opening the lift lock release bolt.

• If you lower the forks by opening the lift lock release

bolt, close and lock the bolt.

User Manual Prins Tiger Summary of components

17

Prins Maasdijk, October-2013

1 – Forward tilting

2 – Backward tilting

Tilt lever

Tilt the mast forward and backward.

Forward – Push forward

Backward – Pull backward

Forward or backward tilting speed can be adjusted by the

extent of pressing the accelerator pedal and operating the

lever.

Note:

• After the OPS System has been activated, return the

accelerator pedal and all of the levers to their neutral

positions and return to the seat before recommencing

operations.

• Always operate the tilt lever from a properly seated

position.

Attachment lever

Operates the attachment.

Attachment speed can be adjusted by the extent of

pressing the accelerator pedal and operating the lever.

Note:

• After the OPS System has been activated, return the

accelerator pedal and all of the levers to their neutral

positions and return to the seat position before

recommencing operations.

• Always operate the attachment lever from a properly

seated position.

1 – Forward

2 – Backward

Joy stick (option)

Control lever

Lever for shifting between forward and reverse

Forward – Push forward

Reverse – Pull backward

The speed of forward and backward traveling can be

adjusted by the extent of pressing the accelerator pedal.

Note:

• Stop the vehicle before shifting between forward and

backward traveling.

• After the OPS System has been activated, return the

accelerator pedal and control lever to their neutral positions

and return to the seat before recommencing operations.

• Always operate the control lever from a properly seated

position.

• Depending on the vehicle specifications, the position of the

control lever may vary.

User Manual Prins Tiger Summary of components

Prins Maasdijk, October-2013

18

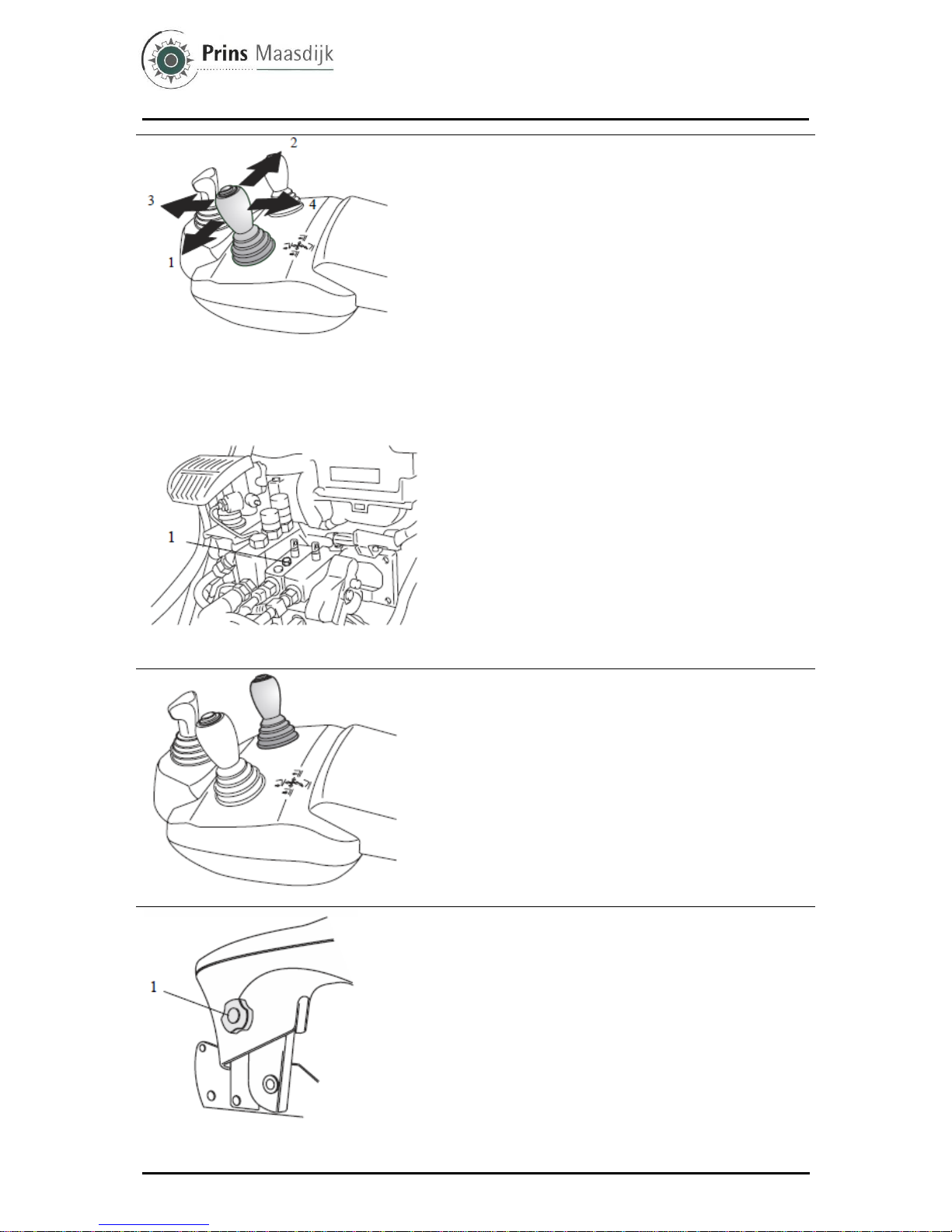

1 – Lower

2 – Raising

3 – Forward tilting

4 – Backward tilting

1 – Lift lock release bolt

Lift tilt lever

Operation to the left and right controls lift, and forward

and backward operation control tilt.

Raising – Operate the lever to the right

Lowering – Operate the lever to the left

Forward-tilt – Operate the lever forward

Backward-tilt – Operate the lever backward

Raising speed and forward and backward-tilt speed can

be adjusted by the extent of pressing down on the

accelerator pedal and operating the lever.

Lowering speed can be adjusted by operating the lever.

Note:

• After the OPS System has been activated, return the

accelerator pedal and all of the levers to their neutral

positions and return to the seat before recommencing

operations.

• If you return to seated position while lowering the lift

lever, the lift will not descend due to the return to neutral

warning function.

• Always operate the load handling lever from a properly

seated position.

• When the ignition switch is turned to OFF, the forks will

not descend even if the lift lever is lowered. (Key-lift

interlock)

• When the forks will not lower due to system malfunction

or other reasons, they can be lowered by opening the lift

lock release bolt.

• If you lower the forks by opening the lift lock release

bolt, close and lock the bolt.

Attachment lever

Operates attachment. Attachment speed can be adjusted

by the extent of pressing the accelerator pedal and

operating the lever.

Note:

• After the OPS System has been activated, return the

accelerator pedal and all of the levers to their neutral

positions and return to the seat before recommencing

operations.

• Operate the attachment lever after you are seated

properly in the vehicle.

1 – Adjustment knob

Armrest position adjustment

Before operating the vehicle, adjust the armrest until the

correct operating posture that matches that of the

operator is reached.

Loosen the adjustment knob and move the armrest into

the desired position.

►Caution!

• After adjusting the armrest, be sure to confirm that the

knob is securely fixed. If it becomes loose during

operation, an operational mistake could occur.

• Do not adjust the position of the armrest during traveling

or material handling operation.

User Manual Prins Tiger Summary of components

19

Prins Maasdijk, October-2013

1 – Release lever

Parking brake pedal

Use the parking brake pedal when parking or stopping.

1. When engaging the parking brake, while stepping on the

brake pedal, fully press down on the parking brake pedal.

2. To disengage the parking brake pedal, while stepping on

the brake pedal, pull the release lever toward you.

►Warning!

• Before operating the parking brake pedal, step on the

brake pedal and always confirm that the vehicle has come

to a stop.

• When parking on a slope, apply wheel chocks to the

wheels.

• Traveling without releasing the brake will decrease the

brake performance.

1 – Tilt adjustment lever

Tilt steering adjustment

1. The steering wheel position may be adjusted back and

forth while the tilt steering adjust lever up.

2. Lowering the lever at the proper position fixes the

steering wheel at that position.

3. After the adjustment, try to move the steering wheel back

and forth to see that it is fixed.

►Caution!

The steering wheel position must be adjusted before

starting the vehicle.

Adjustment during traveling must be avoided.

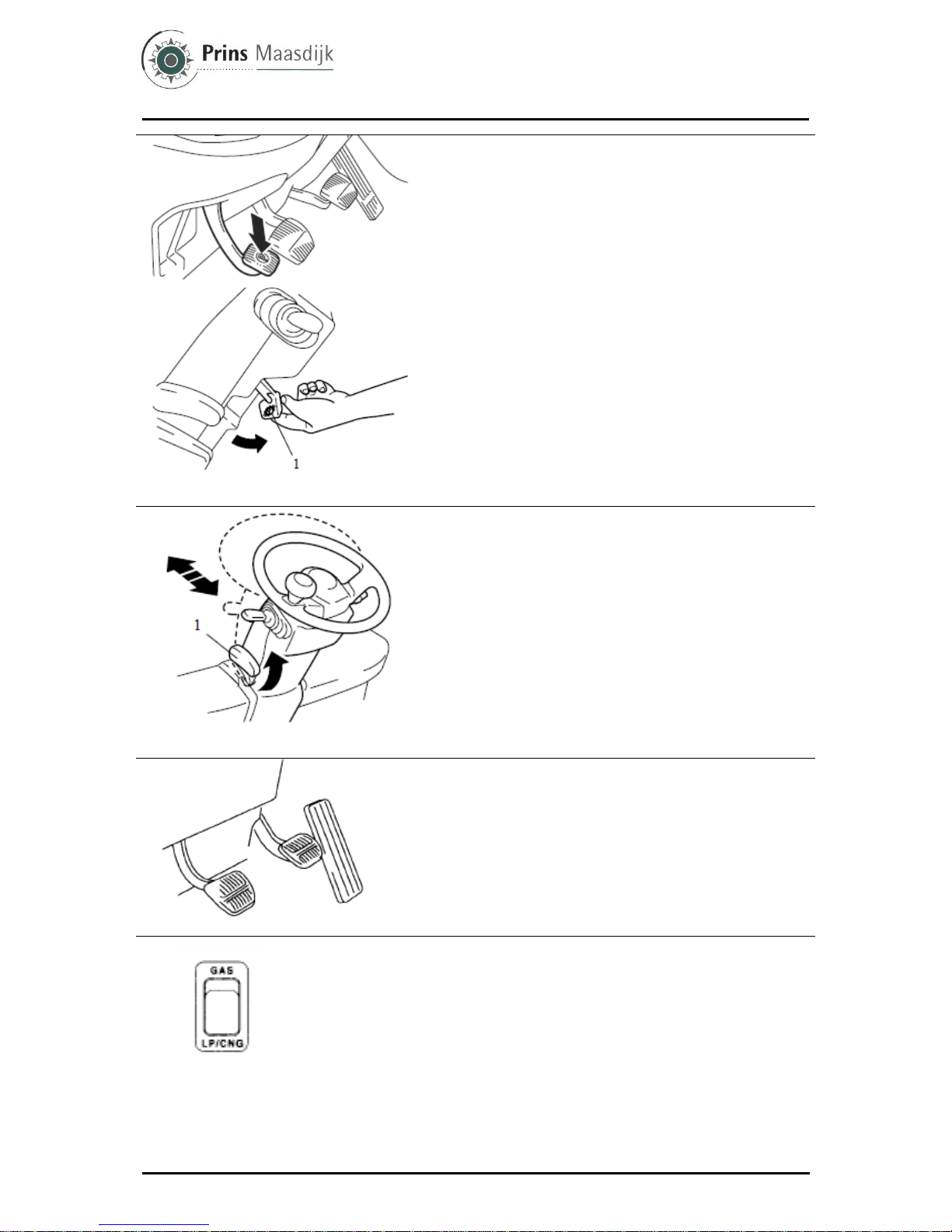

Pedals

From the right: accelerator pedal, brake pedal and inching

pedal.

Accelerator pedal stays neutral even when control lever is

shifted to forward-reverse, due to accelerator switch.

The vehicle will move only when accelerator pedal is

depressed.

Fuel switch (Gasoline/LPG models)

This is a switch to turn on and off the LPG or gasoline fuel feeder

OFF – horizontal position

Engine cannot be started up since no fuel is fed

LPG – low position

GAS – upper position

Note:

• With the ignition switch OFF, no fuel will be fed even if the fuel switch is

positioned at LPG or GAS.

• To turn off the LPG model engine, turn the fuel switch OFF, and run the

engine until it naturally stops. After the engine has stopped, take out the

gas tank, close the valve, turn the ignition switch OFF, and remove the key.

Table of contents